The Best Retail Management Software

Retail management software combines ERP and POS systems to create an all-in-one solution for all different types of retailers.

- Extends Microsoft Dynamics 365 Business Central

- Gives the client full control over business operations

- Includes customer loyalty mobile app

- Handles transactions in multiple currencies

- Inventory management supports multiple warehouse locations

- Extensive integrations

- Intuitive, consistent, and user-friendly interface

- Effective General Ledger module

- Quick search feature

Retail management systems provide businesses with an all-in-one solution by combining ERP and POS software. This allows retailers to control all facets of their business, including accounting, inventory, and sales. Using our advanced review methodology, we researched the top systems on the market and reviewed our favorites below.

- LS Central: Best Overall

- Brightpearl: Best for Independent Retailers

- ECI Spruce: Best for Lumber, Home, and Building Supply Retailers

- Oracle Retail: Best for Supermarkets

- Epicor Eagle: Best for Convenience Stores

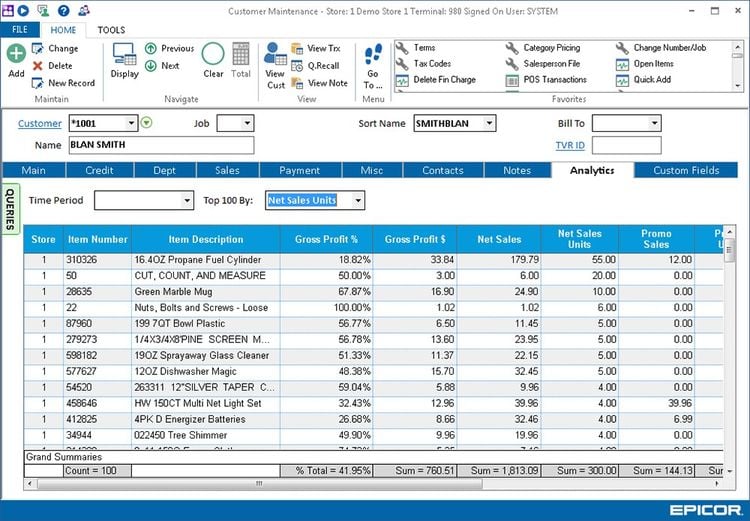

LS Central - Best Overall

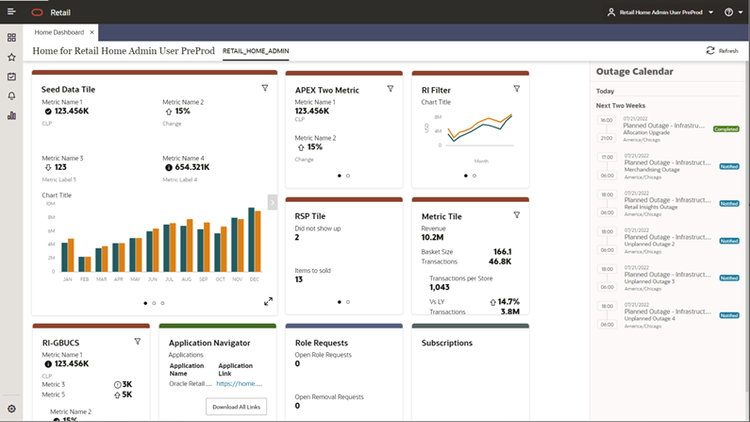

Why we chose it: We chose LS Central, developed by LS Retail, as the best overall because of its complete solution that includes a full ERP and Point of Sale (POS) system. The software extends Microsoft Dynamics 365 Business Central’s ERP solution with retail-specific functionality to manage stores of all sizes and industries, earning an 8.7 score. Managers can set up automatic replenishment and use allocation planning to forecast future stock and purchase accordingly to ensure the shelves are never empty. The system uses real-time data from the ERP, another benefit of the all-in-one solution.

LS Retail’s cloud-based POS system utilizes Microsoft’s interface for intuitive navigation, which can lower employee training time. We appreciate its flexibility, as businesses can select from standard check-out tills or self-checkout terminals to fit their needs. Employees can check out customers, see product details, and locate inventory availability directly from a computer, tablet, or phone. To cap it off, companies can analyze KPIs and financial data from personalized dashboards. These can be specific to one store or consolidated from the entire company, giving both broad and granular insights.

