The Best Distribution Inventory Management Software

Distribution inventory management software can help optimize product storage, movement, and tracking. We evaluated the best solutions for consumer goods, food and beverage, retailers, pharmaceuticals, and 3PLs.

- Competitive pricing; does not require a subscription

- Integrates with QuickBooks

- Can function as a light MRP system

- Intuitive user interface with logical navigation

- Several different automation options to streamline workflows like eCommerce and order processing

- Real-time inventory tracking and order processing

- Integrates with QuickBooks Online, ShipStation, and Shopify

- Affordable pricing for SMBs

- Mobile app for warehouse inventory management

We consulted our advanced review methodology to rank the top products on the market today.

- Fishbowl Inventory: Best for Consumer Goods

- Cin7 Core: Best for Retailers

- SOS Inventory: Best for Pharmaceuticals

- Extensiv Order Management: Best for 3PLs

- Finale Inventory: Best for Wholesalers

- Infoplus: Best for Building Materials

- Acctivate Inventory Management: Best for Food and Beverage

- HandiFox: Best Mobile Option

- Gofrugal: Best for Restaurant Supplies

- NorthStar WMS: Best for Multi-Entity Distribution

Fishbowl Inventory - Best for Consumer Goods

Fishbowl Go is a mobile application that works seamlessly with Fishbowl Inventory. It allows your warehouse staff to perform essential inventory management tasks using a smartphone, tablet, or barcode scanner.

With Fishbowl Go, your team can scan items to update stock levels, pick orders following the system-generated routes, and track movements between store locations. By providing accurate inventory data, you can avoid stockouts or overstocking. This can be highly beneficial if you manage large inventories, with thousands of SKUs ranging from personal items to household products across various locations.

When a new shipment arrives, a warehouse worker can scan the barcodes using the mobile app, which automatically records the quantity and updates reordering needs in real time. For an order of 50 shampoo bottles and 100 toothpaste tubes, the app guides the picker through the most efficient route in the warehouse using the shortest path to minimize travel time. Your team member scans the items, and this distribution inventory software will verify accuracy before proceeding.

The app can also perform a cycle count of different warehouse sections, recording any discrepancies and automatically updating the central inventory system. Once your team packs the items, Fishbowl Go integrates with their shipping carriers, such as UPS and FedEx, to generate labels and track shipments, ensuring timely deliveries to retailers.

However, while Fishbowl Inventory syncs with QuickBooks, transactions do not post to the accounting software in real-time. This requires a manual or scheduled sync to reflect data in QuickBooks accurately.

Read our full profile on Fishbowl Inventory for key features and pricing details.

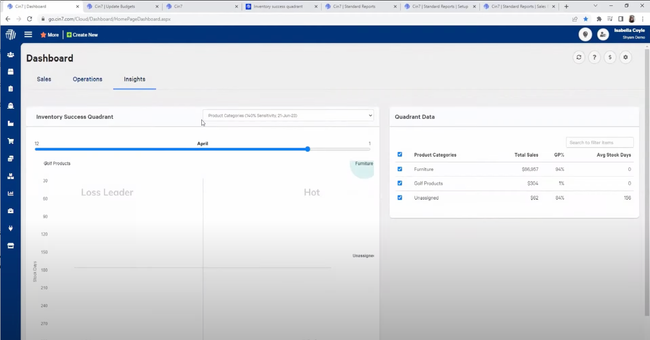

Cin7 Core - Best for Retailers

Cin7 Core features a built-in point-of-sale module that offers a suite of features that can streamline retail operations by integrating sales, inventory management, and customer interactions. It offers strong barcode scanning capabilities, enhancing efficiency and flexibility with in-store transactions.

The POS is configured to use product-based barcodes, allowing for quick item identification and an efficient checkout process. When a customer makes a purchase, the transaction will update your central inventory system immediately to reflect the sale. This can be highly beneficial if you have multiple store locations, as it allows you to monitor stock levels, manage orders, and analyze sales performance in one platform. The POS also includes features for low-stock notifications and backorder alerts.

Cin7 Core allows you to apply discounts at various levels, such as by product, customer group, or individual customer. Additionally, percentage-based customer discounts can be applied across all products a customer purchases. The module also includes a loyalty program that enables you to reward customers based on their purchases. You can configure loyalty settings to issue rewards such as gift vouchers, promotions, or store credits based on individual order values or cumulative spending over time.

