The Best RFID Software

We tested the most popular RFID software on the market and cross-referenced thousands of user reviews. We picked our favorite systems and provided a complete buyers guide below.

- Integrates with Sage, Oracle PeopleSoft, ServiceNow

- Strong security features

- Highly customizable

- Bundling and kitting features for diverse inventory types

- Intuitive app for mobile data input

- Low learning curve for beginners

- Supports barcodes, RFID, and QR codes.

- Integrates with most leading ERP systems.

- Intuitive UI accessibility via mobile and web devices.

RFID software has powered asset and inventory tracking for years, and modern software systems are taking it further. Today, RFID technology enables real-time item tracking without barcodes or manual input, delivering faster, more accurate visibility across warehouses, job sites, and supply chains.

- CG4 Asset and Inventory Tracking: Best for Inventory Tracking

- Wasp Inventory Cloud: Best for Asset Tracking

- RedBeam: Best for Logistics and Yard management

- eTurns TrackStock: Best for Automated Stock Replenishment

- Infor WMS: Best for Warehouse Management

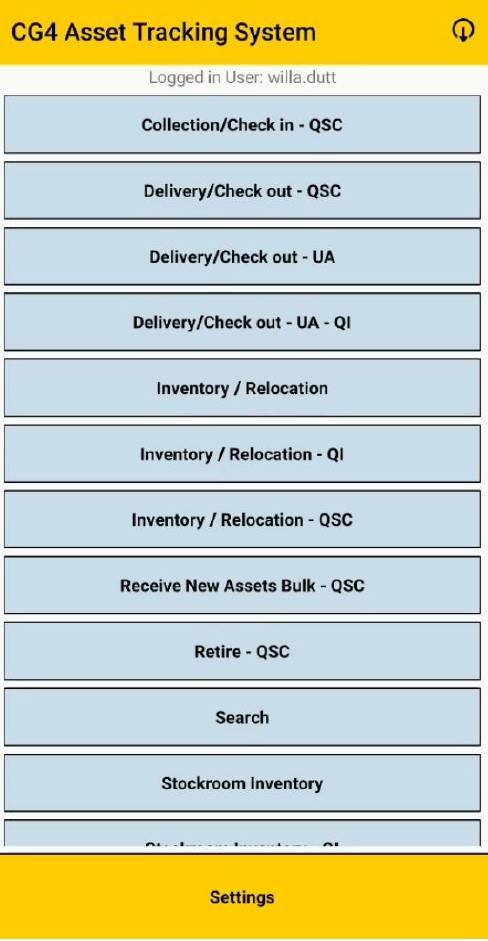

CG4 Asset and Inventory Tracking - Best for Inventory Tracking

CG4 delivers an RFID-driven inventory management platform built for organizations managing high-volume, fast-moving consumables across multiple stockrooms or warehouses. Unlike barcode systems that require line-of-sight scanning, CG4’s RFID implementation allows teams to perform rapid cycle counts and inventory transfers simply by walking through a space with a handheld reader. RFID tags respond wirelessly in bulk, enabling accurate data capture without individually scanning each item.

Each scan updates inventory records in real time and syncs directly with integrated systems such as ServiceNow, Sage, or Oracle PeopleSoft. CG4’s cycle counting tools can flag misplaced, expired, or transferred items without prior authorization. It also automates inventory reconciliations by instantly comparing expected values versus the actual detected items. This hands-free scanning not only increases the speed of tracking inventory but also ensures it’s highly accurate. This is optimal for highly regulated environments like medical labs, healthcare facilities, or expensive IT environments.

While pricing for CG4 isn’t publicly listed, you can expect implementation costs to start around $6,000. However, each deployment is customized based on hardware requirements and individual business use cases.

Learn more about CG4 Asset and Inventory Tracking.

