What is Procurement? The Procurement Process Explained

Procurement Definition

Procurement is the act of acquiring goods or services for a business from suppliers. Sometimes known as sourcing or a section of supply chain management, procurement is the process of finding the best raw materials or parts to use in manufacturing your own products. In service-oriented industries, this might refer to finding the best talent in the labor pool. Whatever resources your organization needs, procurement finds and obtains them.

The relationship established with suppliers sets procurement management apart from simply purchasing goods. Ideally, procurement will look for the best sources of high-quality materials available at the best prices. The process is primarily streamlined through the use of procurement software.

Types of Procurement

There are four key types of procurement processes:

| Procurement Type | Definition | Example |

|---|---|---|

| Direct Procurement | Obtaining any materials for direct use in the manufacturing and production of the company’s products. | Raw materials, software, equipment |

| Indirect Procurement | Obtaining goods and services for company use separate from production. | Office supplies, maintenance crews not affiliated with the business offerings |

| Services Procurement | Acquiring third-party labor or consulting services. These are non-tangible purchases for the business, both direct and indirect. | Consultants, security guards, facilities repair |

| Goods Procurement | Any physical or tangible object purchased for the business, either direct or indirect. | Office supplies, raw materials |

Each procurement type requires mostly the same processes to complete, particularly direct and indirect. Services procurement has the most differences, especially since it may address one-time service needs, such as software implementation, rather than recurring purchases, which are common when dealing with raw materials and consumables. Direct and indirect procurement is sometimes called goods procurement or purchasing.

4 Stages of the Procurement Process

Depending on your exact business, the procurement process from start to finish can range from as few as 5 to as many as 9 steps. Regardless of the total, several of these steps can overlap, which is why they can be organized into 4 main stages:

- Identify what is needed

- Research vendors, goods, and services

- Create purchase orders and quotes, proposals, or bids

- Receive and pay for goods

Identify Need

The modern procurement process begins with taking stock of what you have and need. Known as “needs recognition,” this is figuring out what is necessary for delivering your goods and services. Based on your industry, this can range from raw materials to heavy machinery and equipment. Some items, like consumables, will need to be regularly reordered, while others will be a one-time purchase.

Research Vendors

Next, you must order the necessary materials from suppliers. If you don’t already have a list of trusted vendors, you’ll have to start building relationships to get the best deals on their wares. At this stage, you’ll need to work out how you will receive the goods and services, along with when and how payment will be made.

Create Purchase Requisitions and Orders

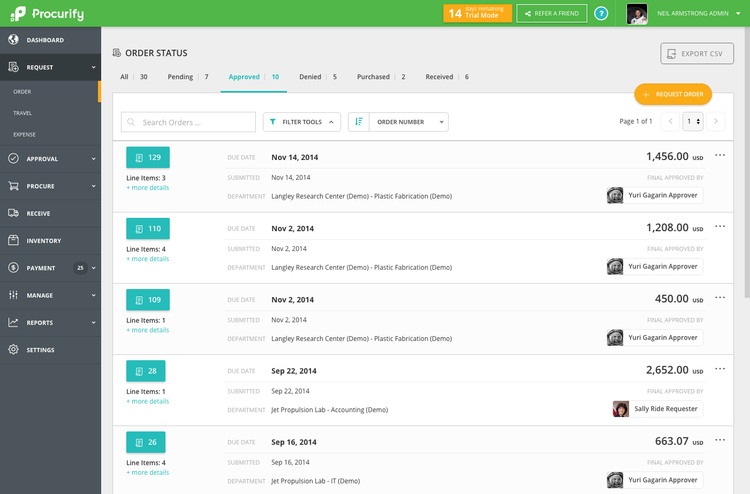

Before any order can be completed, you’ll need to consult any authorizing managers or stakeholders to approve purchasing decisions. This might be an office manager approving a bulk order of staples or a CEO confirming the purchasing of new industrial-grade equipment. In some companies a chief procurement officer (CPO) will be the one overseeing all company purchases. This is where the KPI data gathered during needs recognition comes into play, as it can prove to whoever is in charge of approval the necessity of the purchase and how it fits into the current budget. In some sales, competitive bidding is necessary, further requiring clear authorization of what is and isn’t within the budget.

Receive and Pay for Goods

Finally, you need to document the purchase, both for potential audits and ease of access for future or recurring procurement. You can use a detailed purchase order software to record data on what has been purchased, how much it cost, and where it was sourced from, creating a clear record for future purchases. Invoices are kept as part of the official records and checked against accounts payable with three-way matching in case of disputes or refunds. You can record supplier performance details, letting you know when it’s time to move on to new vendors for better deals or short-term savings.

