The Best Healthcare Supply Chain Software

Get the best software for your business. Compare product reviews, pricing below.

What is Healthcare Supply Chain Software?

Healthcare supply chain software manages the movement of medicine, pharmaceuticals, and personal protective equipment (PPE) from the manufacturer to medical facilities around the world. These logistic software suites make it possible for hospitals, clinics, and long-term care facilities to control how they order and receive their medical inventory from manufacturers, suppliers, and distributors.

General supply chain software doesn’t address many of the common issues encountered in the medical field. Healthcare facilities regularly deal with controlled substances, confidential patient care materials, and sanitary medical supplies. The extra levels of regulation for these products means manufacturers, distributors, and medical providers need a specific software to handle real-time supply chain logistics.

Features of Healthcare Supply Chain Software

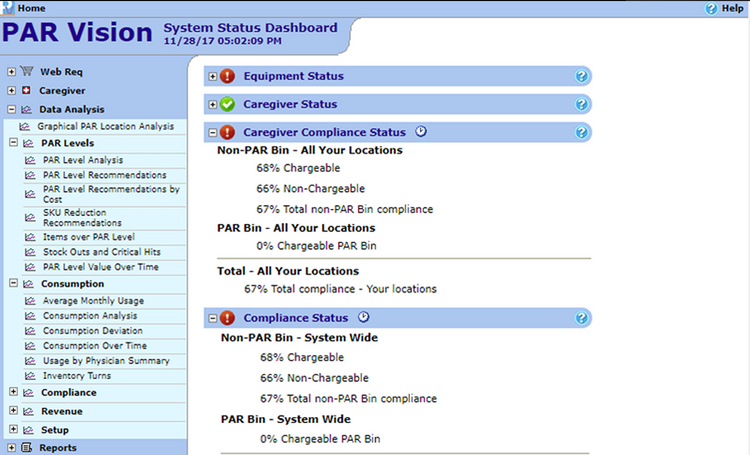

- Medical inventory control: Track all your onsite medical products and devices ranging from pharmaceuticals to surgical supplies.

- Purchase order management: Store all key order info including in place, like vendor contact information and communication, purchase quantities, delivery timeframes, and payment terms.

- Demand planning: Utilize global information like manufacturing timeframes, warehouse data, or healthcare trends to predict demand. Set custom performance benchmarks in order to better allocate medical resources.

- Risk management: Prepare your healthcare facility for “What If” situations now to prevent supply chain disorganization in a real emergency scenario like a pandemic or large-scale trauma event.

- Vendor and supplier relationship management: Manage all levels of communication with your vendors and suppliers to prevent mistakes from miscommunication. Maintain order accuracy with automated quality checks on purchase orders.

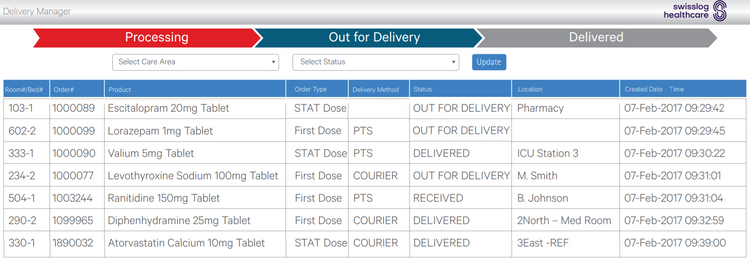

- Medication traceability: Easily trace medication and pharmaceuticals from the manufacturer to your patients. Use barcodes to keep drugs organized in shipping or storage. Manage product recalls when necessary.

- Warehouse control: If you manage a warehouse, control your workflow to maintain stock levels and generate accurate product reports.

- Analytics reporting: Whether you’re the initial manufacturer or end customer, keep accurate pricing and cost information about the items your company builds, buys, stores or sells in one easy to access location.

Benefits of Health Supply Chain Systems

There are many benefits for hospitals and healthcare centers using specific supply chain software:

Easier Hospital or Medical Practice Management

Managing any medical facility isn’t easy. Administrators need to stay on top of finances, schedule staff, and update payroll all while trying to make patients healthier. While there are hospital management and medical practice software options, your facility may benefit from a dedicated healthcare supply chain system.

If you automate your supply chain solutions, you can go back to focusing on other aspects of facility management. And budget-related decision making is easier when you know you have upcoming replenishment needs or if your pharmacy is fully stocked.

Prevent Shortages and Overstock

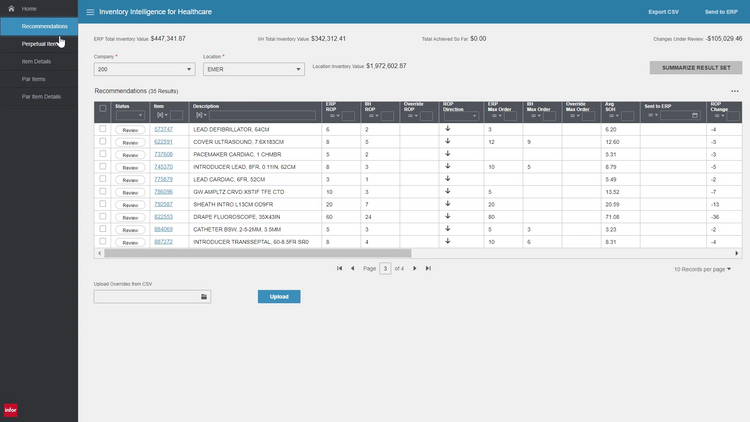

Inventory management applications help retailers and suppliers balance their stock levels. The cost savings from only supplying what is necessary are substantial. But within the healthcare field, inventory can range from expensive medical equipment like CT machines to regular aspirin. As a type of logistics software, a supply chain system allows for the cost-effective flow of medical goods to where they’re needed most.

