The Best Asset Tracking Software

We’ve reviewed the top asset tracking software on the market based on different functionalities, such as fixed asset management or equipment and tools tracking. Whether you’re renting out equipment or managing IT assets, we can help with your business needs.

- User-defined actions for each asset

- Fully customizable asset hub

- Reserve, maintain, and track multiple asset types

- Includes over 50 depreciation methods

- Offers integration with accounting and ERP systems

- Provides fixed asset lifecycle management

- Real-time tracking system

- Offers a variety of different trackers

- Includes geofencing for detailed asset tracking

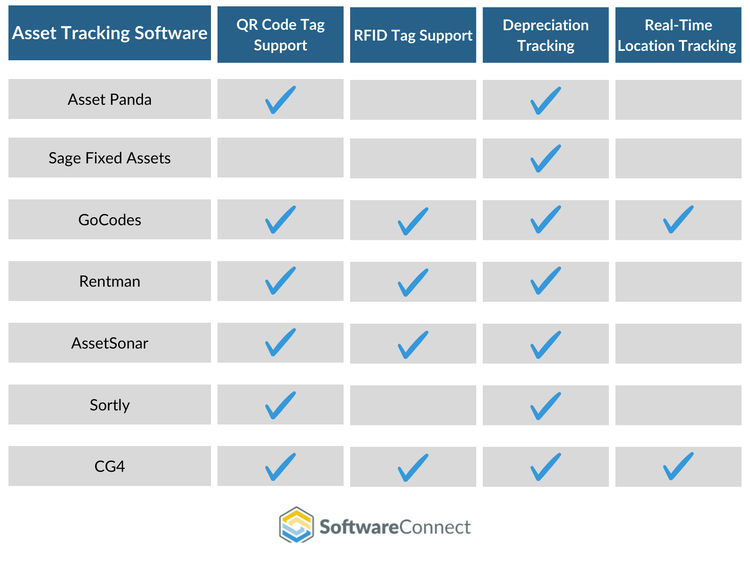

We’ve ranked the best asset tracking systems based on their support for different use cases, including asset rental tracking, IT asset management, and fixed asset management.

Whether you’re looking for different asset tag options or a system to calculate complex depreciation methods, these solutions offer diverse strengths to meet your business’s needs.

