The Best Fresh Produce Software

Fresh produce software helps manage the supply chain, logistics, and operations of perishable goods businesses. Our top picks prioritize features like inventory control, shelf-life tracking, traceability, and mobile order management.

- Offers real-time data integration

- Features are easily accessible

- Can easily share between desktop and mobile apps

- Optimizes delivery routes and schedules

- Offers flexible pricing strategies and controls to adapt to market changes

- Automates order-to-cash cycle

- Comprehensive food traceability features

- Advanced inventory control and slotting

- Supports one-pass picking methodology

Using our review methodology, we ranked the best solutions for distributors, wholesalers, processors, growers, packers, and shippers.

| Software | Best For | Deployment Options | Price |

|---|---|---|---|

| Famous ERP | Best Overall | On-Premise | N/A |

| Produce Pro | Packers and Shippers | Cloud | N/A |

| Visual Produce | Wholesalers | Cloud or On-Premise | N/A |

| Food Connex | Processors | Cloud | $10,000 - $14,000/year |

| Acctivate Inventory Management | Distributors | Cloud or On-Premise | $5,000 - $14,000/year |

| Produce Inventory Control System (PICS) | Growers | Cloud | N/A |

| Fusionware | Order Management | Cloud | Starting at $12,000/year |

| Prophet ERP | Production | Cloud or On-Premise | N/A |

- Famous ERP: Best Overall

- Produce Pro: Best for Packers and Shippers

- Visual Produce: Best for Wholesalers

- Food Connex: Best for Processors

- Produce Inventory Control System (PICS): Best for Growers

- Acctivate: Best for Distributors

- Fusionware: Best Order Management Tools

- Prophet ERP: Best Production Tools

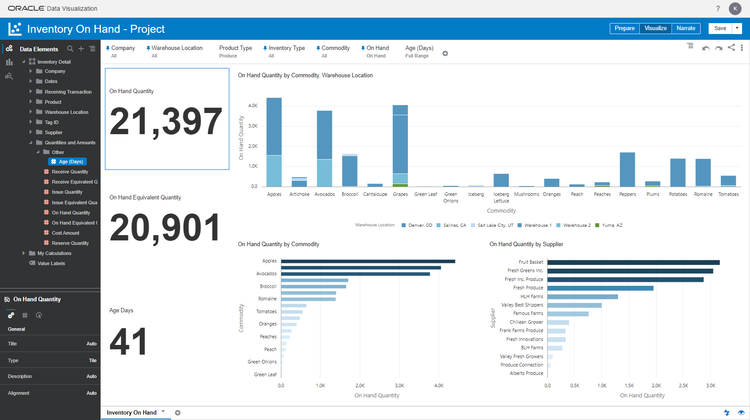

Famous ERP - Best Overall

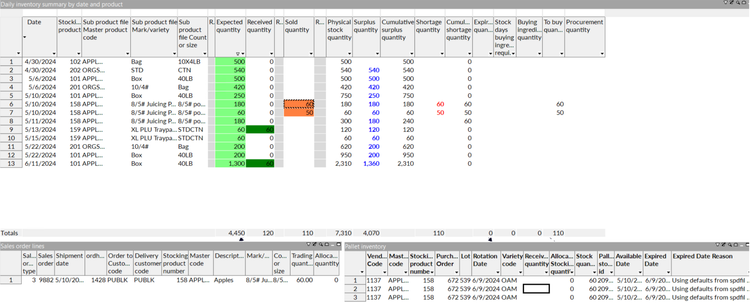

Famous ERP offers an effective suite of modules that help enterprise produce companies manage everything from sourcing to financials. Specifically, the inventory management module stands out for all types of fresh produce companies, including growers, packers, shippers, distributors, and wholesalers. The system allows for accurate product tracking through every stage, from the field to final purchase and shipment. This enables you to always view up-to-date stock counts, which leads to better decision-making.

The system lets you easily find products across every warehouse or storage facility. The real-time location tracking gives you visibility while managing multiple trucks, warehouses, coolers, and docks, enabling efficient on-hand stock tracking and expiration date monitoring. You can even trace products down to a single pallet or case for better compliance.

