The Best Electronics Manufacturing Software

Electronics manufacturing software can streamline production workflows and optimize inventory for components with long lead times. We tested and reviewed the best solutions for consumer, medical, and high-tech electronics and picked our favorites.

- Built-in payroll capabilities

- Controls inventory of raw materials, finished goods, and assemblies

- Fully configurable dashboard

- Scalable Modern Web-Based SaaS Platform

- Deep Manufacturing-Focused Functionality

- Transparent Affordable Pricing ($50/user)

- Multi-site and multi-company support

- Built-in business intelligence

- Comprehensive supply chain management

We evaluated the best systems for various manufacturers, focusing on key features like BOM management, traceability, and advanced materials planning. Using our review methodology, we selected our favorites.

- ECI M1: Best Multi-Level BOM Management

- Cetec ERP: Best for Contract PCBA Manufacturers

- Infor CloudSuite Industrial: Best for Industrial and High-Tech Electronics

- SYSPRO: Best for Medical Electronics

- Epicor Kinetic: Best for Consumer Electronics

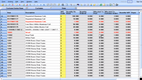

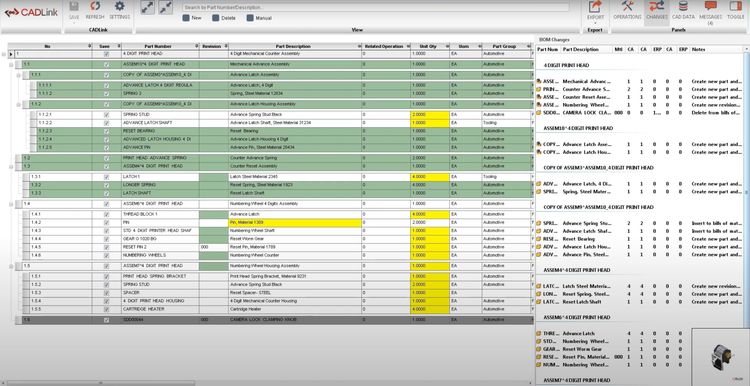

ECI M1 - Best Multi-Level BOM Management

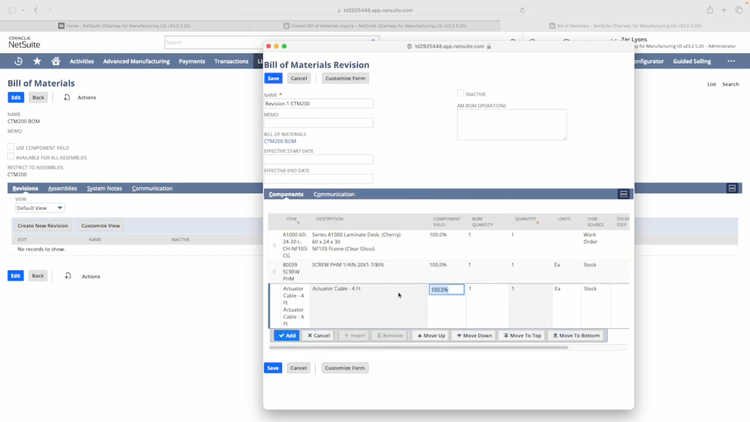

Electronics manufacturers often deal with tiered assemblies, where products include intricate designs with numerous parts and subassemblies. ECI M1’s ability to handle multi-level bills of materials (BOMs) ensures that every component, from circuit boards to individual chips, is accurately tracked and organized.

If you make changes to materials, quantities, or configurations, the system automatically updates the BOM. It also includes revision control, enabling you to maintain a history of edits, which can be particularly useful for tracking improvements and managing regulatory compliance.

Let’s say you create custom-printed circuit boards (PCBs) for medical devices. Your team must first import the PCB design specifications, including material stack-up and component placement, into ECI M1’s system. The BOM details the copper thickness and FR4 grade needed for medical device compliance.

ECI M1 calculates the total production cost, considering the high-grade materials required for the PCB’s functionality and the labor needed for assembly, testing, and quality assurance. If the client requests modifications during production, the BOM will update instantly, reflecting your changes.

The software will link all components to their lot numbers and supplier certifications, ensuring full compliance with medical device regulations. Because the database records every revision and batch produced, you’ll also have a complete audit trail for regulatory inspections.

Read our full review for more details on ECI M1, including advantages, drawbacks, and key features.

