What is IIoT? Definition and Benefits of Industrial Internet of Things

The industrial internet of things (IIoT) is an ecosystem of intelligent devices connected to form systems that collect, monitor, and exchange data with one another, primarily for manufacturing and energy management. IIoT focuses on machine-to-machine (M2M) communication through big data and machine learning via interconnected sensors, instruments, and other devices within a manufacturing and energy management environment. This concept of connecting devices with an electronic interface to one another via the Internet serves the purpose of optimized process controls and digital transformation through a higher degree of automation.

Sensors within machines in a factory can connect to wireless networks to gather information and share data. These sensors are generally tiny and low-cost and can connect via high-bandwidth wireless networks, meaning even the smallest devices can be connected. This provides a new layer of digital intelligence and tracking across varying industries, such as manufacturing, retail, utilities, and transportation.

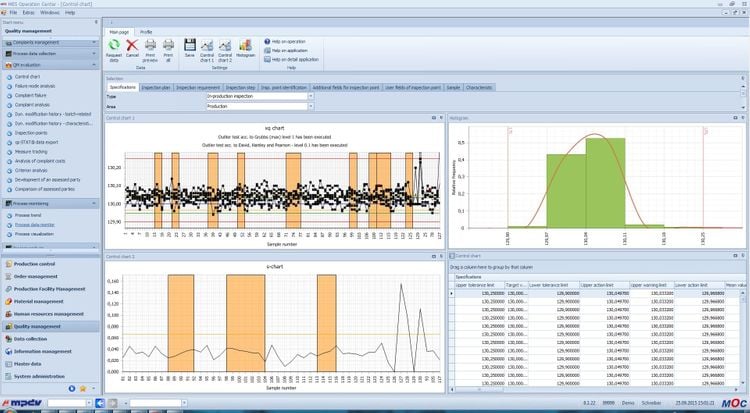

While IIoT solutions are disrupting manufacturing, a modern manufacturing execution system (MES software) will continue to spur initiatives, pilots, and studies. MES software manages industrial assets, collects data, and ensures traceability in an industrial setting.

Software bundles help manufacturers track and document processes, get an overview of shop food operations, and maintain transparency across assets. IIoT can be thought of as an enabler and a complement to MES, allowing manufacturers to reduce line downtime and increase overall equipment effectiveness (OEE) in a matter of days without the substantial investment that MES typically requires.

How Does Industrial IoT Work?

Equipment connected to the Industrial IoT is fitted with sensors that collect data from the machine and send it to the cloud. Once in the cloud, the data is passed to the quality management software or equivalent monitoring system. This analyzed data is then sent to the end-user. In short, the sensors gather production data and use the cloud to transform the data into valuable insights.

Real-life examples of IIoT include:

- Predictive Maintenance: Collect data from sensors and devices to assess current conditions, identify warning signs, deliver alerts, and trigger maintenance procedures.

- Asset Tracking: Detect and monitor key assets along the supply chain to maintain inventory levels and prevent quality issues.

- Business Intelligence: Connect disparate silos of data from varying sources around your organization–providing unified visibility across manufacturing, supply chain, and logistics.

- Extending ERP/MES capabilities: Put industry 4.0 initiatives into effect through connectivity, interoperability, mobility, and crowd-sourced intelligence.

What Industries Use Industrial IoT?

Countless industries can use IIoT, covering many use cases and applications. Originally intended as a convergence of IT and OT, the Industrial Internet of Things creates automation, optimization, asset performance, and intelligent manufacturing opportunities.

Manufacturing

The biggest benefactor is the manufacturing industry, which is the largest IIoT market. In the automotive industry, industrial robots can be maintained through IIoT, which helps spot potential problems before production is disrupted. In agriculture, sensors can detect data about soil moisture and nutrient levels, allowing farmers to produce optimal crop yields.

In 2016, manufacturing operations alone accounted for an IoT spend of $102.5 billion on a total of $178 billion, all IoT use cases in manufacturing combined. This means manufacturing operations outweigh all other IoT use case investments across all industries.

Logistics and Transportation

Other industries that benefit from Industrial IoT include logistics and transportation. These firms value advanced communications and monitoring systems that are enhanced by the Internet of Things. One big example is freight monitoring, which allows operations centers the chance to gain visibility into blind spots in their freight processes. Examples include the condition of freight, humidity levels in trucks, temperature, and ambient light intensity. Geofencing can also be established to determine if freight is outside established boundaries.

Energy and Utilities

Industrial IoT in the energy and utilities industry powers oil and gas, including smart grid operations and other use cases. Many utility companies have initiatives that prioritize energy conservation, such as using motion-sensitive energy-efficient lights or limiting the use of their HVAC systems. This method of conservation focuses on the facility’s overall equipment effectiveness (OEE), which in turn leads to energy conservation and savings.

In wastewater treatment plants, water leakage detection can detect loss, theft, and pressure management. Water quality, temperature, pressure, consumption, and more can be tracked via smart devices that communicate directly with water utility companies to analyze data and share information with the consumer.

