ShiftWorx MES

While ShiftWorx may not dazzle with ERP platform integration, it impresses with its machine monitoring and predictive modeling. It’s the real-time insights that truly make it stand out. Its affordable pricing at $100 per machine per month, coupled with its scalability, adds to its appeal.

On the flip side, startups or very small companies might struggle to fully utilize their capabilities. There are alternatives better suited to their unique requirements–but ShiftWorx is still a solid choice for those in the manufacturing industry who seek a tool to optimize processes.

- Competitive pricing with a "pay as you go" model

- Predictive modeling through AI integration

- Real-time machine monitoring

- No full supply chain management

- No native integrations with major ERP platforms

- Developer FreePoint Technologies

- Client OS Web

- Deployment Cloud Hosted

What is ShiftWorx?

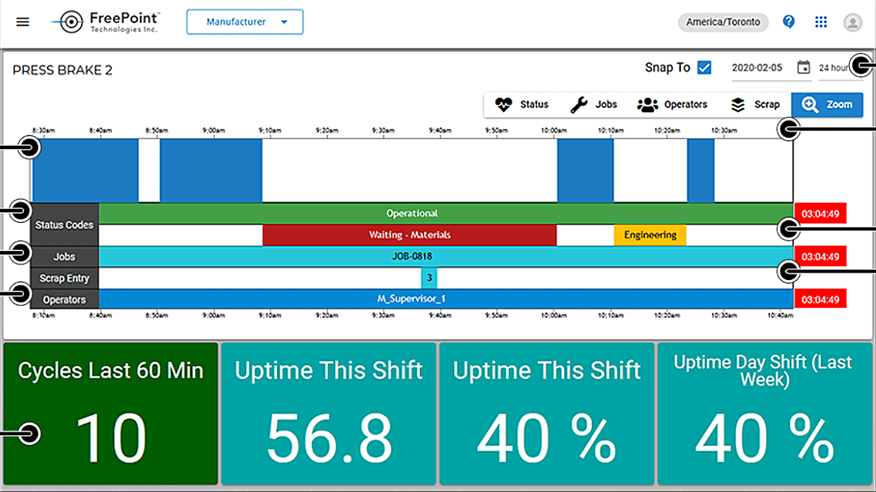

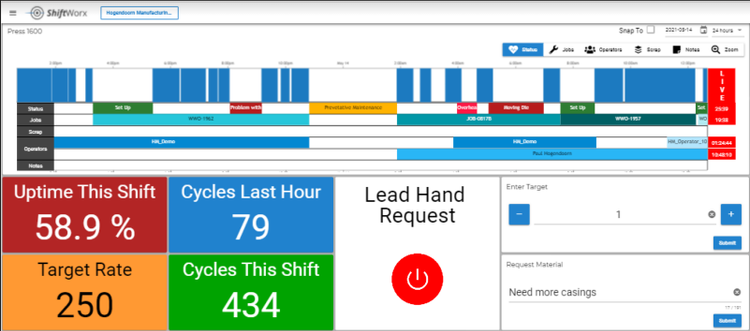

ShiftWorx by FreePoint Technologies is a machine monitoring and data visualization MES software designed for the manufacturing sector. It enables operators to monitor machine performance in real-time and document any shortcomings with the click of a button. This provides businesses with actionable insights to improve productivity and reduce waste.

The system leverages a combination of sensor and software technology to connect directly to machines, regardless of their age or type, and to extract valuable data. In addition to monitoring, it offers modules for detailed reporting, analytics, and dashboard visualization, allowing for data-driven decision-making.

The platform is also supplemented with services such as TPS (Toyota Production System) to facilitate the adoption of lean manufacturing principles. ShiftWorx’s future roadmap includes enhancements in reporting capabilities, more personalized reports, and the application of AI for predictive modeling in scheduling and maintenance.

Who is ShiftWorx For?

ShiftWorx by FreePoint Technologies is primarily designed to serve small to medium-sized manufacturers in the discrete manufacturing sector. Their software is especially suitable for companies that need detailed and real-time insights into their production processes. The platform primarily benefits businesses seeking to increase operational efficiency, reduce waste, and improve overall productivity.

They serve a range of industries from automotive to food processing. It’s also worth noting that while they cater to companies of different sizes, FreePoint Technologies does not actively target very small companies or start-ups due to the nature and scope of their solutions. They believe their product would not be fully utilized or provide substantial value to such businesses, given their pricing model and service offering.

