The Best OEE Software

The best OEE software helps manufacturers monitor machine output and identify production losses in real time. Explore our expert buyer’s guide and top-rated OEE tools for automotive, food and beverage, electronics, and other high-throughput industries.

- Platform is adaptable to wide range of business types

- Implementation takes 8-12 weeks on average

- Offers role-based access

- Automatic part qualification and rejection

- Flexible deployment options

- Over 1,000 out-of-the-box analysis choices

- Gathers real-time shop floor data

- Great customer support

- Logical, intuitive UI

After evaluating over 15 OEE software systems, we’ve selected the top options based on real-time monitoring, usability, and industry fit. Explore our top picks and buyers guide below.

- ShopVue MES: Best Overall

- Epicor Advanced MES: Best for Discrete Manufacturing

- HYDRA X: Best for Machine Performance Monitoring

- Aptean: Best for Process Manufacturing

- Evocon: Best for High-Volume Manufacturing

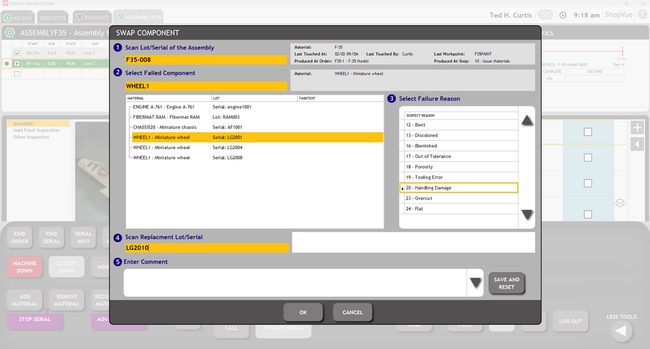

ShopVue MES - Best Overall

ShopVue MES offers detailed OEE tracking through its modular MES platform. It connects directly to manufacturing equipment and collects real-time machine data without manual input for key metrics like downtime, machine availability, and production yields. These values feed into live, color-coded dashboards that provide visibility into production across all machines and work centers. The system enables continuous monitoring and supports data-driven decision-making on the shop floor by capturing cycle times, scrap counts, and throughput.

Because ShopVue is modular-based, manufacturers can adopt only the functionality they need. This may include just OEE tracking or expand to more MES features like labor management, production scheduling, traceability, and quality control. The system integrates with most major ERP platforms such as SAP, Oracle NetSuite, and Microsoft Dynamics, enabling data to flow between operations and the back office systems.

ShopVue MES is typically used by mid-sized to enterprise-level manufacturers as it can be deployed at a single site or across multiple facilities. Unfortunately, pricing is not listed publicly and requires a consultation for a quote.

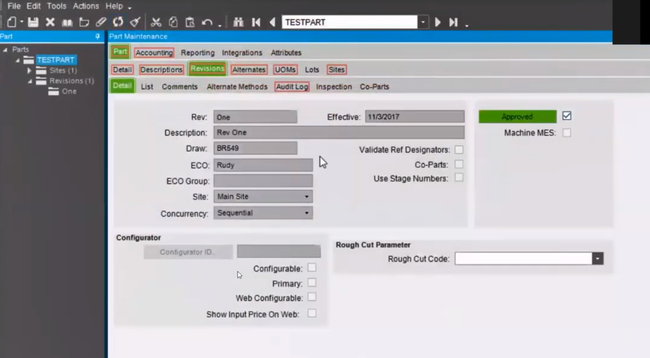

Epicor Advanced MES - Best for Discrete Manufacturing

Epicor Advanced MES connects to any workshop machine and generates key metrics, from overall equipment effectiveness (OEE), run rates, and yield to material consumption and energy performance. Its part-centric design makes it exceptionally well suited for discrete manufacturing environments, where tracking individual components and assemblies is critical. The system captures data at a granular level, enabling real-time traceability of parts as they move between work stations.

Dashboards and automated alerts provide immediate insight into performance deviations, machine downtime, and scrap output. Statistical process control (SPC) and quality control (SQC) features are integrated directly into the system, automatically detecting trends and predicting equipment failure, minimizing rework. All collected data can be linked to specific machines, jobs, or part numbers, giving manufacturers a clear view of where losses occur and how to address them for the future.