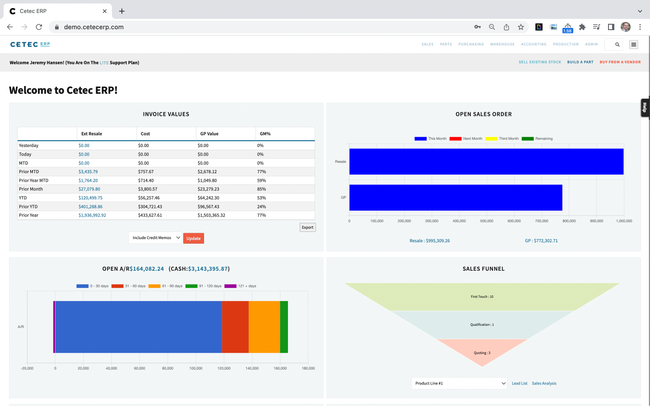

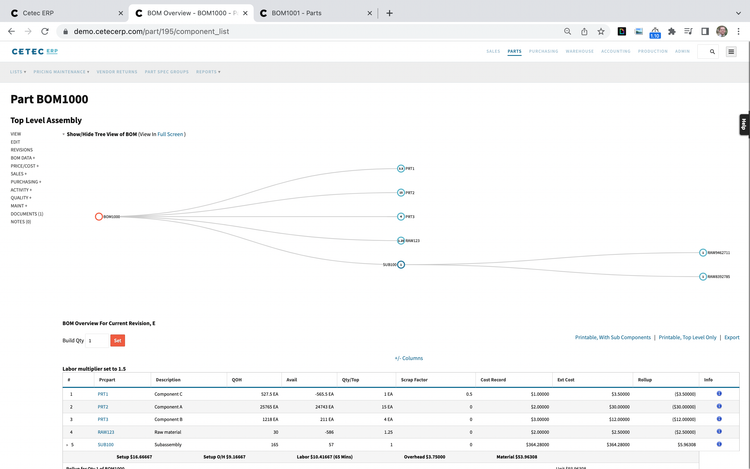

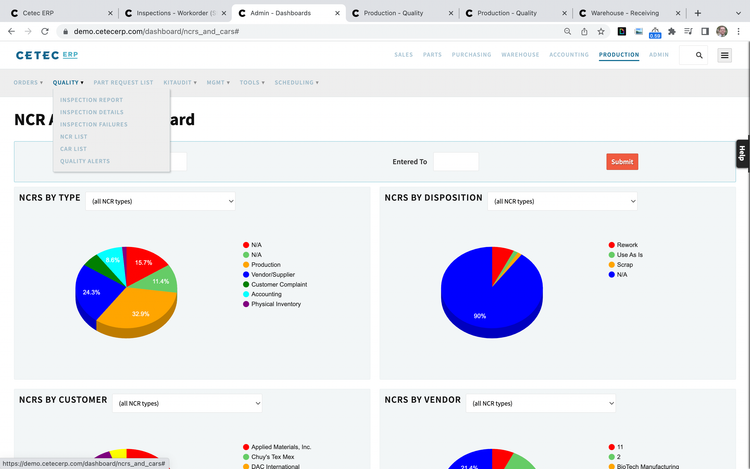

Cetec ERP - Best for Contract PCBA Manufacturers

Cetec ERP is a cloud-based ERP software built for small to mid-sized electronic manufacturers, especially those who specialize in PCBA contract manufacturing. It’s designed to run your entire business, offering tools for procurement, inventory management, production scheduling, and accounting in one place.

With Cetec ERP, you can quickly quote new jobs and build unique BOMs for each customer. Using the CalcuQuote premium integration, customers simply submit their Excel files or component lists, and the system automatically scans the files and calculates costs for materials, labor, and overhead. Cetec ERP supports BOMs with hundreds of components and reference designators, along with vendor-approved lists of substitute parts. This is essential for electronic manufacturing, as supply chain shortages and constant price shifts force manufacturers to use alternative components to complete jobs on budget and on time.

Cetec ERP is best for small to growing businesses that want a complete ERP without the complexity of a global enterprise system. Its pricing reflects that, with all plans starting at just $50/user/month and a one-time implementation fee. While Cetec requires a custom quote for most plans, it is a practical option for contract manufacturers looking to move to a digital platform for job quoting, BOM control, production scheduling, and financial management.