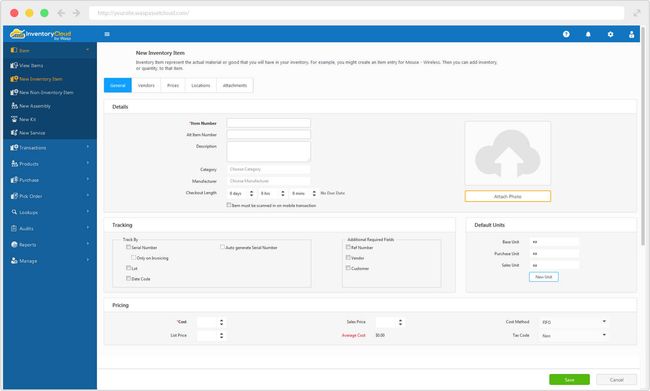

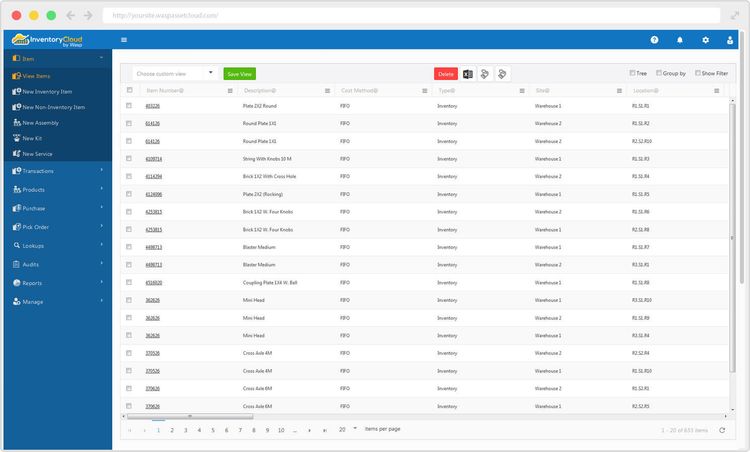

Wasp Inventory Cloud - Best for Asset Tracking

Wasp AssetCloud with RFID is purpose-built for fixed asset tracking, giving organizations detailed visibility into each asset’s location, status, and assigned user. Its RFID-based check-in and check-out system allows users to record asset movements automatically when items pass near a reader. Each transaction is time-stamped and linked to a specific employee, department, or customer, creating a clear record of responsibility for every asset.

This real-time tracking method simplifies audits and prevents loss by improving accountability. With RFID, users can scan an entire room’s worth of assets in seconds, verify their locations, and identify missing or unregistered items without needing to handle them one by one. This makes Wasp especially effective for organizations with mobile or high-value equipment, such as IT departments, healthcare facilities, or construction teams.

Wasp supports both cloud-based and on-premise deployment options depending on your business requirements. Pricing for Wasp starts at $1,295 per user, but RFID-enabled packages begin at $7,990 annually for five total users, including hardware and software bundles.

RedBeam - Best for Logistics and Yard management

RedBeam’s RFID technology has been rigorously tested and used across industries for over 20 years and excels at tracking the movement and location of vehicles and equipment within a yard or distribution facility. The RFID yard management system was built to track assets like trailers, containers, vehicles, and equipment moving through gates, lots, and loading zones.

Its RFID readers will automatically log movement the moment an asset passes through a checkpoint, eliminating the need for manual scans or gate check-ins. Each record includes a timestamp, an asset ID, and the entry/exit point, giving yard managers real-time visibility into the exact location and movement of all vehicles on site.

This automation helps monitor mobile assets spread across large yards or facilities. The simple dashboard makes it easy to identify idle trailers, spot bottlenecks, and confirm if a bay is open without walking the yard or checking paper clipboards. You can configure alerts for trailers that have idled for too long or entered an unauthorized area, helping keep your facility safe and moving efficiently.

RedBeam integrates with many of the leading RFID hardware, including Zebra devices, and offers a REST API for easy syncing with ERP and WMS systems. Pricing for RedBeam starts at just $1,200 per user per year, but discounts are offered for 3-year and 5-year contracts.

eTurns TrackStock - Best for Automated Stock Replenishment

eTurns TrackStock sets itself apart with its no-touch inventory replenishment system powered by its RFID SensorBins. At its core, each inventory location has two stock bins embedded with RFID technology. When one bin empties, your staff places it near an RFID reader, automatically triggering a reorder without scanning barcodes, entering part numbers, or logging anything. Just move one bin over, and the software does the rest.

The system is ideal for environments where replenishment speed and accuracy are critical but time is limited, such as maintenance rooms, service vans, hospitals, and laboratories. eTurns SensorBins also provide purchasing departments with visibility into stock usage and allow the purchasing team more insight into usage levels to avoid over- and understocking items.

Pricing for RFID and SensorBin functionality starts at the Manage Lite plan, which starts at $100 per month per stock room when billed semi-annually. More advanced plans with features like reporting, tool crib tracking, and ERP integration range from $250 to $400 per month per stock room.

Infor WMS - Best for Warehouse Management

Infor WMS is an enterprise warehouse management system that supports advanced RFID tracking for manufacturers, distributors, retailers, and third-party logistics providers. Built for high-volume operations, it manages everything needed to run a warehouse on a single platform, including receiving, put-away, picking, replenishment, and shipping. While barcode scanning is included out of the box, full RFID tracking requires additional hardware and configuration.

