The Best Direct Store Delivery Software

Direct store delivery (DSD) software can help distributors of all sizes deliver their goods on time. Key features include route optimization, inventory management, and dispatching.

- Delivery verification through electronic signatures & image uploads

- Auto-route and auto-suggest capabilities

- Live mobile SDK with map

- Effective route optimization tools

- Add custom delivery windows for customers

- Capture proof of delivery

- Integrates with QuickBooks

- Includes inventory management tools

In this guide, we’ll review the top DSD software options to optimize your delivery processes.

- Elite EXTRA: Best for Last Mile Delivery

- Route4Me: Best Routing Tools

- RouteStar DSD: Best for QuickBooks Users

Elite EXTRA - Best for Last Mile Delivery

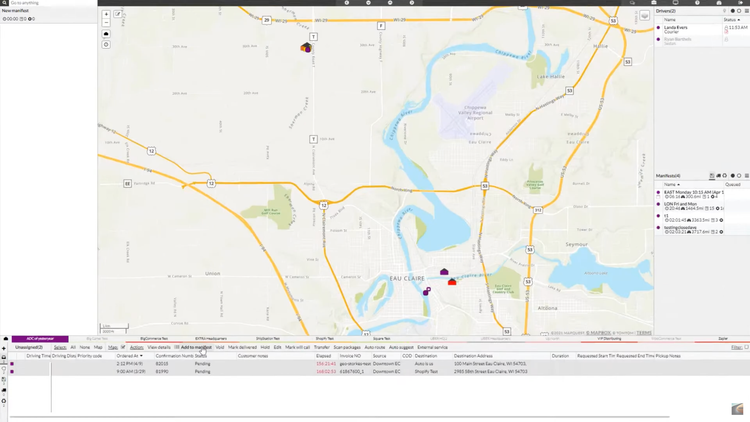

Elite EXTRA simplifies the dispatching process. The routing and dispatch tool integrates with your ERP or eCommerce system for seamless order processing. From there, it takes the orders and optimizes the delivery for the most efficient routes. This helps you reduce delivery costs while ensuring customers receive their packages on time.

Once a route is ready, you can dispatch it to a driver from your fleet or to a third-party courier. The route is then sent to the Elite Extra mobile app that lets your driver see their route, real time ETAs, and tasks. This gives deliverers full visibility into their stops to streamline their workflow.

While the drivers are out on the road, Elite EXTRA lets you view every vehicle in your fleet in real time from the office. See which drivers are on schedule or falling behind and why. The system lets you make adjustments on the fly to ensure every order reaches its destination. You can even send customer ETA notifications through email or text so they know when to expect their packages.

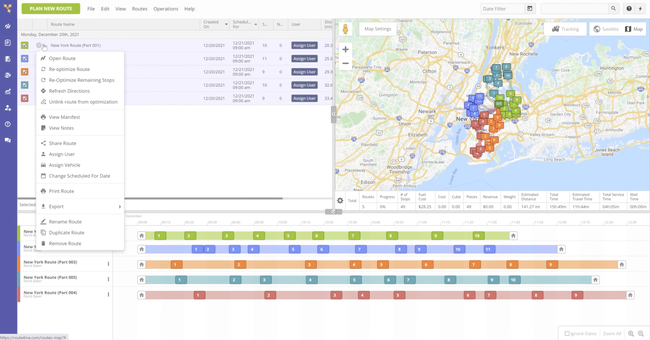

Route4Me - Best Routing Tools

Route4Me’s route optimization tools help you ensure goods are delivered on time. The system lets you enter custom time windows for each customer to make sure they are available to receive the goods. This is essential when delivering to a diverse range of businesses, like restaurants and retailers, as each have specific delivery windows that you need to abide by.

Once the data is entered, Route4Me creates the most efficient route possible while adhering to each custom timeframe. The times are displayed on the mobile app for your drivers, so they know the latest delivery time if they are running late. This gives your driver foresight to know that the business will be expecting them, and helps avoid costly perishable food returns.

