The Difference Between MRP I and MRP II

MRP systems (I and II) help plan and optimize manufacturing production lines. The difference is that MRP II uses additional data from accounting records and sales to further analyze and forecast manufacturing requirements, replacing MRP I.

MRP I stands for material requirements planning, while MRP II stands for manufacturing resource planning. However, the terms are often used interchangeably. This is because MRP I is a historical and academic term. For all intents today, any MRP software on the market is effectively an MRP II system.

History of MRP

In the mid-1960s, a researcher at IBM coined the term MRP in a research paper. He documented a simple model for just-in-time inventory. MRP is about taking inputs (material cost, material availability, expected demand, forecasted demand, staffing ability, machinery capacity) to ensure that you have the right amount of materials/labor/machinery on hand at any given time to satisfy the market or your company’s production goals.

MRP II Evolution

By the mid-1980s, Oliver Wight popularized the term manufacturing resource planning (MRP II). MRP II was developed to expand upon MRP I, providing additional functionalities, including finances and general accounting, demand forecasting for inventory requirements, machine and labor capacity planning, and quality assurance. Due to the extra functionality, MRP II effectively replaced MRP I.

In the early 1990s, ERP (enterprise resource planning) was popularized when MRP II was extended to include more components of the entire organization: project management goals, financing abilities, staffing capability, and more.

MRP I and II Functionality Differences

These are some of the basic features and functionalities of MRP I and MRP I:

| Features | MRP I | MRP II |

|---|---|---|

| Inventory Control | X | X |

| Bill of Materials (BOM) | X | X |

| Master Production Scheduling (MPS) | X | X |

| Equipment Maintenance Scheduling | X | |

| Accounting & Financial Planning | X | |

| Forecast Demand | X |

Examples of MRP Systems

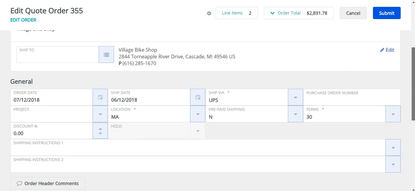

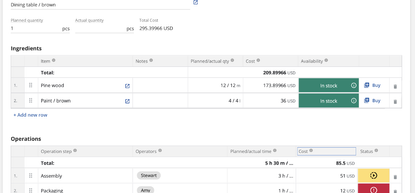

Here are a few examples of popular MRP II products:

For more popular systems, visit our MRP software category page.

What’s the difference between MRP and ERP?

Enterprise resource planning (ERP) software was developed to build upon the existing functionalities of MRP II software. This occurred when MRP II began to include more company-wide modules, such as accounting and demand planning.

ERP systems are historically and most commonly used by manufacturing and distribution companies. However, the term has been extended to any type of organization that want to use data from customer demand to help manage staffing and inventory levels.