Famous ERP also sets itself apart because of its Oracle-powered database. It uses online transaction processing, which updates the system in real time, allowing you to always see current data. It’s crucial for not only the inventory module but for the entire ERP system, which includes modules for sales, financials, and sourcing. And because it’s all connected, regardless of the module you’re in, the data is consistently accurate.

One potential drawback of Famous ERP is that the system can only be installed on-premise, which may turn away companies looking for a cloud-based solution. That said, the Oracle database is effective for enterprise produce companies.

For more information on Famous ERP, read our full review.

Produce Pro - Best for Packers and Shippers

Produce Pro features shelf-life tracking, a critical component that can help you better manage fresh fruits and vegetables. This capability can help you maintain product quality, minimize waste, and ensure compliance with food safety standards.

The system tracks expiration dates in real time, allowing you to monitor your inventory’s freshness continuously. Whenever a new shipment arrives, Produce Pro records the products’ expiration dates and batch numbers and assigns them to specific lots.

The software supports the FEFO method, prioritizing selling produce with the earliest expiration dates first. This helps reduce waste and optimize inventory turnover. As stock moves throughout the warehouse, the system automatically updates each item’s status to prioritize products nearing their shelf-life limits. This proactive approach ensures that your products reach customers while they’re still fresh, enhancing their satisfaction.

For more information on Produce Pro, read our full review.

Visual Produce - Best for Wholesalers

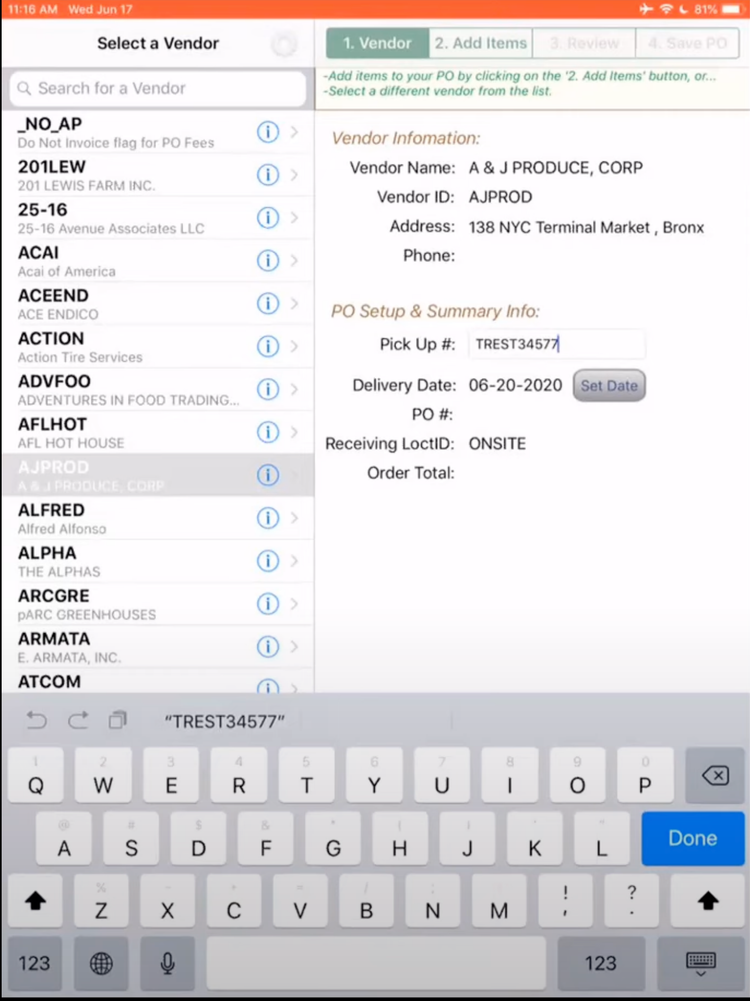

Visual Produce offers a mobile order management feature that streamlines order processing and enhances customer service. The feature operates through dedicated applications compatible with iPads and smartphones, allowing your team to handle transactions from virtually anywhere.

With the mobile app, you can do a variety of tasks, including:

- Enter new orders or modify existing ones

- Check inventory levels in real time to confirm product availability

- Review customer profiles and order histories to tailor sales approaches

- Track order progress, including shipping and delivery statuses

These capabilities ensure you access critical information instantly, facilitating prompt and informed decision-making. For example, if you receive an order for 100 pounds of apples, you can input it directly into the system for immediate processing using your tablet.