- Asset Panda: Best for Tools & Equipment

- Sage Fixed Assets: Best for Fixed Asset Management

- GoCodes: Best for Mobile Asset Tracking

- AssetSonar: Best for IT Asset Management

- Canfigure: Best for Engineering Asset Management

- Rentman: Best for Rental Asset Tracking

- Sortly: Most Affordable Option

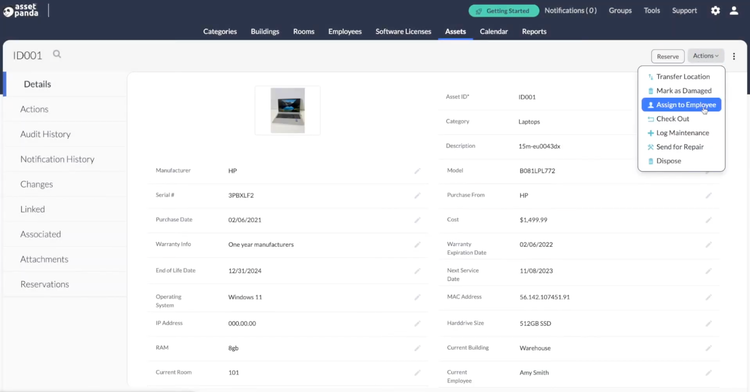

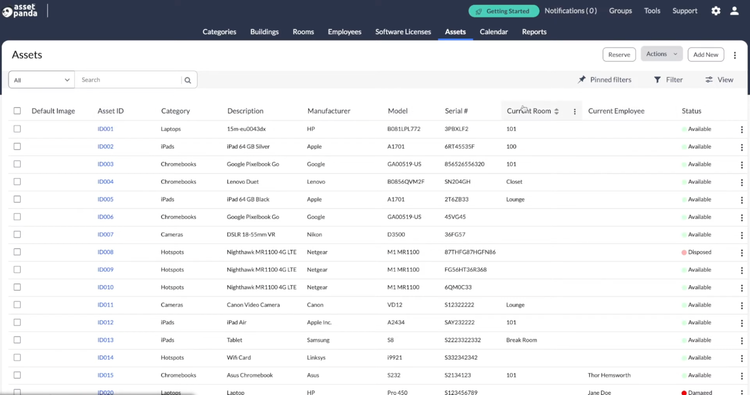

Asset Panda - Best for Tools & Equipment

Asset Panda’s asset management module enables you to track tools, equipment, and other assets efficiently. You can maintain up to 5,000 assets and assign each one a barcode or QR code, check it in and out during use, and enter information like warranty expiration and purchase date. This is ideal for companies like service providers that track company equipment used by crews in the field to prevent theft or total loss.

While asset management modules can be found in other systems, Asset Panda is one of the most customizable systems we’ve seen. For example, you can add user-defined actions for each asset to streamline workflows for important functions. These can include several multi-step functions, such as log maintenance, marking as damaged, or assigning to an employee, and the system will automatically update the status. eSignatures can be added to ensure an extra layer of accountability when loaning equipment.

Asset Panda can be used by several different industries, including:

- Construction: Track equipment and tools like power drills, excavators, or forklifts across multiple job sites, ensuring items are checked in and out properly. As assets become damaged, quickly create a work order to reduce downtime.

- Manufacturing: Monitor equipment and machinery across the production floor. Give barcodes to machinery for fast information reference.

- Education: Rent out devices like laptops or tablets to students and faculty without losing track of availability.

Read more on our Asset Panda product page.

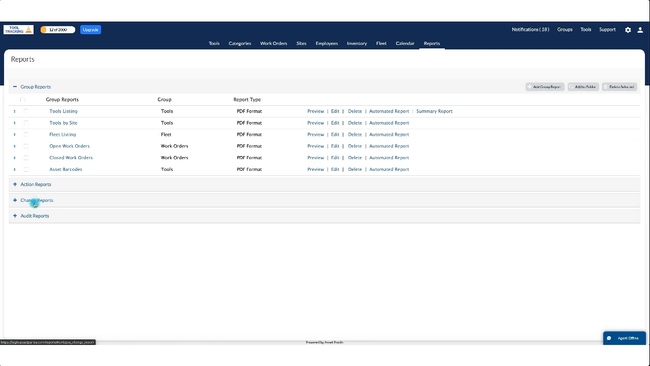

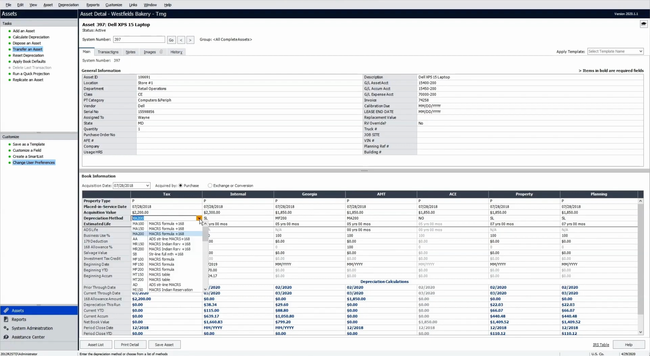

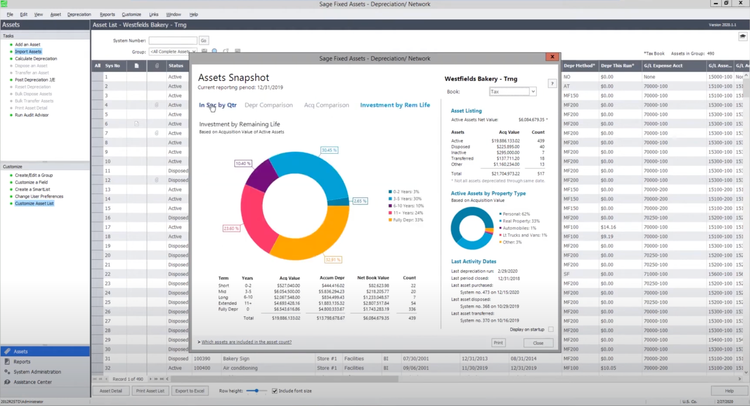

Sage Fixed Assets - Best for Fixed Asset Management

Sage Fixed Assets offers a streamlined depreciation module with over 50 depreciation methods for all your assets. These can include property, high-value equipment like production machinery, or vehicle fleets. This helps you track their entire lifecycles, from initial purchase through disposal, tracking their value along the way.

