Preventive vs. Predictive Maintenance: What’s the Difference?

The main difference between the two types of maintenance is when they are performed: Preventive maintenance is generally scheduled based on calendar dates regardless of performance, while predictive maintenance is arranged based on real-time condition monitoring regardless of date.

| Differences | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Schedule | Scheduled based on calendar dates regardless of performance | Scheduled based on real time condition monitoring regardless of date |

| Necessity | Work is done whether it needs to be or not | Work is only done when deemed necessary |

| Complexity | Standard and routine maintenance cycle for low complexity | Requires lots of training and technology for complex processes |

A Computerized maintenance management system (CMMS) is often used to protect assets like machines and equipment by reducing maintenance costs and boosting equipment health. These systems can usually perform both predictive and preventive maintenance, but you must first determine which approach is best for your business.

What is Preventive Maintenance?

As the name suggests, preventive maintenance is scheduled maintenance on assets to reduce the likelihood of breakdown or failure. While there are many different types of preventive maintenance practices, all PM programs are designed to extend the usefulness of assets for as long as possible to keep costs down and production up. There is even separate preventive maintenance software to help streamline this process.

Preventive maintenance tends to begin with an in-depth analysis of how a piece of equipment or machinery is performing over a period of time. Sometimes, this data can come from manufacturer warranties or other sources. This helps create an ideal schedule for when various maintenance tasks should be performed to preserve assets and improve overall performance. A business using a preventive maintenance schedule might arrange large-scale maintenance activities even if assets operate within acceptable parameters and do not appear to need any maintenance based on performance.

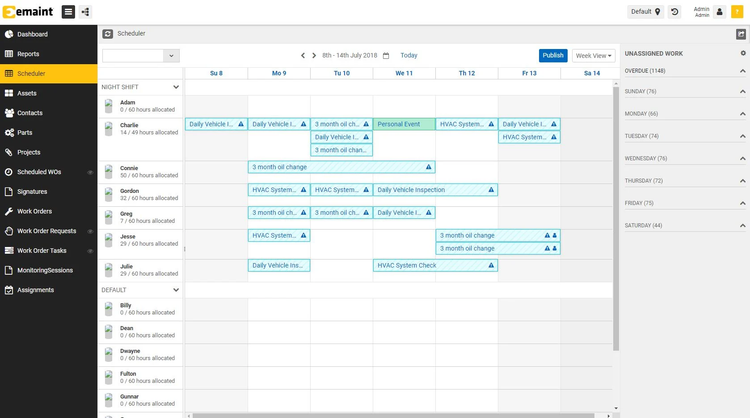

Effective PM programs use everything from shared calendars to automated notifications to ensure the timely maintenance of critical assets. Specific examples of this maintenance approach vary depending on the asset management necessary: computers might get new software, machines might have spare parts installed, and gears might be oiled between production cycles.

Types of Preventive Maintenance

There are several types of preventive maintenance that can be customized to fit your business needs.

Prescriptive Maintenance

Prescriptive maintenance practices determine when maintenance is needed and, more importantly, why. The goal here isn’t just to make timely repairs; it’s to improve the overall process to reduce failure. This is done by studying data on production to find commonalities before, during, and after problems in order to identify solutions.

For example, a company might have an HVAC system to keep the machines running at the correct temperature. Buildup on filters can overwork the system, leading to overheating. A preventive maintenance plan can schedule monthly, quarterly, or annual filter cleanings or replacements.

Time-Based Preventive Maintenance

Time-based preventive maintenance uses a calendar to schedule maintenance far out in advance, regardless of whether it is needed. Keeping a shared calendar of preventive maintenance tasks can help maintenance technicians coordinate and streamline work in advance.

For example, a company specializing in seasonal products might know there will be a convenient time to schedule maintenance in the off-season. Critical assets can be ordered in advance, ensuring the necessary spare parts arrive right as work winds down and scheduled maintenance is set to begin.

Usage-Based Preventive Maintenance

Usage-based preventive maintenance initiates maintenance only after an asset has achieved some sort of predetermined benchmark. Occasionally, this may include maintenance after a scheduled inspection or audit has revealed a need for it. Or maintenance technicians on an assembly line might schedule equipment downtime based on manufacturer recommendations.

This type of preventive maintenance is primarily aimed at extending asset life as much as possible. This can lead to long-term savings by preserving existing assets instead of regularly buying brand-new replacements. Further, facilitating large repairs is time consuming, so usage-based maintenance can keep costs down by allowing for smaller repairs over time rather than big projects with unplanned downtime.

What is Predictive Maintenance?

