The Best Supply Chain Planning Software

Supply chain planning software can help you predict demand and optimize inventory across national or global operations. We’ve reviewed top platforms for businesses in multiple industries, including manufacturing and retail.

- Cloud-native platform with rapid deployment

- Enterprise-level capabilities without complexity

- Intuitive interface

- Automates manual supply chain tasks

- AI-powered forecasting tools

- Real-time visibility and control

- Effective constraint planning

- Intuitive user interface

- Customizable dashboards, alerts, and exceptions

In this guide, we’ve ranked the top supply chain planning software based on their support of different industries, such as distribution, manufacturing, and retail.

- Deposco Supply Chain Planning: Best Overall

- Oracle SCM Cloud: Best for Manufacturers

- Kinaxis Maestro: Best for Sales & Operations Planning

- o9 Solutions: Best for Retail Planning

- Pyplan: Most Customizable Platform

- Lumina: Best for Scaling eCommerce Brands

Deposco Supply Chain Planning - Best Overall

Deposco Supply Chain Planning provides a complete platform with connected modules for demand, inventory, and procurement planning. Built as part of Deposco’s broader distribution and fulfillment platform, the system gives businesses an end-to-end environment to manage complex omnichannel supply chains.

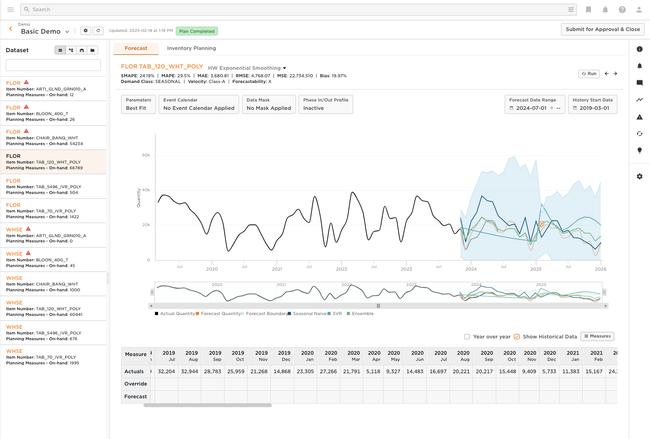

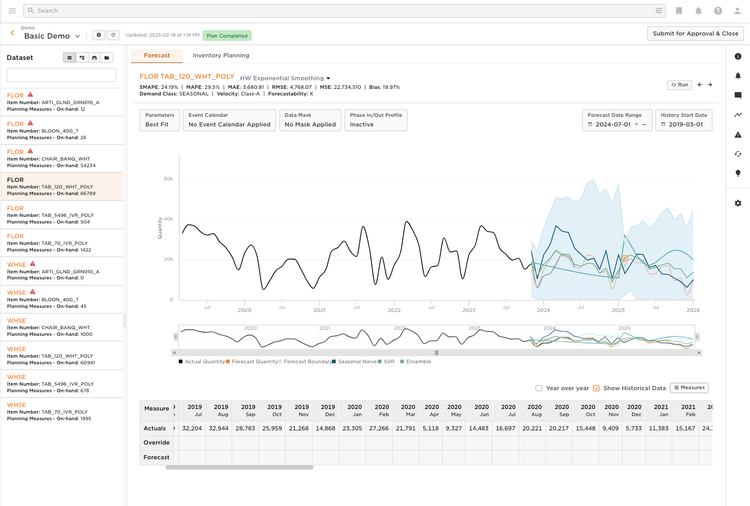

At the center of the platform is the Bright Forecast Module, which makes Deposco especially strong for companies balancing multi-channel operations in retail, eCommerce, CPG, and third-party logistics. The system uncovers demand patterns across sales channels using MIT-developed forecasting models and historical data from millions of supply chain transactions. Planners can overlay external factors like holidays or promotions to refine forecasts, and model new product launches with phase-in and phase-out curves. For sudden anomalies, like price wars or market disruptions, the system allows data to be masked or smoothed so forecasts remain realistic to your typical supply chain plans.

While its forecasting and planning tools are strong, they are less mature for heavy industrial manufacturers that require advanced capacity and production scheduling. Deposco is best suited for retailers, 3PLs, and consumer brands managing large order volumes. Pricing is available by quote, and costs vary by facility count, modules, and deployment complexity.