Within the depreciation module, you can see an asset snapshot that shows a more general overview of all your active assets. This can include several charts and tables, including:

- Service by quarter: See how many assets were placed under service in the past year and their total value.

- Depreciation comparison by book: Compare active assets acquired value vs. accumulated depreciation to better understand each group’s net value.

- Investment by remaining life: See the value of assets categorized by their remaining life in years, from brand new to fully depreciated. This helps you gain a holistic view of the current state of your assets and each category’s net value.

However, one potential drawback is that Sage Fixed Assets’ interface is a bit dated. While it doesn’t take away from its strong functionalities, users looking for a more modern look and feel may want to consider a different option, like EZOfficeInventory or Asset Panda.

Learn more on our Sage Fixed Assets product page.

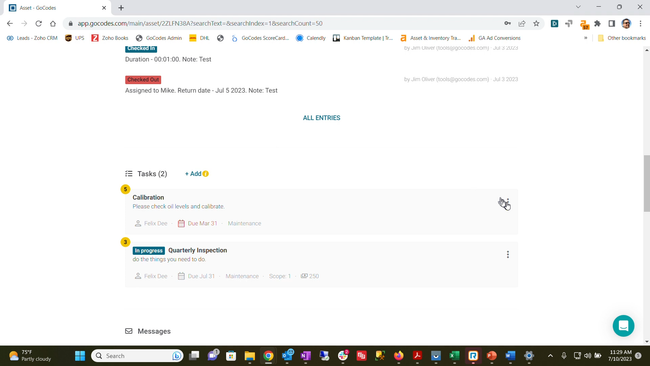

GoCodes - Best for Mobile Asset Tracking

GoCodes offers real-time tracking devices for monitoring vehicles or other high-value mobile assets. Simply plug the trackers into your fleet of vehicles, and you can easily obtain key metrics like vehicle speed, hard braking, and engine hours. Along with minute-by-minute GPS tracking, the trackers help you oversee all the vehicles in the fleet and ensure they are being driven responsibly.

Within the map view, you can set up a geographic boundary around the area your asset should be in. For example, a construction company sends vehicles and equipment like bulldozers and dump trucks to a site for a two-month-long project. You can set up a geofence around the site and be notified when equipment leaves the area, helping prevent theft or unintended use of company equipment.

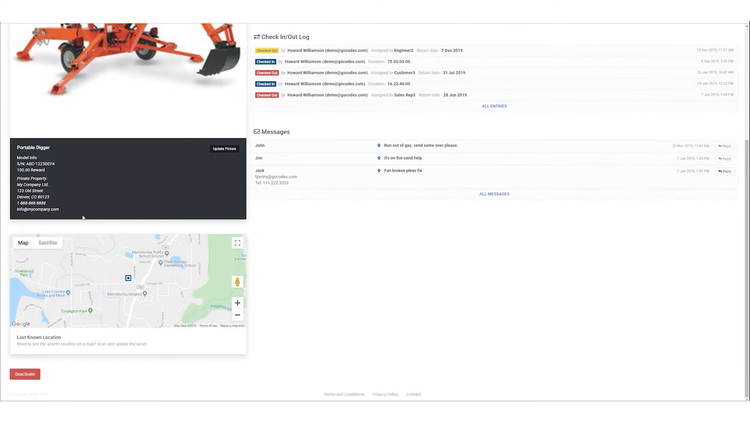

For smaller tools and equipment, GoCodes offers QR codes to track their use and location. These can be scanned using the mobile app, which updates the last known location of the asset on the map. The check-in/out log lets you see usage history, ensuring accountability if it goes missing. This is particularly useful for construction or field service companies that want to reduce tool theft and keep better track of equipment use out in the field.

Read our full GoCodes product page for more info.

