The Best Aerospace Manufacturing Software

Aerospace manufacturing software balances compliance, precision, and operational efficiency. We’ve reviewed and ranked the top solutions for OEMs, tiered suppliers, and specialized manufacturers, evaluating their strengths in quality control and production planning.

- Multi-site and multi-company support

- Built-in business intelligence

- Comprehensive supply chain management

- HANA database

- Large network of resellers

- Strong BI tools

- Multi-site and multi-company support

- Built-in business intelligence

- Comprehensive supply chain management

The best aerospace software needs to have a mix of features like compliance management and engineer change control to be effective. Our selection meets sector-specific demands for large OEMs and tier suppliers.

- Infor CloudSuite Industrial: Best for Large OEMs

- SAP S/4HANA: Best for Tier 1 Suppliers

- ECI M1: Best Production Planning Module

- xTuple: Best Revision Control Tool

- Dynamics 365 Business Central: Best BOM & Routing Functionality

- Acumatica: Best for Best for Tier 2 Suppliers

- Epicor Kinetic: Best for Tier 3 Suppliers

Infor CloudSuite Industrial - Best for Large OEMs

Infor CloudSuite Industrial handles complex agreements like time-and-materials, firm-fixed-price, and cost-plus contracts. Its contract management module helps streamline execution and manage financials with built-in cost tracking and invoicing tools.

This aircraft manufacturing software supports multiple contract structures for large-scale production projects. It accomplishes this through flexible billing schedules, milestone tracking, and detailed work breakdown structures (WBS). OEMs can link contract line items to specific deliverables, providing insights into project expenses and progress at every stage.

Cost tracking is built into the system at the contract line item number (CLIN) level for more precise reporting. It also helps you better align with customer or government requirements. Features like borrowed load payback and co-mingled costing ensure compliance with DCAA and other accounting standards, even with costs distributed across different contracts.

Additionally, Infor CloudSuite supports contract flow-down, making it easier for OEMs to enforce compliance and quality standards across their supply chain. The system automatically pushes AS9100, ITAR, and DFARS standards to suppliers and subcontractors. This helps you meet material certifications and inspection criteria without extra manual work. Plus, linked workflows help maintain seamless integration, reducing the risk of delays or compliance issues down the road.

Read our full review of Infor CloudSuite Industrial.

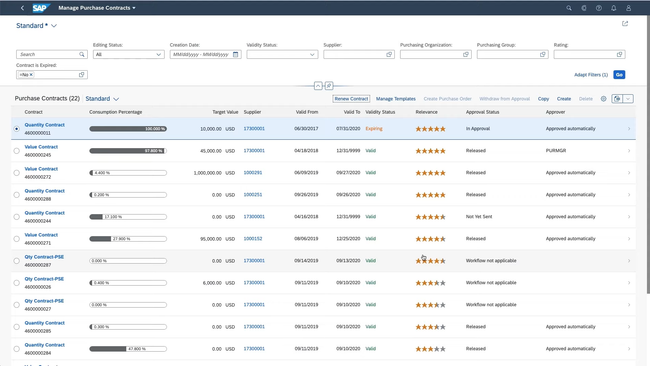

SAP S/4HANA - Best for Tier 1 Suppliers

SAP S/4HANA’s multi-level bill of materials (BOM) tool keeps complex assemblies flexible and organized. With aircraft manufacturing involving thousands of interconnected components across multiple levels, logging any changes to the BOM is vital—especially for suppliers producing jet engine components like turbines, casings, and compressors.

The system simplifies BOM management by tracking versions, automating change approvals, and ensuring full traceability. If an OEM updates a design or swaps out a material, your engineers can apply and review changes without halting operations. Version control keeps configurations in check across different product lines, helping youmeet regulatory standards and maintain consistency.

For faster decision-making, S/4HANA also includes a BOM comparison feature that highlights differences between versions, so your team can quickly pinpoint shared or unique components. Impact analysis models take it a step further, predicting how a BOM change—like a material substitution—will affect production schedules, resource availability, and costs. Together, these capabilities help tier 1 suppliers adapt to shifting OEM demands while minimizing errors and delays.

Learn more about SAP S/4HANA, including ratings and key features.