By leveraging real-time RFID inventory data, Infor enables intelligent planning and 3D visualization of large, complex warehouses. Warehouse managers can release work based on live inventory availability, order priority, and shipping or labor constraints. As RFID scans update inventory locations instantly, warehouse logic dynamically adjusts to prevent short picks and bottlenecks. Using Infor’s 3D visual warehouse interface, managers can see where stock is moving in real time, potential points of congestion, and the progress of ongoing warehouse tasks. For large facilities running high-volume fulfillment, the combination of real-time data and spatial awareness of live operations provides a level of control that static barcode tracking cannot match.

Infor WMS is best suited for mid-to-large enterprises managing multi-site complex warehouse operations. Organizations running simple or single-site facilities may find its advanced features overkill for their needs. Pricing requires a custom consultation that scales based on user count, deployment model, and operational complexity. Infor WMS can be added onto any Infor CloudSuite ERP or offered as a standalone WMS deployed on the cloud or on-premises for more control.

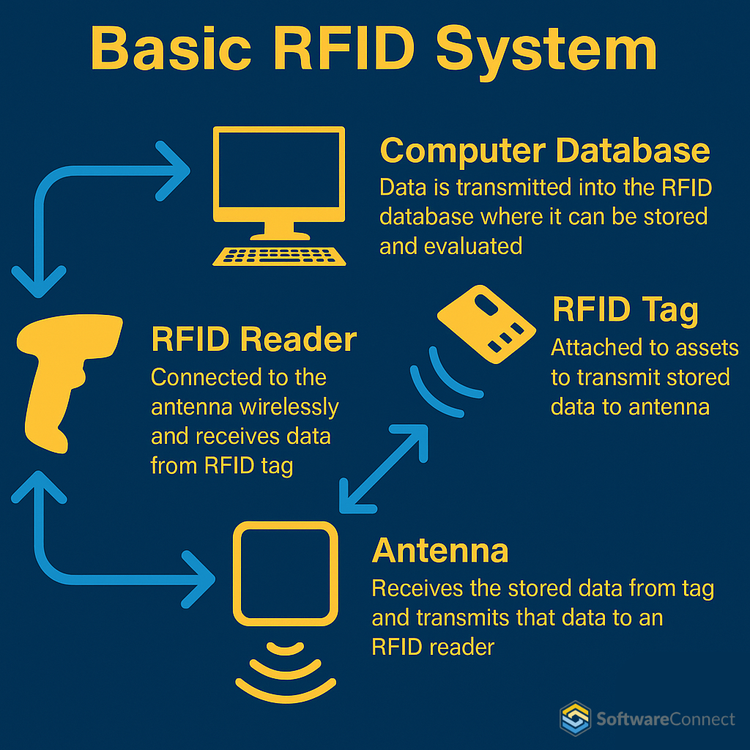

What is RFID Software?

Radio Frequency Identification (RFID) software uses radio waves to automatically identify, track, and manage data from tagged objects, people, or assets. Unlike traditional barcode systems, RFID software doesn’t require direct line-of-sight of the tags, allowing for faster, more accurate data collection from greater distances.

RFID software captures attributes of the tagged assets or equipment, such as location, status, value, service history, and even real-time movements. It then integrates this data with existing enterprise applications such as warehouse management systems (WMS), ERP, inventory management, and asset management systems to greatly improve their tracking capabilities.

Components of an RFID system

RFID software requires many hardware components to utilize the software effectively. They include:

RFID Tags

Small physical devices attached to items, assets, or equipment that store important identifying information about the item. RFID tags consist of a small microchip and an antenna. RFID tags come in various forms, including passive (no battery), active (battery-powered), and semi-passive types, each suited for various use cases.

RFID Reader

RFID readers use antennas to send and receive radio signals to and from RFID tags. Readers energize the RFID tags using frequency signals and prompt the tags to transmit their data back to the reader. Readers can be fixed and mounted in strategic locations such as warehouse entrances and conveyor belts, or simply hand-held for mobile scanning.

RFID Printer

These are specialized printers designed to encode RFID tags and print visual information onto labels, such as bar codes or serial numbers. These printers program data directly into the RFID tags’ microchip and are commonly used in environments requiring rapid-scale tagging. Think of businesses in the manufacturing, logistics, or retail environments.

Core Features

-

Tag Encoding: Easily encode RFID tags to store rich information about the item it is attached to. This data can be anything the owner wants, such as identifying information, its lifecycle history, and inspections.

-

Inventory Tracking: Track inventory in real time by continuously capturing RFID tag reads to monitor items’ or pallets’ location, movement, and status across the supply chain. Fixed readers automatically log items as they pass through key checkpoints, while handheld readers enable on-demand location scanning anywhere in the facility. Advanced systems will time-stamp movements, flag discrepancies, and automate cycle counting.