Our Ratings

| Usability - 9 | Real-time visibility into performance data that is simple to install, customize, and monitor remotely; sensors on machine quickly display uptime and downtime info into the software. |

| Support - 8 | 24/7 support team; support calls received at all hours of the day through a mobile and email system; live support only handled between 8AM-5:30PM Eastern; service calls can occur overnight if necessary; Help Center built into the software; each customer assigned an Account Manager. |

| Scalability - 10 | Can get started with a modular system and later progress into a roadmap plan (configured product based on your needs); can customize the right-fit modules that complement your current technology platforms. |

| Security - 8 | Avoids physical connections between ShiftWorx and machines to mitigate invasive attacks; ensures the confidentiality of customer data; protects against unauthorized access to machines and data. |

| Value - 9.5 | Plans start at $125/machine/month; competitors tend to average at $150-$200/machine/month; offers pay-as-you-go setup |

| Performance - 10 | Performed efficiently and effectively in monitoring manufacturing processes and providing real-time operational insights. Quickly shows performance and efficiency of factory floor; displays live display of metrics such as downtime, run time, parts produced, etc. |

| Key Features - 9 | Can set machine priorities and identify processes needed to run and what others can stay idle if you are understaffed; reporting tab lets you drill down into efficiencies broken up by different codes |

Features of ShiftWorx

ShiftWorx software is packed with several key features that make it stand out from its competition:

- Real-Time Data and Insights: The platform collects and provides real-time machine data, allowing manufacturers to gain actionable insights into their processes instantly.

- Data-Driven Decision-Making: It empowers companies to make data-driven decisions by providing essential metrics related to machine uptime, productivity, quality, and cost.

- Scheduler: The visual production scheduler gives you more control over the production process and your machines.

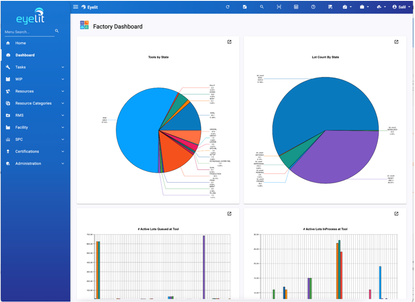

- Advanced Reporting Capabilities: ShiftWorx has enhanced its reporting capabilities, allowing for more customization and personalization of reports. It offers the ability to tell a story through data for everyone in the manufacturing process, from the executives to the plant managers and machine operators.

- Integration with Microsoft Azure and Power BI: This has further improved the depth and flexibility of data analysis and visualization that the platform can provide.

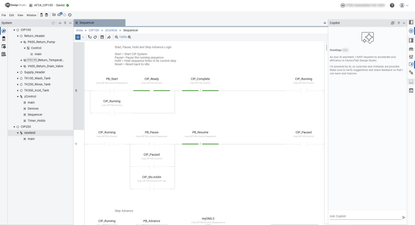

- AI-Powered Predictive Modelling: ShiftWorx is integrating advanced analytics and AI capabilities into the platform for predictive modeling, which can greatly assist in areas such as scheduling and maintenance.

Pricing

ShiftWorx is designed as a “pay as you go” modular system. The pricing model is $125 per machine per month (the number of users is not limited).

ShiftWorx prides itself on being deeper in their scheduling and machine monitoring features compared to ERP solutions that are more cursory and more canned. These ERP systems tend to offer these capabilities but include many additional features not needed, which increase the overall cost.

| Plan | Pricing |

| Starting Price | $125/connection or machine/month or $1,500/machine/year |

Alternatives

Summary

ShiftWorx is a good choice for data visualization and machine monitoring. It offers real-time insights, advanced reporting, AI-powered predictive modeling, and integration with Microsoft Azure and Power BI. However, it may not suit businesses needing extensive integration with major ERP platforms.

The software targets small to medium-sized manufacturers, but may not provide substantial value to very small companies or startups. Its performance is efficient, offering real-time operational insights. The “pay as you go” pricing starts at $100/machine/month, positioning it as a cost-effective alternative to larger MES systems.

User Reviews of ShiftWorx MES

Write a Review- Containers & Packaging

- 1-10 employees

- Annual revenue $0-$1M

ShiftWorx was focused on our needs

We spoke to several software options that attempeted to pitch an ERP but we are a smaller organization, not sized to support the investment of an ERP. ShiftWorx was focused on our needs relating to data collection on the overall efficiencies of our machines. The project has been tabeled for a short period but once the compnay is ready we will be pursuing the software to streamline our manufacturing processes.