Before confirming the order, you can check the current inventory levels on the mobile app to verify if sufficient stock is available. You can also access the client’s purchase history to identify popular items and suggest additional products that align with their preferences. After placement, you can monitor its status through the app to ensure timely delivery and address any issues that may arise quickly.

For more information on Visual Produce, read our full review.

Food Connex - Best for Processors

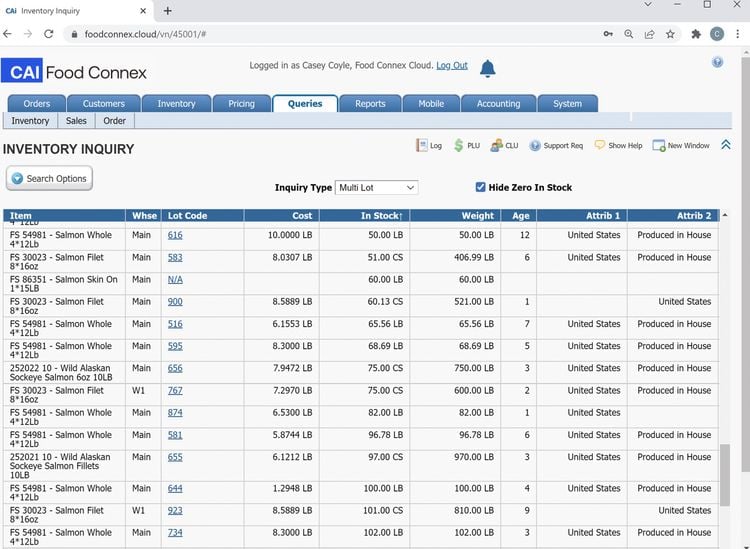

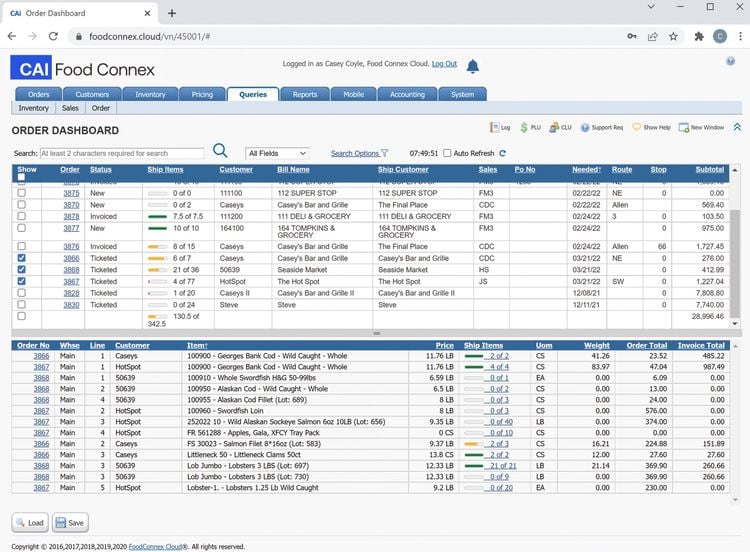

Food Connex ERP has strong batch tracking capabilities, which can enhance control and visibility throughout the production process. This functionality enables you to trace each batch from its arrival at the facility to processing and distribution.

When produce arrives at your facility, Food Connex assigns a unique lot number to each batch. The lot number links to detailed information, such as supplier details, harvest date, and quality assessments. The system will update the batch’s status and location as the product moves through various stages.

If you discover a batch contaminated with a pesticide residue that exceeds regulatory limits, you can identify the defective product by searching the batch number. The software will show which retailers and customers received the batch, allowing for an immediate targeted recall. You can work with distributors and retailers to retrieve the affected products from the shelves and prevent them from reaching customers. This advanced traceability can help resolve issues and ensure compliance with food safety regulations by providing a clear record of the product’s journey from farm to table.

One drawback of Food Connex is that it may not fully support complex multi-slot storage systems, which may impact you if you have intricate warehouse configurations.

For more information on Food Connex, read our full review.

