The Best Sales and Operations Planning Software

Sales and operations planning (S&OP) software can help large manufacturers and retailers align finances across departments. We evaluated top platforms for functionalities like demand forecasting and “what-if” scenario modeling.

- Connected Planning platform enables collaborative planning

- Hyperblock™ modeling and calculation engine

- Unified cloud-based software

- Good fit for small businesses

- Very accurate forecasting

- Impressive customer service

- Strong data analysis tools

- No coding knowledge needed

- "What-if" scenario modeling tools

To help you choose the right S&OP solution for your business, we found and reviewed the best on the market, including Anaplan, IBM Planning Analytics, and GMDH Streamline.

- Anaplan: Best Overall

- GMDH Streamline: Best for Demand Planning

- IBM Planning Analytics: Best for Analytics

- NETSTOCK: Best for Integrations

- Board Intelligent Planning: Best for Budgeting

- Logility Solutions: Best for Inventory Management

- Kinaxis Maestro: Another Good Option

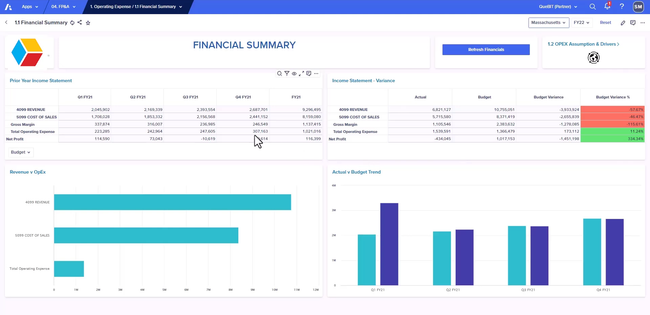

Anaplan - Best Overall

Anaplan combines statistical forecasting and machine learning to power its demand planning application. While most top-tier S&OP software covers the basics like these, Anaplan’s multi-dimensional modeling is more flexible than what’s typical. It lets your planners build top-down and bottom-up forecasts using different currencies, time buckets, and units without forcing you into fixed structures.

Its interactive statistical forecasting and PlanIQ machine learning forecast regular, promotional, and irregular demand by linking market indicators with your internal sales data. PlanIQ isn’t just an add-on; it’s built on Amazon Forecast, and you can enhance it with R/Python or other custom ML models. This makes combining data sources with tailored algorithms easier without you ever having to leave the platform.

We also found the consensus demand planning process highly configurable. Anaplan collects input from sales, marketing, and customers through tailored views in web, mobile, or Excel. You can set consensus-building rules that automatically weigh or discount inputs based on past forecast accuracy and time horizons. This means your final forecast reflects reality more than departmental politics, supporting better alignment with your production capacity and sales goals.

Though Anaplan doesn’t list pricing publicly, it’s generally considered a high-end solution, often exceeding $100,000/year. For that reason, it’s best suited to large enterprises in industries like manufacturing, retail, finance, and tech.

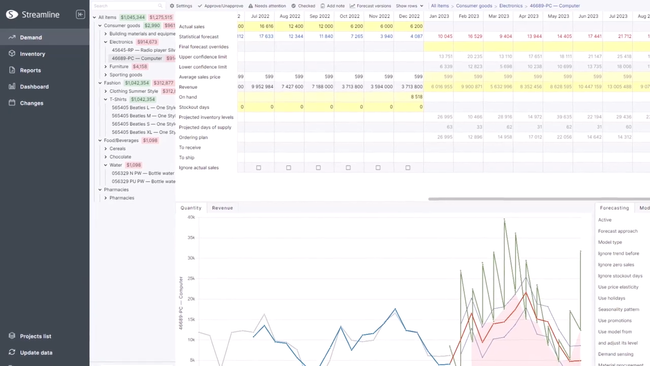

GMDH Streamline - Best for Demand Planning

GMDH Streamline is a demand planning software designed to optimize inventory management and boost sales, aligning seamlessly with business objectives. GMDH Streamline’s comprehensive suite of features encompasses demand forecasting, inventory planning, inventory optimization, and material requirements planning (MRP).