The software supports standard payment methods like cash and card and several payment platforms, including Square, Vantiv triPOS, Linkly, and Windcave. It can also integrate with various eCommerce platforms, such as Shopify, WooCommerce, and Magento.

The system starts at $349/month. If you need a more affordable option, you might want to consider HandiFox or SOS Inventory.

For more information on Cin7 Core, read our full review.

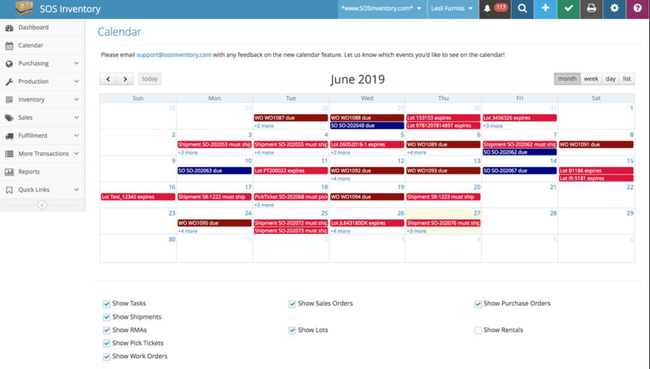

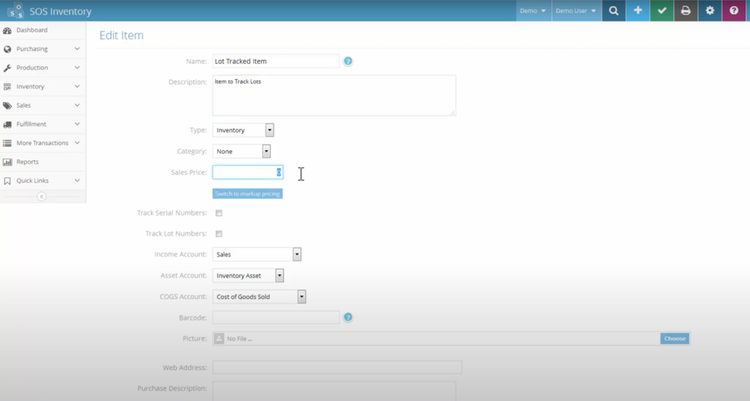

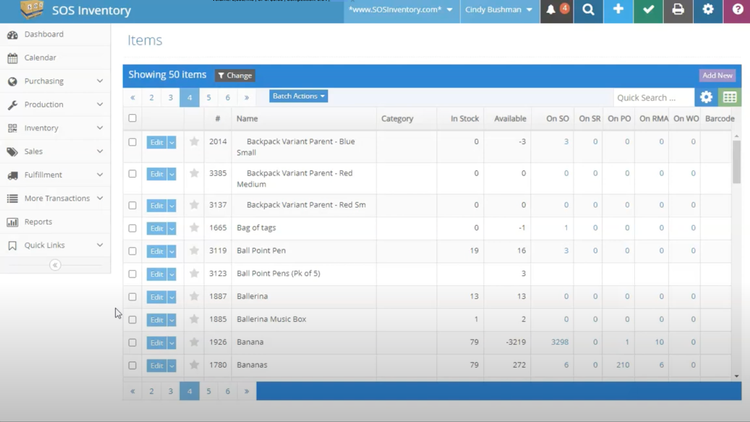

SOS Inventory - Best for Pharmaceuticals

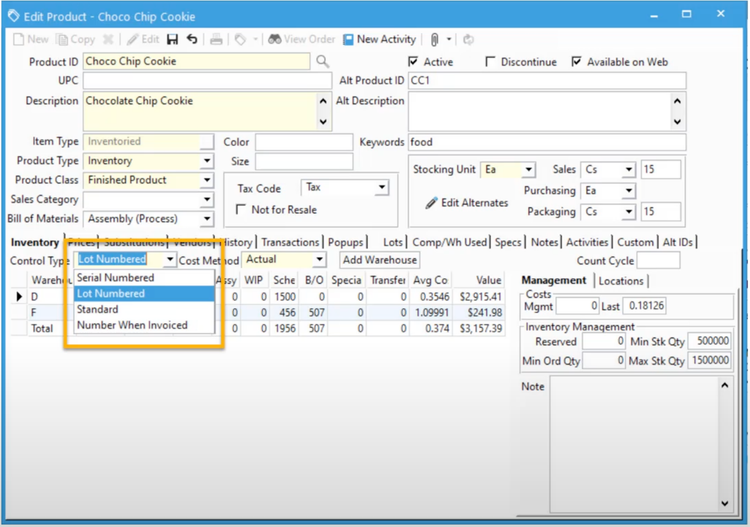

Pharmaceutical distributors often oversee various medications with different shelf lives. SOS Inventory’s lot tracking feature ensures meticulous management of medication batches from production to distribution.

Upon receiving the shipment, you can assign each batch a unique lot number that records critical details such as manufacturing date, expiration date, and other relevant information. When fulfilling orders, you can select medication based on lot number, prioritizing those with earlier expiration dates to ensure product quality. If a recall is issued for a specific lot due to a quality concern, you can quickly identify and remove all affected units from inventory, mitigating potential risks. You can also alert stakeholders through automated emails or an online dashboard.

Additionally, SOS Inventory provides detailed reports on lot statuses, including quantities on hand, expiration dates, and recall statuses. These insights can help you make informed decisions, optimize inventory management, and maintain compliance with the FDA’s regulatory standards.

Read our full profile on SOS Inventory for pros, cons, and key features.

Extensiv Order Management - Best for 3PLs

Extensiv Order Management’s picking and packing feature can help you reduce time and errors in fulfilling orders for 3PLs. By batching, you can assign your team to collect multiple orders simultaneously based on similar SKUs or locations within the warehouse.