Despite these features, LS Retail does have some downsides. One of these is that integration options are limited due to using Microsoft Dynamics 365 Business Central. Also, pricing is not made public, so companies must request a customized quote.

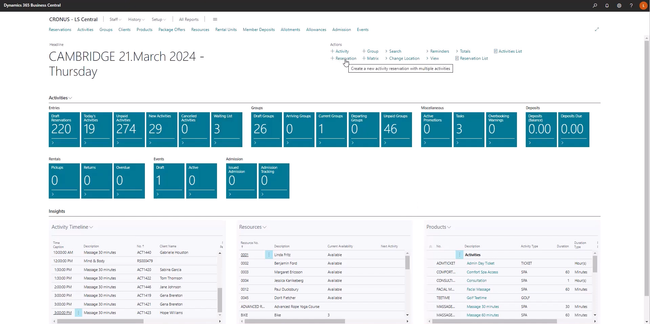

Brightpearl - Best for Independent Retailers

Why we chose it: We like Brightpearl best for independent retailers because of its scalability and feature set suited for small businesses, earning an 8.5. After being acquired by Sage in 2022, Brightpearl’s POS combines with Sage Intacct’s ERP for an all-in-one solution. The system integrates with several eCommerce platforms and marketplaces for streamlined omnichannel selling. This allows owners to optimize all sales channels to promote growth.

We also like Brightpearl’s retail accounting module, which allows companies to oversee all financial data and transactions in one place. Owners can view real-time P&Ls, balance sheets, budgets, and AR/AP for full accounting functionality. The system also has multi-entity support, so independent retailers with multiple locations or those looking to expand can view financial data across all locations. Finally, its shipping and fulfillment module offers automated fulfillment and channel-specific shipping to streamline the supply chain process.

One downside to Brightpearl is that the initial cost can be expensive for small businesses because it is a full ERP system.

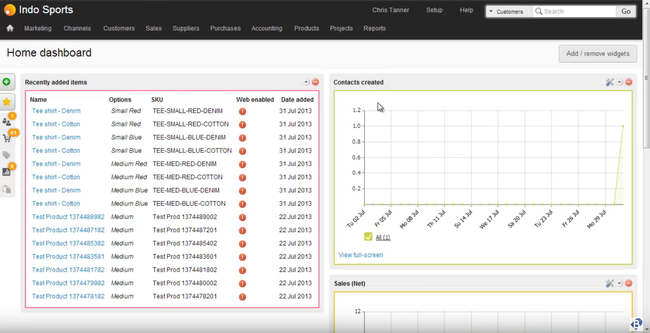

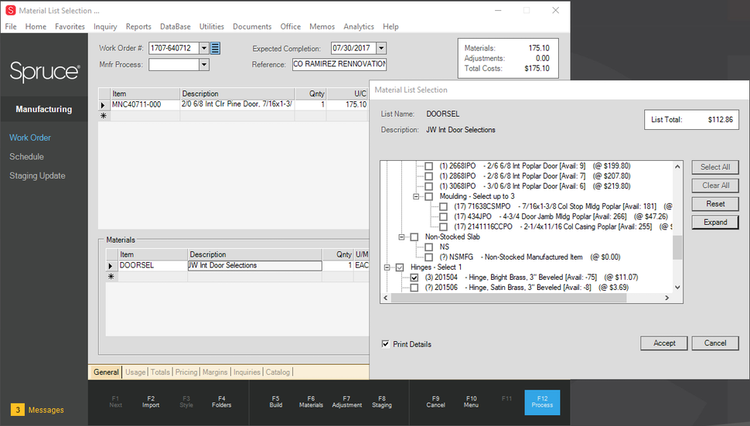

ECI Spruce - Best for Lumber, Home, and Building Supply Retailers

Why we chose it: We found ECI Spruce best for Lumber, Home, and Building (LBM) supply retailers because of its industry-specific features, earning an 8.1 score. The system allows for inventory, purchasing, and sales tracking under one roof, allowing retailers to keep accurate stock counts in real-time. It also eliminates manual data entry by automatically re-stocking inventory when specific products become too low through vendor purchasing.