Another benefit of GMDH Streamline is the ability to integrate with top platforms like Microsoft Excel, Microsoft Dynamics, and QuickBooks with existing tools and data sources. Coupled with exceptional customer service, GMDH Streamline is a valuable asset for businesses striving to streamline sales and operations planning processes.

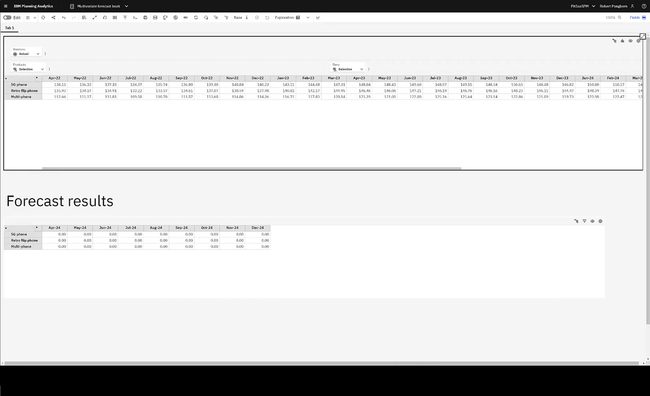

IBM Planning Analytics - Best for Analytics

IBM Planning Analytics is a cloud-based solution that goes beyond traditional planning and forecasting by offering self-service analytics capabilities. By automatically generating key insights from real-time data, this software keeps users agile in the face of changing market conditions.

Integration with various data sources, including ERP and CRM systems, ensures real-time access to critical information. With pricing options catering to different user requirements, IBM Planning Analytics offers a cost-effective approach to enhancing S&OP processes while maintaining data integrity and security.

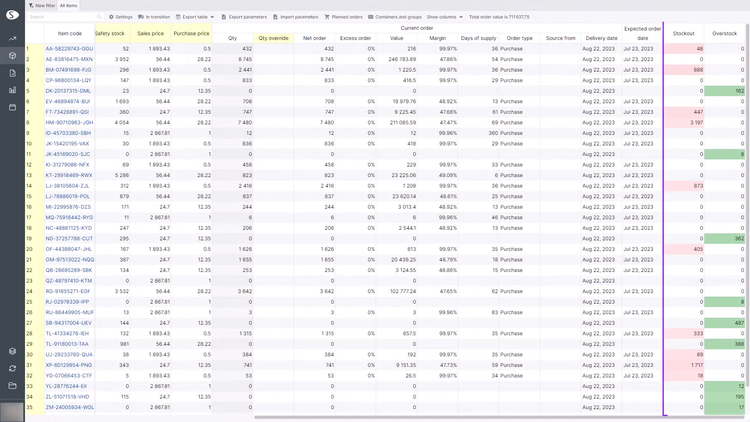

NETSTOCK - Best for Integrations

NETSTOCK is a demand planning solution capable of integrating with top ERPs, including:

- Acumatica ERP

- NetSuite

- MYOB

- Microsoft Dynamics 365

- SAP Business One

- Sage

In addition to integrations, this cloud-based software offers a range of features designed to optimize inventory control and boost sales. NETSTOCK’s ability to help users place orders quickly, minimize stock-outs, and reduce excess inventory is a significant advantage, ultimately saving time on planning, forecasting, and ordering processes while ensuring customer satisfaction and increased sales.