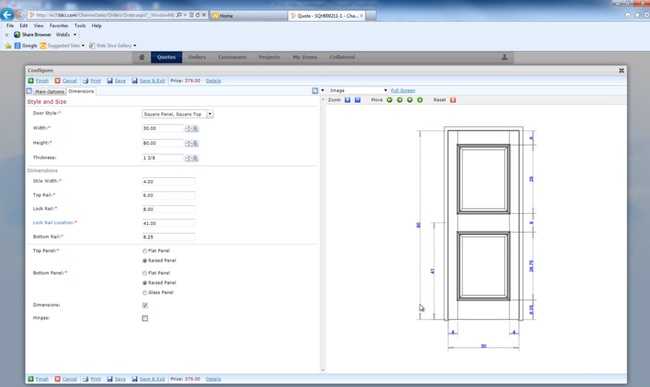

ECI M1 - Best Production Planning Module

ECI M1’s production planning module handles high-complexity workflows for increased precision and improved resource allocation are critical. It starts with the manufacturing requirements planner (MRP), which automates job scheduling based on factors like demand forecasts and material availability. You can filter jobs by facility location, production deadlines, and specific aircraft component requirements so that the system generates relevant work orders only.

When working with high-value resources like titanium, specialty alloys, and composites, M1’s MRP calculations prevent waste and stockouts by factoring in lead times and production schedules. Define parameters like the end-of-month cutoff date, and M1 retrieves demand data and calculates resource requirements, helping you optimize your supply chain.

Once you establish demand and material needs, M1 automates job creation and management. The system analyzes current material levels and open orders to generate a job summary. This accounts for complex assemblies, multi-tier BOMs, and FAA or AS9100 compliance requirements. Manufacturers can review and approve these jobs before bulk creation, making sure everything stays on track with capacity plans and compliance needs.

M1 also delivers live tracking and adjustments for open MRP sessions. For missing data or incomplete sessions, the system flags issues before they disrupt operations. Built-in barcode scanning and digital shop floor tracking make it easier to monitor labor hours, material usage, and machine costs. This makes operations like precision machining and avionics assembly more accurate, helping you meet on-time delivery goals while maintaining strict quality standards.

See our ECI M1 review for more details.

xTuple - Best Revision Control Tool

xTuple’s revision control tool helps aerospace manufacturers manage complex product configurations. It also supports compliance with industry standards like AS9100 and FAA regulations. By tracking every design change in BOMs and routings, it offers full traceability—critical for audits and regulatory approval.

When you create a new revision for a part or assembly, it builds directly from the version currently in production–or the active version. This helps keep updates consistent while capturing important changes along the way, whether structural or material substitutions. Each revision falls into one of three states:

- Active: The version currently used in manufacturing.

- Pending: A proposed update awaiting approval.

- Inactive: A historical version that you can reactivate or reference if needed.

xTuple ensures only one active revision is in use at a time, reducing confusion in production. However, whether you’re testing a new aircraft component or fulfilling a customer order for a previous revision, you may need more flexibility. Fortunately, xTuple’s pending revisions tool allows engineering teams to validate changes while keeping production running.

You can manually select an inactive or substitute revision when needed. This makes it easier to accommodate legacy orders or comply with specific design standards so you can keep production smooth without compromising quality.

Read our full review of xTuple.

Dynamics 365 Business Central - Best BOM & Routing Functionality

Microsoft Dynamics 365 is designed to handle intricate, multi-level BOMs, where precision and compliance are key. When building an aircraft, you’re dealing with multiple sub-assemblies like fuselages, wings, and turbines—each with its own set of components.

Business Central helps you track every part, ensuring full traceability throughout production. This helps you adhere to compliance standards and quickly identify any faulty parts you may need to recall. It also provides visibility into each component’s cost, helping you manage spending in an industry where margins can be especially tight.

The routing tool then maps out the specific operations and processes for each component. Routings detail which machine to use, the time required for each step, and the labor involved. For example, assembling an aircraft engine might include tasks like precision milling and welding. Business Central tracks machine setup times, labor requirements, and work center load to ensure everything runs smoothly and on schedule.

Learn more about Microsoft Dynamics 365, including features and pricing.

Acumatica - Best for Best for Tier 2 Suppliers

The engineering change control feature in Acumatica makes it easier for aerospace suppliers to track, manage, and approve engineering changes without slowing down operations. For example, if a supplier receives multiple design adjustments for a turbine component—one for material substitution and another for a structural tweak—Acumatica lets them combine those changes into a single engineering change order (ECO). This prevents fragmented updates, cuts down on repetitive approvals, and ensures the entire team is working with the latest version.

