Why Do ERP Implementations Fail?

11 High-Profile Examples

ERP implementation failure can lead to lost time and revenue. It can even lead to lawsuits. Avoid the most common reasons for ERP implementation failure to help your company succeed.

Why Do ERP Implementations Fail

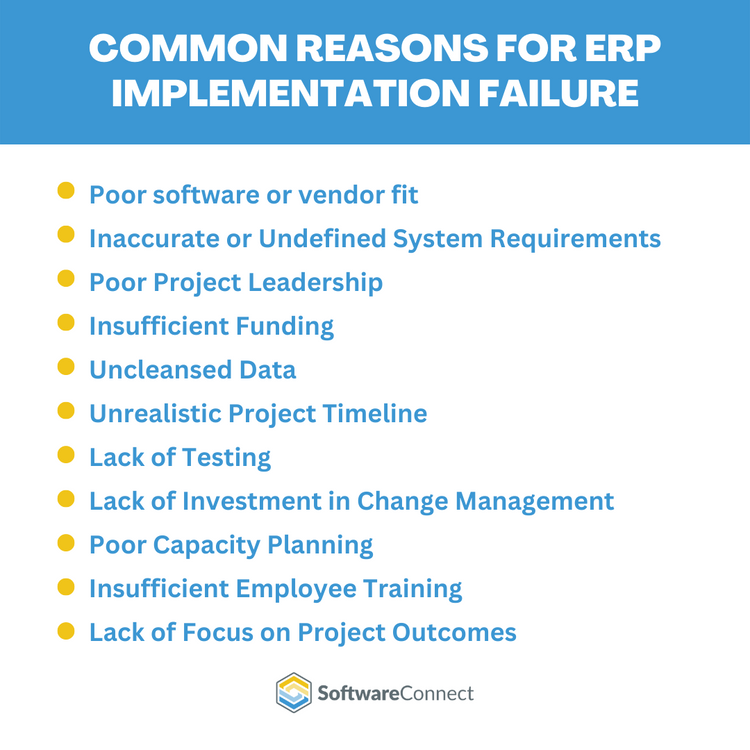

ERP implementations fail due to:

- Poor software fit

- Poor vendor fit

- Inaccurate or undefined system requirements

- Poor project leadership

- Data errors

- Unrealistic project timeline

- Lack of testing

- Lack of employee training

- Budget issues

What Are ERP Failure Factors

These are the top 9 reasons an ERP implementation can fail:

1 Poor Software Fit

Not all enterprise resource planning software is made for the same end users or industries. Selecting a well-known name, even if the ERP is highly reviewed, doesn’t mean it’s a good match for your specific needs. One of the key phases of successful implementation is to create an interdepartmental team to find the right ERP based on your organization’s specific needs.

2 Poor Vendor Fit

If the ERP isn’t the problem, the developer or vendor might be. The reason so many companies exist to resell software is because they focus on different market segments. One might specialize in helping small businesses, while others are intended for certain industries. Even if you’ve found the right ERP solution, you need the right vendor to make it work for you.

To minimize this risk, organizations should conduct a thorough vendor evaluation process. This includes assessing the vendor’s overall reputation, relevant industry expertise, and customer references beyond basic testimonials.

3 Inaccurate or Undefined System Requirements

ERP systems are only as good as the hardware they run on. There are products made specifically for Windows, others for Mac, and some for other operating systems. Committing to an ERP that won’t run on your existing hardware is a recipe for inevitable failure.

Another major issue is sometimes system requirements are undefined. ERP software is customizable to a certain degree, but the more significant the change, the more likely it will cause other systems to break. If the need for customization isn’t discovered until the process has begun, failure is likely.

4 Poor Project Leadership

Sometimes an ERP fails because of poor leadership on the buyer’s side. This is where the interdepartmental team will be vital. If they’re not fully invested in the new ERP, they can make mistakes when implementing software. And the rest of your employees need to be on board with the changes too, as resistance to a new ERP can also cause a failed implementation.

Resistance may manifest as pushback against new processes or technology, resulting in decreased productivity and user dissatisfaction. To prevent this challenge, organizations should invest in change management strategies that engage employees throughout the process. Make them feel connected to the new ERP, either through how it will make their job easier or the overall benefits it brings to the company. Another way to address this risk is by involving end-users in training.

5 Data Errors

Unless you’re a brand new startup, your company will have existing data to transfer to the new ERP. Data migration is tricky under ideal circumstances, and any errors in the data only make it worse. Data cleanup means reviewing old files, removing duplicates, and ensuring the formatting is compatible with the new system. As a safety measure, creating a secure backup doesn’t hurt either.