-

Asset Tracking and Management: Assign RFID tags to tools, equipment, vehicles, and other assets that update their location and status as they move. Systems can trigger maintenance reminders, assist with check-in/check-out procedures, and alert you when something goes missing or is not returned on time.

-

Access Control and Security: Control who can access specific areas or equipment using RFID badges and keycards. RFID readers installed at entry points check credentials in real time and grant or deny access based on the tags’ permissions. The system logs all entry attempts and can trigger alerts for specific tags or unauthorized activity.

-

Integration with other Systems: RFID software connects with other business systems like inventory management, ERP, and maintenance programs to share data. RFID tags can trigger actions like receiving goods, updating stock counts, or opening work orders to reduce double entries.

-

Alerts and Notifications: Get notified when something needs your attention, like when inventory drops too low or an asset tag moves out of bounds. Alerts can be sent by email, text, or have an in-app popup so you don’t have to watch the system or RFID readers constantly.

RFID vs Barcodes vs QR Codes

RFID technology offers many advantages over traditional identification methods like barcodes and QR codes. It enables faster and contactless tracking, making it ideal for high-volume, complex, and automated environments. The comparisons below highlight how RFID stacks up against both QR codes and barcodes.

RFID vs Barcodes

RFID and barcodes both track items and equipment, but RFID works without line of sight and allows bulk scanning, making it faster and more durable for highly automated environments. Some RFID tags can even print a barcode to offer both barcode and RFID capabilities. Below is a breakdown of how they compare:

| Feature | RFID | Barcodes |

|---|---|---|

| Line of Sight | Not required | Required |

| Read Range | Several feet (up to 30+) | Inches |

| Scan Speed | Hundreds per second | One at a time |

| Data Storage | High (can store more information) | Low (limited to item ID) |

| Durability | Resistant to dirt/damage | Easily damaged or obscured |

| Cost per Tag | Higher (especially active tags) | Very low |

| Automation Friendly | Ideal for automated environments | Requires manual or semi-manual use |

RFID vs QR Codes

QR codes, on the other hand, store more data than traditional barcodes, like web links, product details, or contact info. But they still require manual, line-of-sight scanning, unlike RFID tags. Below is a comparison of both technologies:

| Feature | RFID | QR Codes |

|---|---|---|

| Line of Sight | Not required | Required |

| Read Range | Several feet | Inches |

| Scan Speed | Very fast (bulk scanning possible) | Slower (one at a time) |

| Data Storage | Moderate to High | Moderate (more than barcodes) |

| Durability | More robust | Can degrade or fade |

| Cost to Print | Higher | Very low |

| Automation Friendly | Hardware-driven (automated use) | Visual/manual (e.g., smartphone) |

Who uses RFID Technology?

RFID software and hardware can be used across a variety of industries, including:

-

Manufacturing: In factories and production facilities, manufacturers use RFID to monitor raw materials, equipment, and finished products as they move through production. This reduces production delays with real-time updates, minimizes inventory errors, and ensures better quality control across the supply chain.

-

Healthcare: Clinics and hospitals use RFID to track medical devices and supplies, and can even track patients in real time. By automating asset management and improving visibility into patient and equipment processes, RFID technology can help reduce misplaced equipment and support safer, more efficient patient care.

-

Retail: Retailers use RFID to maintain accurate inventory levels and prevent theft by providing real-time storefront and warehouse stock visibility. RFID technology can see how many items are on a shelf and where they are located within a store. It can also be embedded into individual product tags, so you know exactly where all merchandise is across the supply chain or individual stores.

-

Transportation and Logistics: Shipping companies and distribution centers deploy RFID to track goods through every leg of the supply chain. RFID can be used to automate gate entries, track individual pallets, and even track the movement of trucks throughout a yard. This can all be done without additional work from internal staff by simply installing RFID readers throughout a distribution facility.

-

Farming and Agriculture: Farmers and food producers can tag livestock, track expensive field equipment, and monitor crop outputs and temperature levels. By using both handheld and fixed readers, farmers can quickly understand where livestock is located across their fields or facilities.

The Future of RFID

RFID technology is rapidly evolving, moving beyond basic item tracking and becoming a cornerstone of smart automation and IoT integration. Here are a few key developments that will be shaping the future of RFID technology:

Smarter Tags

Modern RFID tags are embedded with environmental sensors that detect temperature, humidity, pressure, and movement. This makes it possible to track not just where an item is but also how it’s being handled. These future capabilities will emerge first in industries like food and beverage, pharmaceutical manufacturing and distribution, and farming.

