The Best Mixed Mode Manufacturing ERP Software

We evaluated mixed mode ERP systems that can support a variety of production methods, from make-to-stock to engineer-to-order. Our picks include affordable options for smaller manufacturers and feature-rich choices for larger companies.

- Open architecture for rapid integrations

- Multi-entity support

- Mobile accessibility

- Built-in payroll capabilities

- Controls inventory of raw materials, finished goods, and assemblies

- Fully configurable dashboard

- Free trial available

- New eCommerce additions

- Low total cost of ownership

In this guide, we cover systems that can handle mixed mode manufacturing, including production strategies like:

- Make-to-stock (MTS)

- Make-to-order (MTO)

- Engineer-to-order (ETO)

- Process or batch production

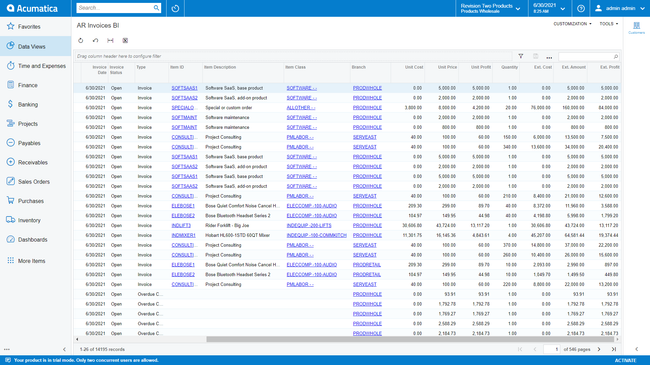

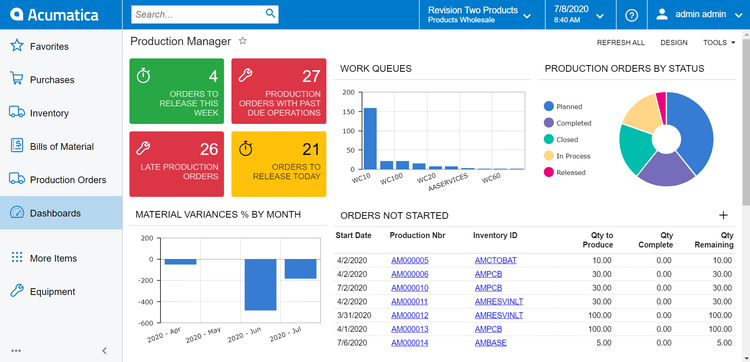

Acumatica - Best for MTO & MTS

Acumatica makes it easier to handle stock for both standard and customized items. For MTO operations, the built-in product configurator lets the buyer choose from various options, like different finishes or dimensions, when ordering. The system then auto-generates a production order directly from a sales line item, triggering the manufacturing process. This ensures that your team is aligned with the customer’s needs from the jump, reducing miscommunication between sales and production.

For MTS items, Acumatica’s material requirements planning (MRP) module creates production orders based on current stock levels and forecasted demand. It takes into account several factors, including:

- Past Sales Data Analysis: Examines historical transactions to identify patterns and trends, like a rise in computer desk orders at the start of each year as businesses set up new office spaces.

- Market Conditions and Trends: Adapts to market shifts like growing demand for eco-friendly light bulbs driven by new industry regulations.

- Forecast Models: Uses various models like the moving average method; the system can average sales over recent months to estimate needed quantities for the upcoming period, preventing both stockouts and excess inventory.

- Safety Stock and Reorder Points: Triggers production or purchasing actions when inventory falls below set thresholds. For example, if the number of printed circuit boards drops below 50 units, the system recommends making more to meet demand.

Acumatica’s manufacturing package starts at $3,500/month for up to ten users, making it a solid option for smaller companies. It’s also versatile, supporting repetitive, engineer-to-order, and batch production to accommodate a range of sectors, from electronics to chemicals.

Read our full Acumatica review to see if it’s the right system for your business.

