The Best Inventory Optimization Software

Inventory optimization software keeps stock levels aligned with demand. We tested and ranked the best systems for manufacturers, distributors, and retailers.

- Connected Planning platform enables collaborative planning

- Hyperblock™ modeling and calculation engine

- Unified cloud-based software

- Integrates with leading ERP systems

- Easy to navigate dashboard

- Automated classification of inventory items based on sales value and velocity

- Effective constraint planning

- Intuitive user interface

- Customizable dashboards, alerts, and exceptions

We tested and chose the best solutions using our advanced methodology for features like demand forecasting, replenishment planning, and scenario modeling. Top products include Anaplan, NetStock, Kinaxis, and Pyplan.

- Anaplan: Best for Manufacturers

- Netstock: Best for Retailers

- Kinaxis: Best for Distributors

- Pyplan: Most Customizable Platform

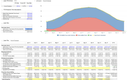

Anaplan - Best for Manufacturers

Anaplan’s planning and simulation tool allows you to create multiple scenarios to understand how changes in variables, such as demand, supply chain disruptions, and production costs, will impact inventory levels and overall operations.

For example, you’re an electronics manufacturer launching a new gadget, but you’re facing unpredictable demand due to market uncertainty. Using Anaplan, you can model various demand levels for this new product and simulate the impact of supplier delays on raw material availability.

The software calculates the amount of inventory you should hold for each demand level, helping you avoid stockouts while minimizing carrying costs. The simulation will also evaluate the effect of supplier delays, suggesting safety stock levels and alternate sourcing strategies.

Anaplan’s dashboard displays high and low-demand scenarios, leading you to choose a medium-demand level while securing a secondary supplier to mitigate risks.

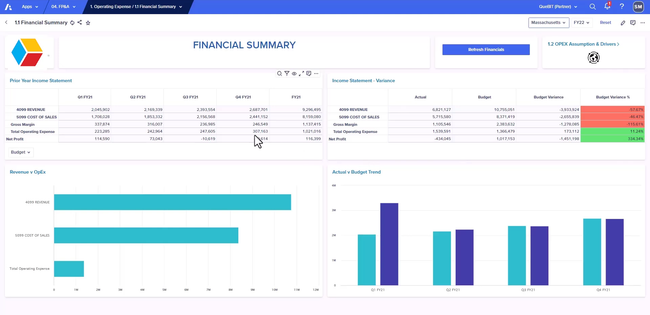

Netstock - Best for Retailers

If you own multiple stores nationwide and struggle to maintain consistent stock, Netstock’s stock optimization feature can help you balance inventory availability and operational efficiency. The system uses advanced algorithms, demand forecasting, and data analytics to optimize and align stock levels with your business needs.

Maybe one of your stores frequently runs out of popular sizes, while another is overstocked with seasonal items, resulting in markdowns and low storage space. Using Netstock, you can analyze historical sales data to predict demand for each store, identifying trends such as increased sales for long winter coats in colder regions. The software can set optimal safety stock levels for product categories, ensuring that each location can handle unexpected surges in demand.

The system can also identify when certain stores have excess inventory and suggest stock transfers to other locations with higher demand. As inventory levels drop to the predefined threshold, the software will automatically generate a purchase order for restocking. If there is an overstock of a product, such as swimwear, in the northern region, the system will send you an alert to either discount the item or redistribute it to your southern locations.

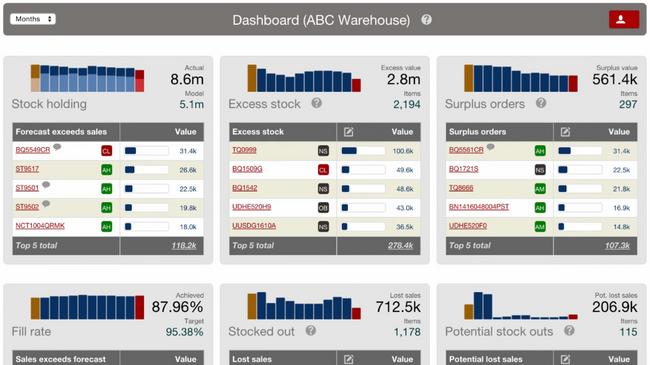

Kinaxis - Best for Distributors

Kinaxis’s end-to-end visibility feature creates a unified view of the entire supply chain. It collects and integrates data from different touch points, ensuring that you have access to accurate and up-to-date information.

For instance, maybe you’re an electronics distributor who supplies products to retail chains. Recently, one of your clients released a marketing campaign, which led to a higher demand for smartphones. However, a critical component used in the phone is delayed.

Kinaxis will send you an alert regarding the supplier delay and its potential impact on stock levels. Based on current inventory and your forecasted demand, the system will predict a shortage of smartphones at specific warehouses.

You can then run a scenario-based analysis to determine how allocating stock from low-demand to high-demand areas could mitigate the shortage. Kinaxis suggests transferring your inventory between regional warehouses to optimize supply. Your team can then collaborate within the platform to expedite shipments and communicate alternatives to clients.

