The Best Printing and Packaging Software

Printing and packaging software helps efficiently manage complex workflows, track high-volume jobs, and meet customer demands. We tested and ranked various systems with key features like quoting and production scheduling.

- User-friendly interface and reporting

- Includes productivity functions that enhance capacity utilization and inventory control

- Specialized features for labels, flexible packaging, folding cartons, etc.

- Built-in CRM module

- Client and B2B portals

- Simple implementation and onboarding

- Customizable reporting and business intelligence

- Supports multiple companies, sites, currencies, languages

- Built and expanded with 30+ years of manufacturing/distribution expertise

Using our review methodology, we determined the best solutions for your business needs, including Radius ERP, WinMan, and Katana.

- Radius ERP: Best Estimating and Quoting

- InfoFlo Print: Strong Production Scheduling

- WinMan: Best Inventory and Material Management

- PrintVis: Best for Large Packaging Manufacturers

- Katana: Best eCommerce Integrations

- Advantive: Best for Commercial Printers

Radius ERP - Best Estimating and Quoting

Radius ERP can help you streamline the process of generating accurate and efficient estimates and quotes from clients. The system factors in raw materials, labor, machine time, and overhead costs to provide accurate pricing.

For example, you may receive a request to print 3,000 brochures with custom finishes and binding. Using Radius ERP, you can input the job specifics, including dimensions, material type, print colors, binding style, and quantity. The database will instantly calculate the cost of materials (paper and ink), machine time, and labor.

Your client requested pricing options for 2,500, 4,000, and 5,000 copies. The software generates multiple quotes with volume discounts calculated automatically. Radius ERP will check stock availability and schedule machine time to ensure the job can be completed within the client’s timeline.

Your sales representative can then send a quote directly from Radius ERP via email, allowing your customer to review their options and make an informed decision. Once your client approves the quote, the system will convert it into a job order, and production planning will begin without requiring manual re-entry.

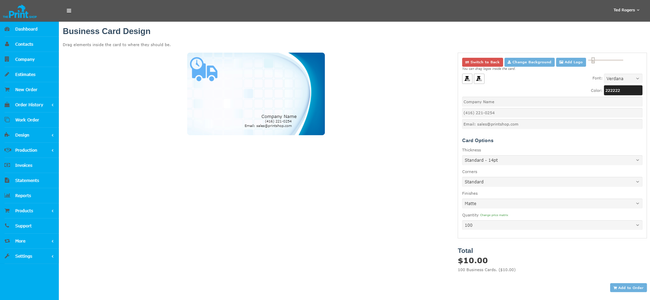

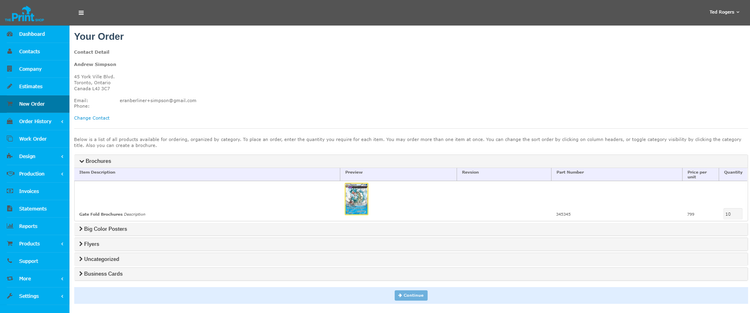

InfoFlo Print - Strong Production Scheduling

InfoFlo Print can optimize your manufacturing workflows by prioritizing jobs based on deadlines, client importance, or complexity. The system provides real-time updates on job statuses, enabling you to track progress across the production floor and complete time-sensitive projects on time.

If you specialize in promotional materials such as brochures, flyers, and posters, you likely receive multiple orders daily, each with unique requirements and tight deadlines. Without proper scheduling, your company risks missing deadlines or overloading specific machines or team members.

InfoFlo Print lets you enter all incoming orders into its system, specifying details like quantities, paper type, and deadlines. The software will automatically schedule each job based on your team’s workload, machine availability, and resource needs.