AssetSonar - Best for IT Asset Management

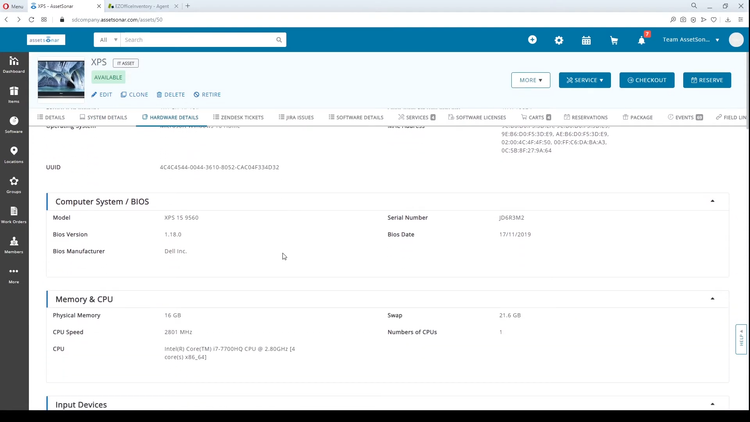

AssetSonar’s IT asset management tool helps you track IT infrastructure across all locations. For each IT asset, you can see comprehensive hardware details like its BIOS, memory and CPU, and external IP address. This allows you to easily access important hardware information during troubleshooting or determine if the device can operate new software.

You can view who has custody of each physical asset, such as laptops or tablets, and its location. It even has a map view that groups devices together if they’re located at the same office or facility, with pinpoints for each. This helps companies with a remote workforce or several global offices manage technical issues for all locations.

Additionally, you can track software licenses to help manage subscriptions and spending. Details within each license include total seats and license availability threshold, so if a new employee requires access to a system, you can quickly see if your plan has an open user seat. You can even create alerts for upcoming license expirations or automatic renewals.

AssetSonar also integrates with Jira and Zendesk to provide integrated IT support management. While troubleshooting a support ticket, you can access vital device and software information from the same system. This helps support teams resolve issues faster by eliminating the need to navigate between two programs.

Canfigure - Best for Engineering Asset Management

Canfigure is a flexible platform that delivers more than standard asset tracking. It combines asset management, IT service management, and engineering process control in one configurable system. This makes it especially valuable for companies managing complex equipment or support infrastructure calibration workflows under a single platform.

For engineering teams, Canfigure excels at **calibration scheduling, inspection logging, and equipment test tracking, helping ensure compliance and uptime across both physical assets and IT infrastructure. Automated workflows can trigger service tickets based on test results, missed calibration dates, or status changes, reducing manual oversight and improving reliability.

Canfigure also includes a centralized configuration management database (CMDB) that allows IT teams to map and track equipment and system configurations, their relationships, and dependencies. It’s a strong fit for engineering, manufacturing, and other regulated industries that require tight control over equipment testing, calibrations, or complex asset configurations. Plans start at $395/month, making it an accessible option for both small and large teams.

Rentman - Best for Rental Asset Tracking

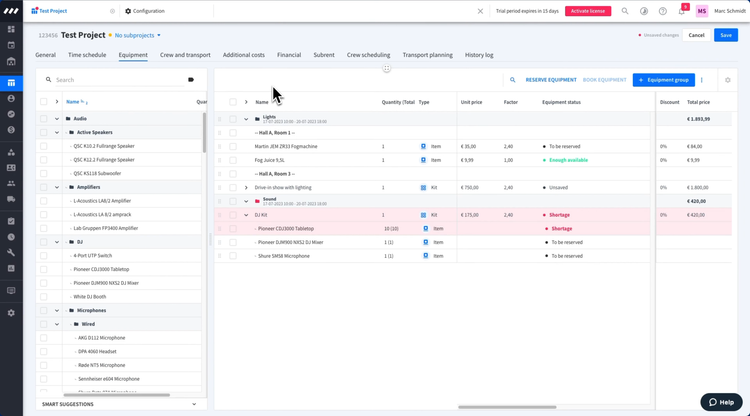

Rentman offers a comprehensive equipment rental module for businesses renting out equipment or other assets. The module lets you add any number of items into a single transaction, showing their unit price, availability, and total transaction price. Equipment can be tracked across a timeline of availability, so you know exactly when it will become available to rent to avoid double-booking.

RFID scanners can quickly scan items in and out of bundled equipment and kits. This works great for kits that include several individual assets like cords, as the scanner can scan each simultaneously for efficiency and to reduce mistakes. Rentman also offers standard QR codes or barcode tags for a more conventional tagging system.