Extensiv integrates barcode scanning and pick-to-light systems to guide team members to the correct items. Once they pick the items, they can move to packing stations. The software automatically generates packing lists for each order, ensuring that each item’s quantity and condition meet the customer’s requirements.

You can monitor the packing process in real-time, tracking the progress of each order. Once complete, the software integrates with the carrier system to automatically generate shipping labels, ensuring the orders are dispatched quickly and correctly. This can help save time and reduce human error, improving order accuracy.

However, while Extensiv is highly functional, certain 3PLs with very specific needs may find the dashboard, reporting, and custom workflows somewhat limited compared to other, more flexible platforms. If you’re searching for a highly customizable solution, visit our best 3PL software roundup.

Read our full review for more information on Extensiv Order Management.

Finale Inventory - Best for Wholesalers

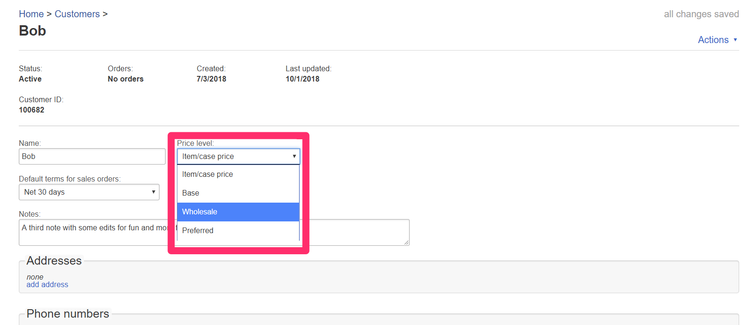

Finale Inventory offers various pricing tiers to help you manage different structures based on customer classifications. This functionality lets you set up multiple payment levels, allowing for more flexible and dynamic pricing strategies. For example, a wholesaler might apply bulk pricing for orders over 400 units, while VIP customers receive a 10% discount on certain purchases.

With Finale Inventory, you can create different price tiers, including:

- Standard pricing: Best for smaller retailers who purchase in lower quantities.

- VIP: For a select group of customers based on their loyalty, high value, or long-term relationship with the business.

- Bulk pricing: Discounts are applied based on the quantity of products purchased. Typically, it is best for large resellers who place high-volume orders.

Customers are assigned a price tier based on buying behavior, company size, or loyalty. You can manually assign each individual to their appropriate tier or via an automated system. Finale Inventory then automatically applies the corresponding pricing during order creation, streamlining the process and reducing the likelihood of errors.