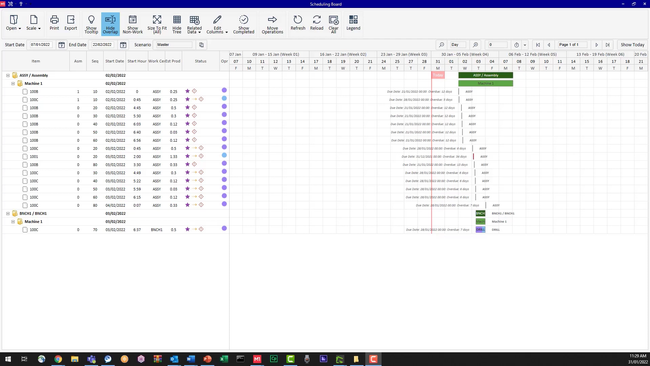

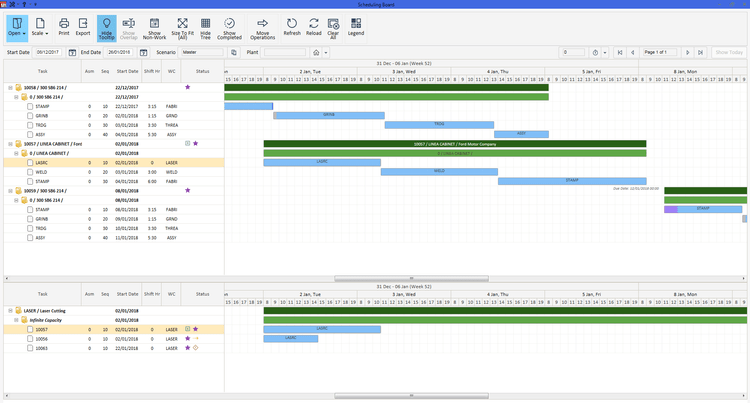

ECI M1 - Best MRP Module

ECI M1’s MRP session tracking tools help manage dependencies between MTO and MTS jobs sharing resources like workers and machinery. Just by clicking the binoculars icon, you can see all open and completed jobs. The system flags resource conflicts so you can tweak production schedules to prioritize high-demand orders.

This MRP tool also automates job creation based on filtering criteria like plant locations, production deadlines, and inventory needs. You can set lead times for raw materials and even configure job cutoff dates, letting M1 auto-update your schedule to show where and when components are required. It also triggers email, SMS, or dashboard alerts when it detects overlapping sessions or unresolved jobs. This aligns your workflows, ensuring make-to-stock operations don’t delay custom production.

ECI M1 is best suited for medium-sized manufacturers and starts at $3,000/month. However, it’s generally designed for discrete processes like MTS, MTO, and ETO. It has limited support for batch production or heavy recall management, making it less suitable for process-based methods.

Read our full review of ECI M1.

xTuple - Best BOM Functionality

xTuple supports multi-level bills of materials (BOMs), with revision control for sectors like furniture manufacturing that require complex, multi-part assemblies. For repeatable designs, xTuple auto-populates your BOM and routing steps when you create the work order. For custom projects, you can manually input details to track unique configurations more accurately.

You can also define tooling items within BOMs. Track specialized equipment, like molds or machine parts, without counting them as regular inventory. For industries like automotive, where the right tools need to be available for specific production runs, this helps better allocate resources such as CNC machines, conveyors, and lifts.

In a mixed-mode setup, not every item needs to be picked at the same time. For instance, packaging materials often aren’t needed until later. Fortunately, xTuple lets you organize your pick lists, excluding any non-essential components in the BOM, saving you time and reducing errors.

You can also specify the total quantity per item in the BOM to ensure it matches production requirements. This is useful when you’re handling materials that must be mixed or assembled in specific ratios, like in food manufacturing where the final product’s weight or volume is important. If the quantity doesn’t align with the preset value, this ERP flags it so you can address any discrepancies.

xTuple is highly affordable, starting at $175/user/month, though pricing can vary based on:

- Hosting option (cloud or on-premise)

- Any additional support packages

- Number of named users, or users accessing the system simultaneously

Learn more about pricing and key features in our review of xTuple.

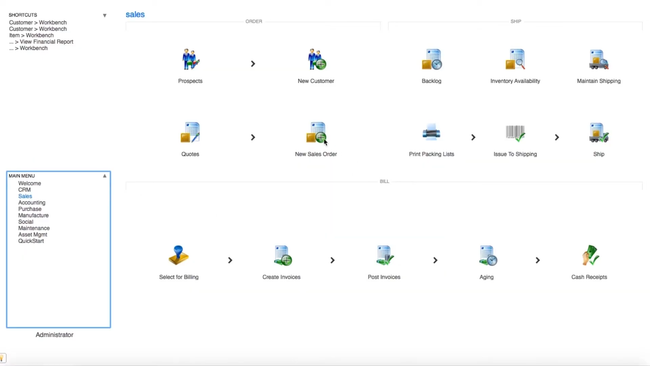

What is Mixed Mode Manufacturing ERP Software?

Mixed mode manufacturing ERP software, sometimes shortened to just mixed mode ERP, allows manufacturing companies to control multiple types of production methods, such as discrete, process, and engineer to order (ETO). These solutions contain many of the same popular features of general enterprise resource planning (ERP) software such as accounting and human resources (HR) while also offering additional advantages designed specifically for manufacturing, like inventory and supply chain management.

Using mixed mode ERP software, companies can combine both make-to-stock (MTS) and make-to-order (MTO) to better fulfill production orders. Or you can combine different manufacturing methods to increase the overall efficiency of production. There are multiple possibilities for optimizing your processes when using mixed mode manufacturing ERP software.