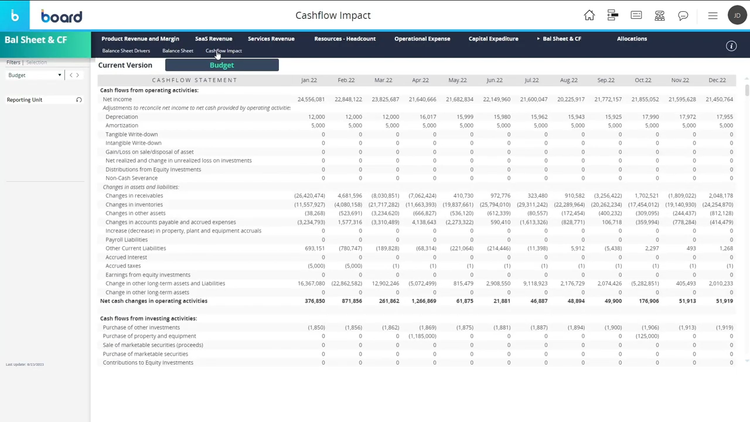

Board Intelligent Planning - Best for Budgeting

Board Intelligent Planning budgeting and forecasting software helps with decision-making by integrating top BI software with corporate performance management (CPM) tools to create Management Intelligence. This software’s unique toolkit approach allows users to create powerful Business Intelligence (BI) and Corporate Performance Management (CPM) applications without the need for programming, resulting in unparalleled speed and ease in application building, customization, and maintenance. What sets BOARD apart is how it combines BI functions like reporting and multi-dimensional analysis with CPM capabilities such as budgeting, planning, forecasting, profitability analysis, scorecarding, and financial consolidation.

In short, Board offers businesses a unified and seamless solution for both their BI and CPM needs, making it a powerful tool to enhance sales and operations planning, strategy formulation, and performance monitoring.

Logility Solutions - Best for Inventory Management

Logility Solutions budgeting and forecasting software helps with decision-making by integrating top BI software with corporate performance management (CPM) tools to create management intelligence. The full feature set of Logility is well-equipped to support businesses in their S&OP efforts.

Logility also offers the ability to categorize various types of inventory, gain new insights into inventory form and function, and analyze partner inventory. Additionally, it aids in determining ideal stocking locations, calculating inventory buffers, and creating inventory policies based on algorithmic optimization and machine learning results.

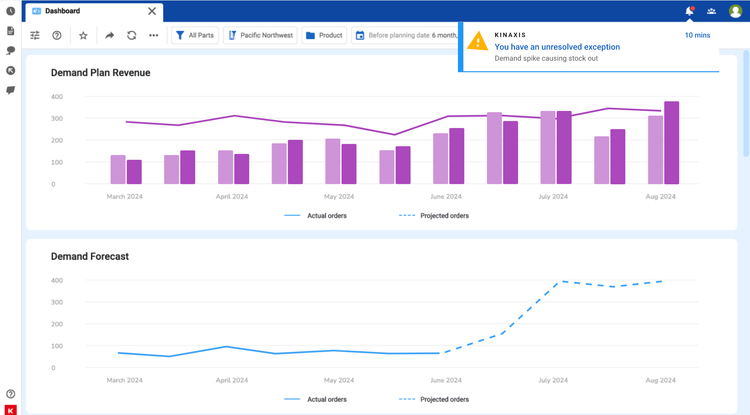

Kinaxis Maestro - Another Good Option

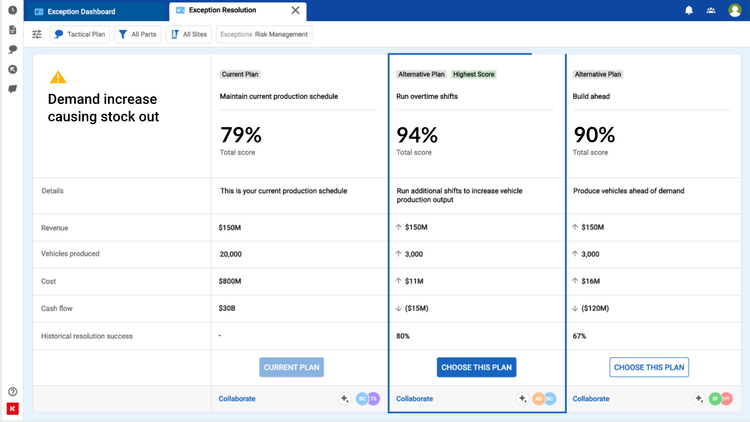

Kinaxis Maestro’s RapidResponse tool lets you consolidate data across your entire company to collaborate between departments. Analyze key metrics on a configurable dashboard, such as monthly revenue, margin percentage, and ending inventory value. Compare actuals vs. the target plan to see exactly where you stand. Drill into any anomalies to identify underperforming products and work with the sales and finance teams to create a solution.