The system can be deployed on-premise or in a hybrid environment and integrates with most major ERP platforms. It’s typically used in industries such as automotive, aerospace, plastics, and industrial equipment, where part-level accuracy and traceability are essential. To receive pricing on Epicor Advanced MES, you must request a consultation to discuss your unique OEE and manufacturing requirements.

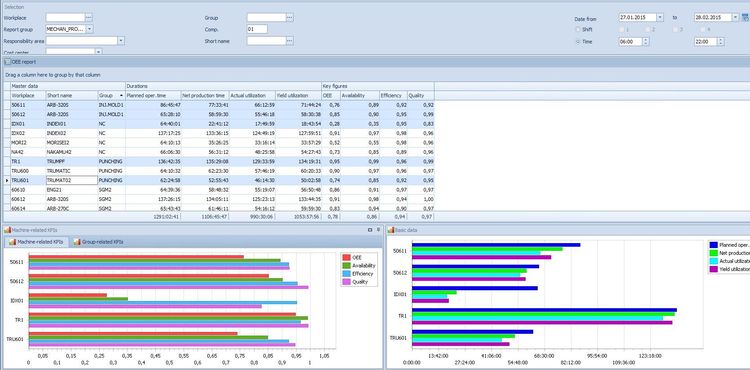

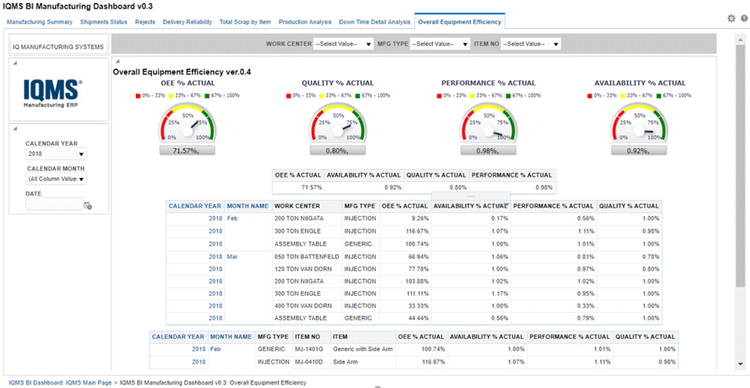

HYDRA X - Best for Machine Performance Monitoring

HYDRA X’s machine performance KPI module is highly effective for manufacturers of all types. The system automatically calculates OEE for every workplace using historical and real time data from your ERP and IoT devices. From there, it creates a report of consolidated OEE figures, so you can view your entire production floor in one place.

The KPI module also provides other crucial statistics on configurable dashboards. These include mean time between failure (MTBF), mean time between repair (MTBR), and capacity utilization. It even has separate figures for availability, efficiency, and quality to see how it calculates the OEE. And because it’s configurable, you can add KPIs specific to your manufacturing industry, like batch yield for food and beverage.

HYDRA X includes several modules and capabilities within its broader MES suite. Because of this, it’s best for growing and enterprise-level manufacturers in sectors like automotive, food and beverage, and electronics. Unfortunately, prices are not listed publicly, so you’ll need a custom quote for specific figures.

Aptean - Best for Process Manufacturing

Used by CPG, food and beverage, and private-label manufacturers, Aptean Process Manufacturing OEE provides real-time shop floor data and promotes productivity. Purpose-built with out-of-the-box functionality, the software is a promising tool for those seeking to streamline their manufacturing processes. The solution can be deployed seamlessly at single sites or across multi-plant enterprises that operate a linear, fast-moving production line.

Evocon - Best for High-Volume Manufacturing

Evocon’s checklists module optimizes quality control for industries like automotive parts or food packaging, where missing even small machine inconsistencies can lead to a high rate of defective products. By using Industrial Internet of Things (IIoT) devices, the module pulls real-time machine data and prompts your technicians to perform checks based on their actual conditions.