Although Kinaxis doesn’t share pricing publicly, it is designed for large-scale enterprises. Therefore, cost may be a concern for smaller distributors with tighter budgets.

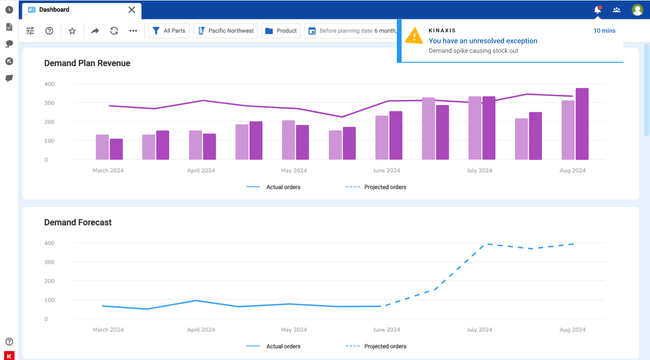

Pyplan - Most Customizable Platform

Pyplan is a Python-powered planning platform that can be adapted to nearly any inventory optimization, forecasting, or supply chain management need. Unlike more rigid systems, it offers prebuilt apps for inventory optimization, allocation, and replenishment, but also allows you to customize or build models from scratch. This makes it well-suited for organizations with complex supply chains or unique planning requirements that don’t fit into standard software templates.

For example, imagine you’re a consumer goods company managing thousands of SKUs across multiple regions. Instead of forcing you into a fixed workflow, Pyplan lets you define your own safety stock policies and replenishment rules for each area. You can simulate scenarios like demand surges in one region or model shipping delays from a primary supplier, and then tailor the inventory plan to balance those scenarios. And with Python at its core, everything can be customized exactly how you want.

While Pyplan’s flexibility is a major advantage, it also means implementations can require more configuration effort than plug-and-play solutions. The platform is cloud-based using AWS with enterprise security. However, pricing is not published and varies by project scope, so buyers should expect a consultation to determine total implementation costs.

What is Inventory Optimization Software?

Inventory optimization is a multi-echelon supply chain management solution for creating optimal product storage and distribution conditions. This software assists small to medium size distribution centers with supply/demand forecasting, product traceability, and overall warehouse management.

Inventory optimization is beneficial to all sorts of businesses. Anyone dealing with perishable products will particularly benefit from these tools as they can reduce the chances of spoilage before the product reaches the buyer. Whether you’re a manufacturer or retail supplier, this management software makes it easier to control your product stock from when it arrives at your warehouse until it’s distributed to the consumers.

Features

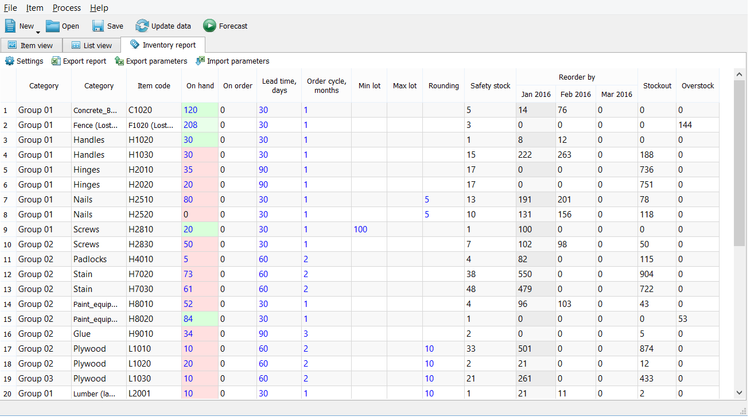

- Inventory Management: Control all information about products your company builds, buys, stores, or sells.

- Supply Chain Forecasting: Review what is currently in stock to plan for future orders. Schedule product replenishment before your shelves are empty.

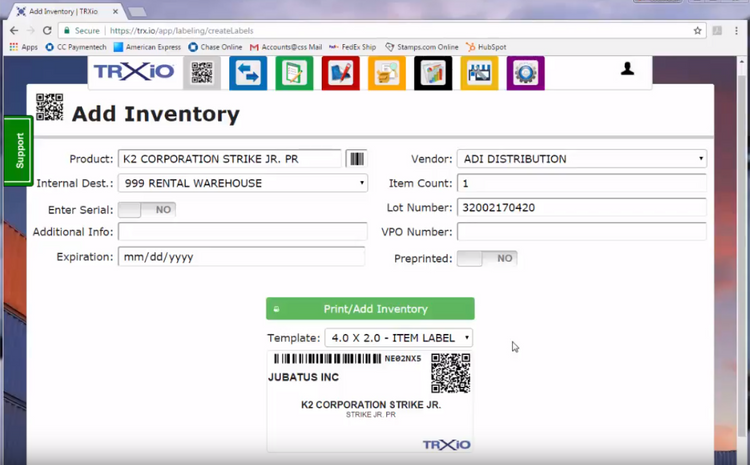

- Traceability: Track inventory along the supply chain using custom barcodes and RFID systems. Scan products in and out to get real-time inventory data.

