Work Order vs. Purchase Order: What’s the Difference?

A work order is an internal document that outlines instructions for completing specific tasks or projects.

A purchase order is an external document issued to a vendor to request the purchase of goods or services. Purchase orders request a good or service, while work orders show how that good or service should be completed.

| Purchase Orders | Work Orders |

|---|---|

| Requests a good or service from a vendor or supplier. | Details how the requested good or service should be completed, outlining specific tasks and timelines. |

| Always initiated by the buyer. | Can originate from various sources, including customers, safety officers, or business owners. |

| Legally binding document that serves as a contract. | Not legally binding; primarily an internal document for managing tasks. |

| Important for balancing invoices in accounts payable. | Does not impact received revenue; focuses on internal management. |

| Contains details about the items being ordered, such as quantity, price, and delivery date. | Includes details on project milestones, start dates, and tasks to be completed. |

| Typically does not detail internal processes. | May sometimes include purchase order numbers and relate to specific service requests. |

| Generally managed through procurement systems. | Can be automated using Computerized Maintenance Management Software (CMMS) for efficient task management. |

| Usually created first in the procurement process. | Often created after a purchase order has been received, although exceptions may exist in certain industries. |

What is a Purchase Order?

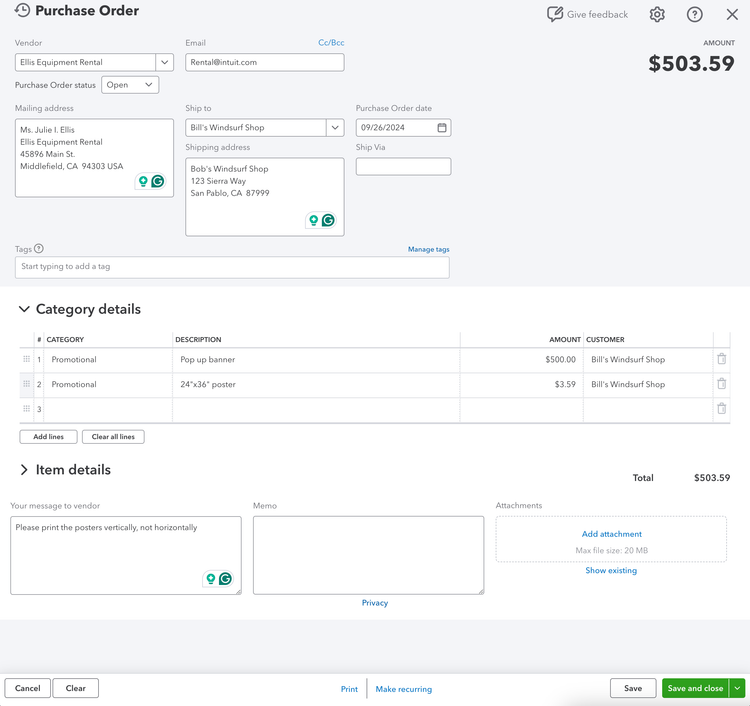

A purchase order, also called a sales order or PO, is a legally binding document that details what a buyer is purchasing, such as a good or service. The PO is made by either the client or customer and then sent to the correct vendor. Every company, from a global enterprise to a small business, will create or receive purchase orders in its regular purchasing process.

If your company provides a good or service, you will receive POs, although you are free to use your own formatting to ensure consistency. If you are sending a PO to a vendor or supplier, you will likely use a form template to ensure orders on your side contain all relevant details, such as purchase order approval from higher-ups.

A PO number is made to identify the purchase as it passes between different departments at the company fulfilling the order. Purchase order software can automatically generate these numbers whenever an is created. Each order will be labeled with a purchase order number for both sides to reference in future interactions.

At some companies, POs are combined with invoices, although there are still some differences between purchase orders and invoices. Both will primarily list:

- Purchase details like the quantity of goods

- Anticipated delivery date

- Customization options

- Total amount due

Even small businesses with limited resources will have separate purchase and invoice numbers to track progress and payment separately.

What is a Work Order?

A work order (WO) includes the actual documents a business uses to ensure a project is completed, listing exactly how and when everything needs to be done. Some work orders refer specifically to internal maintenance work, though this can vary. Others may resemble a purchase order by including information on the purchase of goods from a business.