Route4Me’s route optimization package starts at $60/user/month with a minimum of 5 users. This makes it a great option for midsize companies, as it lacks functionality for larger operations like automatic weekly route scheduling.

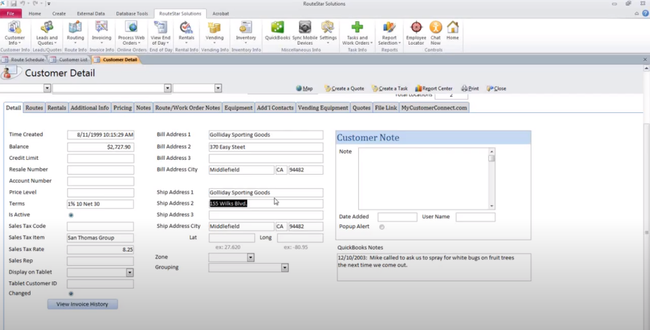

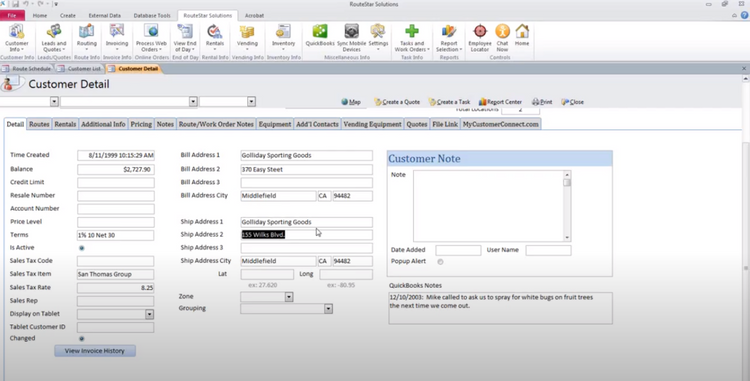

RouteStar DSD - Best for QuickBooks Users

RouteStar DSD integrates directly with QuickBooks Online for two-way data sync to optimize truck inventory management. You can pick and choose which inventory items to transfer from QuickBooks, giving you a custom list specific to your DSD operation. From there, quickly pull stock from multiple warehouses and assign them to a specific truck. This allows you to pull items out of the warehouse easily as drivers make sales.

The inventory management module also includes pre-kit capabilities. This allows your warehouse to assemble future deliveries. It determines the current truck inventory and its replenishment amount so the delivery is ready to go immediately. This helps automate the loading process and gets vehicles on the road faster daily.

RouteStar DSD’s pricing starts at $450/month plus a $650 onboarding fee. It includes up to four office users and two mobile driver users. However, most businesses will want to opt for the Medium plan at $550/month, as it includes 8 office users and 15 mobile drivers. This is better suited for midsize teams, as the starter plan may be too steep for small companies.

Direct store delivery is a retail solution for optimizing delivery routes of perishable goods directly from the producer to the retailer. DSD distribution essentially skips over other steps on the supply chain, like warehouses and storage centers, and goes directly to the point of sales (PoS) or point of consumption (PoC).

What is Direct Store Delivery (DSD) Software?

Direct store delivery (DSD) software is a way to automate route optimization between manufacturers or suppliers and their PoS/PoC retail partners. This method of route accounting is used as an alternative to more centralized distribution methods. DSD software is usually used by food producers and manufacturers to deliver fresh perishables, though other suppliers may also benefit from implementing a direct delivery system.

DSD is best suited for distributing to:

- Grocery stores

- Restaurants

- Convenience stores

- Pharmacies

- Retail stores

A type of real-time distribution software, DSD focuses on replenishment along the final stretch of the product supply chain. Big vendors with high consumer demand merchandise are behind most DSD systems, though smaller distributors can be involved as well.