The RapidResponse tool also includes built-in demand planning, which lets you make adjustments to plans and preview them before committing. For example, if there’s an unexpected shift in the market, you can create different scenarios to see future impacts for every department, like supply planning and sales. This helps you stay flexible through continuous planning and adjusting to ensure company alignment.

Once each scenario is made, you can consider the pros and cons of each using the evaluation scorecard to see which plan is most beneficial. It compares key metrics like revenue and shows if the adjustments will improve each area. It even shows revenue at risk, so you can be aware of any potential downfalls of the adjusted plan.

What is Sales and Operations Planning (S&OP) Software?

Sales and operations planning software (also known as S&OP software) integrates your supply chain planning processes to create a unified business plan surrounding supply chain demand. It draws data from sales, marketing, manufacturing, and distribution to better manage inventory planning, demand planning, and supply planning.

S&OP software can run multiple “what if” scenarios that help reduce risk while letting you understand the pros and cons of a varying range of possibilities. For example, you’ll be able to input projected inventory numbers to create a forecast for sales. You may also be able to weigh the pros and cons of adding a new supplier based on their delivery times and the expected amount of inventory they can supply you.

Anytime your business is looking to add products, change manufacturers, or alter delivery routes, sales, and operations planning software is available to help. Analyzing change history, annotations, and assumption tracking will give your business the foresight it needs before pulling the trigger on something that may cost you time, money, and customers.

Sales and operations planning goes beyond what typical statistical forecasting offers. S&OP capabilities rely on the same algorithms for producing estimates but also take into account revenue, profit projections, and marketing events. Together, this provides a holistic view of planning through the combination of sales, marketing, finance, and operations.

S&OP Flowchart

Demand Planning > Inventory Optimization > Replenishment Planning > Master Production Scheduling and Procurement > Finite Scheduling

This process not only deals with supply chain planning but also the finance and sales involved. With S&OP systems, you’ll be able to create a forecast, determine the inventory necessary to support the forecast, determine the time needed to acquire this inventory, figure out what factories are capable of completing these plans, learn what your purchasing department needs to buy, and finally schedule out the work at your factory.

Key Features

- Demand Planning: Forecast demand for a product so it can be developed and shipped as efficiently as possible. Collect historical data on order volumes and inventory turns while mixing it with continually updated forecasts from your sales personnel.

- Inventory Optimization: Identify non-performing inventory SKUs and avoid overstocking. Scale for error to ensure under and over-forecasting situations even each other out. Creates optimal product storage and distribution conditions by aiding in supply/demand forecasting, product traceability, and overall warehouse management.

- Supply Planning: Helps strategically plan and manage interactions with any vendors or suppliers of goods. Set reminders for reorders and reduce risk in your supply chain.