If an essential machine breaks down at midday, you can utilize InfoFlo Print’s drag-and-drop feature to reschedule any affected jobs to alternate machines, minimizing delays. Team members can mark tasks as completed or flag any issues in real-time, allowing you to monitor progress and adjust plans if needed.

However, InfoFlo Print’s pricing begins at $349/month for up to four users. If you’re a smaller company needing something more affordable, you might want to try Katana, which starts at $179/month for one inventory location.

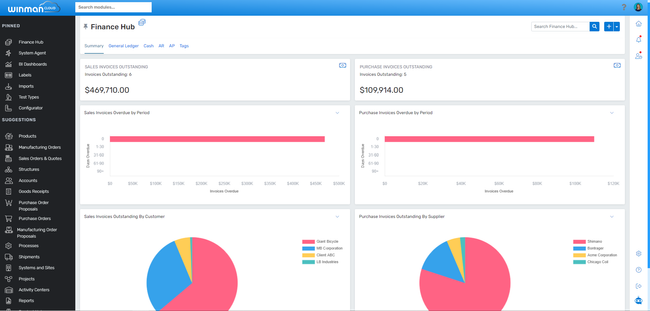

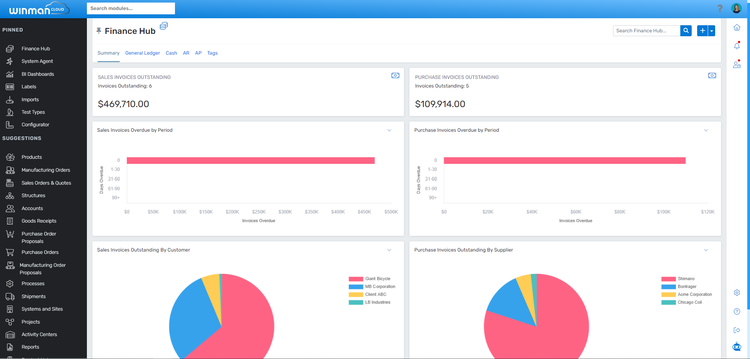

WinMan - Best Inventory and Material Management

WinMan’s inventory and material management functionality allows you to track stock levels in real time, ensuring you have a clear understanding of available materials for ongoing and upcoming projects.

This feature also integrates with the production and job management modules. WinMan monitors all material stock levels and alerts you when levels are too low for specific items.

Based on upcoming print jobs, the system can forecast the required quantities of specific items, such as cardboard and ink, ensuring timely procurement. You can also analyze waste data, allowing you to identify opportunities to reduce excess material usage.

Although WinMan supports printing and packaging, it is a general ERP solution and may lack some specific features that a niche printing or packaging company requires.

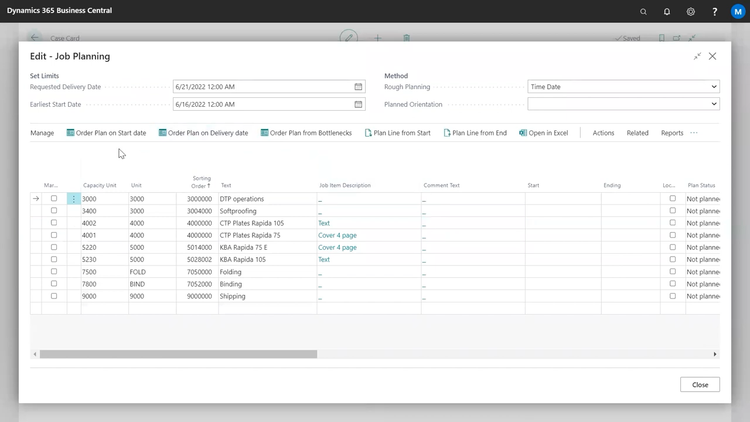

PrintVis - Best for Large Packaging Manufacturers

PrintVis can help all types of packaging manufacturers, whether you’re folding cartons or labeling pharmaceuticals. Built on Microsoft Dynamics 365 Business Central, it offers a flexible production operations module that allows you to set multiple grouping levels. This helps optimize your different production stages based on shared characteristics, like material type, ink, or finishing processes. It’s a great way to minimize waste while keeping production efficient.