Healthcare organizations can use this software to plan all of their inventory needs, from the latest medical devices to state-of-the-art technology, all within one system. And with cloud-based software, you can monitor inventory levels across each step of the multi-echelon supply chain.

Save Money for Medical Use

In order to provide the best care possible to your patients, you want to spend more money on what matters. Analyzing your medical billing system may reveal some ways to cut costs, but for many facilities savings comes down to optimizing the supply chain.

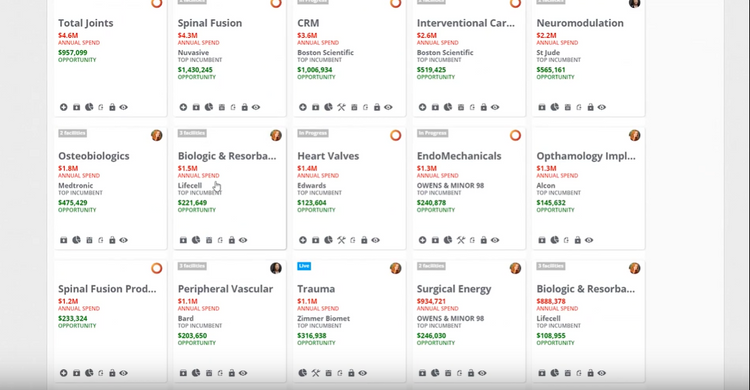

How often do you negotiate with a supplier or manufacturer directly? How do you know you’re getting the best value for the valuable medical supplies you order? With a healthcare supply chain management system, you can review your average costs with a value analysis module to compare offers from competing suppliers to get the best value.

Reduce Inventory Waste

Many pharmaceuticals have strict expiration dates. And single-use PPE needs to be replaced on a regular basis. Supply chain processes provide multiple ways to reduce waste. Instead of letting these valuable drugs expire, use a product lifecycle management tool to create a FIFO system. This will ensure your supplies are used in the most effective order possible.

Next, you can automate replenishment of high volume PPE consumables and medications to prevent shortages. Analytics reporting may reveal cost savings if you buy certain products in bulk.

CDC and FDA Compliant Logistics

There are many rules about the manufacturing, transportation, and distribution of pharmaceuticals. Whether a medication is OTC or prescription only controlled substances, you need to be aware of the Center for Disease Control (CDC) and U.S. Food and Drug Administration (FDA) compliance guidelines to avoid potential citations and fines.

Risk Management Event Monitoring

For example, many healthcare providers were caught off-guard by the COVID-19 pandemic. Critical shortages of ventilators and PPE have left many hospitals and medical practices unable to safely care for their patients. Fortunately, there are risk management applications which can analyze disruptions to your supply chain before they happen. Event monitoring tools allow you to generate “What If” scenario models to see how your facility would respond to a crisis.

Healthcare vs General Supply Chain Systems

Generic supply chain management (SCM) software companies control the flow of their goods and services along a multi-echelon supply chain. Known as a type of logistics software, it provides automated tools for manufacturing, selling, and distributing everything from the raw materials to the finished product.

Healthcare-specific supply chain software accounts for the everyday work done in the medical industry. Other industries don’t need to trace medical devices back to the manufacturer to stay compliant with regulatory agencies. And they don’t order and distribute controlled substances. These are all parts of your health system’s supply chain.

Current Healthcare Supply Chain Problems

Among the healthcare industry, there are several common problems along every step of the supply chain:

Quality Control for Medical Device Manufacturers

The manufacturing of medical devices is subject to regulatory agencies such as the FDA, the International Organization for Standardization (ISO), and even the CDC. Specialized production tracking software gives you the tools for staying compliant with the medical requirements of each organization.

Regulated devices includes:

- Pacemakers

- Defibrillators

- Heart valves

- Prosthesis and implants

- Ventilators and monitors

Medication Recalls

Fortunately, traceability measures like barcodes make it easy to know which products originated from the same batch and need to be recalled. If a drug is recalled, traceability modules can organize your collection and disposal efforts. The Food and Drug Administration (FDA) has guidelines for how to properly handle and dispose of harmful and defective medication. After the drug is safely removed automatically update your stock to reflect the new counts and mark which medications are safe alternatives.

Controlled Substance Storage and Distribution

Any medications labelled as “controlled substances” cannot be dispensed except under very strict guidelines. Even manufacturing and storing these drugs requires stringent adherence to federal regulations. Stay in compliance by using healthcare supply chain software to ensure medication is carefully controlled on every step of its journey to your patients.

Opioid Crisis and COVID-19 Pandemic Preparedness

Specific issues, like the opioid crisis and COVID-19 global pandemic, can cause very unique product shortages without affecting the rest of your stock. In particular, N95 respirator masks were once used only by doctors handling tuberculosis cases. Hospitals didn’t need to stockpile those masks. Yet COVID-19 has caused a shortage of those masks and other PPE for medical staff and the general population. Healthcare supply chain software with risk management tools let you plan for potential “What If” scenarios from a local crisis to a global pandemic. You can use the data from these scenarios to better plan your long-term inventory needs during a potential disaster.