Main Features

- Work orders: Create work orders for every partner to know who needs new product deliveries and when those orders should be fulfilled

- Route optimization: Set the best routes for your drivers to cut down on delivery times, reduce vehicle usage, and increase fuel efficiency

- Inventory management: The supplier or manufacturer keeps track of product inventory to forecast when replenishment is necessary

- Food traceability: Know where food products came from and are going while staying compliant with storage methods such as first-in/first-out (FIFO) and last-in/first-out (LIFO)

- Barcoding: Mark products with custom barcodes and use barcode hardware like scanners and mobile devices for on-the-go tracking

- Loss prevention: Reduce shrinkage by controlling exactly how inventory is delivered to PoS or PoC

- Seasonal demand forecasting: Plan ahead for distribution of seasonal products based on changing demands

Primary Benefits

There are many benefits to utilizing a DSD system with your delivery operations:

Faster Deliveries of Perishable Goods

The biggest challenge for all food distributors is getting food products to consumers before they expire. By using a DSD software to optimize routes, you can speed up deliveries of goods which might expire if first sent to warehouses or storage centers. And new orders can be fulfilled within 1 to 2 business days, a much faster turnaround than going through a third-party or centralized distribution center. Your retail partners can enjoy fresher products which can be passed on to consumers, building brand loyalty and customer satisfaction simultaneously.

Certain foods simply cannot be held in storage, even for a short amount of time. Whether these foods go bad in a warehouse, delivery truck, or on a shelf, it’s a loss for the distributor and the retailer. DSD with route management tools accommodate for specific product storage requirements by creating efficient delivery routes. In turn, this minimizes the days a product spends in transport along a multi-stage supply chain, maximizing freshness for the end consumer.

Preserve Temperature Controlled Goods

Many goods need to be stored and transported in controlled temperatures. While this primarily applies to food and beverage, other products like sensitive electronics also need to be stored in carefully controlled environments. Direct store delivery software makes it possible to track temperatures when transporting goods. This makes it possible to maximize inventory without risking product stability.

For example, ice-cream needs to be kept frozen from production through delivery. A grocery store only has so much space in their frozen food section. Making a premature delivery can mean there’s not enough room for new stock. DSD software helps the store and supplier know when there’s room for more by examining sales data and forecasting future deliveries through pre-sales.

Better Inventory Management

One major benefit of DSD software is having a direct source of product replenishment. Instead of using resources on an inventory management system, the supplier is responsible for keeping track of their individual stock at a store or restaurant in order to reduce on-shelf shortages or overstock situations. This gives the retailer more time to focus on other sales tasks. Additionally, this cuts down on their labor costs for scanning products and checking shelves.

Traditionally, manual inventory practices take time and can delay orders for new stock until there’s already a shortage. Replenishment delays can cause disappointed consumers to shop elsewhere, hurting both brand and store loyalty.

Fortunately, DSD software helps distributors tighten their delivery windows with lean or “just-in-time” inventory practices. Consistent route sales reduces waste and costs by only stocking products as they are needed. This saves the distributor, manufacturer, and retailer from the expenses associated with additional inventory storage, especially those associated with one-time, high volume seasonal goods.

Reduce Shrink and Loss

Finally, direct store delivery systems help reduce expensive shrink from merchandise theft and inventory errors. DSD solutions provide real-time visibility which reduces the opportunities for loss. Since the distributor is in more control of how their products are delivered with this platform, there are fewer opportunities for mistakes from delivery staff.

DSD solutions provide GPS tracking applications as well, so suppliers can always know where their drivers are at all times. Proof of delivery and inventory tracking can be performed on specific hardware or iOS or Android smartphones with on-the-go signature capture. Barcoding scanning of the products confirms the delivery as well. Any unusual activity or changes to predetermined route sales can be immediately identified. For example, if a truck is stolen GPS tracking can allow the company to begin recovery efforts instantly.