Additionally, PrintVis helps optimize your production scheduling to ensure operations stay smooth with diverse product offerings. If you have constraints on certain equipment, the system lets you bottleneck the schedule to accommodate its threshold. Or you can forward the schedule based on artwork or material availability dates to ensure approval. Either way, the tool lets you view all orders on a Gantt chart or a Histogram of equipment availability, ensuring production is on schedule.

PrintVis’s pricing is not publicly available, but you can expect to pay anywhere between $10-$150/month/user. Because of the breadth of features and higher cost, we wouldn’t recommend this for smaller companies that need more basic functionality.

Katana - Best eCommerce Integrations

Katana’s integration capabilities with eCommerce and sales platforms can help you streamline order management, inventory tracking, and production workflows. The system automatically imports sales orders from platforms like Shopify, WooCommerce, BigCommerce, and Amazon, ensuring you don’t miss any orders.

For example, you specialize in producing custom-branded products for retailers and sell nearly 100 orders daily using Amazon and Shopify. When a customer places a purchase through one of these platforms, the order will automatically appear in Katana’s dashboard.

The system ensures that all raw materials are in stock by updating inventory levels in real time. If any inventory is running low, the software will trigger a notification to reorder materials, preventing production delays. Katana will assign the job to the printing, cutting, and assembly workstations, scheduling each task by priority.

Katana offers three pricing options, starting at $179/month for small businesses and increasing to $799/month for complex workflows.

Advantive - Best for Commercial Printers

Advantive’s automated scheduling feature can help meet the fast-paced demands of commercial print shops. It leverages advanced algorithms and machine learning to analyze production data, considering variables such as machine availability, workforce capability, job complexity, and delivery deadlines. The system then creates a schedule, dynamically adjusting as new jobs come in or unexpected issues arise, which is essential for print environments where turnaround time is critical.

If a last-minute print job arrives, the software can automatically reprioritize tasks and adjust schedules to accommodate the new order without compromising existing commitments. This enables you to handle fluctuating demands efficiently, avoid production delays, and maintain strong client relationships. It can also minimize set-up times, reduce material waste, and prevent overprinting, helping you keep costs under control.

Advantive’s user-friendly interface visually represents the schedule, making it easy for you to monitor active jobs and press statuses. By integrating with other systems, like inventory and order management, you can ensure seamless end-to-end workflow synchronization.

Other Systems We Like

- ShopWorks OnSite serves as an all-in-one solution for managing the entire lifecycle of a printing and packaging business. From the initial quote to final delivery, it manages everything from quote generation to order management, inventory tracking, and shipping.

- ePRO Print MIS is a suitable, inexpensive option for web-print companies, with pricing starting at $1,500/year. The system can streamline the lifecycle of a print order from estimate and production, to stock control, delivery, and accounting.

What is Printing and Packaging ERP software?

Printing and packaging ERP software is a packaging-specific manufacturing software with industry-specific features such as lot traceability, part labeling, and production planning and monitoring. Any business involved in both the manufacturing and distribution of boxes, bottles, containers, and packs can benefit from the advanced features this specific enterprise resource planning (ERP) software provides–including serial traceability, UPC labeling, pack-outs, document control, and bill of materials (BOM) specific for dyes and inks involved in your packaging processes.

Packaging businesses have unique requirements for product configuration and order registration. Whether dealing with paper, corrugated packaging, or folding cartons, all flexible packaging environments will benefit from the order entry, price/margin management, and master data management and compliance offered by packaging manufacturing software. Likewise, packaging distributors can benefit from the same business processes an ERP system offers for the printing and packaging industry.

Key Features

- Bill of Materials: Specify the raw materials, parts, and sub-assemblies needed to manufacture each specific packaging product. Provide precise instructions on what is required for each manufacturing job. Use information from order entry systems, inventory control, and master production schedule modules. Handle your dyes and inks to meet the unique needs of packaging production operations.

- Inventory Management: Track all information about the items that your company builds, buys, stores, or sells. This simplifies product pricing and helps maintain the most effective stock levels. It includes lot and serial traceability.

- Material Requirements Planning (MRP): Handle production planning, scheduling, and inventory control during a manufacturing planning process. Calculate material requirements, coordinate personnel and machine workloads, and optimally plan purchasing to meet customer demands. Identify capacity constraints and maintain optimal stock holdings in a multi-warehouse environment.