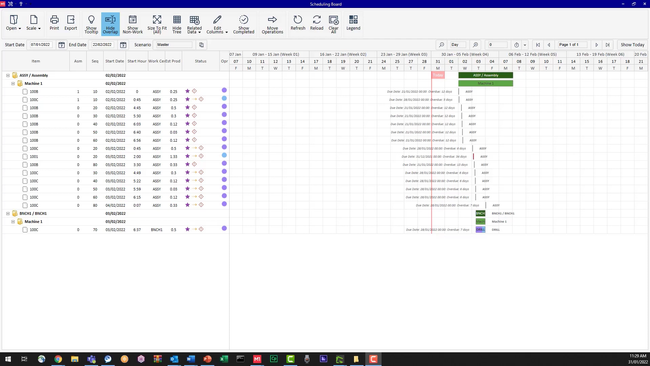

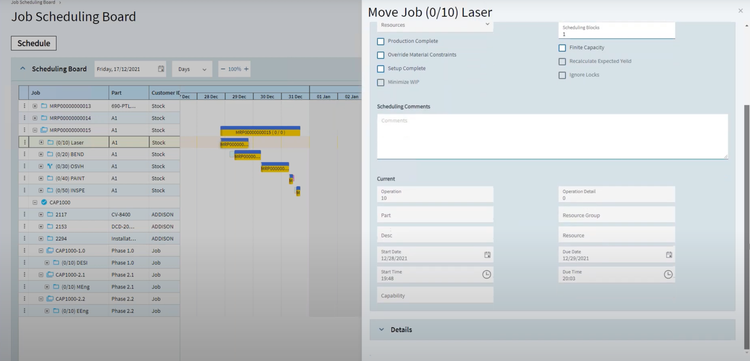

Infor CloudSuite Industrial - Best for Industrial and High-Tech Electronics

Infor CloudSuite Industrial’s advanced planning and scheduling (APS) functionality keeps manufacturing operations efficient and cost-effective. It focuses on managing resource availability to avoid overloading machines or personnel and ensures realistic production timelines.

The APS capability integrates data from across the enterprise, including inventory levels, resource availability, and customer orders. Using this live data, APS ensures that all planning decisions are based on the most up-to-date information. The system considers real-world constraints like machine availability, labor shifts, and material shortages to avoid overloading resources. It will create schedules prioritizing high-value and time-sensitive jobs and sequence tasks to minimize downtime.

The functionality integrates seamlessly with MRP to ensure that all materials are ordered and available just in time for production, helping avoid overstocks and shortages. APS allows you to simulate various scenarios to test the impact of changes, like adding a new production line or adjusting order priorities, and evaluate different resource allocations to optimize outcomes.

For instance, if you struggle with frequent production delays due to microprocessor shortages from overseas suppliers, you can utilize Infor’s ADP to predict orders and adjust production schedules. The system integrates with global suppliers and tracks lead times for microprocessors.

If there is a chip shortage scenario, the software can test how different production sequences can reduce downtime and prioritize alternate product lines while waiting for delayed components. Infor’s real-time scheduling adjustments and what-if scenario planning enable you to navigate supply chain uncertainties and meet market demands efficiently.

While Infor Cloudsuite Industrial doesn’t share pricing publicly, the software best suits companies with $50 - $250 million in revenue.

To learn more information about Infor Cloudsuite Industrial, read our full review.

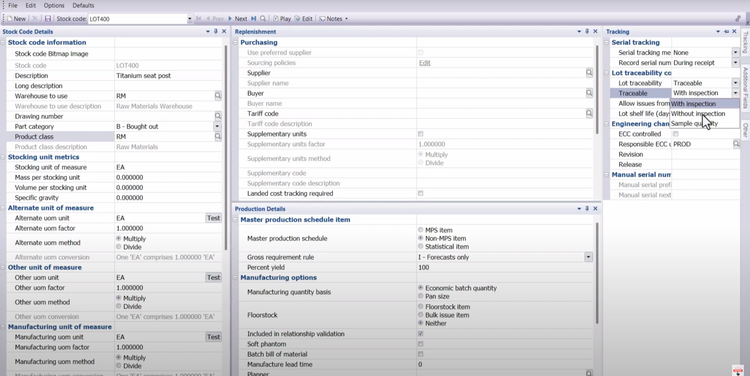

SYSPRO - Best for Medical Electronics

SYSPRO’s traceability and compliance capability tracks raw materials, parts, and finished products by lot or serial number. This can help you trace items from suppliers throughout production and delivery to customers while ensuring you adhere to regulatory standards.