Technically, predictive maintenance falls under the broader category of preventive maintenance. However, it focuses on scheduling data-driven maintenance on an as-needed basis to reduce unplanned downtime as much as possible. To achieve this, predictive maintenance uses asset data and reporting to determine when maintenance is most likely needed. This usage-based method requires significantly more data from condition monitoring to work correctly without causing more strain on production cycles.

For instance, a company might arrange weekly tests to measure asset conditions like output. Maintenance is deemed unnecessary as long as asset performance is within acceptable parameters. Once any variance is detected, a prediction is made on how effective the asset is and when maintenance should be scheduled to avoid a total failure of operations.

In some companies, this results in maintenance tasks like updates, tuneups, and parts replacement being put off to the point of potential machine failure. This approach is riskier than scheduled maintenance, but it does keep equipment running as long as possible while still preparing for the possibility of breakdown.

Main Differences Between Preventive and Predictive

First, preventive tasks are scheduled regardless of usage or performance. While there may be some analytics to determine when parts should be replaced, there’s always the possibility a fully functional part is scheduled to undergo unnecessary maintenance. Predictive maintenance software uses data and observations to determine when work should be done.

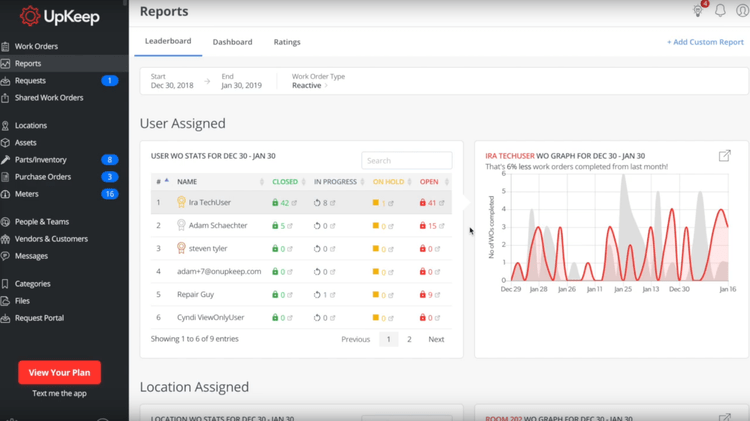

With predictive maintenance, work is only done when it is deemed necessary based on data. Preventive work is done whether it needs to be done or not. Unfortunately, it can be hard to measure how much difference preventive actions make in performance and longevity. Predictive fixes are easier to quantify since they may align with corrective maintenance, sometimes coming after a machine has broken down or needs repair.

Lastly, predictive maintenance requires high upfront costs, extensive training, and advanced technology to be implemented correctly. While almost all CMMSs include preventive maintenance, only some include predictive. In fact, there are even dedicated predictive maintenance software due to the complexity of the process. On the other hand, preventive maintenance is routine and operates on a set schedule for straightforward processes.

However, there are still significant overlaps between the two types of maintenance to consider:

Similarities in Proactive Maintenance

Both offer a proactive maintenance strategy for businesses across every industry. As mentioned before, predictive maintenance is preventive. It’s no wonder so many people use the two interchangeably! Each is an alternative to reactive maintenance, which occurs after a machine or piece of equipment has failed.

Next, preventive maintenance can be usage-based, just like predictive maintenance, although it may not always be as detailed. For example, a company might perform maintenance based on conditions described in a manufacturer warranty (preventive) rather than their own observations and data analysis (predictive).

Both predictive and preventative maintenance applications can be part of larger computerized maintenance management software (CMMS) systems. However, each can be used separately in order to reduce implementation costs and ease of use. The software optimizes both predictive and preventive maintenance schedules through automated alerts and notifications indicating when technicians need to perform routine maintenance.

Preventive vs Predictive Maintenance for Business

Preventive and predictive maintenance both benefit businesses, though in slightly different ways. Which is best suited for your operations will depend on the exact type of maintenance your assets need. Your maintenance team might have a preference for one or the other, depending on variables like:

- Cost of maintenance

- Availability of spare parts

- Material costs

- Expected downtime

- Ease of condition monitoring

For instance, a machine might have gears that need to be lubricated regularly to operate at optimal conditions. Scheduling weekly oiling would be an example of preventive maintenance work. Another piece of equipment might be connected to a computer that records real time performance data. That information can allow the maintenance team to perform quick check-ups in a predictive maintenance plan.

Another way to look at it is to consider how costly and time-consuming an unplanned breakdown would be. Equipment failure and related maintenance costs can quickly add to lost revenue over time. If you’re looking at thousands of dollars in lost revenue, preventive maintenance at regular intervals would likely be beneficial as a “better safe than sorry” insurance policy. However, if repairs are minor, such as swapping out consumable spare parts, you might be better suited to a cost-effective predictive maintenance system. Both proactive maintenance types can lead to cost savings by keeping assets up and running.