6 Unrealistic Project Timeline

In a perfect world without any complications, ERP implementation can take 4-6 months. In most cases, it takes months or years to complete. Trying to rush implementation or setting unrealistic deadlines are signs of failure to come.

Additionally, inadequate planning and project management can lead to ERP implementations running off track. Without a well-defined project plan, organizations may encounter delays, scope creep, and misaligned expectations. This makes it critical to establish clear goals, milestones, and responsibilities from the outset.

7 Lack of Testing

Actually installing an ERP software is only the first step of the implementation process. The next step is testing if the software works as intended. Detailed quality assurance measures can reveal any shortcomings of the ERP which, hopefully, the vendor can address.

8 Lack of Employee Training

Getting employees on board with the new ERP is another indicator of whether an implementation will be successful. Some users will resist any changes to their familiar workflows. Others just need a little training to adapt. Most vendors offer some degree of training, though it might involve an additional cost.

9 Budget Issues

Finally, budgeting problems can cause ERP implementation to fail by simply running out of resources. Due to how long an implementation can take, all those delays can add to the proposed budget. It can also cut into revenue for every day the system isn’t yet up and running.

Hidden costs are another challenge, as some vendors charge for change orders as the project scope evolves. There may also be unforeseen costs associated with upgrading hardware or employee training sessions. To mitigate this risk, organizations should conduct a thorough cost analysis that includes not only the software licensing itself, like hardware, training, and ongoing maintenance.

Because of the solution’s complexity and the detailed planning that must go into the implementation process, there are seemingly endless opportunities for failure. While the above reasons are the main culprits, other causes can happen without proper planning.

Examples of Famous Failures

A Gartner study found up to 75% of ERP implementations end in failure. It can happen to any company, even globally recognized industry leaders. Here are just a few famous examples of ERP failure at big companies:

Hershey (1999)

One of the most famous cases of an ERP implementation failure comes from Hershey’s 1999 SAP fiasco. In an earnest attempt to avoid the (perceived) impending chaos of Y2K, Hershey sped up the implementation timeline from 48 months to 30 months. This hasty timeline led them to a launch that not only didn’t allow enough time to train employees properly but also coincided with Halloween.

The launch was a complete failure. Fulfillment could not process $100 million worth of orders during their busiest season. This snafu led to a 19% profit decrease and a 12% decrease in sales.

Hershey taught the business world a lesson that highly complex software solutions require enough time, a low-risk launch date, and thorough employee training to have a successful implementation.

Nike (2000)

“This is what you get for $400 million, huh?” - Phil Knight, co-founder of Nike, in response to the catastrophic software glitch that threw Nike’s supply chain into a tailspin.

In an effort to get an even greater edge on the world’s market, Nike decided to implement i2 Demand Planner software in 2000. The plan was that this ERP would automate their supply chain by forecasting demand for certain products rather than relying on the intel of retailers.

A 2002 CNET report explains how rushed implementation contributed to a problematic start. It was slow and full of bugs, and Nike needed to devote more resources to training employees to run it. A software glitch ordered too many of the Air Garnett, a lower-demand sneaker, while failing to predict demand for the famous Air Jordan. The supply chain collapsed altogether, highlighting the need for rigorous software testing before launching.

On top of the $400 million spent on this ERP implementation fail, $100 million worth of revenue was lost, stock value dropped 20%, and multiple class action lawsuits were filed. After five more years and at great expense, Nike was able to fix its ERP and repair its supply chain.

Hewlett Packard (2004)

In a 2004 effort to replace decentralized legacy systems, HP decided to migrate their North American divisions to the SAP ERP solution. What they ended up facing was a host of problems that individually were manageable, but added together became uncontrollable.

Employees were accustomed to the decentralized legacy systems, so training them on the new system proved difficult. Missing data orders delayed fulfillment and upset customers. Legacy system data was also lost, hidden by data silos and nearly impossible to access. Demand jumped for HP products, but the teams were so focused on managing the dysfunctional software that they could not handle the increase in orders. Ultimately the software became riddled with bugs and broke down.

The failure cost HP $160 million in lost sales and orders they could not process, which was five times more than the initial estimated cost of the implementation. They also lost $400 million in revenue for their Enterprise Servers and Storage (ESS) group.

U.S. Air Force (2004)

What started as an honest effort to consolidate financial systems within the U.S. Air Force ended in a financial drain on taxpayer funds to the tune of $1.03 billion. According to an IEEE Spectrum report, the Air Force decided to consolidate and modernize its financial systems and supply chains with ERP technology in 2004. Unfortunately, there were failures on many fronts, starting with the goal of combining 240 data silos into one system. While not an impossible feat, budget and timeline expectations needed to be much better understood for the implementation to be remotely successful.

