Best HACCP Software

Ensure regulatory compliance and maintain food safety with HACCP plan software. In this guide, we cover picks that support functionalities like hazard analysis, traceability, and recall organization.

- Pricing includes unlimited users and transactions

- Effective digital document management

- Automated product release and compliance management

- Includes over 80 pre-built HACCP plan templates

- Automates process flow charts for every production step

- Customizable to different businesses with pre-built templates

- User-friendly and intuitive interface

- Reduces time spent on repetitive tasks

Review the top options available for sectors like food manufacturing, distribution, and service establishments. These customizable platforms can ensure compliance with FDA, USDA, and state regulations.

- Smart Food Safe: Best Overall

- FoodReady: Best HACCP/PCP Builder

- FoodDocs: Best Monitoring System

- Safefood 360°: Best Risk Analysis Tools

- SafetyChain Compliance Manager: Best for Dairy

Smart Food Safe - Best Overall

Smart Food Safe includes a Process Flow Diagram (PFD) module that makes it much easier to pinpoint hazards and define preventive controls–core elements of HACCP. Using drag-and-drop components, you can quickly map out intricate production lines. Tag each process step with predefined chemical, biological, or physical hazards chosen from a customizable risk database.

Smart linking automatically ties hazards in your PFD to preventive control points (PCPs) and critical control points (CCPs). Based on risk matrices, Smart Food Safe automatically flags CCPs and PCPs at different stages so nothing slips through the cracks. This lowers your risk of missing contamination points, which is critical for food manufacturers.

You can edit your PFDs in real time, letting you adapt as workflows evolve or new threats arise. These diagrams comply with Codex, USDA, CFIA, and FDA standards. These include USDA’s HACCP regulations (9 CFR Part 417) for meat, poultry, and eggs. These guidelines require identifying areas where control measures are needed for safety.

Smart Food Safe starts at $200/month for an annual site-based subscription with unlimited transactions and users. While some user reviews report occasional bugs, the software delivers a fully featured, affordable solution for small to midsize food producers.

See our Smart Food Safe profile page for more insights.

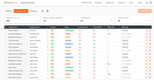

FoodReady - Best HACCP/PCP Builder

The HAACP/PCP Builder in FoodReady provides over 80 pre-built HACCP plan templates for industries like distribution, dairy, meat, and produce. These templates include SOPs, process flows, and hazard controls, and they are easily configurable to your exact workflows.

The platform also includes ready-made standard operating procedure (SOP) templates with adjustable checklists. These help you monitor operations at key stages, whether daily, weekly, or by batch. You can also fine-tune these to fit your processes with minimal effort.

Like Smart Food Safe, this platform has process flow chart automation, generating granular PFDs to give you a clear view of each operational step. This HACCP management system helps you identify potential hazards to mitigate risks at critical points, like sealing and labeling. In the event of a recall, the system traces any affected products back through every phase; this can shrink your recall scope overall and help protect consumer health.