Rentman is one of the more inexpensive systems on the list, starting at $67/user/month for the platform, plus equipment scheduling and tracking add-ons. However, the RFID equipment does have a high upfront cost, which may turn away smaller businesses.

Sortly - Most Affordable Option

Sortly is a budget-friendly option for industries requiring a simple equipment tracking system, such as manufacturing, construction, and healthcare. The asset tracking module helps manage equipment with a built-in mobile barcode scanner. Manufacturing employees can easily scan the spare parts they need for the day from their mobile devices for an efficient check-in and check-out process.

The system is easy to use, with a simple user interface that is easy to navigate. Inventory and assets can be sorted into custom fields for better organization across different asset types. This is effective for tracking medical supplies and equipment for different departments within a hospital. Different assets and supplies can be assigned specifically for each department, such as MRI machines for the radiology department.

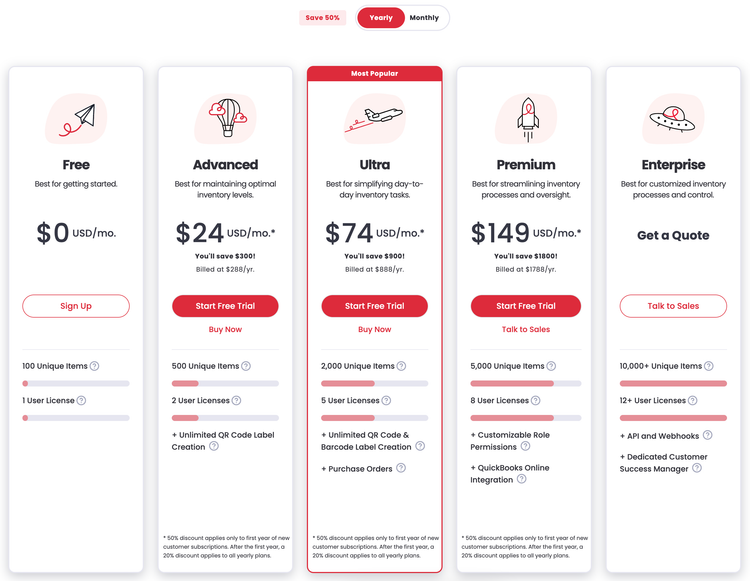

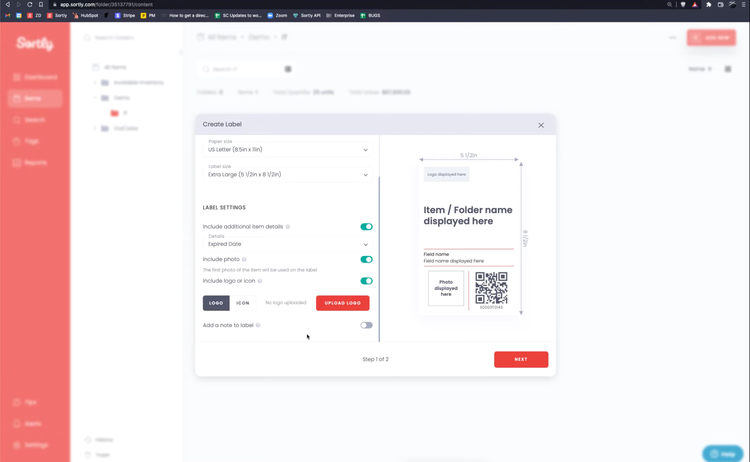

Sortly offers a free plan for startups and small businesses with fewer than 100 unique items to track, which is rare for asset tracking software. The plan includes in-app barcode and QR code scanning, along with custom folders and tags to help sort inventory efficiently. This plan is useful for small retail stores or schools that need basic inventory management and asset tracking functionality. Industries like manufacturing or healthcare will most likely require one of the paid plans to manage more complex inventories.

In its advanced plan, Sortly offers unlimited QR code label creation for assets that don’t have barcodes already attached. However, these must be manually printed on paper, which can wear down easily. If you require more durable QR code tags for heavy machinery or construction equipment, GoCodes and CG4 offer plastic and metal tags.

Read our Sortly review for more info.

Other Systems We Like

CG4 is a good option for the distribution industry, as it offers a wide range of scanning device support. It has especially effective RFID tracking capabilities, helping streamline receiving and inventory.