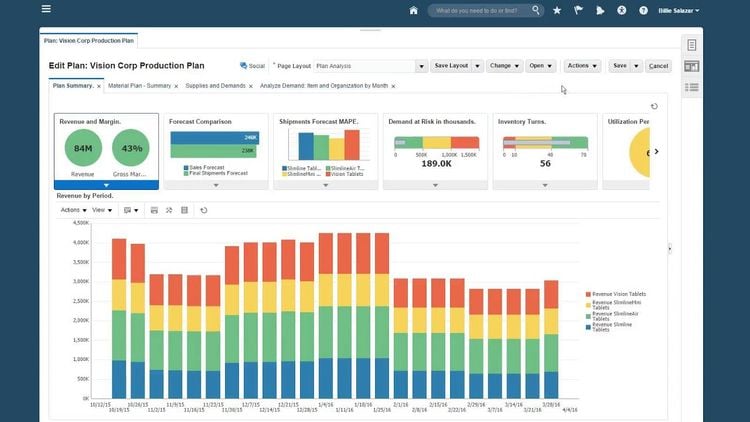

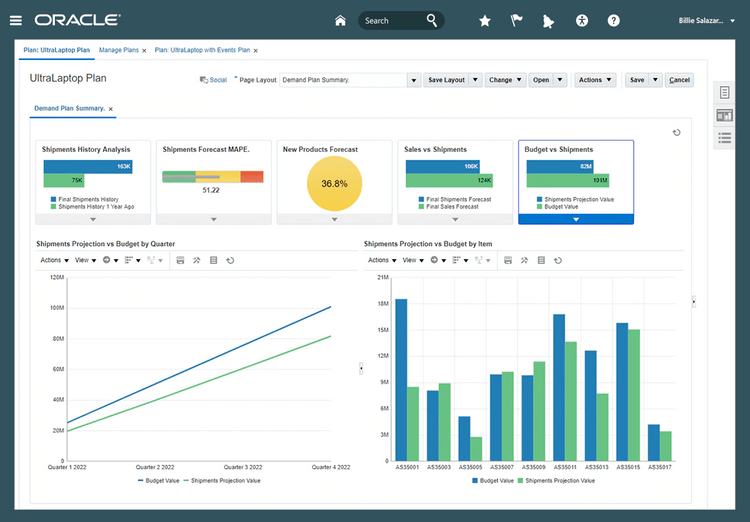

Oracle SCM Cloud - Best for Manufacturers

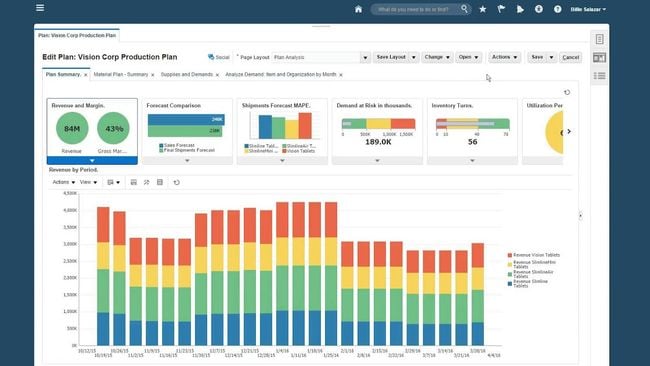

Oracle SCM Cloud’s demand management module uses machine algorithms to help manufacturers forecast more accurately. It combines several metrics, like internal history, customer data, and marketing signals, so you can gain a more holistic view of demand beyond previous sales. From there, set custom rules to segment items and locations to make more granular forecasts, and monitor KPIs to see any changes.

Once you have all the data, you can create a comprehensive demand plan. The system uses machine learning to improve your plan’s accuracy. It evaluates fluctuating variables, like collinearity, price changes, holidays, and anomalies, helping you prepare for the most volatile items and seasons. You can also forecast different scenarios or new products and channels to ensure nothing is missing. When your plan is active, track outcomes and diagnose errors as they occur to optimize it.

Oracle SCM Cloud is best for large to enterprise-level manufacturers exceeding $100M in annual revenue. It’s built for companies with extremely complex supply chains, managing thousands of parts, suppliers, and assembly processes. Unfortunately, pricing is not publicly available.