We also like ECI Spruce’s document management module for LBMs. It allows users to access customer quotes, purchase orders, and sales orders in one system for streamlined filing. This is essential for LBMs, which often have bulk and customized orders to manage. Furthermore, the system includes several different integrations, such as RewardsPlus for customer loyalty programs, eCommerce, and credit card processing for further functionality. However, some users have reported slow customer support response times.

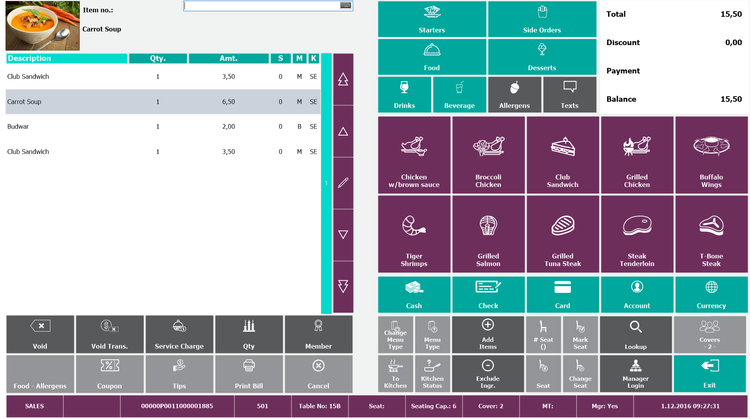

Oracle Retail - Best for Supermarkets

Why we chose it: Oracle Retail is best for large supermarkets because of its grocery-specific features and ability to handle large data input volumes. We like its enterprise resource planning module, which is optimal for supermarkets, as it can make more accurate predictions of consumer demand for perishable goods, helping maintain full shelves without overstocking. Also, the system allows for real-time financial data viewing across all sales channels and stores, helping companies with hundreds or thousands of locations analyze broad or granular analytics.

We also found Oracle Retail’s supply chain management effective for enterprise-level supermarkets. The module includes warehouse management, which enables tracking the distribution process from order to delivery. Companies can manage their transportation and shipping methods to ensure efficient processes and minimize costs. In addition, its Xstore POS system is mobile-optimized and offers scheduling, task management, and sales goals.

Because of its comprehensive set of features, this system is built for large to enterprise-level retailers, as smaller companies will be priced out.