Intelligent RFID Readers

Traditionally, RFID readers simply capture tag data and pass it along to a local database or server for processing, serving a data collection role. Now, with smarter reading technology, these devices act as mini-computing devices. They can execute logic, trigger local alerts, and interact with other systems without connecting to other software solutions. This enables quicker decisions such as diverting a package or opening up a gate with minimal human intervention.

Printable and Embedded RFID

Advancements in printable electronics make it possible to print RFID antennas and chips directly onto packaging, labels, and fabric. By embedding RFID into fabric, apparel companies can track inventory more efficiently without attaching separate tags. Printed RFID on medicine packaging in pharmaceuticals allows for quick authentication and better traceability. And for retailers, embedding tags into packaging allows for automated checkouts, eliminating the need for visible stickers or manual scans.

IoT Integration

RFID is becoming a core puzzle piece for complex IoT environments. Using many RFID readers and tags, these systems can communicate directly with other smart devices to share data or perform actions. Think of a manufacturing floor where an RFID-tagged component is scanned as it enters workstations. This can automatically trigger a machine to adjust its settings or begin an automated process, eliminating the risk of human error.

Smart Dust Technology

Extremely new technologies such as “smart dust” are still in the conceptual phase, but are getting closer to becoming mainstream as computer chips continue to get smaller and smaller. These microscopic chips can be applied to objects and items similar to standard RFID technology. However, by being small, they can be embedded into materials that traditional tags won’t fit. Think of tracking pharmaceuticals, monitoring soil health, or applying directly into finished products. To learn more about smart dust, explore this article from FuturSide.

Pricing Guide

Pricing for RFID solutions varies widely based on system size, use case, and deployment complexity. While hardware costs are a factor when initially implementing, most long-term investments are tied to software and support costs. Below is a general overview of RFID software pricing:

Software Pricing

| Pricing Model | Typical Range | Notes |

|---|---|---|

| Small Business Cloud | $100 – $500/month | Best for light use cases like asset tracking or basic inventory. Typically includes 1–3 users, limited customization, and core reporting. |

| Mid-Sized Business Cloud | $500 – $2,000+/month | Designed for more complex workflows, higher tag volumes, multiple users, and integration with systems like WMS or ERP. |

| Enterprise Cloud | $25,000 – $250,000+/year | Tailored solutions with advanced features, API access, multi-site support, SLAs, and dedicated onboarding. Often priced by asset volume or system integrations. |

| On-Premise License | $50,000 – $500,000+ | One-time fee for self-hosted deployments. Requires IT infrastructure and is typically used in regulated or high-security environments. |

Hardware Costs

Hardware can either be sourced through your software vendor or purchased separately from reputable RFID vendors like Zebra, Honeywell, and Impinj. It’s important to confirm compatibility with your chosen software before making any hardware investments.

RFID tags range from just a few cents for basic passive tags to $30 or more for specialized or active tags. Handheld RFID readers generally cost between $1,000 and $2,500, while fixed readers tend to fall around the $5,000 range, depending on their features and antenna support.

How to Choose the Right RFID Software

-

Use Case: Define the process and application you plan to implement with RFID technology, such as inventory tracking, asset management, access control, or supply chain automation. The best software will offer the features, workflows, and RFID configurations that align with your defined process.

-

Scalability: Choose RFID software that can support increasing tag volumes, multiple reader types, and the expansion of new facilities. A scalable solution should handle large volumes of tag reads without slowing down and allow you to add devices or users easily. You should be able to grow from a small pilot project to an enterprise-wide deployment without needing a full overhaul.

-

Hardware Compatibility: Ensure the software you select supports the readers and tags you plan to use. This is extremely important if you’re sourcing hardware separately from your software vendor. Most vendors can provide you with hardware that integrates with their tech stack.

-

Integration: RFID data is most valuable when it flows into your existing systems. Make sure the software can integrate with the existing software you are using, or ensure the software you purchase is compatible with advanced tracking capabilities. Work with your software vendor to understand what level of customization is required or if it’s a standard integration already built in.

-

Deployment Model: Decide whether a cloud-based or on-premise deployment fits your work environment. Cloud deployments offer faster setup, automatic updates, and lower IT overhead. On-premise deployment may be preferred for high-security or highly customized settings. However, current cloud-based systems offer a similar level of security to on-premise systems in this day and age.

-

Support and Vendor Expertise: RFID deployments involve more than just installing and setting up software. They require physical infrastructure, tag placement strategies, and reader fine-tuning. Choose a vendor with proven experience in your field or RFID application and ask for previous case studies to better understand their expertise for your expected use case.