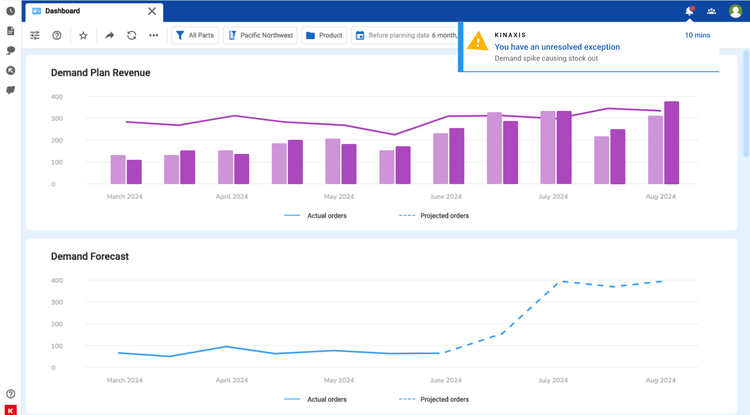

Kinaxis Maestro - Best for Sales & Operations Planning

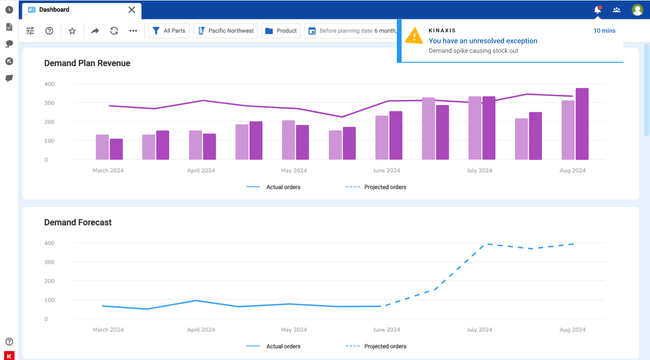

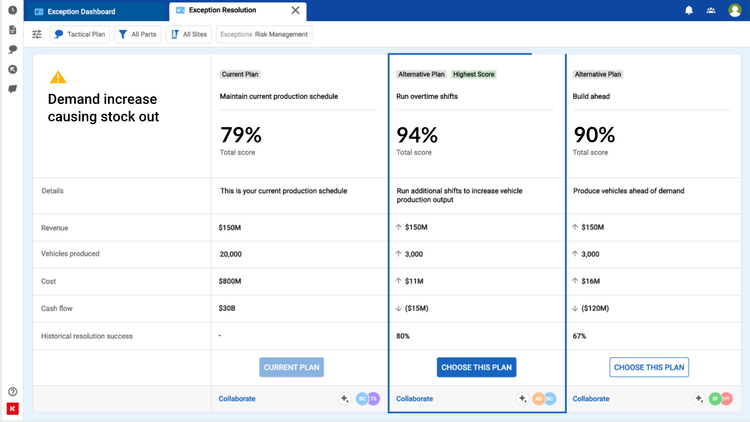

Kinaxis Maestro offers a dynamic sales and operations planning module to help global companies achieve alignment. It breaks down silos between different departments, such as sales, production, and finance, to keep everyone working towards the same goals. This way, you can balance supply and demand, and make tough trade-off decisions, like keeping production lean to reduce costs, or investing in more capacity.

It achieves this through advanced scenario planning, with unlimited what-if simulations. Performing these can help you see impacts across every department. When you run a plan through the system, it gives you a total score with possible issues or bottlenecks. Then, it builds alternative plans using AI that aim to fix the problems and create better outcomes. From there, you can choose which plan you want, and collaborate with your team and adjust as needed.

The system offers pre-built connectors for multiple leading ERP systems, like SAP and Oracle, for real time data sync. It’s best for large, enterprise corporations in manufacturing, electronics, or wholesale industries needing advanced scenario planning capabilities.

o9 Solutions - Best for Retail Planning

o9 Solutions is an AI-based supply chain system, offering a strong replenishment planning module to help retailers never run out of stock. It uses the built-in AI forecasts to optimize inventory in complex omnichannel environments, from global locations to webstores. And based on demand signals, forecast changes, or supply chain constraints, the system automatically triggers replenishment orders so you can ensure optimal inventory levels, even as variables change.