The system triggers these digitized, automated checklists to guide your operators through maintenance. Trigger points are based on production events, like after manufacturing a set number of units. You can also set custom thresholds when key metrics, like scrap rates or speed, fall outside your specified ranges.

Evocon integrates these checks into a production timeline to give your supervisors and engineers a clear view of quality and safety inspections. Color-coded results indicate green for passed, red for failed, and yellow for pending. This makes it easier to track progress and catch any missed or incomplete checks before errors cascade further down the line.

You can create custom tasks tailored to your unique production environment, including parameter logging, visual inspections, and measurements. Operators can even log values, accept and reject results, and add comments as needed. Because data from completed checks feeds into reporting tools, you can pinpoint recurring quality issues or machine failures. This helps you reduce scrap and rework that commonly derail high-volume manufacturing.

What is OEE Software?

OEE (overall equipment effectiveness) software grabs measurements of machine availability, throughput, and quality and turns them into a score that grades your manufacturing performance. This OEE score is considered a key performance indicator (KPI). These KPIs can be configured with alarms and analyzed to ensure maximum production on your manufacturing shop floor. Examples of data captured include downtime, counters, design speeds, and contextual data.

OEE systems help implement a continuous improvement cycle in your business and measure equipment effectiveness by identifying the ratio of fully productive time to planned production time to determine lost time. OEE is a method of measuring the potential for improvement in your production process. OEE is calculated by:

Availability X Throughput (Performance) X Quality = OEE

- Availability is calculated by dividing run time by planned production time. This takes into account all events that halt planned production for longer than expected periods.

- Throughput (performance) is calculated by multiplying the ideal cycle time bthe y total count and dividing that by run time. This monitors the root causes of anything slowing down the manufacturing process.

- Quality is calculated by dividing the good count by the total count. This includes parts that require specific or unique quality standards and reworked parts.

Go more in-depth by reading our How to Calculate OEE page.

The goal of overall equipment effectiveness software is to help eliminate waste and implement a lean manufacturing process. OEE solutions can be applied to discrete manufacturing processes (the most common) as well as continuous processes. OEE data can be entered manually via PC or mobile smartphones, imported from gauges, or imported from Excel.

OEE software is often part of a larger MES software in a manufacturing environment. This is because MES applications allow decision-makers to use OEE to their advantage through reports, Pareto charts, and a corporate overview of performance. Those with more manual processes (and thus, no MES system in place) may want to consider OLE (overall labor effectiveness), which helps measure how effective your workforce is through their productivity levels (such as how much they are producing per day).

Key Features

- OEE Data Collection: Calculate machine availability, productivity, quality ratio, TEEP, actual cycle time, actual speed, and productivity.

- Key Performance Indicators (KPIs): Create performance measurements measuring the success of your manufacturing processes or of particular manufacturing activities.

- Performance Feedback: Display real-time visibility of performance to your production team. Intelligent systems will take into account slow periods (such as a cycle taking longer than ideal due to a low-sales period) or pauses in production (due to occasional idling or work stoppages due to staffing issues).

- Downtime Management: Track downtime at the company level, department level, or at a specific machine. Traceability is provided by root cause analysis and can help identify needed revisions. Ensure downtime hours do not go over the specified allotments.

Benefits

OEE software is an incredibly valuable tool that management can use to uncover capacity they didn’t think possible, which will help lower production times and/or reduce overtime expenditures. This type of production tracking software has a number of benefits your business can take advantage of. Some of the top benefits of OEE software include:

Reduce Downtime and Rate Losses

Downtime can be defined as an event that occurs for a long enough period that a reason is assigned for the occurrence. Downtime is one of the leading reasons a manufacturing plant may have poor overall equipment effectiveness. This is because downtime takes away from valuable planned production time. Without good insight into where this downtime is coming from and why it’s happening, it can be difficult to fix.

OEE software will help collect the lifecycle performance of your manufacturing equipment. This will help find, fix, and improve downtime—no matter how big or small. Even the tiniest variations in overall equipment effectiveness will affect the business performance of your manufacturing plant.

The condition-monitoring data provided by OEE Solutions can help you schedule and handle any events or needed responses to issues on your plant floor. This complete visibility into your operations will help you maximize the availability of your machinery and production line and ensure you can increase production whenever possible.