You can set discounts for certain tiers, applying them across all products or specific groups of items. You can set rules for each customer tier, including the ability to assign fixed prices, percentage-based discounts, or volume-based pricing. The system also supports seasonal sales events through time-defined promotions, and can apply discounts to specific product categories, such as electronics.

For more information on Finale Inventory, read our full review.

Infoplus - Best for Building Materials

Infoplus’s flexible warehouse setup allows you to manage multiple warehouses or locations, assigning specific products or types of inventory to different facilities based on demand, proximity to customers, or handling needs, such as high-value or temperature-sensitive items.

When setting up a warehouse, you can define the layout and allocate inventory to various locations within the building. For example, you can set up a zone for heavy construction materials like cement and another zone for lighter materials such as insulation. The system can direct workers to pick and pack orders based on your warehouse layout, ensuring efficiency.

You can also set customizable rules for inventory handling at each location. This includes setting up automated workflows for receiving, picking, packing, and shipping based on the warehouse’s capabilities and the type of materials.

The flexible warehouse setup provides options for creating and managing bins, shelves, and pallets within the building. This allows you to optimize storage by organizing materials based on size, weight, or other factors. This feature also supports cross-docking for efficient material flow, where goods are received and immediately shipped out without long-term storage, which can be beneficial if you have high-turnover materials like cement or construction aggregates.

Acctivate Inventory Management - Best for Food and Beverage

Acctivate’s lot and serial number traceability feature tracks products through every stage of their life cycle, from production to delivery. This capability provides real-time visibility into every item within the warehouse, ensuring compliance and efficient inventory handling.

Acctivate will scan and assign lot or serial numbers to the products when you receive inventory based on the vendor’s information or manually entered details. For example, if you receive a shipment of fruit juices, each batch will contain a unique lot number that can track its manufacturing date, ingredients, and expiry date.

Whenever a worker makes a sale, the system records the lot number of the product sold, ensuring traceability in case of complaints or recalls. If a customer reports an issue with one of the juices, Acctivate can help you quickly identify which batch the product came from. You can check the lot number in the system and immediately initiate a recall process for that specific batch. The database will also alert you when a batch is approaching its expiration date or if there are any stock discrepancies through reports, dashboards, and workflow task lists, helping you avoid selling expired or defective products.

Acctivate links directly with QuickBooks, making it a good, affordable solution if QuickBooks is your current accounting software. If you’re not a QuickBooks user, then you may want to consider other affordable food distribution systems, such as Food Connex.

For more information on Acctivate, read our full review.

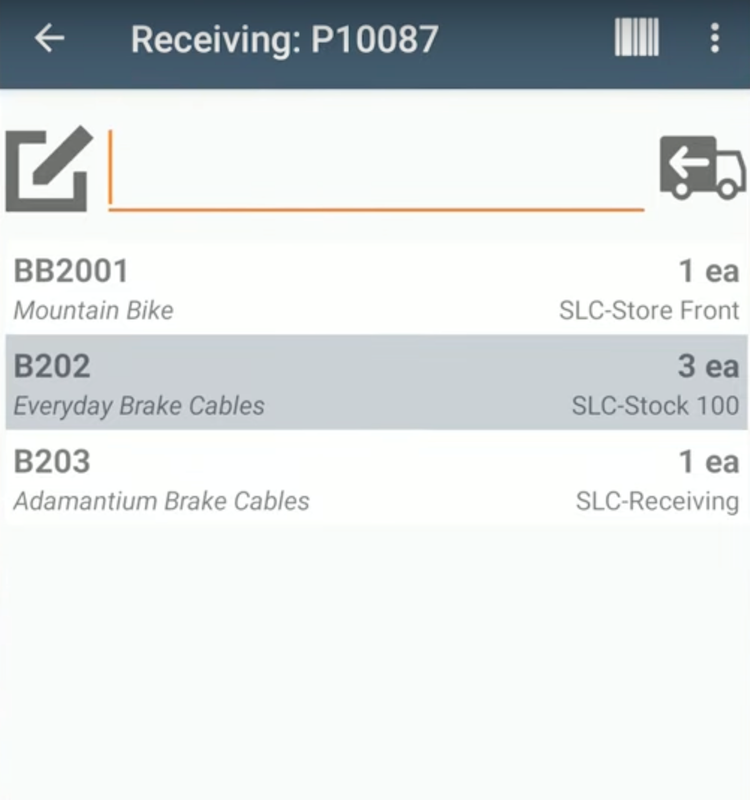

HandiFox - Best Mobile Option

HandiFox offers a multi-location tracking feature that allows you to manage inventory in different areas using its mobile app. This includes locating inventory in real time across multiple warehouses, retail outlets, or client sites to ensure that you maintain accurate stock levels and reduce the chance of stockouts or overstocks.