Additionally, o9 Solutions supports flow planning at different intervals, from one day to 90 days. It’s great for grocery or apparel stores, as you can manage the continuous movement of products through your network, from distribution centers to cross-docks. This helps retailers with different demand volatility plan around their unique environments. Avoiding under- or over-ordering increases product availability and reduces logistics costs.

o9 is a distinct supply chain planning system, and can integrate with all of your platforms through an open API network. This includes ERPs, WMS, TMS, and any other software in your supply chain. However, all the connections can make the initial implementation challenging, often requiring significant resources.

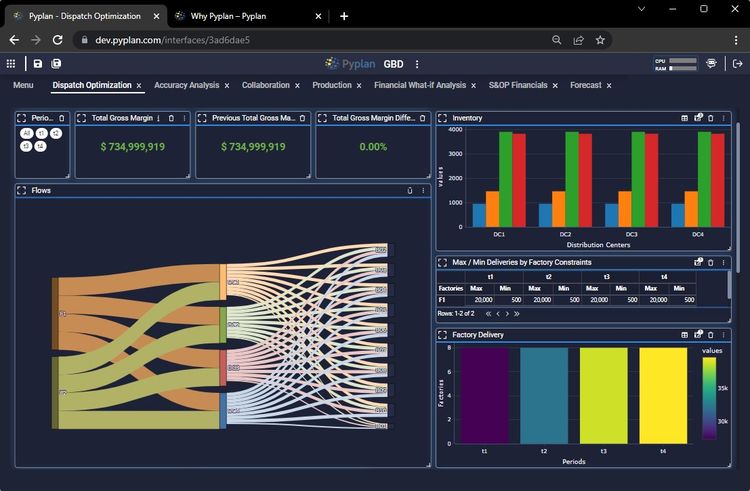

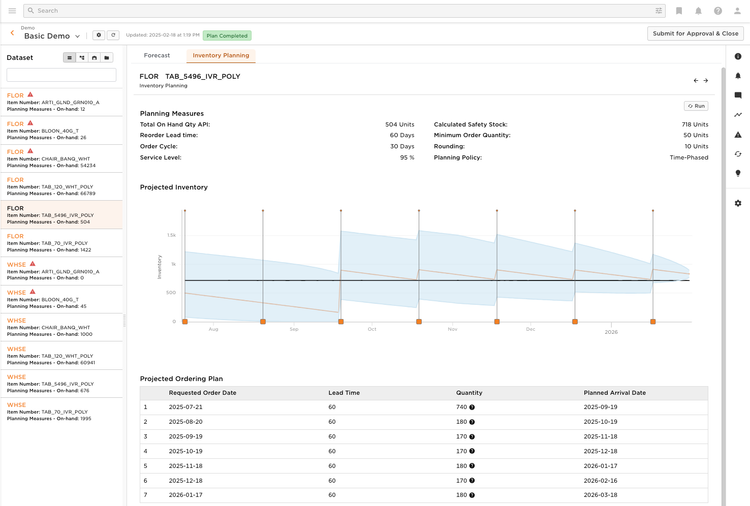

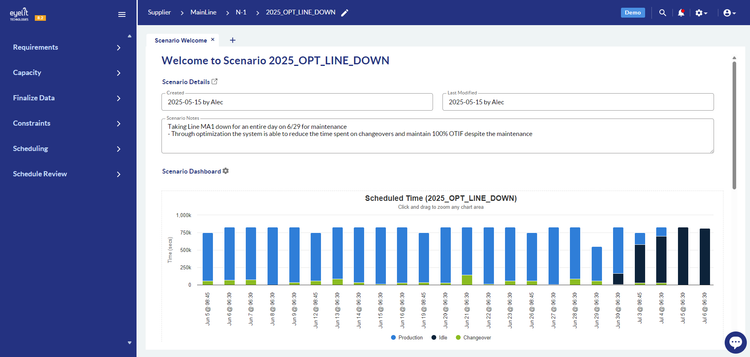

Pyplan - Most Customizable Platform

Pyplan is a Python-powered platform designed to adapt to nearly any planning requirement, from demand forecasting to supply and production planning. Unlike traditional systems that follow rigid workflows, it combines prebuilt applications with the flexibility to create or customize modules from scratch. This makes it especially strong for companies with complex supply chains or unique planning processes that standard templates can’t accommodate.