In a report, the Air Force cited six root causes for the failure of what they dubbed the Expeditionary Combat Support System (ECSS). Ultimately the ECSS flopped because of a failure to instill trust in the new system. Few wanted to change how they conducted business, and many used this project as a promotion opportunity. Management turnover included six Program Managers, five Program Executive Officers, and even more changes that led to a lack of consistent leadership.

With seven years down the hole and a projected $1.1 billion more to get the ECSS up and running, they opted to scrap the project entirely and cut their losses.

Waste Management (2005)

In 2005, Waste Management chose SAP to implement an ERP software purported to be an “out of the box” solution specially designed for their industry. SAP claimed the product had been used by companies in Germany and was scaled for use in the United States. Despite those promises, the implementation failed within 18 months.

In 2008 Waste Management filed a lawsuit against SAP for $100 million, then increased the lawsuit to $500 million to recoup the implementation costs and the $350 million in promised benefits. The case claimed that SAP had deceived Waste Management with fake demos to show the software could handle the complexity of American business.

SAP admitted that the demonstrations used to convince Waste Management to purchase the software were not created with the actual software. The companies settled the lawsuit out of court in 2010.

Avon (2009)

Avon’s eagerness for a digital transformation with SAP wasn’t enough to keep the company from moving backward. Although Avon tested the eCommerce project in Canadian sales regions, they failed to align it with the actual business processes properly. As a result, what started as an effort to streamline operations quickly became an even more complicated mess.

One-third of Canadian sales representatives quit because of an inability to handle the intricacies of the new system, with many unable to even log in to the website portal. Since Avon sales reps are independent contractors rather than employees, it is imperative to implement a system that is easy to use. This issue could have been avoided if Avon had invested in proper training and developed a system that could work for the skill level of its end users.

In 2013, $125 million and four years later, the issues came to a head, and they scrapped the project.

National Grid (2009)

National Grid, a power distribution company serving New York, Massachusetts, and Rhode Island, was eager to replace its old Oracle system with SAP software. Already three years into the project, they couldn’t afford delays. Then Hurricane Sandy struck in October of 2012. Less than a week later, they decided to go ahead with their intended launch date in November. Any savings they would have had from launching on that due date were blown away by the ensuing chaos of the storm.

There was no strategy. National Grid was under the incorrect assumption that their system integrator Wipro would take charge of it. Next, testing of the ERP was only done under best-case conditions, not simulated emergency scenarios. This testing would have shown the system’s inability to properly coordinate with the hundreds of outside utility vendors needed to manage the aftermath of disasters like Hurricane Sandy.

The aftermath was a financial storm of its own. 15,000 vendor invoices couldn’t be processed, and many paychecks were the wrong size. National Grid ended up shelling out $8 million for overpayments and went into debt to the tune of $12 million for short pay. To make matters worse, financial reporting collapsed, so the short-term loans they relied on for cash flow were unavailable.

National Grid sued Wipro for $75 million and won, but this was a fraction of the $585 million sunk into this failed implementation.

Lidl (2011)

In 2011, German supermarket chain Lidl chose SAP to help them upgrade their outdated in-house inventory management system. Problems stemmed from their insistence on retaining a record-keeping method, as their inventory records are based on the price they pay for products instead of the price they sell them. Because of this non-standard approach, SAP needed to be customized in a way that created problems for implementation. These significant changes pushed the system to its breaking point.

Executive leadership turnover also played a hand in the failure of this implementation. When leadership changes, priorities often shift. Despite successful system rollouts in Austrian, U.S., and Irish stores in 2015, the newest CEO decided to scrap the project and revert to their original in-house system. By 2018 Lidl had spent seven years and $580 million on the implementation.

Target Canada (2011)

What happens when undertrained entry-level employees with tight deadlines are responsible for entering your ERP’s critical data? Your supply chain might just completely collapse. This scenario played out for Target Canada’s 2013 launch, which ended up making them pull out of the Canadian market altogether.

The aim was to use all new data to avoid any issues importing legacy data, but afterwards it was discovered that only 30% of the new data was error-free. Roughly 70% had errors partially from the manufacturers that Target did not train employees to notice. These errors caused incorrect pricing that left products too expensive for the Canadian market, and store shelves were empty while the warehouses remained fully stocked.

Another downfall of Target Canada was its rush to implement the ERP in all of its new stores instead of using a phased approach. If they had tested the software in 1 or 2 stores, they would have been able to catch the glaring data errors that would eventually lead to their demise. By 2015, Target decided to close all 133 of its Canadian stores, leaving over 17,000 employees out of jobs and $7 billion down the drain.