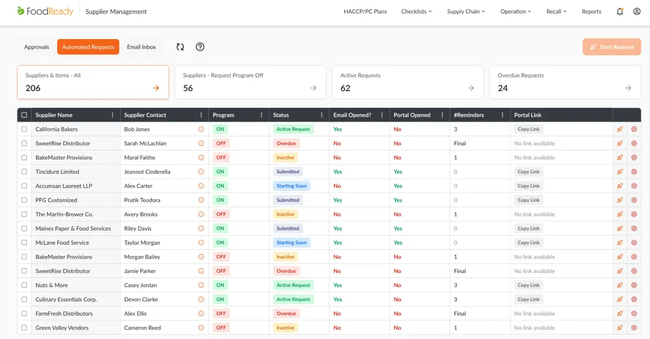

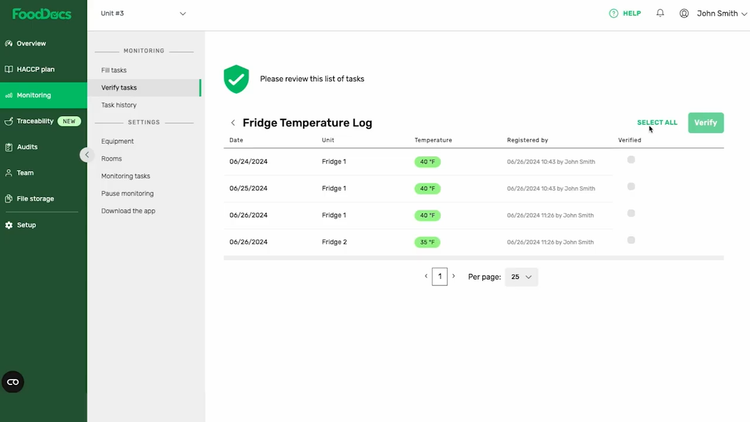

FoodDocs - Best Monitoring System

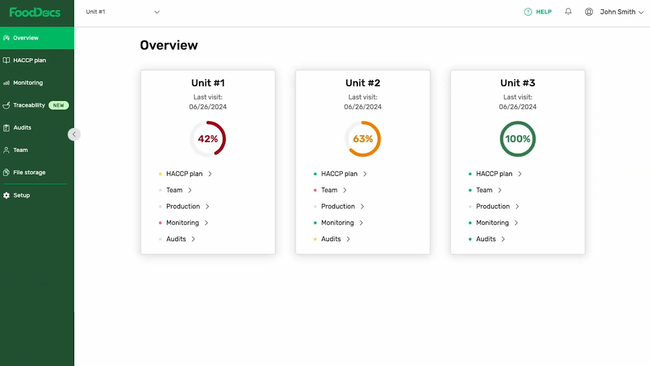

FoodDocs’s mobile-connected monitoring system syncs with the desktop platform so you can better manage daily safety checks through task alerts. These keep operations running smoothly across all checkpoints. These tasks are customizable and flexible:

- Simple Checklists: For basic assignments that need to be marked complete.

- Detailed Tasks: For entries requiring multiple data points like weight, temperature, and timers, with image or video guidance.

- Ad-Hoc Tasks: For one-off needs that pop up unexpectedly.

This HACCP software initiates corrective actions based on your pre-set conditions if data, like temperature readings, falls outside acceptable ranges. These are critical parameters for CCP monitoring, aligning with HACCP’s requirement to address hazards anytime deviations arise.

A digital log records who completed each task and when, streamlining audits and providing instant proof of compliance. The system stores all monitoring data, which is searchable by data range and exportable in CSV or Excel files.

FoodDocs starts at $84/month billed annually. The monitoring system is flexible and efficient, but you’ll need to download the mobile app for daily operations. Available for Android and iOS devices, the app allows your staff to manage tasks and ensures full oversight, no matter where they are.

Learn more about FoodDocs.

Safefood 360° - Best Risk Analysis Tools

Safefood 360° includes a fully customizable database that streamlines the workflow from assigning hazards and assessing risks. You can manage all biological, physical, chemical, and allergen hazards in a single library, with every entry detailing risk factors and past incidents. So when you’re building your HACCP plan, you can select the relevant hazards, like egg yolks or sulfites, for each process step without manually punching them in.

After assigning hazards, those records auto-populate the risk analysis section. You can then score the probability and severity of each hazard, and Safefood 360° uses your inputs, plus any preset weighting, to calculate a total risk score. Every hazard you identify from the database requires a risk assessment before you can finalize your HACCP plan, which means you’ll avoid any potential gaps down the line.

This HACCP management software also reflects updates you make to a hazard’s details, like new allergen data or a higher risk level, in all linked plans. Your auditors and internal teams can trace every risk-rated hazard in your plan back to the database entry, including control measures, corrective actions, and documentation. This supports Codex, GFSI, and USDA compliance and ensures you’re always audit-ready.

Read our full Safefood 360° review.

SafetyChain Compliance Manager - Best for Dairy

SafetyChain’s Ignition-powered integration syncs equipment and sensor data to its HACCP execution capabilities. This provides your team with a live view of critical control points. Sold as an optional module, it pulls live plant floor data directly into SafetyChain, enabling teams to trigger corrective actions automatically and maintain audit-ready records.

In a dairy operation, you can map Ignition tags like temperature, flow, and valve status to CCP parameters in SafetyChain. Once you set limits and sampling cadences, the platform continuously collects readings and pushes them to digital HACCP records. It turns requirements like maintaining pasteurization into simple, color-coded visualizations and alerts that your supervisors can act on immediately.

SafetyChain’s alerting engine sends on-screen notifications and messages as readings approach or exceed set limits. And if a breach occurs, automated CAPA workflows launch. These guide your operators through mobile forms built around your plant’s SOPs, while your QA team monitors live progress. Because Ignition feeds raw machine data into SafetyChain alongside operator entries, you get a single source of truth that supports BRC, SQF, and USDA compliance.

SafetyChain is best for mid-sized to enterprise manufacturers; it’s particularly effective in regulated, high-throughput operations, including dairy, meat and poultry, beverage, and CPG food products. However, it also supports packaging, chemicals, plastics, and general manufacturing sectors needing to digitize QA and compliance workflows across one or multiple plants.

What is HACCP Software?

Hazard Analysis Critical Control Points (HACCP) software assists with food safety and traceability compliance. Every international governing body has set out rigid rules and regulations designed to protect consumers from unsafe food. For example, the United States sets food-safety standards with the Food and Drug Administration (FDA) and the Department of Agriculture (USDA). Other countries have different agencies in control.