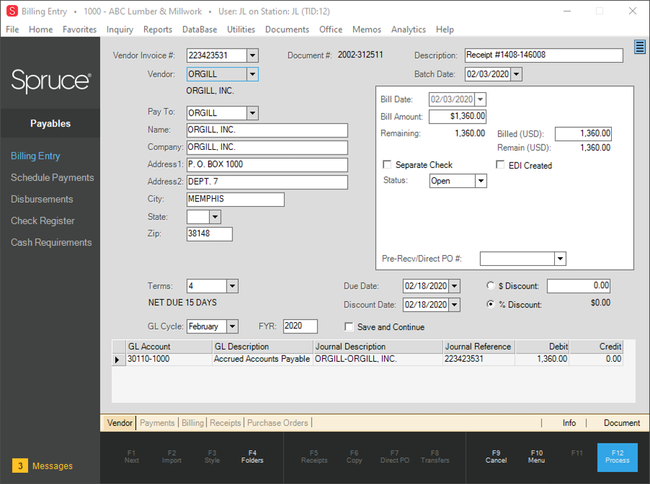

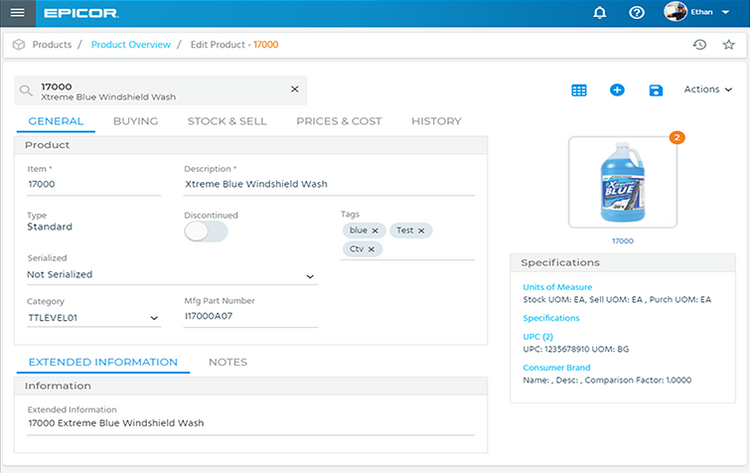

Epicor Eagle - Best for Convenience Stores

Why we chose it: We like Epicor Eagle best for convenience store retailers that require an integrated solution with inventory management and POS in one place. The software includes on-demand training and intuitive navigation to streamline the new hire process. Additionally, its inventory management system syncs directly with the POS for real-time stock levels. This helps the back office and on-the-floor employees manage inventory, as it can be accessed from anywhere.

We found that Epicor Eagle’s purchasing capabilities are also ideal for convenience store retailers. It streamlines supplier replenishment to adjust to inventory valuations and fluctuating consumer demand. Furthermore, its business intelligence and reporting features help stores drill down into sales and inventory metrics to gain insights. The data is even exportable in various file formats for security and sharability.

One drawback we found of Epicor Eagle was that some customers have reported slow response times for customer support tickets, which could disrupt daily operations if the problem is serious.

What is Retail Management Software?

Retail management software is the combination of a point of sale software along with back office functions that allow a retailer to manage every aspect of their business–from financials, operations, and their overall supply chain. The functionalities included point-of-sale transactions, accounting, inventory management, procurement, and warehousing. These all-in-one systems are commonly ERPs that include POS.

Any retail business, from a single mom-and-pop store to a large multi-national chain with hundreds of locations, can benefit from using retail management software. While POS solutions can be sold by themselves, retail management software will encompass accounting capabilities such as accounts payable and accounts receivable. It also includes more in-depth inventory control that goes beyond a simple stock count and customer data collection through business intelligence.

Retail systems are more than just point of sale systems. An integrated retail software provides a suite of tools designed to make your operations more efficient, easier to manage, and more profitable. Increase margins with better inventory control, generate additional sales due to suggestion selling, track staff performance, and optimize your marketing efforts.

Many new-age retail management systems will also include eCommerce capabilities, which allow setting up online stores on your website. These shopping cart experiences let customers order your products online, complete with shipping options and payment processing. When synched, these systems will automatically communicate with your back office and reorder goods when needed or automatically trigger when items need to be shipped from your store.

Key Features

- Point of Sale: Handles the payment collection, receipting, and inventory updating involved with a retail sale in real-time at the point of purchase. Scans items at checkout, calculates the amount owed, and prepares an invoice that a customer can pay right away via credit card, cash, or check.

- Retail Inventory Management: Manages the stock and merchandise across multiple stores, eCommerce operations, catalog orders, and marketplaces. Coordinates to reflect on-hand quantities in real-time across all of your sales channels.

- Purchase Orders: Creates the financial document issued to vendors when you are buying supplies or services. Purchase orders will include product type, quantity, and pricing information.

- Reporting: Create reports with detailed inventory data, profit margins on products, customer buying patterns, expense details, and waste information.

- Customer Relationship Management (CRM): Stores data on customers such as sales history and personal information. Uses this information to identify high-quality customers and increase upselling opportunities.

- eCommerce: Lets businesses sell their product or services online. Creates a web store complete with a shopping cart, shipping options, and payment processing. Helps manage inventory, calculate taxes and everything else that may be needed to fulfill orders.

Primary Benefits

Manage Purchase Transactions

POS software handles all aspects of the purchase transaction. The ability to provide a quick and easy purchasing experience is one of the key differentiation opportunities for your retail business. The biggest reason is due to increased efficiency. When cashiers have the right tools in order to speed up transactions with customers, your business can ultimately serve more people and increase sales.