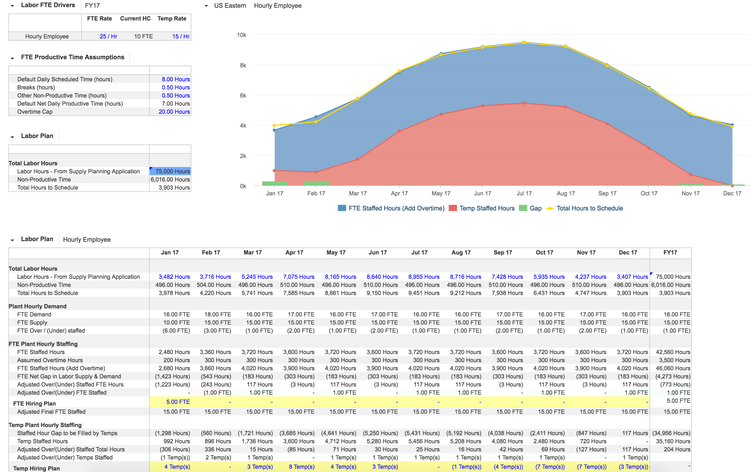

- Production Planning: Determine the need for materials and capacity to complete a manufacturing production order. Includes schedule that accounts for resources, staffing, and inventory.

- Financial Planning: Determine raw material input costs, volume manufactured in each facility, transportation costs, use of overtime to meet production and distribution goals, and more. Evaluate unit cost and profitability.

- Alternative Scenarios: Subject your business model to data conditions that emulate a likely business condition. Includes “what if” scenarios that let you practice what limits your business is capable of. Test out various production schedules by moving orders to different time slots via drag-and-drop functionality. Find the one most efficient for your business by syncing resource availability and any constraints. Find the production window that will push orders out the fastest without strain on your employees or resources.

Primary Benefits

The benefits offered by sales and operations planning software will have a real impact on your business value. For example, S&OP processes will help reduce inventory, meaning you will carry fewer costs carrying this inventory–leading to improved cash flow. S&OP systems can also reduce the time to market for new products, increasing revenue by staying ahead of the competition.

Integrate Your Financials For Greater Cost Control

Companies deal with shifting inputs, changing promotional campaigns, a vast array of available products, and variances in their supply chain delivery schedules. By integrating financials into your S&OP software processes, you’ll be able to take your supply chain planning to the next level.

One way this is possible is through translating the constrained supply chain plan using standard costs. This makes financials an input in your supply planning–making the requirement of including material costs, labor costs, transportation costs, and processing costs within forecasts. Once your business can understand costs and profitability, you’ll be able to test out the impacts to your financials in varying scenarios.

To truly optimize your plans, you’ll want to calculate financials in your S&OP software on a more recurring basis. That way, varying costs such as raw materials, the volume being manufactured, and transportation costs can continually be adjusted. Now that your advanced scenario analyses are coming in, you’ll be able to create marginal profitability analyses and analyze situations where the next unit of output can swing from profit to loss (such as using overtime labor to complete orders).

Improve Inventory Management

One of the most vital inputs in sales and operations planning software is your inventory management data. In order to increase supply chain profitability, you’ll need to have a better idea of inventory levels and your supply. An S&OP solution establishes the framework to analyze inventory costs down to each individual shipment. This includes import/export fees, method of transportation, the cost of the vendor, and any opportunity cost of leaving inventory on your shelves for an extended period of time.

Improved inventory optimization will improve sales and budgeting forecasting. In a competitive market, you want to ensure you are beating your competition to the punch. Gaining visibility into your forecasts will ensure your production planning is aligned with your organizational goals and your customer’s needs. One example is running scenarios with a bill of materials that can calculate stock at each production stage, cost of goods sold, purchases, and trade creditors.

Create a Plan

There are major steps involved in creating a perfect sales and operations planning process. Developed by Thomas Wallace and Robert Stahl, the below steps can help you achieve your S&OP goals quicker through the use of sales and operations planning systems.

- Data Gathering: Compile sales figures, create statistical forecasts, compare to actual supply figures and weigh in marketing data.

- Demand Planning: Conduct your first pass of forecasts using the data gathered in step 1. Analyze multiple scenarios based on new items and discontinued products. Sprinkle in various scenarios such as one-time events or plans for promotional pricing which may have an effect on demand.

- Supply Planning: Material requirement planning and production planning.

- Plan Reconciliation: Document supply chain gaps and resolutions and view recommendations for improvement.

- Finalize and Release: Make final decisions based on issues that came about and review KPIs.