Procure-to-Pay Process

To go a step further, you can like the purchasing department with the accounts payable department for a more streamlined supply chain process. This is called the procure-to-pay process and is widely adopted by many businesses. There is even specialized procure-to-pay software that manages both the purchasing process and finalizes proper recording within accounts payable.

Modern vs Traditional Procurement Processes

The traditional procurement process used to involve a lot of paper, from spreadsheets to scheduling calendars. Physical requests for quotes (RFQ) and proposals (RFP) would be passed around from CPOs to procurement teams, leading to potential delays from lost or misplaced paperwork. It was also easy for human error to create inaccurate records like purchase orders and invoices when calculating purchase costs.

Procurement could take weeks or months to complete with traditional, paper-bound methods. Any project involving competitive bidding would get bogged down by repeated back-and-forth between procurement teams and whoever was authorizing the budget, leading to a long paper trail and higher bids that might eat into the bottom line.

Now, the majority of the work can be automated through procurement software, which streamlines the entire process into real-time with digital accessibility. A floor manager can instantly mark they are out of supplies from the comfort of their office, automatically informing the CPO and instantly starting the procurement process without the need to generate new purchase orders. If bidding is necessary, approval can be sent directly to procurement departments without endless back-and-forth paperwork.

How Software Helps

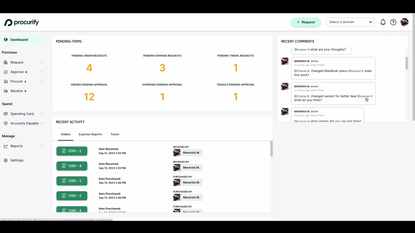

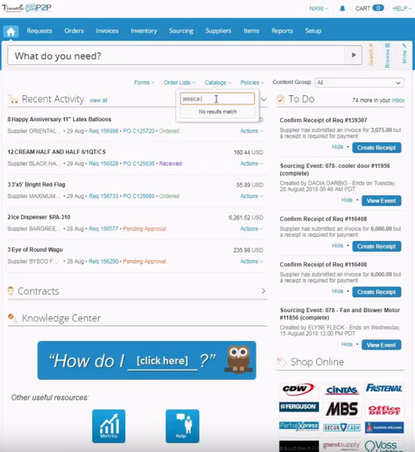

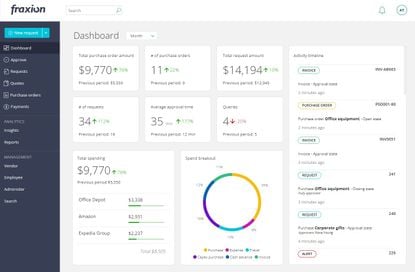

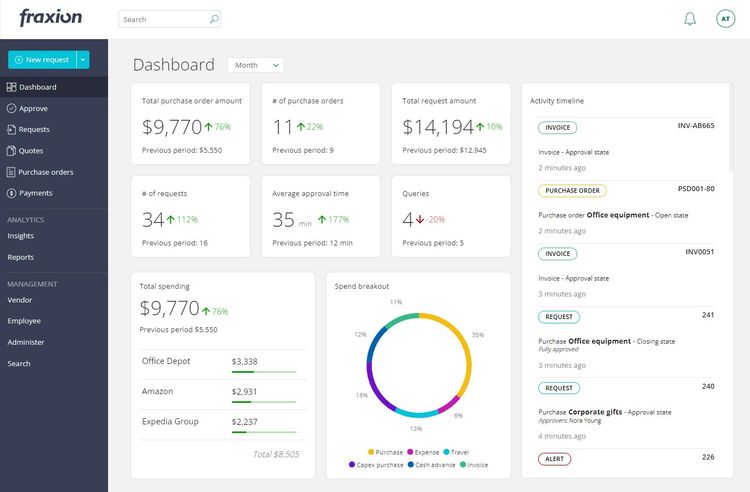

Procurement software streamlines the traditional purchase processes by tracking all key order info in real time, including the vendor, purchase quantities, item or service purchased, delivery timeframes, payment terms, and costs. Once implemented, procurement software ensures you make profitable choices in your procurement practices through faster delivery times, economies of scale, better supply chain efficiency, and lower overall costs.

Another major benefit of subscription-based procurement software is setting automatic or recurring purchase orders. Support for recurring purchases enables the creation of procurement orders in the future whenever particular conditions have been met, significantly decreasing the labor associated with needs recognition and authorization.

The procurement strategy of each company will depend on a wide variety of factors. Fortunately, software automation can make it easier to meet your business needs at the best price. Perfect your procurement process with a new system made possible by software.