For example, a manufacturer or consumer goods company operating across multiple regions can use Pyplan to define custom demand models, create sourcing policies, and simulate what-if scenarios for supplier delays or demand spikes. Because all workflows are configurable, planners can tailor the system to reflect their real-world constraints and tradeoffs. With Python at its core, Pyplan lets you extend or refine every calculation and rule.

The one trade-off for this level of flexibility is that implementations usually require more setup and input compared to plug-and-play planning tools. That’s because the Pyplan team will often work with you to understand precisely how your planning workflows operate. Pricing for Pyplan is quote-based and varies by project scope, user count, and business complexity.

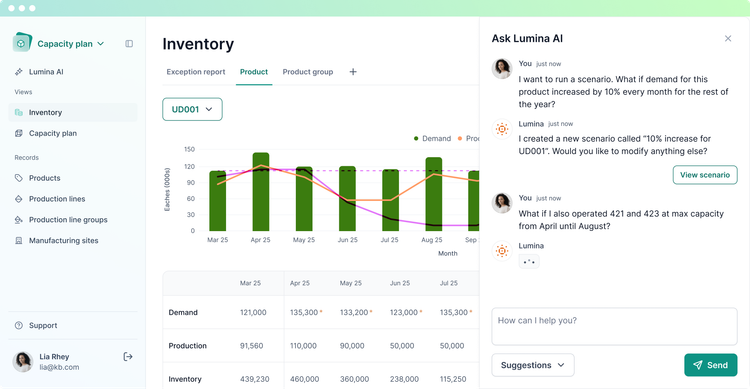

Lumina - Best for Scaling eCommerce Brands

Lumina is an AI-powered inventory and supply chain planning software built for growing product-based businesses. Its strong demand planning engine integrates with your existing software or spreadsheets to pull in all relevant data needed to create detailed supply chain forecasts. This allows you to get up and running in days rather than months, which is critical for eCommerce, retail, and manufacturing brands seeking a fast return on investment.

Lumina moves brands beyond basic forecasting and turns their demand plans into clear purchasing and inventory replenishment decisions. Users can simply ask, “What should I reorder right now, and how much?” or “What changes if supplier lead times slip by two weeks?” This is especially important for fast-growing eCommerce businesses where rigid supplier lead times and multi-channel fulfillment can lead to mistakes like stockouts and overbuying. And with Luminas’ AI-powered scenario planning, purchasing teams can quickly model the impact of running promotions, supplier delays, or seasonal demand spikes without rebuilding complex spreadsheets from scratch.

Pricing for Lumina starts at under $400/month for small brands, with more advanced customization and workflow automation introduced in the most popular Core plan. Lumina is best for growing teams that struggle with Excel or disconnected systems and need a centralized place to manage their entire supply chain and operations. Large multi-national companies might find its features limited when compared to platforms like Oracle Supply Chain Management.

What is Supply Chain Planning Software?

Supply chain planning software develops real-time demand forecasts, establishes supplies needed to fulfill orders, plans and schedules manufacturing operations, and develops key performance metrics to monitor the lifecycle of your operation. A properly implemented system will fulfill requirements created from the demand plan, and streamline supply and demand to achieve the financial objectives of the business and improve overall decision-making.

Supply chain planning is a key part of the overall supply chain management software process because it’s the first step in the overall supply chain execution process. The strategic planning involved includes planning a product from raw material all the way to the customer. This ties in closely with production scheduling, demand planning, and overall sales and operations planning.

If you were to look at a flowchart of an overall supply planning process, it may look like this:

Demand Planning > Inventory Optimization > Replenishment Planning > Master Production Scheduling and Procurement > Finite Scheduling

This sales and operations planning (S&OP) process not only deals with supply chain planning but also the finance and sales involved. With supply chain planning systems, you’ll be able to create a forecast, determine the inventory necessary to support the forecast, determine the time needed to acquire this inventory, figure out what factories are capable of completing these plans, learn what your purchasing department needs to buy, and finally schedule out the work at your factory.

Features of Supply Chain Planning Software

- Sales Forecasting: Creates financial reports of expected sales based on historical trends, economic conditions, industry behavior, changes within your company, and selected time periods.

- Demand Planning: Coordinates data from separate units of the business (primarily sales, marketing, and operations) to make more informed supply chain decisions. Collects historical data on order volumes and inventory turns while mixing it with continually updated forecasts from your sales personnel.