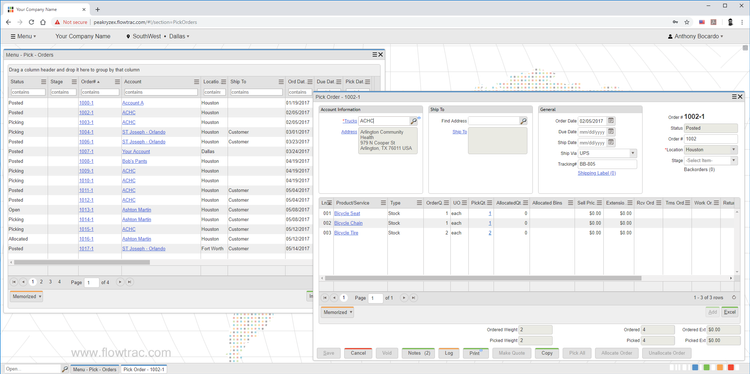

- Product Distribution: Handle order management directly from anywhere in your warehouse. Control the delivery of B2B or B2C sales orders.

- Analytics Reporting: Measure key performance indicators (KPIs) to study the flow of inventory levels at your warehouse or distribution center.

Challenges

When optimizing your inventory system, be aware of the following issues:

Unexpected Supply Chain Interruptions

Multi-echelon supply chains have points of vulnerability. Is a manufacturer falling behind on orders? Did unusual weather cause a surplus of orders for normally seasonal products? Outside factors could interrupt your supply chain for all sorts of reasons. Inventory optimization solutions make recovering from these unexpected difficulties easy without draining your safety stock.

For example, imagine a textile manufacturer’s dye error ruins an entire batch of fabric. You can review your current stock levels to see how long you can wait for a new batch before accessing your safety stock.

Overstock and Product Shortages

Predicting customer patterns isn’t easy, even with forecasting tools. Inventory optimization software can give you real-time updates on which products are coming in and how they’re being distributed. Adding this daily data to your forecasting allows you to get more accurate metrics and predict upcoming buyer trends. Then, you can plan ahead to avoid getting stuck with unreasonable overstock. Or start replenishing popular products before your competition gets the chance.

Communication Failures

Related to supply chain disruptions, just because your distribution center is optimized doesn’t mean your suppliers and buyers are. You could have every shelf perfectly stocked only to receive a surprise shipment from a supplier who doesn’t know you’re at capacity. Effective communication with your multi-echelon supply chain partners can prevent these costly mistakes.

Managing Recalls and Returns

Product recalls can be costly for everyone involved. While some defective products can be immediately destroyed, others must be returned to the manufacturer for testing. As the distributor, you may be responsible for taking in and storing recalled goods. Lower your losses by optimizing your warehouse to manage recalled stock.

Benefits

More Accurate Stock Metrics

Like a warehouse management (WMS) software, inventory optimization makes it easier to track all of your product stock. Traceability methods like barcodes and RFID let you automate adding new stock into your tracking system. Create checkpoints throughout your warehouse to scan inventory and ensure everything is where it should be.

Accurate multi-echelon inventory tracking also allows you to allocate safety stocks. You keep these products on hand if a shortage or delay occurs elsewhere on the supply chain.

Real-Time Inventory Level Updates Anywhere

Inventory optimization software is usable on mobile devices like smartphones and tablets. You can follow your entire multi-echelon supply chain using cloud-based solutions from anywhere.

If you regularly travel to meet with investors and business partners, you’ve probably dealt with the hassle of printing out spreadsheets and reports in advance. What happens if you arrive and realize you’re missing documents? Don’t let a missing statistic jeopardize your business relationships. With mobile access to inventory levels, you can provide your partners, suppliers, and retailers with digital copies of real-time data.

Faster Stock Replenishing

By optimizing your inventory, you can better forecast stock replenishment. Follow real-time inventory level updates to determine when to order replenishments and use forecasting applications to identify emerging market trends.

Knowing when to replenish your stock can give you an advantage over your competitors. You’ll enjoy shorter lead times by placing your reorders early. And your customers will enjoy higher service levels as their orders are completed faster. Inventory optimization uses forecasting applications and real-time stock levels to provide accurate product predictions.

FIFO/LIFO Compliance Tracking

Certain products, such as food, beverages, and medications, must be distributed according to FIFO rules. This means your warehouse has to make it easy to sort perishables based on their sell-by date. Optimize your inventory policies so you always know which batches are close to expiring and need to be sold next.

How is Inventory Optimization Different from Inventory Management?

While inventory optimization has some overlap with inventory management software, the two have several distinct differences. Inventory management is designed to track information about your products. While this can include some distribution data, it’s primarily aimed at pricing. Multi-echelon inventory optimization tracks products to find better ways to store, organize, and distribute stock across the supply chain.