The Top Lean Manufacturing Tools and Techniques

Lean manufacturing tools include anything meant to reduce waste or increase productivity during production. This can include physical equipment, production tracking software, production processes, or employee training methodologies. Some are self-explanatory based on their names and incredibly easy to implement in any business setting. Others are highly detailed and well-documented concepts tested and perfected in factories worldwide.

Companies that want to take advantage of these tools should understand the basics of lean manufacturing. In this article, we’ll discuss the definition of lean, the top tools, common techniques, principles, and its overall benefits.

What is Lean Manufacturing?

Sometimes known interchangeably as just-in-time (JIT) manufacturing, lean manufacturing is a production methodology that aims to minimize waste and maximize productivity within a manufacturing system.

The idea of lean manufacturing originally began as early as the 1930s with what is now known as the Toyota Production System (TPS) or Toyota Way of Manufacturing in Japan. The main goal was to use smaller factories with specified goals to minimize inventory levels and the waste of natural resources. By the 1980s, this had evolved in America enough for John Krafcik to publish an article on the values of “Lean” production systems.

The modern definition from James P. Womack and Daniel T. Jones in the 1990s identified five key principles:

Precisely specify value by specific product, identify the value stream for each product, make value flow without interruptions, let customer pull value from the producer, and pursue perfection. “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” - Womack & Jones

To achieve their desired level of productivity, many producers have turned to lean manufacturing tools.

Top Lean Manufacturing Tools

While there are many dozens (if not hundreds) of lean manufacturing tools out there, 6, in particular, have become prominent for their ability to reduce waste in a variety of industries consistently:

5S

The 5S tool is a methodology that focuses on cleaning and eliminating inefficiencies in the workplace. It was introduced by the Toyota Production System in the 1950’s. The five Ss stand for:

- Sort: Reduce clutter in the workplace by removing unnecessary items and keeping only essential tools, materials, and equipment.

- Straighten: Organize remaining items for easy access and optimized workflow.

- Shine: Clean your workspace regularly.

- Standardize: Standardize procedures across the entire organization to avoid confusion. This includes guidelines, checklists, and routines.

- Sustain: Apply these standards and continually improve them across the organization.

Kaizen

The concept of kaizen is loosely translated as continuous improvement. This is achieved by following several steps to identify problems, review possible solutions, test improvement methods, implement those changes, and then analyze the results. This process has no formal end, so new solutions are always being sought and tested for viability.

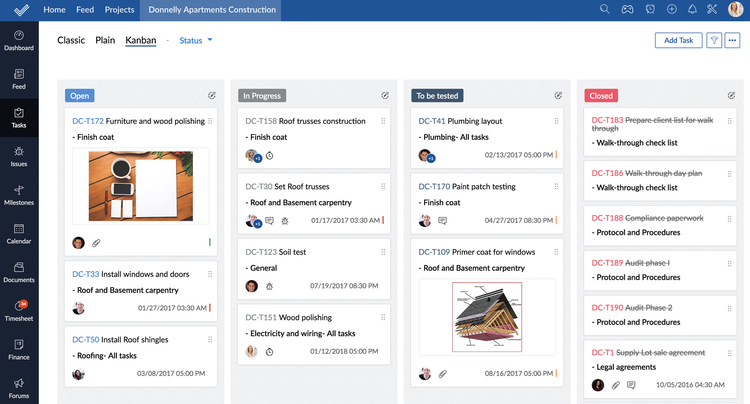

Kanban

If you’ve ever heard of a Kanban board, you’re likely familiar with some aspects of this lean manufacturing tool: a pull system that coordinates between your factory and customers to streamline product replenishment. Real-time visuals ensure everyone knows what needs to be done to meet customer demand.

Jidoka

Jidoka is the focus on automation in your manufacturing processes. The goal is to identify any area which can be automated without sacrificing quality. Jidoka tools can significantly reduce labor costs as equipment takes over previously manual tasks requiring minimal supervision.

Value Stream Mapping (VSM)

This methodology creates a visualization of current and forecasted production flow. A literal flow chart is used to show important details on production logistics, such as real-time inventory numbers, production time, and labor levels per shift.

Total Quality Management (TQM)

As the name suggests, Total Quality Management (TQM) is all about ensuring quality from every department involved in production. TQM seeks improvement at every level of an organization. It is often paired with Total Productive Maintenance (TPM) to focus on the equipment being used in production.

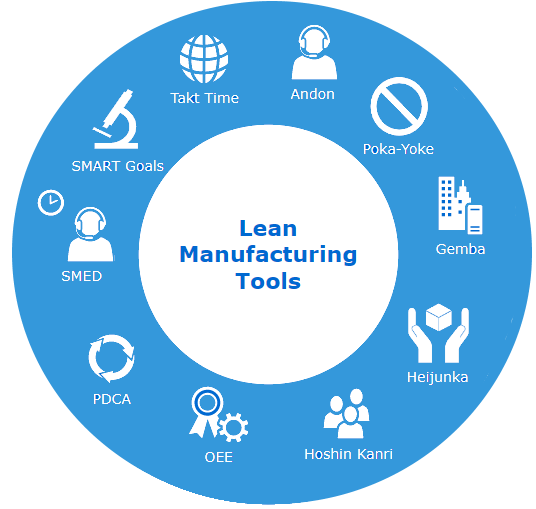

Rounding out the top 15 tools are:

| Tool | Definition |

|---|---|

| Andon | A visualization of production status which includes a fail-safe for operators to instantly stop production |

| Error Proofing | Known as poka-yoke in Japanese, this is the concept of preventing mistakes and achieving no defects during production |

| Gemba | Focuses on getting management away from the office and other distractions to be in “The Real Place,” aka the shop or factory floor where they can observe how the real work is happening |

| Heijunka | This level of scheduling minimizes lead times and inventory by producing smaller batches with product variants |

| Hoshin Kanri | Also known as Policy Deployment, this tool is based on a company structure, starting with Strategy from the top, to the Tactics of middle management, ending with the actual Action on the shop floor |