Produce Inventory Control System (PICS) - Best for Growers

Produce Inventory Control System (PICS) allows you to simultaneously post multiple variables to inventory without manually entering each detail, reducing errors and saving you time.

You can enter treatments and labor for an entire produce batch in one action, including details like treatment type (i.e. fertilizer or pesticide), quantity applied, and labor hours. For example, if a team spends eight hours harvesting, the total labor hours can be logged and distributed across the produce handled.

This capability can be highly beneficial if you manage a large farm that produces various types of fresh produce. It ensures compliance with regulations and provides insights into resource allocation and treatment effectiveness.

For more information on Produce Inventory Control System (PICS), read our full review.

Acctivate - Best for Distributors

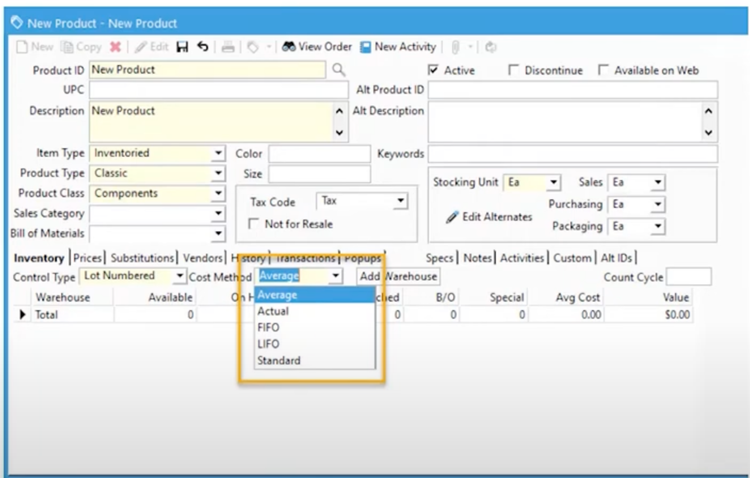

Acctivate’s lot number tracking feature with First In, First Out (FIFO) support helps ensure produce freshness and quality. This functionality can help reduce waste and spoilage, increasing your bottom line.

For instance, you might receive a large shipment of tomatoes in various batches. Upon arrival, the tomatoes will be assigned lot numbers based on when they were harvested. Acctivate ensures the oldest lot, like one expiring on September 10 instead of September 16, is selected first when fulfilling orders, reducing the risk of spoiled products.

Acctivate alerts you a few days before the lot expires, allowing you to prioritize orders for that lot. This ensures product quality and safety and enhances customer satisfaction and regulatory compliance. The system also utilizes Last In, First Out (LIFO) to manage perishable products and ensure customers receive fresh items.

You can integrate Acctivate with QuickBooks for full ERP functionality, syncing financials with inventory management. However, QuickBooks is the only accounting system that can be integrated, so companies using other accounting systems may find this restrictive.

For more information on Acctivate’s, read our full review.

Fusionware - Best Order Management Tools

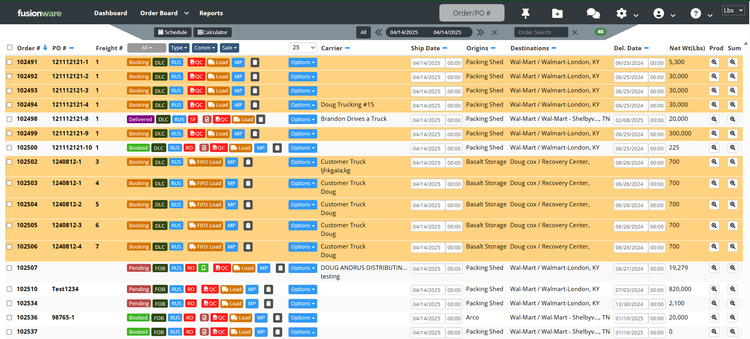

Fusionware offers a comprehensive order management module that tracks everything from initial creation all the way to fulfillment. Specifically, the order board shows crucial details like shipping origins, destinations, and trucking details. This helps ensure all loads arrive on time, giving you more control over the transportation of your goods.

Additionally, you can access every order’s financial information for easy reference. This can be found in the order details section, which gives you a breakdown of the product, freight, and fee costs, with the percentage of profit for each. It’s extremely useful to see exactly how much profit you’re making to make sure you or your customer isn’t overpaying for something like shipping.