- Sales and Operations Planning (S&OP): Create plans to maintain current business and take on new customers with new products through proper management of the supply chain. Assists in increasing the speed of planning to improve forecast accuracy and on-time delivery.

- Inventory Optimization: Creates optimal product storage and distribution conditions by aiding in supply/demand forecasting, product traceability, and overall warehouse management.

- Order Fulfillment: Automates order processing via sales order entry, inventory management, picking and packing items, and tracking shipments of goods to customers.

Benefits of Supply Chain Planning Software

The top benefits of supply chain planning software include:

Decrease Costs and Improve Efficiency

The goal of any supply chain software will be to make your business more efficient. But at what cost? Many businesses strive to find the sweet spot of not only becoming a more efficient business but also saving costs on their supply chain planning. If software can help cut costs, great. If new strategies may cost more in the short-term but lead to a more profitable operation, it’s definitely an option that should be explored.

Supply chain planning software will help you create a network design with as few conflicts as possible. It’s important to be concerned about conflicts, as the costs associated with some SCM services can indirectly affect others.

For example, spending more on product sourcing may mean less money on manufacturing costs. If your raw material sourcing times run high, you may impact the run time of your manufacturing. This may affect logistics (i.e., the space in your warehouse) and lead to customers not getting the goods they ordered on time.

Integrate Supply Chain Planning With Your ERP Software

A supply chain planning solution on its own may help you answer some questions, but its real potential can be realized once integrated with your enterprise software. Alternatively, some businesses may think that a supply chain planning module offered by their ERP software vendor means they can do without a stand-alone option.

ERP solutions, or even just spreadsheets, used for supply chain planning will rely heavily on historical data, and allow for less variance and “what-if” analysis should any disruptions happen. Therefore, it’s hard to do the “planning” part of supply chain planning. Where ERP software becomes beneficial is in providing you with material management (inventory), production planning, and controlling your SCM performance.

For example, ERP systems with integrated supply chain planning can control and manage their inventory levels better:

- Your SCP software may be indicating your inventory needs to be at a specific threshold.

- Your inventory management module of your ERP software will know when this shipment has arrived and the quantity.

- You’ll be able to better organize and categorize this inventory and record any movements that your SCP software is indicating need to be done, such as if another location of your business requires more raw materials to complete an order.

- Integrating MRP software capabilities will only improve the strength of transactions, material planning, and more.

Harness Your Demand Management Strategies

Supply chain planning software differs from traditional supply chain management (SCM) software due to the weight it puts on demand planning strategies. This includes channel demand, inventory optimization (rather than simply stock count tracking via inventory control), and advanced analytics via KPIs that drive intelligent responses.

Incorporating a supply chain planning software into your logistics environment may be a rough start, but it will lead to a longterm return on your investment. Some benefits of improved demand management include increased adaptability to demand volatility, better collaboration between your departments and any external vendors, and more efficient resource allocation.

Demand Planning vs Supply Planning

Demand planning aids in forecasting customer demand, while supply planning manages inventory to meet the targets of the forecasted customer demand. This means demand planning is meant to guide supply chain operations, while supply planning relies heavily on demand forecasts.

Supply planning is used to fulfill the demand plan while meeting the benchmarks of the organization, as it relates to inventory production and logistics. In short, it tries to meet the demand forecasts as efficiently as possible. Supply planning has a bigger focus on manufacturing lead times, minimum order quantities, leveling production, and managing safety stocks.

Read more here: Demand Planning vs Supply Planning: What are the Differences?

Supply Chain Planning Software Pricing Guide

The cost of supply chain planning software starts at $150/user/month for cloud-based systems. However, it’s important to be aware of advertised pricing over what your true cost may be. If the software has a minimum user count of 5, the real cost of owning the software would be $750/month.

The cost of your investment will be dependent on a number of factors, such as how many users you’ll need, the level of integrations needed with any supply chain management or ERP software, and the number of services required upfront (such as for implementation and training).

Many supply chain planning solutions will have hefty setup costs, which can start at $30,000 depending on how complex your supply chain operations are. The best way to determine not only your setup costs but also your ongoing costs (for subscriptions or annual maintenance) is to have a needs-analysis interview with a qualified supply chain planning software provider.