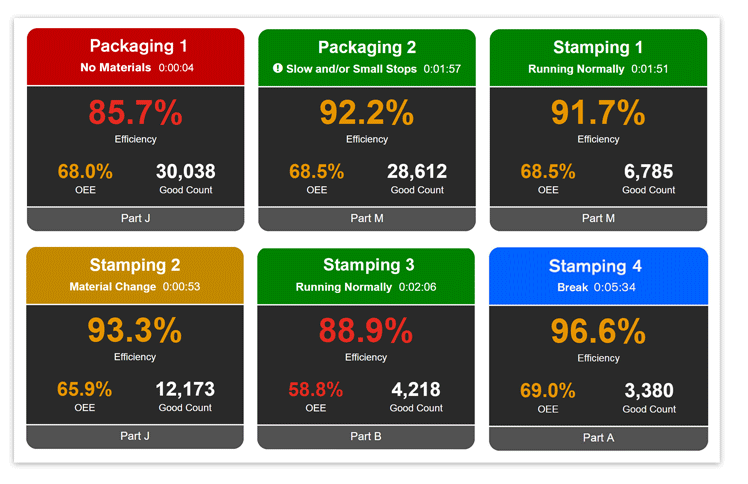

| Overall Equipment Effectiveness (OEE) | A way to measure waste attributed to equipment based on availability, performance, and quality |

| PDCA (Plan-Do-Check-Act) | An established order for testing new improvements, also called a PDCA cycle |

| Single-Minute Exchange of Die (SMED) | Minimizing setup or changeover between tasks to under 10 minutes |

| SMART Goals | Any goals which are Specific, Measurable, Attainable, Relevant, and Time-Specific |

| Takt Time | A carefully calculated cycle time based on production time and customer demand |

This is just a sampling of some of the most well-known and widely implemented methods of achieving lean manufacturing. Many can be combined to create customized systems to best serve your manufacturing needs.

Lean Tool Techniques

The right tool techniques can improve your lean manufacturing process. However, all lean manufacturing tools aim to get to the root cause of waste. Did you know there are different types of production waste? The main three, translated from Japanese, are:

- Muda: Waste from the production process

- Mura: Waste from new or changing demand

- Muri: Waste from overburden or lost motivation

The concept of Muda can be further broken down into the 7 wastes of business process:

- Motion: Are employees or equipment being moved around the shop floor unnecessarily?

- Waiting: Are there periods of downtime between tasks that could be productive?

- Overproduction: Are you creating excess with large batch sizes without considering customer demand?

- Overprocessing: Do your products include unnecessary extras that increase production time but not value?

- Inventory: Are you holding on to too much inventory, thereby taking up space and other resources?

- Defects: Are too many low-quality products making it to customers?

- Transportation: Are you moving resources too far between different locations?

What sort of waste your business generates will determine which tools you need the most. You’ll need different tools to address the common issues and pain points associated with each type.

You might notice a lot of overlap between the various lean manufacturing tools described above. For example, bottleneck analysis is sometimes treated as an independent tool. Yet identifying a bottleneck scenario that slows down production can be done with continuous flow or error-proofing tools. The definitions for JIT and Kanban are often used interchangeably. How you use or interpret a specific lean manufacturing tool is entirely up to you.

Finally, it’s important to remember no single tool is infallible. Poka-yoke, despite being a methodology based entirely on preventing errors, cannot stop genuine mistakes from happening in some capacity. In manufacturing, accidents can always happen. This is why utilizing multiple tools can provide ways to mitigate damage from unanticipated issues or human error.

5 Principles of Lean Manufacturing

Knowing the 5 principles of lean manufacturing will help you when considering various tool applications and implementation. Established in “The Machine That Changed the World” by Womack and Jones, the 5 principles are:

- Value: Precisely identify the value of each product

- Value stream: Map the entire value stream

- Flow: Minimize interruptions to optimize the value stream’s flow

- Pull: Allow the customer to pull the value of products, i.e., determine what they want

- Perfection: Aim for perfection in production

Continuous improvement, along with being the tool kaizen, is another key goal of lean manufacturing. There will always be processes and methods that can be improved. Whatever tools you use should address these principles in some way.

Benefits of Lean Tools

While the reduction of waste is the number one goal of lean manufacturing, there are other advantages to utilizing a lean system:

- Increase productivity

- Deliver better quality

- Lower operating costs

Utilizing lean manufacturing tools in your production process can lead to many secondary benefits as well. For example, tools that increase productivity can also improve lead time reduction by waiting to know what orders are guaranteed instead of trying to forecast customer demand.

As mentioned previously, the exact tools you need largely depend on what you produce and your anticipated customer demand. If you build chairs, assembling cushions in batches may be more effective than using continuous flow to complete one chair at a time. Yet this method, if unchecked, can lead to overproducing chair legs when demand decreases. Your lean manufacturing tools must be specific to what works best for your business.

Pain Points of Lean Manufacturing Tools

As with all production methods, the many lean manufacturing tools available can have drawbacks. For example, SMED aims to reduce changeovers to a maximum of 10 minutes. While this undeniably increases production speed, it can place a lot of pressure on the human workers responsible for completing 10 separate steps within one minute each. Fortunately, with so many lean manufacturing tools available, finding the right one (or more) to fit your workflow is simply a matter of problem-solving.