A work order might include the following information:

- Purchase order number

- Current order status (estimate/quote stage, completed, etc)

- Start date

- Project milestones and time frame

- Due date (estimated completion or requested date)

- Delivery date

- Customer contact information

- Payment terms and schedule

Once completed, the work order may be sent to management for review and approval. Depending on the detailed work, it might be automatically sent to the various departments involved to begin immediately without the need for further authorization.

A maintenance work order may also be called a service order, and these terms are almost completely synonymous. Each determines the necessary workflow for a project from start to finish. For example, a maintenance work order may detail exactly what tasks must be completed to fix a broken pipe at a manufacturing facility. This might include a step for shutting off the water, ordering a replacement pipe, and scheduling a plumber or maintenance employee to make the actual swap. Without a work order, the plumber might show up only to learn no spare part was ordered, wasting time and money. By listing out all relevant tasks in advance, nothing gets overlooked.

You can add a work order in MaintainX with a photo of instructions, description, assigned employee, priority, and recurring due date.

Learn more in our article: What Is A Work Order?

Purchase Orders vs Work Orders: Main Differences

Purchase orders request a good or service; work orders detail how that good or service should be completed. And for some businesses, work orders are only used for managing maintenance, while POs play a critical role in B2B procurement practices. Yet, there are some circumstances where the two can overlap.

Like a purchase order, some work orders are actually arranged by the buyer and delivered to the seller. This may happen when the buyer is after something very specific, and they need to lay out exactly how their order should be fulfilled. One example of a customer defining the work order may be requesting a specific employee to work on a task rather than allowing the company to assign someone from that department at random. Or the client might set out the project timeline based on their own schedule. Of course, all these details can also be laid out in a purchase order, although that is a legally binding contract, and a work order is not.

The next key difference is who creates each order. The purchase order process will always originate with the buyer of a good or service. Work orders, however, have many potential points of origin. A customer might submit a work order for repairs on a purchased product, or a safety officer might put in a maintenance request after an audit. Even the business owner could be the one to put in a work order in the right circumstances. The work order number might include identifying details to clarify where each order originated.

Purchase orders are also important for balancing invoices in accounts payable. Work orders do not impact received revenue since they are primarily internal. Each might reiterate payment terms, though only the PO is legally binding.

Finally, work order automation is possible through computerized maintenance management software (CMMS). They can create a template document identifying what maintenance work needs to be done and how it should be accomplished. It’s even possible to use advanced features for rules-based approval management, scheduling, initiating change orders, and real-time reporting on task progress.

Creating Purchase and Work Orders

Purchase Orders

- Identify Need: Identify the goods or services required for your company.

- Select Vendor: Choose a supplier based on quality, price, and delivery options; obtain a quote.

- Prepare Purchase Order: Fill out details, including:

- PO number

- Supplier details

- Description of goods/services

- Quantity and price

- Delivery date

- Payment terms

- Send Purchase Order: Submit the completed purchase order to the vendor.

- Receive and Process: Confirm the receipt of the requested goods and services and process the invoice.

Work Orders

- Identify Task: Identify the specific project or task requiring a work order.

- Gather Information: Record details on the scope of work, required materials or services, timeline and deadlines, and assigned personnel.

- Fill Out Form: Add details like:

- WO number

- Task description

- Start date

- Due date

- Project milestones and status

- Customer contact information

- Payment terms

- Submit Work Order: Send the work order to the appropriate personnel or department.

- Monitor and Close: Track progress, complete the tasks, and close the work order after review.

The Order of Orders

With so many orders, you might be wondering which comes first. In general, work orders are made after a company receives a purchase order. For instance, a company might request a highly specific service with several predetermined conditions, such as due date and time frame, which influence the creation of the internal work order. As such, it’s easier to create a work order after a PO has been received.

However, there are a few industries where a work order might be prepared before an official PO is received due to the time needed to complete an order. This would mostly occur during the quote or estimation process if the company knows the sale is likely to go through. It might also happen in the event of expediting recurring orders from a returning customer.

Depending on your exact line of business, you might need a system to create purchase orders and work orders. Fortunately, software makes it possible to automate the entire process for both types of orders.