Acumatica also streamlines working with multi-level bills of materials (BOMs). Its tree view makes it easy to see how different components fit together, while built-in cost breakdowns show how each change affects pricing at every level. This level of visibility helps tier 2 suppliers keep margins in check while ensuring every part complies with aerospace standards.

Plus, this aerospace software offers BOM comparison capabilities, so your engineers can compare historical records or new ECRs side-by-side. Acumatica includes clear visual indicators for any modifications, with green for no changes, red for additions, and yellow for modifications. In this way, the software makes change management faster and more precise, allowing you to consolidate, review, and approve changes in a fraction of the time.

See our Acumatica review for more details.

Epicor Kinetic - Best for Tier 3 Suppliers

Epicor Kinetic’s quality management capabilities help tier 3 aerospace suppliers stay on top of non-conformance tracking, inspections, and discrepant material reviews (DMR). These features help you catch deviations before they reach tier 1 or tier 2 manufacturers, reducing rework, scrap, and financial penalties for non-compliance.

With non-conformance tracking, you can log defective materials and trace them across job production, inventory, or purchase receipts. If a batch of aluminum fasteners arrives with improper dimensions, for example, this ERP flags the issue instantly. This prevents defective parts from ever reaching assembly. Users can also input failure reasons, assign serial or lot numbers, and route flagged materials for inspection.

During inspections, flagged items either pass or fail. Passed items return to stock or production. The system routes failed items for corrective action, such as rework, scrap, or supplier rejection. For example, if an incoming shipment of titanium rods is out of spec, Epicor Kinetic logs the rejection. It also documents communication with the supplier and tracks whether a replacement shipment was received.

By automating these quality processes, Epicor Kinetic helps tier 3 suppliers minimize defects and maintain compliance—all while keeping operations running smoothly.

Read our full review of Epicor Kinetic.

What is Aerospace Manufacturing Software?

Aerospace manufacturing software helps aircraft and parts manufacturers manage the complex processes inherent to the aerospace industry. This sector needs everything from supply chain management and production planning to compliance management and quality control. The evolving software landscape is fueling competition in the aerospace market by giving manufacturers greater control and visibility over their processes.

Software needs can vary based on the type of market you’re in. These markets include military and defense, commercial air transport, general aviation for civilians, and space technology. These markets have different manufacturing regulations to follow. The right aerospace manufacturing software will help ensure your processes and finished products are in line with the regulations for your market.

Many aerospace manufacturers opt for ERP software to handle manufacturing processes alongside other business processes like human resources or customer relationship management. CRM functionality is most important for manufacturers of restricted or classified products, as they need to send product information like shipment notifications and change requests directly to customers. ERP systems can also integrate with warehouse management.

Key Features

| Feature | Description |

|---|---|

| Supply Chain Management | Track the flow of goods from raw material acquisition to final product delivery. |

| Quality Management | Keep track of defects in supplied materials or finished products. Manage corrective actions to ensure the manufactured parts are up to code. |

| Manufacturing Project Management | Create task lists, manage employees’ schedules and material deliveries, and set deadlines. |

| Inventory Management | Track quantities and prices of raw materials, assemblies, and finished parts that are currently on hand. Purchase orders can be automated when supplies are running out. |

| Production Planning](/production-scheduling/) | Set schedules of the labor and resources needed for each job. |

| Compliance Management | Ensures manufacturers in the aerospace industry meet federal and international regulations, including ITAR and AS9100 |

| Document Control | Securely store and maintain important documents for aerospace manufacturing jobs. |

Advanced Features

| Feature | Description |

|---|---|

| Business Intelligence (BI) Tools | Provides detailed reports on financial and non-financial data, including profitability, parts used for each manufacturing job, scrap materials, employee productivity, and more. |

| MRP | Includes shop floor control, demand forecasting, equipment maintenance scheduling, and purchase planning. |

| EDI | Automate secure data transfer between your business and vendor,s including invoices, shipping status, and customs information. |

Benefits of Aerospace Manufacturing Software

Software offers many benefits for the aerospace manufacturing industry, including:

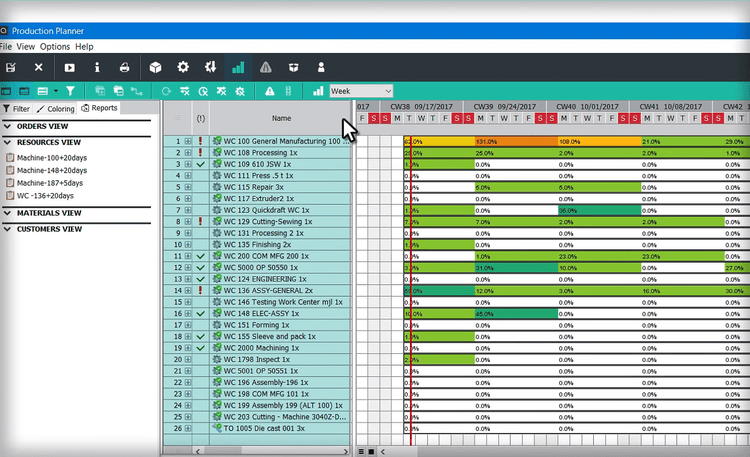

Improved Lead Times and Reduced Costs with Production Planning

Production planning for airframe and aerospace part manufacturing helps bridge personnel scheduling and material ordering while remaining flexible enough to respond to changing plans. Having the right amount of resources on hand allows manufacturers to improve lead times and cut costs overall.

Production planning also allows you to have better control over engineering change orders. Unexpected changes need to be scheduled and planned for to avoid manufacturing delays.

Maintain Regulatory Compliance

Maintaining regulatory compliance is of prime concern to aerospace manufacturers, who operate in one of the most tightly regulated industries in the world. Some of the regulatory compliances that software assists with include:

ITAR: International Traffic in Arms Regulations (ITAR) governs the export of US military technology to foreign nations. Enterprise resource planning (ERP) software is an important part of maintaining an export compliance program.

AS9100: The AS9100 standard expands upon ISO 9001 requirements for the FAA and other federal agencies. A well-implemented quality management system (QMS) is vital to maintaining compliance for commercial and government contracts.

Markets for Aerospace Manufacturers

Each sector of the aerospace industry has its own unique challenges. Aerospace manufacturing software is available for these markets:

Commercial Air Transport

Commercial aerospace manufacturers deliver products for:

- Wide-body and narrow-body jet airliners

- Regional or short-haul airliners

- Commuter aircraft

Manufacturers of commercial airliners, parts, tooling, and support equipment feed a hyper-competitive market. They need robust software systems to reduce waste and eliminate risk throughout their processes.

General Aviation

Aerospace manufacturers for non-scheduled civil aviation focus on:

- Single-engine propeller aircraft

- Multi-engine propeller aircraft

- Very light jets

- Ultralight and unpowered aircraft

Software for general aviation manufacturing helps manufacturers and distributors streamline customer interactions, as each customer has a higher volume and lower value. A software solution designed for commercial air transport suppliers won’t address the unique challenges of the general aviation market.

Military/Defense Contractors

The aerospace defense industry builds airframes, systems, and parts for:

- Fixed-wing and rotary aircraft

- Rockets and military spacecraft

- Missile systems

Defense manufacturing contractors deal with very stringent regulations governing the quality, supply chain security, labor and contract compliance. Poorly selected, built, or maintained software can threaten lucrative defense contracts and your relationship with governmental agencies.

Space Technology Manufacturing Software

Software for space technology manufacturing industries, including:

- Private

- Government

- Military

Commercial spaceflight is a growing industry that is set to expand rapidly into space tourism and transport over the next few decades. Businesses trying to create these markets have to meet high standards in terms of agility and process controls that are practically unparalleled.

Software for Aerospace Replacement Part Manufacturers

Aerospace manufacturing companies can gain an edge in the replacement part industry with the right software.

Original Equipment Manufacturer (OEM) Parts

OEMs need robust software to manage the supply of replacement parts for their customers. When aircraft operators are considering changes to their fleet, the reliability of the replacement parts supply chain is a serious concern. On-time production and delivery are vital to maintaining brand loyalty in an incredibly competitive market.

Parts Manufacturer Approval (PMA) Parts

PMA part manufacturers produce replacement and modification parts under the FAA. A fully-integrated software solution will track the relationships between the original components and the PMA parts. It should also help PMA manufacturers account for market trends, seasonality, and product life cycles to accurately predict demand.