Fortunately, Hazard Analysis Critical Control Points (HACCP) was developed to create a global standard requiring food producers to develop management systems to analyze and control the biological, chemical, and physical hazards involved in the manufacturing, handling, and distribution of all food products.

Similar to quality management systems, this software is useful for establishing control points at all levels of the food supply chain, from initial production to final retail distribution. The 7 basic principles are:

- Conduct a hazard analysis

- Determine the critical control points (CCPs)

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping and documentation procedures

The system then has tools to analyze all possible dangers and health risks associated with food production. Whatever your role in the food and beverage industry, you can benefit from the use of HACCP software.

- There are different types of HACCP designed specifically for:

- Water

- Dairy

- Juice

- Seafood

- Retail and food service

If your specific food and beverage industry is not included, you can build a comprehensive HACCP plan with software to keep your business up-to-date with safety regulations and risk assessments.

Key Features

- Labor management: Streamline employee workflows to ensure all tasks are carried out as efficiently as possible

- Food traceability: Use barcodes and RFID to trace food production from start to finish; monitor food storage conditions like temperature

- Labeling and packaging: Determine the best way to properly package all food products and label them for easy organization and distribution

- FIFO/LIFO: Use first-in, first out (FIFO) or last-in, first-out (LIFO) systems to keep food as fresh as possible before distributing to merchants and consumers

- Distribution logistics: Plan for the best distribution methods for different types of food and beverage products

- Hazard analysis: Review possible risks to your production processes and supply chain, create mitigation plans for these scenarios

- Recall organization: In the event a recall is required, determine where all affected food was distributed and then track all units coming back to your facility to ensure no products are still available to retailers and consumers

- KPI analysis: Analyze historical data to plan out your future production schedule and streamline your safety decision-making process

Benefits

F&B companies that utilize HACCP software can enjoy many benefits, including:

Keep Track of Changing Safety Standards

Food regulations are always changing as new technologies allow for safer food handling techniques. In order to keep up with new and modified standards created by organizations like the FDA, use a HACCP software to automate the process. The system continually identifies hazards, which are:

- Biological

- Chemical

- Physical

HACCP software provides an overview of all your current safety regulations so you can double-check compliance in real time. This allows you to keep your production facility or warehouse up to date with the latest standards from every governing organization.

Since HACCP is global, you can track different countries’ safety standards in one convenient setting. If a country you distribute food to changes its practices regarding chemical hazards, you can know and adjust instantaneously.

More Cost-Effective Packaging Methods

Food packaging can add to your overall distribution costs. The more packaging material you need, the more you have to pay, and the more chances there are for a physical hazard to contaminate your food products. HACCP software has tools for calculating exactly how much you really need to transport and store food safely.

Better packaging can also reduce the possibility of food recalls. HACCP software monitors temperature conditions in real-time so you can avoid accidental overheating or cooling. For example, a broken refrigerated storage unit can spread foodborne pathogens like Salmonella and Listeria in chicken products. These biological hazards can cause hospitalization if consumed. If retailers report multiple customers becoming ill, a recall has to start. Businesses can prevent outbreaks that would otherwise prompt recalls by monitoring storage conditions with HACCP software. Additionally, safe packaging can temporarily protect food from the effects of temperature changes.

An Adaptable Supply Chain

In the wake of COVID-19, many food producers have had to adapt their supply chain practices while still adhering to safety standards. Being able to change quickly can be the difference between meeting demand and falling behind.

With a HACCP software and risk management system, you can establish new or modify existing control points to better react to possible supply chain disruptions. Since some of these hazards are unavoidable, HACCP software helps you prepare corrective actions if the risk becomes a reality.

Cheaper Product Distribution Practices

Using better packaging can also lead to better product distribution. Reduced packaging can lower overall batch weight and product dimensions, allowing more individual units to fit into a delivery vehicle or in a long-term storage facility.

For example, your refrigerated warehouse may only have room for a set amount of frozen food. In order to keep the food at the right temperature as long as possible, you need to have an efficient distribution system. HACCP software can automate the movement of products through your production center, warehouse, or store to ensure food does not expire in storage.

Why Industries Require HACCP

Every year, there are millions of cases of foodborne illness, with thousands requiring hospitalization. Most illnesses directly result from consumers ingesting food exposed to bacteria, either through damaged packaging or the food being stored at the wrong temperature. Without HACCP measures, this contamination can occur anywhere along the supply chain during:

- Food production

- Food manufacturing

- Distribution

- Retail and restaurant chains

In short, every step of the supply chain needs to account for HACCP regulations in order to reduce foodborne illnesses in consumers. Even minor cases of food poisoning are a liability for your company. According to the FDA, food recalls can cost millions, so preventative measures established by HACCP software can be the difference between happy customers and huge expenses.