SYSPRO provides tools for maintaining electronic records and signatures to meet validation requirements. It can also generate reports that include essential details like material certificates, inspection records, and shipping documentation. The system ensures adherence to standards like ISO 13485, FDA 21 CFR Part 11, and EU MDR.

You can use barcoding or RFID scanning to automate data capture for lots and serial numbers. The system will also cross-reference batches, components, and finished goods to ensure detailed trace paths.

Visit our roundup page for more details on SYSPRO.

Epicor Kinetic - Best for Consumer Electronics

Epicor Kinetic’s advanced materials planning and scheduling feature can help you set production schedules to ensure you meet consumer demand on a timely basis. This functionality combines real-time insights and demand planning to ensure that materials and resources are readily available when needed, helping minimize downtime.

Epicor Kinetic integrates with various modules, including inventory management, production operations, and supplier networks, to ensure timely and accurate data. The database analyzes existing sales orders and future demand based on historical trends to determine the required materials. It then creates detailed schedules that are automatically updated in case demand, inventory levels, or production capabilities change.

The functionality will use advanced algorithms to prioritize tasks and recommend actions like rescheduling production. This can help ensure that materials are readily available during assembly and prevent delays.

Review key features, pros, and cons of Epicor Kinetic through our roundup page

Other Systems We Like

- FactoryLogix is a suitable MES system for electronics manufacturing due to its advanced traceability, production scheduling, and quality management features. It’s best suited for businesses with over 50 employees.

- Acctivate is a solid option if you currently use QuickBooks and want to continue using the software alongside an MRP system.

What is Electronics Manufacturing Software?

Computer components and electronic goods must be manufactured according to stringent standards to operate properly. As such, electronics manufacturing software optimizes the essential processes used when building new electronic products. These processes include controlling product designs, streamlining production lifecycles, and providing merchandise traceability.

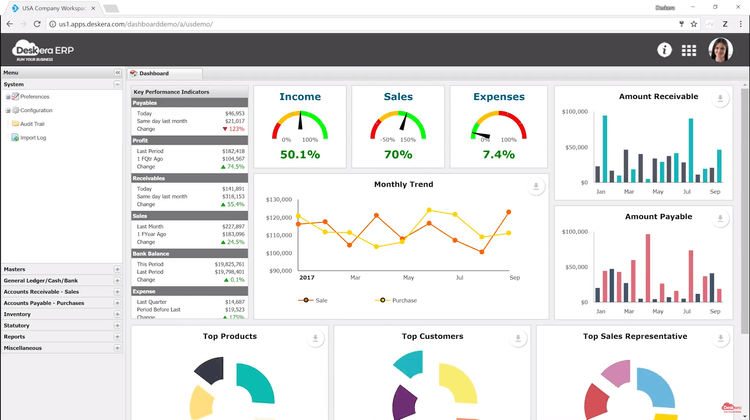

In some cases, this software may be advertised as an electronics ERP (enterprise resource planning), which covers many of the same manufacturing applications but adds features such as financial tracking, forecasting, and comprehensive analytics.

Common Challenges

- Complex Supply Chain Management: Electronics manufacturers often source components from multiple global suppliers, resulting in delays, quality issues, and increased costs. A manufacturing solution can provide real-time visibility into supplier performance, inventory levels, and shipment tracking.

- Overstocking and Stockouts: Electronic components often have short lifecycles or obsolescence risks, which can lead to overstocking or stockouts. Manufacturing software with inventory management functionalities offers demand forecasting, a tool that can predict how much stock you need. This can help minimize waste and ensure optimal stock levels.

- Product Compliance Manufacturers must adhere to strict regulations, such as RoHS and REACH, and ensure the complete traceability of parts. These features track materials throughout the supply chain, confirming compliance.

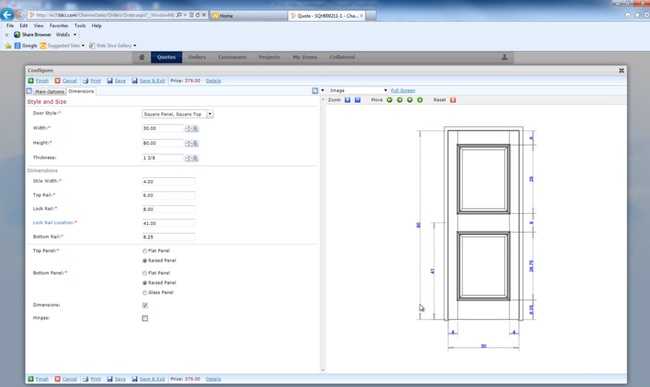

- Customization and Product Variability: Customized products often require flexible manufacturing processes and accurate quoting. Configurator tools and BOM management help manage customization efficiently and support precise cost estimation.