Traditionally, POS software ran on a computer located at the sales counter. Today, many retailers are also taking POS software to the sales floor through the use of tablets such as iPads. Providing sales associates the ability to conduct part or all of the transactions on mobile devices can improve the customer experience and make a memorable impression on customers. Rather than waiting in line, a customer’s needs (such as ordering something out of stock exclusively for the customer) can be met right where the customer is.

Effective POS software must handle multiple payment options regardless of where the transaction occurs. Modern POS systems optimize the purchasing experience whether customers purchase via cash, credit cards, checks, or even gift cards. POS software integrates with your hardware to allow for cashier item inputs, product bar code scanning, check and credit payment processing, and receipt/invoice printing.

Streamline Your Accounting Processes

A growing retail business may have started with generic accounting software such as QuickBooks before realizing it was missing industry-specific capabilities (such as point of sale and inventory). This may lead to the business buying an add-on system that works alongside its existing financial management software.

Integrating your accounting with your retail management software will help lower your retail business’s overhead costs. A complete accounting solution will provide functionality to manage accounts payable transactions, bank reconciliations, and fixed asset depreciation.

Tight integration between your cross-platform sales channels and accounting allows you to import full transaction details to create an auditable record of purchase histories. The ability to document assets, liabilities, expenses, and revenues in your general ledger is a key component of effective retail financial management.

Identify Trends and Transactions in Customer Purchase Records

Most reputable retail software will store information on and allow access to purchase transaction records. The ability to identify trends and transactions in customer purchasing is critical to spotting profitable business opportunities.

For the multi-store retail operation, it’s very important to be able to not only report on the enterprise as a whole but also to flexibly break reporting down to the store, district, or channel level. Advanced retail reporting capabilities allow retail executives and store owners the ability to identify sales trends and adapt to shifting customer demand. Dashboards and business intelligence systems are incorporating more and more sophisticated capabilities to turn key performance indicators into actionable business information.

Together, these reports will help connect your team, drive data-backed strategy, and reduce inventory risk. Cross-departmental decisions can be easily made after breaking down organizational silos. These silos and bottlenecks can be reduced to boost productivity and equip staff with better insights into cost, revenue, and profitability.

Better Store Retail Inventory Data

Retail inventory control modules allow you to track and access critical product information. Typical data points that inventory management solutions will track include item titles, SKU numbers, product descriptions, supplier SKUs, stock counts, item locations, and pricing.

One unique feature of retail inventory is multi-channel inventory, which orders and sells products across multiple online channels. Your retail management software can connect to eCommerce apps such as Shopify, WooCommerce, and BigCommerce, automatically adjusting inventory levels based on online, marketplace, social media, or in-person sales.

Retail inventory software manages stock and merchandise across multiple stores, eCommerce operations, catalog orders, and marketplaces. Today’s retailers may have a variety of locations while also selling on online platforms such as Amazon or even their own web store. This means inventory will need to be coordinated to reflect on-hand quantities in real-time across all of your sales channels.

Inventory management software specific to the retail industry helps your business allocate merchandise to stores, plan assortments per store, stock inventory received from purchase orders, pull stock for sales orders, transfer items between multiple stores, process returns, and manage a variety of different styles and brands.

Determine Appropriate Product Pricing

One of the main challenges facing your retail business is determining appropriate product pricing. Price management modules bring a normalized, data-driven approach to this challenge, helping you optimize pricing to find the right balance between maximum margins and keeping products moving.

Retail price management software utilizes rules-based management that integrates real product histories to help you set optimal pricing points. Planning for phase-out dates and stock movement rates can help you determine when it is appropriate to discount items and by how much.

Repricing will help you set minimum and maximum prices for your goods, create custom rules for these values, and be notified when competitors change their prices. When prices are updated across your sales channels, retail software will ensure your inventory costing figures are updated as well.

Manage Online Sales Through eCommerce Stores

The ability to execute sales online has revolutionized the way many retailers do business and added a very important sales channel. Full retail management and accounting suites are available that integrate complete eCommerce capabilities, including web stores. More often, though, what’s critical is that the transaction and order details from separate web stores can be integrated easily into the accounting records. Whether you require a fully integrated solution or the ability to incorporate web transaction histories, there are solutions available that can help you optimize your online selling to maintain the integrity of your accounting records.