- Quoting and Estimating: Generate quotes based on materials, labor, overhead, and more costs. Sometimes referred to as cost estimating, this analyzes past estimates and win rates and customizes efficiency rates, scrap percentages, and other variables.

- Purchasing: Issue orders for services and products by tracking all key order info, including the vendor, purchase quantities, item or service purchased, delivery timeframes, payment terms, and costs. Access exact real-time stock quantities, movement history, seasonal trends, and supplier lead times. Accounting:** Track revenues and expenses. This includes modules such as accounts payable, accounts receivable, a general ledger, and payroll for employee compensation.

Benefits

One Fully Integrated Solution

A centralized, comprehensive manufacturing ERP software solution for the printing and packaging industry is necessary for the modern business environment. Packaging ERP software provides better financial tracking and forecasting by enabling collaboration and eliminating the need to re-enter data into systems. Comprehensive analytics allow businesses to improve insight and productivity by delivering reliable, real-time data.

By enabling sales to access information about product availability, lead times, order schedules, and purchasing, sales employees can better manage the delivery of products and services to customers. Packaging ERP software will maximize economies of scale, highest machine allocation, and supply control.

Meet Every Type of Print Specifications

Packaging includes folding boxes, printing labels, and using different materials such as flexible packaging or corrugated boxes. Finishing processes include laminating, perforating, embossing, and gluing. Beyond that, there are process stages such as cutting and confectioning. As such, those within the printing industry should have an all-in-one, end-to-end solution catering to the needs of every type of printing scenario.

Given the range of finishes, materials, processes, and even dyes and colors, creating the perfect print specification or quote on the first try can be complex. A product configurator within printing and packaging software will allow you to upload all costs for your catalog, enabling you to create streamlined quotes and invoices. This data is also saved for future access to speed up repeat orders.

Designed Exclusively for Packaging and Labeling

A printing and packaging ERP software is designed specifically for your business. Rather than purchasing an industry-neutral solution and paying extra for customizations that will work for your business, many software vendors provide out-of-box solutions that meet your needs immediately. This type of specialized vendor will help your business benefit from a development, implementation, training, and support team that knows the ins and outs of your industry.

When using software specific to the printing and packaging industry, you’ll be using a solution that understands your unique specifications, workflows, and standards that go into label converting and manufacturing packages. Companies that produce labels, folding cartons, and bendable packaging have different needs than a standard manufacturer and will want to implement a software system that thousands of printing plants use.

Optimize the Profitability of Your Operations through Business Intelligence

Integrate your workflow through new job acquisitions, estimating, CAD and prepress, scheduling, production, shipping, and accounting. The software eliminates unnecessary touchpoints, all while collecting data from every corner of the company. This will help lower costs and improve efficiency.

Data collected can be used in business intelligence (BI) modules, giving your decision-makers enterprise-wide visibility. As your data comes to life, you can identify trends and simplify complex decisions to drive your business forward. Due to the uniqueness of the industry and the roadmap that your customers usually find themselves on during an order process, your customers will feel more comfortable when you can better understand their needs. This can all be accomplished through smart plant optimization software.

Business intelligence will also consolidate transaction data and present it in an easy-to-use manner–letting your managers and decision-makers quickly report and analyze broad enterprise-wide details or down to a specific criterion you’ve selected. “What-if” scenarios can let you understand the pros and cons of potentially raising your prices, switching suppliers, and more.

Find Inventory Easier and Don’t Fall Behind on Orders

An outdated or manual system will slow your inventory process–meaning your employees may be walking down aisles looking for what they need. Inventory not properly noted in your stock will create callback problems and slow down customer orders.

Accessing up-to-date inventory data gives you information customized for your industry. Your packaging job will be tracked at every point, and each part, unit, or material involved will be properly recorded with ERP software for packaging manufacturers.

When items are running low, your procurement team will be notified, allowing them to handle any reorders. New contracts and scheduling agreements can be set up and handled if needed. Finally, call-off contracts can facilitate bulk orders that will help improve the long-term supply of the same type of goods from a supplier you trust, ensuring you will never be without the inventory you require to fulfill orders.