PC Connection (2013)

In 2022, PC Connection sued IBM for what they claimed was a “negligent misrepresentation” of the time and money it would take to upgrade their ERP system. PC Connection previously relied on JDE World from J.D. Edwards for all aspects of its business. In talks with IBM since 2013, IBM convinced them to upgrade their system to another J.D. Edwards product, Enterprise 1 (E1). IBM promised an implementation time of 17 months at $9.2 million.

Although IBM promised a rockstar team to help implement the software, the team assigned to PC Connection was inexperienced with E1. This created problems during implementation, and deficiencies in the software started to arise. Since the fixes needed to run the software correctly were considered outside the contracted specifications, they required change orders which increased the contract’s price.

The changes ultimately delayed the implementation. PC Connection reported that IBM insisted on going live with the system despite concerns that the ERP was not ready. Sure enough, business-critical systems were not functioning after going live and could not be reverted to the original system as IBM promised.

PC Connection had to spend $3 million in additional fees to IBM and tens of thousands of hours on internal labor to fix the issues and their fallout. They also spent significant money to hire a new partner to complete the E1 implementation. As of the posting of this article, IBM has not yet responded to the lawsuit.

Revlon (2016)

After a 2016 merger with Elizabeth Arden, Inc, Revlon sought an ERP to fully integrate the company’s existing Oracle and Microsoft Dynamics systems. They chose SAP HANA, but the 2017 rollout of the ERP ended in disaster. One of the manufacturing facilities was left unable to fulfill orders. As a result, $64 million worth of products could not be shipped, and $53.6 million had to be spent to fix the lapse in customer service.

When the failure came to light in 2019, stock prices fell, and multiple class action lawsuits were filed in response. One lawsuit was filed on behalf of Revlon shareholders, citing Revlon’s failure to design and monitor the implementation of a system that would be able to handle their manufacturing and distribution.

The issue ultimately stemmed from the unreasonably short timeline to complete the software implementation, especially for a newly merged company. That should have increased the need for more planning to ensure that the ERP system requirements were suitable for what the combined company needed.

| Company | ERP System | Reason for Failure | Mitigation Strategy |

|---|---|---|---|

| Hershey (1999) | SAP ERP | Rushed implementation timeline | Select a low-risk launch date, adopt a conservative timeline, and ensure thorough training |

| Nike (2000) | i2 Demand Planner | Rushed implementation and software glitch | Extend the implementation timeline and conduct thorough testing |

| Hewlett Packard (2004) | SAP ERP | Data loss during migration, software bugs, employee transition difficulties | Ensure efficient data migration, perform thorough testing, and use change management strategies |

| U.S. Air Force (2004) | ECSS | Lack of trust in the system, underestimated budget and timeline | Enhance change management, conduct cost analysis, and allow more time for implementation |

| Waste Management (2005) | SAP ERP | Misleading demos, software not scaled for U.S. operations | Insist on live demos, test the software firsthand, and thoroughly vet vendors |

| Avon (2009) | SAP ERP | Misalignment with business processes, sales reps struggled with system complexity | Identify workflow inefficiencies during planning and provide comprehensive training |

| National Grid (2009) | SAP | Launch coincided with Hurricane Sandy; insufficient testing for real-world scenarios | Conduct tests in simulated emergency situations |

| Lidl (2011) | SAP ERP | Over-customization due to insistence on non-standard record-keeping methods | Choose software that aligns with existing workflows |

| Target Canada (2011) | SAP | Undertrained employees, rushed data entry, failure to catch manufacturer errors | Provide thorough training and allow more time for critical data entry |

| PC Connection (2013) | Enterprise 1 | Inexperienced vendor team, change orders beyond project scope | Clearly define project scope and vet vendor’s implementation experience |

| Revlon (2016) | SAP S/4HANA | Inadequate handling of manufacturing/distribution, rushed timeline for post-merger implementation | Extend timeline and identify workflow inefficiencies early |

What causes ERP system failure?

ERP system failures often stem from inadequate planning and a mismatch between the software and an organization’s needs. Insufficient training, resistance to change from employees, and budget overruns further complicate implementations.

In addition, poor data quality, technical issues, and the lack of post-implementation support can jeopardize the system’s success.

What is implementation failure?

An ERP implementation is considered a failure when the company cancels implementation before launching the system, the system is underemployed, or the company withdraws the system after the intended financial or operational gain is not attained.

Which is the most important failure factor of ERP system implementation?

The most important failure factor of an ERP implementation is software that is a poor fit for the company or requirements that are undefined or unmatched to the actual needs of the company.

How can an ERP implementation be successful?

- Get continued support from executive leadership

- Hire an implementation partner that is familiar with your industry

- Work with partner to clearly define requirements of the ERP

- Involve employees in the project’s development

- Make a plan to transform business processes during and after implementation

- Create a dedicated team to conduct change management

- Establish project management tools to help the ERP launch on budget and on time