EZO is great for tracking almost any asset, from vehicles to construction equipment. The system is easy to use with support for QR codes, RFID, and barcodes to track fixed assets across several offices or locations.

What is Asset Tracking Software?

Asset tracking software helps users track and optimize the use of an organization’s physical assets, including equipment, tools, and machinery. These systems commonly help with work orders, maintenance schedules, location tracking, and equipment rental management. Asset tracking systems are considered a subset of computerized maintenance management systems (CMMS) or enterprise asset management (EAM) software.

Assets are labeled or tagged with barcodes or RFIDs to retrieve information like where they are, how they’re being used, who is using them, and when they will be returned. GPS and Bluetooth also provide real-time location tracking.

Asset Management vs. Tracking

The biggest difference between asset management and asset tracking is scope. Tracking acts as a component of overall asset management, focusing primarily on location and checking in and out, compared to managing the overall lifecycle and condition.

Key Features and Benefits

The primary purpose of asset tracking software is to track the location, status, and condition of your company’s physical and digital assets. On a high level, most systems will include:

- Asset tagging: Tag assets with barcodes, QR codes, or RFID tags. These show detailed asset information, including its purchase date, upcoming maintenance schedule, and its model or serial number.

- Location tracking: You can see your asset’s real-time location using Bluetooth or GPS tracking.

- Rental management: Manage bookings for renting out equipment, track maintenance, and log who used each asset last. This ensures assets aren’t double-booked, and all damages are recorded during check-in and out.

- Depreciation tracking: Calculate depreciation of high-value assets like properties or machinery. Track acquisition cost vs. accumulated depreciation and remaining useful life to determine when to replace.

- IT asset management: Manage software subscriptions, devices, and hardware across the entire company.

- Maintenance: Create work orders for damaged assets and view maintenance history.

- Spare parts inventory management: Keep a record of spare parts needed to perform maintenance on equipment.

Common Tags and Hardware

Asset tracking software typically requires tags and scanners to track the assets effectively. Common hardware includes:

| Hardware Type | Description |

|---|---|

| Handheld scanners | These can come in many types, including barcode, laser, or imager scanners. These are typically wireless and are used to scan your assets’ barcodes to pull up their information or add them to inventory. |

| Mobile devices | Mobile devices are most often used to scan tags and view asset information. Nearly all asset tracking software offers a native mobile app for scanning asset tags in the field. |

| RFID tags | RFID tags use radio waves to communicate with readers to scan without needing a direct line of sight, and all tags within range can be scanned simultaneously. |

| Real-time location systems | Track mobile assets like vehicles or construction equipment with real-time GPS location tracking. |

| QR code tags | QR code tags are the most common tags next to barcodes and can be printed manually on paper or purchased with more durable material like plastic or metal. Simply attach them to your asset and scan them to check them out or reference important data. |

Pricing Guide

Asset tracking software can cost anywhere from $15-150/asset/month. While some systems, like Sortly, have free options, they most likely won’t include enough features to be a viable option for most businesses.

However, asset tracking software pricing models can vary by system. GoCodes, for example, uses per-year pricing. The system starts at $500/year (200 assets and 3 users) and goes up to $2,500/year (2000 assets and 20 users) for the Professional plan. Sortly and Rentman, on the other hand, use a monthly pricing model for their plans. Below is a table summarizing estimated asset tracking software pricing:

| Size | Annual Cost | Notes |

|---|---|---|

| Small (up to 1,000 assets) | $1,000 – $5,000/year | Entry-level plans; pricing scales with asset count |

| Midsized (1,000 – 5,000 assets) | $5,000 – $20,000/year | Tiered pricing often based on asset blocks; includes integrations |

| Enterprise (5,000+ assets) | $20,000 – $75,000+/year | Includes real-time tracking, ITSM, CMMS, and advanced automation |

Hardware Costs

Also, there are additional costs to consider when purchasing asset tracking software. The physical tags (QR codes, barcodes, RFID), sensors (real-time tracking), and scanners have their own cost. These vary based on the complexity of the system, but generally, the equipment costs as follows:

- Basic barcode stickers: $0.15 - $10 per tag depending on the material

- Barcode scanners: $200 - $1,000 per device

- RFID tags: $0.50 - $5 per tag

- RFID readers: $500 - $2,500 per device