Improved Operational Cost Control

Many manufacturers pride themselves on the quality of their products. A high-quality product can be one of the key reasons you receive return business from your customers. This is of huge importance to ensuring your quality of cost stays at an appropriate level.

Cost of quality, or COQ, can be described through a number of varying costs involved in production:

- Prevention costs: Associated with the maintenance of a quality management system.

- Appraisal costs: Associated with an evaluation of purchased materials and services.

- Internal failure costs: Associated with failed work that doesn’t meet quality standards detected before transfer to customers.

- External failure costs: Associated with failed work that doesn’t meet quality standards detected after transfer to customers.

These hidden costs can be hard to detect but greatly affect machine priority. OEE software is intended to eliminate these weaknesses in your quality management process.

OEE is a great metric to identify if you are incurring losses in your manufacturing operations. Most job costing software will track your material costs, labor costs, and overhead costs. Once you improve the quality of your product, you’ll see the greatest return. This is because quality impacts all cost elements. When you incur a quality loss, you have to consider how many goods you’ll need to produce to offset the lost costs.

Improved Manufacturing Performance

A quick way to improve your manufacturing performance is by focusing on top losses, which is the smallest set of improvement actions that will yield the biggest results. In other words, it’s the low-hanging fruit of your production processes.

OEE software can create top loss reports. These reports show sources of lost production time and any increase in rates the loss is responsible for. As long as your team has an idea of where their top losses are (data provided by a top-notch OEE system), they will be able to take the appropriate actions and minimize the number of resources that are affected.

An example of appropriate actions to take include improvement cycles, improved scheduling, improved procurement practices, and better shop floor management.

Integrated OEE and SPC

Overall equipment effectiveness software ties in closely with statistical process control (SPC) software:

- OEE software creates the KPIs that show a high-level appraisal of operational performance

- SPC software is in charge of collecting quality and performance data in real-time for statistical analysis.

Data from OEE systems give insight into your manufacturing performance and can help reduce costs by ensuring you get the most use out of your equipment and facilities. SPC data is used to identify product quality issues and process variations and allows management to take corrective action before issues occur.

There are many benefits to applying SPC to OEE data. According to Northwest Analytics, a manufacturing analytics provider:

An isolated OEE value provides only a small amount of decision support. The single value can be compared to a specification, but it does not provide any indication of previous process behavior and reasonable expectations for future performance. When put into context with SPC, that same OEE delivers substantially greater process management information. “Combine OEE and SPC for Real Decision Support” - Northwest Analytics

Some real-life examples of their combined effectiveness include:

- Analysis of the correlation between downtime and quality issues

- An integrated approach to keying in both OEE and SPC data and avoiding double-entry

- Complying with all major regulations

How to Choose

Choosing the right OEE software involves evaluating how well each solution aligns with production needs, technical infrastructure, and long-term goals. The following factors can help guide the selection process:

Machine Integration: Assess whether the software supports direct data collection from equipment using PLCs, OPC UA, or IIoT devices. Automated data capture improves accuracy and reduces manual input.

Real-Time Dashboards: Look for systems that display live metrics such as OEE, availability, downtime, and throughput using configurable, easy-to-read dashboards.

Deployment Model: Determine whether a cloud-based, on-premise, or hybrid deployment fits best with IT resources, data governance, and scalability requirements.

ERP and MES Compatibility: Consider whether the platform integrates with existing ERP, MES, or SCADA systems. Seamless integration supports data consistency and end-to-end traceability.

Modular Design: Opt for solutions that allow phased implementation—starting with core OEE tracking and expanding to modules for labor, scheduling, or quality control as needed.

Data Analysis and Reporting: Evaluate the system’s ability to generate detailed reports, such as downtime analysis, top loss tracking, and trend identification across shifts or machines.

Support and Training: Review available onboarding tools, documentation, and technical support. Reliable vendor support is important for implementation and long-term use.

These considerations can help manufacturers select a system that tracks overall equipment effectiveness and supports broader operational improvement efforts.