Very easy to use

Collecting all data from the operators like downtime or real time spindle run . Which could help us with scheduling jobs or meeting customer satisfaction. The product is very easy to use , the best thing I liked about the product is that I can monitor all the spindle time on every machine from the cottage or from the office at work.

ShiftWorx MES Review

Great stuff! Ease of use and accurate data output from machines.

40% decrease in machine downtime

After implementing ShiftWorx, Excel experienced a 40% decrease in machine downtime. Runtime on our cutting machines increased by 50%. All employees could see how their machine was running and this helped engage machine operators in keeping their machines running and identifying reasons for downtime.

ShiftWorx MES Review

We have had a great experience with ShiftWorx and their crew of people who support the system. Added features we needed were implemented and it’s a tool we use daily. Good customer service which made choosing ShiftWorx easier.

Great remote factory floor visibility

Great remote factory floor visibility. Overall, the product was easy to install, customize and use to monitor and identify ways to improve productivity. Especially during Covid when travel to our 4 factories was restricted, the Shiftworx software was very instrumental in allowing me to monitor the progress that our manufacturing equipment was making. The software also allows you to quickly see variances both over time and compared to similar equipment and take corrective actions if needed. The Shiftworx software and freepoint hardware allowed visibility to our oldest and newest machines including Oxy fuel flame cutters, Blanchard Grinders and CNC milling machines. We have made an overall machine efficiency improvement of 15% in the last 2 years using shiftworx to monitor the progress.

the support has been great

The support has been great that’s the biggest comment I have. The idea of this package is great. I like that the program is very easy to use and the amount of options is really great; as an engineer I like the way I can tinker with it. Its a great interface to work with.

ShiftWorx MES Review

Overall Good Price for the product. Very much like it , and will implement in a broader scheme. The direct visual bars and KPIs are great for machining/ production. Reporting feature very nice. It’s a mature product and is low cost.

We improved production uptime by using concrete data

We improved production uptime by using concrete data. The overall experience is pleasurable. The technical support we receive is always second to none. The team at ShiftWorx is always willing to help - even to the point of designing or redesigning aspects of the software to make our company more productive. The data collected on our KPI’s helps us make well informed decisions.

ShiftWorx MES Review

Understanding the reasoning behind our downtime improves the efficiency of the machine. Measuring the efficiency of a machine is critical to our business and then being able to understand the reasons behind downtime improves on our efficiency.

Feature rich management system with exceptional ROI

Feature rich management system with exceptional ROI. Easily deployable by anyone with reasonable ability to follow directions. Dashboard visuals require less setup than many other systems and are focused around real business needs. The price is extremely affordable and you’re not forced to use proprietary hardware beyond that which is needed to communicate to the cloud backend.

ShiftWorx MES Review

Great for automotive manufacturing use. Nice oversight of production results or issues.

ShiftWorx MES Review

After the initial set up, everything has been running rather smoothly. It’s great that I can access the real-time data via the web-based dashboard.

Makes a difference right away

Makes a difference right away! This simple to use software drives performance on the shopfloor right away. It allows for simple metrics that drive bottom line results. I saw immediate changes to how our machinists decided to process jobs as they got visual feedback of the importance of spindle uptime. At a glance I can see what has happened in the last 24 hours and understand our performance - and so can everyone else in the company.

Real time data is key

Real time data is key - Overall I am satisfied with ShiftWorx. Ability to effectively display production information real time and quickly identify/correct issues as they arise. Also really like the “Time Shift” functionality that has been brought back from previous versions.

ShiftWorx MES Review

We have focused on downtime issues. Finding out where the problems are and correcting them as needed. The reporting and scheduled reporting makes it easy for our Group Leaders to provide updates to management and employees.

ShiftWorx MES Review

Favorable. Good and quick tech support. Quick easy installation and set up. Clean Graphics with easy customization of views.

Great advantage using Shiftworks for Paper machine processing

Great advantage using Shiftworks for Paper machine processing roll to roll. Machine operator’s performance and Order processing time have given us a new approach to order plannning and Inventory scheduling. Its user friendliness, installation time, and ease of learning and implementation are all pros of ShiftWorx MES.