Benefits of Industrial IoT

The Industrial Internet of Things can augment existing assets and maximize workforce efficiency. Some of the biggest drivers behind Industrial IoT implementations include a desire for improved operational efficiency, improved productivity, creating new business opportunities, and reducing downtime. Usually, it’s the combination of the below benefits that makes the decision to move forward with Industrial IoT an easy one to make.

Increase Manufacturing Efficiency

A study by the American Association for Quality found that those businesses shifting to digital processes and Industrial IoT have seen as high as 82% increase in efficiency accompanied by 49% fewer defects. Why? According to the study, relying on smart connected factories (a complete integration of computers and machines made possible through artificial intelligence (AI), machine learning, and deep analytics) can provide the following benefits:

- These technologies can perform at a micro level that humans cannot.

- They can work faster than humans.

- They can allow for faster, objective, and more accurate decision-making.

- Systems can process and analyze data to “see” patterns and trends not readily discernable by humans.

- They can decentralize decision-making by allowing many autonomous or semi-autonomous decisions from the platforms themselves.

Manage Predictive Maintenance

Predictive maintenance is the act of analyzing performing trends and using condition-based monitoring to alert your team to potential problems. By tracking material and equipment degradation over time, you should be able to reasonably predict when maintenance is necessary. This is opposed to reactive maintenance, which only occurs after equipment or assets have already broken down, or preventive maintenance, which offers more routine scheduling regardless of performance.

According to the Aberdeen Research Group, downtime across all manufacturing types equates to an average cost of $260,000/hour–something usually blamed on a lack of proper and predictive maintenance. This is because reactive maintenance equals a huge time loss in determining what the issue is, how it can be fixed, and the cost of repairs. These are issues that can be prevented completely with the use of Industrial IoT solutions.

Industrial Internet of Things technologies predict equipment health and maintenance needs by using the following:

- Sensors: Outfit machines with sensors to detect variances and monitor for performance abnormalities. Measure conditions, motion, and vibration.

- Connectivity: Link machines and sensors to one another.

- Machine Learning: Enable systems to learn and operate independently

- Cloud Computing: Pull all data together for complete visibility

The combination of these things creates a baseline level of consistent performance. Any variance from this baseline allows companies to see issues before they occur–allowing them to schedule maintenance prior to the downtime. It also provides companies with the time needed to order parts required for the job, calculate the cost beforehand, and move production to another area of the facility.

Improve Safety

Many industries turn to IoT devices to improve efficiencies and safety. Examples include being able to auto-adjust thermostat settings for optimal energy efficiency, accessing security cameras remotely when they provide alert notifications, or controlling door locks to ensure your facilities are secured when you are not in operation.

71% of manufacturers used IoT devices in 2019, citing reasons such as keeping employees safe and healthy while also lowering operating costs. The most popular use of IoT within a manufacturing environment is through sensors. Sensors on manufacturing equipment can pinpoint failures and breakdowns (as mentioned in the previous section). But sensors can also serve further safety purposes:

- Camera sensors: Computer vision can identify safety risks and trigger alerts of unsafe behavior and uncover areas to promote a safer working environment. Ensure employees wear proper safety equipment, abide by zones, ensure proper clean-up, and more.

- Wearables: Track employee location during a crisis and detect falls.

- Energy Management: Monitor water, temperature, humidity, and overall flow to reduce the risk of property damage or accidental water events.

Whether wearable technologies or smart security devices, integrated safety systems protect workers and limit damages in the event of a workplace accident. Additional benefits include corrective actions that can be determined based on monitoring employee engagement regarding proper workplace safety procedures.

Challenges of IIoT

IIoT can be beneficial to many businesses, but it does come with its challenges and risks.

Security

The largest risk associated with implementing IIoT is its security. Since the devices are native to the cloud and exist on the Internet, they are prone to cyber attacks that can compromise sensitive information. In addition, IIoT devices issue data as clear text, making it easy to interpret and intercept outgoing data.

Implementation

While IIoT aims to streamline processes, adding new technology to an organization comes with its own set of challenges. Businesses must understand the inner workings of their devices to respond to problems and set up the devices quickly. This is especially true for companies using legacy systems, as scalability and new technology integration can be challenging.

Using MES and IIoT

To streamline operations on the shop floor, many businesses over the years have turned to solutions such as manufacturing execution systems (MES software), which enables complete shop-floor control and scheduling capabilities via monitoring and corrective action guidance for quality and performance continuous improvement. These solutions monitor industrial processes and assets by collecting data and ensuring traceability.

MES systems can connect to almost any solution in the cloud, including any Industrial IoT. IIoT platforms typically enter the MES conversation when:

- An organization chooses an IIoT platform instead of an MES

- An organization decides to extend its MES with an IIoT platform

The second option is becoming a more popular choice for organizations in regulated industries. These businesses primarily focus on improving visibility and reducing costs. By syncing MES with an Industrial IoT platform, their existing MES can essentially build on new functionality on top of the existing system. MES will remain the system of record while the IIoT platform collects the data on the shop floor and serves the front-line workers.

An IIoT platform can make data more readily available through connection to sensors, machines, other business systems (such as an ERP application), and employee records. Together, this provides a complete real-time picture of your manufacturing performance. And since MESs can be considered critical systems, incorporating an Industrial IoT platform means engineers can analyze processes and solve problems as they come up without disrupting the manufacturing chain.