Fusionware is best for growers, packers, and shippers who need total supply chain control. Pricing starts at $12,000/year, but you’ll need a custom quote for exact pricing. If you’re a smaller company that just needs order fulfillment, a system like Freshbyte’s Lite plan may be a better fit.

Read more on our Fusionware product page.

Prophet ERP - Best Production Tools

Prophet ERP’s built-in production planning and control module allows growers to accurately track costs and outputs. Measure sort interval productivity and efficiency on your product line to evaluate resource and labor usage. That way, you can spot inefficiencies and conduct root cause analysis to increase outputs and become more profitable.

Additionally, the system helps you maintain accurate inventory levels through its full live modeling of sales and production demand. You can set complex allocation rules, schedule production at the pallet level, and perform rapid re-assessments in minutes. It’s extremely flexible and lets you adapt to the fresh produce market’s fluctuating demands.

Prophet ERP helps businesses working across the entire supply chain, from growers to corporate food companies. Its ERP suite comes with several integrated modules, including accounting, warehouse management, and sales. Because of the many features it offers, it has a steeper learning curve and requires a higher time investment for training.

Read our Prophet ERP product page for more info.

What is Fresh Produce Software?

Fresh produce software is a type of food distribution software tailored for the fresh fruit and vegetable sector. It integrates various functions like quality control, sales, and logistics, focusing on real-time perishable food inventory management and traceability. This software aids in handling complex costs and operations in the produce industry, including production, transportation, and handling fees.

These systems offer accounting, buying, selling, processing, packing, growing, and brokerage modules, ensuring efficient supply chain management and quick response in recall situations. It caters to industry growers, packers, shippers, wholesalers, and distributors.

Key Features and Primary Benefits

- Inventory Rotation: Reduce spoilage by using the FIFO and LIFO methods to ensure that older stock is used first, prioritizing distributing products with shorter shelf lives.

- Cold Chain Management: Fresh produce must be set at specific temperatures to maintain freshness; this tool can help monitor and control temperature during storage and transportation.

- Traceability: Track your produce from the farm to customers’ tables, recall products quickly if necessary, and provide full transparency throughout the supply chain.

- Shelf Life Management: Track expiration dates for perishable products and send out alerts when stock nears expiration, reducing spoilage risk.

- Demand Forecasting: Predict consumption patterns, seasonal fluctuations, and market trends to help you optimize sales and purchases and decrease your risk of overstocking or understocking.

- Supply Chain Visibility: Monitor and report shipments, deliveries, and inventory status to reduce bottlenecks and inform customers about product availability.

- Quality Control: Perform inspections at different stages, including harvesting, receiving docks, and before shipping to ensure compliance with food safety regulations.

Pricing Guide

Fresh produce systems pricing can vary drastically based on your company size, user count, and required features. Here are some general ranges you can expect depending on the size of your business:

| Tier | Size | Average Cost | Examples |

|---|---|---|---|

| Low Tier | 1–10 employees | $3,000 – $10,000 per year | Produce Pro Go (basic mobile access), QuickBooks with produce-specific add-ons, FreshByte Lite, Food Connex, SOS Inventory |

| Mid Tier | 10–50 employees | $10,000 – $35,000 per year | Waudware PICS, FreshByte, Produce Pro Core, Fusionware, Food Connex |

| High Tier | 50–200 employees | $35,000 – $100,000 per year | Visual Produce, Famous Software (core ERP), Aptean Food & Beverage ERP (Produce Edition) |

| Enterprise Tier | 200+ employees | $100,000+ per year | Famous Software (with full modules), Produce Pro Enterprise, Aptean Food ERP (multi-location deployment), NetSuite with fresh produce customizations |

Specific Product Prices: Acctivate’s pricing starts at $5,000/year but can extend to $14,000/year. On the other hand, Food Connex is a little higher in price, starting at $10,000, and can increase to $14,000/year. These are just yearly subscription costs; most products will also include additional implementation charges that can lead to a higher price point.

On-premise deployment will have a higher initial cost as businesses purchase the software outright. Most businesses can expect locally installed options to have licensing, implementation, and training fees rolled together. Services such as support and data migration will usually be billed separately.