Primary Features

- Parts and Material Traceability: Tracks components’ origin, movement, and usage through all production stages.

- Multi-level BOM Management: This system handles complex BOMs with multiple layers of parts and variants. It accommodates design changes by quickly connecting and updating the system.

- Supply Chain Management: Controls how raw materials and finished goods move through the supply chain to comply with local regulations and fulfill customer demands in a timely manner.

- Engineering Change Control (ECC): Manages design revisions and updates all departments with the latest changes to reduce errors and downtime.

- Quality Control: Provides tools for inspecting, testing, and validating parts and finished products. Flags non-conformance issues automatically and initiates corrective actions.

- Manufacturing Execution System (MES) Integration: Improves shop floor performance and production quality through functionalities like scheduling and corrective action guidance.

- Defect Tracking: Tracks defects at all stages, from incoming materials to finished goods, and decreases scrap and rework rates through continuous process improvement.

Benefits

Electronics manufacturing software allows you to monitor production workflows and maintain consistent product quality.

Greater Visibility into Production Practices

Electronics manufacturers looking to gain better visibility into key performance indicators both in the back office and on the shop floor can do so by using custom software. For instance, production cannot truly begin until the prototyping is complete. With electronics, this is a particularly vital stage, as a single fault with wiring or smaller components can render a finished product defective. Dedicated research and development can reveal potential issues before large-scale manufacturing begins. Identifying these weaknesses and finding solutions during the prototype phase can prevent the need for costly fixes later.

An electronics ERP and manufacturing software program allows you to share critical key performance indicators (KPIs) across every department. Use this data to synchronize manufacturing controls in purchasing, sales, and receivables to plan production runs accurately, meet delivery dates, forecast expenses, and order inventory without over- or under-stocking.

Remaining Compliant with Industry Regulation

The electronics industry is notorious for strict safety guidelines and manufacturing regulations. After all, a single mistake during production can lead to expensive problems further down the line. In a worst-case scenario, damaged electrical components can even lead to catastrophic failure of finished products.

For example, in 2016, Samsung Galaxy Note 7 smartphones with incorrectly sized batteries would overheat and explode in customers’ faces. This resulted in a costly recall of all devices to prevent further injury and incidents. Fortunately, electronics manufacturing software with regulatory compliance and quality control tools helps you avoid creating defective products.

First, quality control measures allow manufacturers to set specifications for their production, from sourcing raw materials to delivery conditions. For instance, sensitive electronics may need staff to wear personal protective equipment when handling them. Next, regulatory compliance provides manufacturers with a way to check and review all relevant regulations related to production, such as safety rules for workers or storage options during transport. This can even be customized based on location, such as manufacturing in a different country from where the product is eventually sold.

Discover Growth Opportunities

Electronics manufacturing companies may compete on a regional, national, or global level. The continuous pressures of the global economy require a constant commitment to finding all possible competitive advantages. Manufacturing software allows manufacturers to delegate some process work to automation. In turn, this frees up valuable time and resources which can be used for other things, such as discovery and refinement processes. All of this can greatly reduce production costs.

Additionally, automating manufacturing can lead to faster turnaround times on assembly and fulfillment. These shorter leads make it easier to meet changing customer demands.

Pricing Guide

Electronics manufacturing software can vary in price, depending on:

- Module additions

- Training

- Initial implementation, including hardware upgrades

- Base and additional users

- Ongoing support

To better understand how these products compare in price, we roughly calculated the cost of their first-year licensing costs for 10 users. It’s important to note that implementation, training, and support would include additional fees.

| Software | Best For | Annual Price |

|---|---|---|

| ECI M1 | Best Multi-Level BOM Management | $36,000 |

| CETEC ERP | Best for Contract Manufacturers | $20,000 |

| Infor Cloudsuite Industrial | Industrial and High-Tech Companies | N/A |

| SYSPRO | Medical Electronics | $64,000 |

| Epicor Kinetic | Consumer Electronics | $48,000 |