MRP vs. MPS: What’s the Difference?

A master production schedule (MPS) is a plan based on independent demand and sales forecasts. A material requirements plan (MRP) determines production based on dependent demand or the need for parts and raw materials.

MPS and MRP software both allocate resources and optimize manufacturing. Read on to learn the differences between them, understand how they interact during the production process, and view examples.

What Is an MPS?

An MPS drives an MRP by using the bill of materials (BoM) to dictate the resources needed to achieve a fixed production rate. Master scheduling accounts for on-hand inventory levels and the output quantity required to meet projected consumer demand.

The MPS process runs weekly to adjust output based on production orders and demand forecasts. The benefits of an MPS include:

- Reduced manufacturing expenses and lead times

- Reduced overstock and shortages

- Better staffing

- Higher profitability

Read More: What Is a Master Production Schedule?

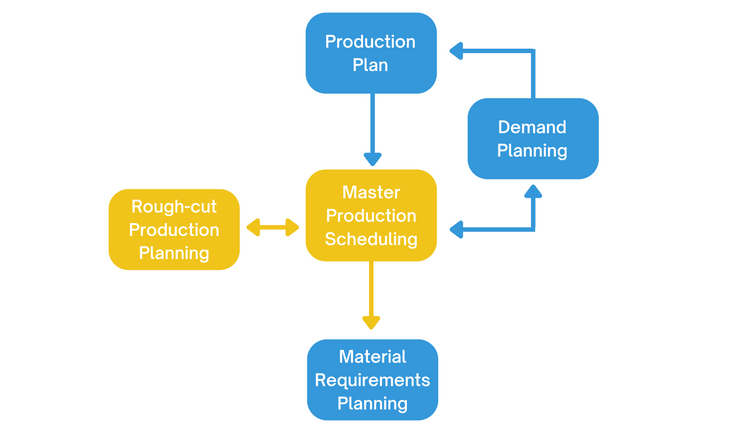

This diagram shows how MPS drives material requirements planning:

What Is an MRP?

An MRP prepares a facility to produce components and parts. It follows the priority plan the MPS establishes to determine which materials to order. The MRP determines manufacturing based on dependent demand or demand taken from the need to produce another product.

MRP runs daily to determine the production resources and raw materials required to fulfill production. The benefits of an MRP include:

- Optimized material planning

- Supply chain transparency

- Improved inventory management

- Fewer manufacturing bottlenecks

MRP vs. MPS

MRP systems and MPS approach manufacturing planning in different ways. The following table outlines the disparate but interconnected methodologies used to streamline production.

| Material Requirements Planning | Master Production Scheduling |

|---|---|

| Is driven by MPS | Directs MRP processes |

| Plans components based on dependent demand | Plans finished products based on independent demand |

| Involves multi-level planning | Involves single-level planning |

| Operates daily to determine required production resources | Operates weekly based on sales orders and demand forecasts |

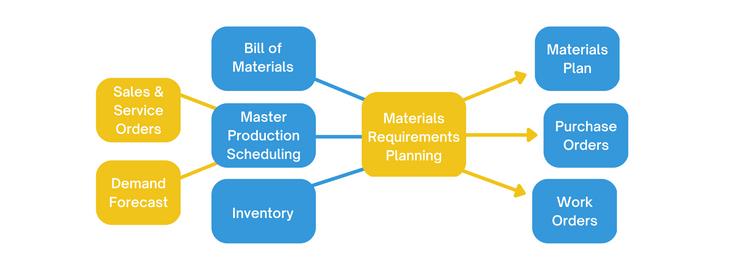

The following flowchart shows how MRP and MPS interact in the larger production planning process:

Dependent vs. Independent Demand

Demand is independent when unrelated to any other product or service. However, it’s dependent when derived from the demand for another product.

-

MRP bases production on dependent demand or the demand for parts and raw materials. It’s passed down the production chain to the finished product.

-

MPS bases production on independent demand or direct customer demand and sales forecasts.

Examples of MPS and MRP

As an example of MPS and MRP in action, consider a manufacturer that generates a product line of backpacks and purses.

-

The MRP items are the canvas, nylon straps, and zippers needed to create the finished goods. MRP ensures the resources are in stock and allocated correctly, with a focus on the requirements needed to produce products.

-

The MPS items include the backpack, purses, and any product variations, such as the range of sizes and colors. MPS derives data from sales or service orders and demand forecasting.

The MRP handles the multi-level planning for various finished goods, while the MPS manages single-level planning for individual products and SKUs.

How is MRP I different from MRP II?

Material requirements planning (MRP I) is a business software used widely in the 1970s to manage inventory, the ordering process, and materials planning. By the 1980s, manufacturing resource planning (MRP II) emerged to add automation of accounting, quality control, procurement, equipment maintenance scheduling, and other modules.

Today, people use the terms interchangeably. Any MRP software on the market today is effectively an MRP II system.

What is demand planning?

Demand planning forecasts customer demand to guide supply chain operations. It strikes a balance between supplier capabilities and market opportunities.

Manufacturers assess historical and current sales, consumer trends, and seasonal data. Demand management aids in efficient production, customized output, and minimized inventory carrying costs.

How is a production plan different from a master production schedule?

Production planning drives the MPS, offering a high-level overview of operations, while MPS has a detailed view of a shorter time horizon.

The master production schedule determines the production output of individual SKUs or finished goods. Production planning determines the output of product families.

How do I prepare a master production schedule?

To prepare a master schedule:

- Compile a complete list of your products and their variations.

- Calculate lead times to determine how long production takes for each product.

- Draft a demand plan.

- Allocate the raw materials your facility needs to hit an optimal production rate.

- Establish a time horizon.

- Split the time first into months and then into weeks.