Key Features

- Supply chain management: Manage the movement of raw materials and finished goods between production facilities, storage locations, and sellers

- Batch management: Control different production batches; record, store, and modify formulas and recipes for specific batches

- Quality control: Ensure compliance control, perform risk analysis, and monitor workflow to ensure your manufacturing meets quality objectives for parts non-conformance; initiate corrective action management when necessary to reduce the risk of defects and errors

- General accounting: Track all internal revenue sources and company expenses through accounts payable (AP) and accounts receivable (AR) within a general ledger

- Budgeting and forecasting: Create detailed corporate financial plans to estimate future revenues and expenses to calculate departmentalized budgeting and payroll for employee compensation

- Bill of Materials (BOM): Provides instructions on the handling of raw materials and assemblies needed to manufacture a finished product

- Human resources (HR): Manage current employees and develop a consistent onboarding process for new employees; handling hiring of new talent for your manufacturing workforce

- Manufacturing execution systems (MES): Maximize resource utilization to decrease manufacturing cycle times, reduce scrap, and increase production targets

- Inventory management: Track all information about the raw materials and finished products you process, build, buy, store, transport, or sell; Measure physical inventory levels in real-time

Benefits

Mixed mode ERP software provides many useful benefits to manufacturers in every field:

Expand Your Manufacturing Options

Mixed mode manufacturing can cover a wide range of manufacturing methods. Two of the main types are defined as:

- Discrete manufacturing: The creation of products from individually created parts, i.e. combining different electronic components to build a computer

- Process manufacturing: The creation of finished goods directly from raw materials for use in other types of production, i.e. treating and cutting timber to create wood boards for construction

These two main categories of manufacturing then open up into more diverse production styles:

- Industrial casting, such as die, resin, and evaporative pattern casting

- Moulding of powder metallurgy and plastics

- Forming (metalworking), including stamping, pressing, and forging

- Machining like milling, turning, and drilling

- Joining, including welding and soldering

- Additive manufacturing (3D printing, etc)

Finally, you have to consider the production approach:

- Make to stock: Preparing products to meet anticipated customer demand

- Make to order (MTO): Building or assembling products based on specific orders

- Engineer to order (ETO): Similar to the above, except the product specifications are not known until the order is made

- Repetitive or continuous: Making the same product over an extended period of time

By using mixed mode ERP software, you can combine these various methods. For instance, perhaps you currently use discrete manufacturing and automation for most of your work assembling furniture. If you’ve found a process manufacturing method, such as sourcing your own textiles for custom upholstery orders, this could decrease the cost of all the ETO batches you complete daily. Mixed mode ERP solutions allow you to incorporate two or more types of manufacturing into your production schedule.

Faster Manufacturing Processes and Results

As mentioned above, mixed mode manufacturing ERP software helps expedite business processes. By providing various ERP and manufacturing tools in one solution, businesses can coordinate various functions simultaneously for faster results.

For example, you may realize you have a few low-volume products that could easily be made-to-order while other merchandise needs to be produced at a much higher volume to meet demand. This would require at least two different methods of manufacturing. Mixed mode ERP software allows you to coordinate between multiple types of production to best fit your current or future needs.

Through mixed mode ERP software, you can gain all the benefits of an individual ERP system or MES without integrating two, three, or more different solutions.

Remain Compliant

The world of manufacturing is full of regulations and rules. No matter what production process you use, there are requirements to ensure worker and consumer safety. Start by performing risk analysis to see if any of your manufacturing methods need additional safety measures to perform. By creating a safe workplace, you can keep your workforce happy and avoid costly fines.

Along with protecting workers on the shop floor, monitor workflow to ensure your manufacturing meets quality objectives for parts non-conformance. Then, initiate corrective actions when necessary to reduce production errors, which can lead to defective merchandise and materials. For example, batch management tools store formulas and recipes necessary for consistent production. No more guessing at ingredient ratios or assembling a product in the wrong order.

Additionally, quality control measures do more than protect consumers: they ensure happy customers receive high-quality products and materials every time they do business with your company.

Pricing

The price of mixed mode manufacturing ERP software varies greatly depending on the main tools you want, the scope of your business, and your exact production needs. Some solutions are available for a one-time licensing fee, while others are SaaS with monthly or annual costs. One-time payment plans range from $4,500 to $25,000. SaaS plans range from $175 per month per user up to $5,000 per month per user.

These main factors affect how cost-effective each solution is:

- Deployment (on-premise or Cloud-based)

- Module additions or customization

- Initial implementation (hardware and software installation)

- Additional users

Employee training, IT support, or upgrades may further increase the total costs. Another major factor to consider is how many facilities will implement the mixed mode software. By integrating these Cloud-based solutions at all your locations, you can better coordinate your production from start to finish.