For example, maybe you have two storehouses in different cities. One warehouse in City A is running low on a popular product, while the other in City B has a surplus. Using HandiFox, you can quickly check stock levels and initiate a transfer from City B to City A. The immediate updates ensure that inventory levels are adjusted immediately in both locations.

The mobile app also allows you to perform stock counts at each facility and update the system while on the go. The inventory data is continuously synced for all locations, ensuring that the master database reflects accurate levels at each point, regardless of where the update occurs.

HandiFox generates area-specific reports that allow you to analyze stock levels, sales, and inventory turnover for each location. This can help you identify trends and forecast needs for each facility.

For more information on HandiFox, read our full review.

Gofrugal - Best for Restaurant Supplies

Restaurant supplies, such as dairy, sauces, and pre-packaged goods, require strict oversight due to their short shelf lives. Failing to ensure that these items are sold or delivered before expiration can lead to significant waste, financial loss, and reputational damage.

GoFrugal addresses this challenge with its advanced expiration date tracking capability, designed to help you monitor and manage perishable or time-sensitive stock effectively.

The database continuously monitors inventory and tags each product with an expiration status. When an item nears its expiration, the system will notify your staff within a given time period, such as 30 days prior. These alerts can appear directly on your dashboard, via email, or mobile app, allowing your team to take action before the product becomes unsellable.

The system adheres to the First Expired, First Out (FEFO) principle. The software identifies products with the nearest expiration dates when processing an order but ensures they remain within safe consumption limits. These batches are flagged for priority order fulfillment, which can help reduce waste and optimize inventory turnover.

As you fulfill the order, the system can notify you of upcoming expiration dates, prompting you to contact other clients or create promotional discounts to move the stock. This proactive approach minimizes financial losses while maintaining customer satisfaction.

NorthStar WMS - Best for Multi-Entity Distribution

NorthStar WMS is a solid fit for companies operating across several inventory environments. You can set specific purchasing, invoicing, and returns workflows for each facility. In particular, the Order Manager module acts as an intelligent allocation engine, and it’s pretty simple to configure this for each legal entity.

You can choose from two different settings:

- Auto Mode: Auto-assigns stock to orders based on predefined rules (like location priority, expiration, etc.)

- Manual Mode: Fine-tune or override allocation down to the lot or serial number level.

This takes the guesswork out of fulfillment across multiple sites. Plus, within each entity, NorthStar lets you customize:

- Zoning: Divides warehouses by volume, staff assignment, temperature, or SKU speed.

- Cubing: Optimizes item placement based on space usage.

- Directed put-away: Auto-suggests best storage locations.

NorthStar WMS starts roughly at $1,000/month, though you’ll need a custom quote for exact pricing. You can choose from on-premise or cloud-based deployment. We generally recommend this distribution inventory software for mid-level distributors with 50 to 500 employees.

Read our full review of NorthStar WMS here.

What Is Distribution Inventory Management Software?

Distribution inventory management software is a specialized tool designed to help manage stock across various supply chain stages. It aids distribution companies by helping them track products from their manufacture to their delivery.

Businesses typically using this software include:

- Distributors: These companies buy products from manufacturers and sell them directly to retailers or consumers. They need efficient inventory management to handle large volumes of products, often with varying demands across different regions.

- Manufacturers: Manufacturers use these systems to track the flow of goods from production to distribution centers and on to customers. It helps them coordinate production schedules with inventory needs to minimize overproduction and understock situations.

- Retailers: Large retail chains manage inventory across multiple store locations and storage facilities. This software helps them ensure that each location is stocked according to demand predictions and sales data.

- eCommerce Businesses: Online retailers, particularly those with a large product catalog, use inventory management software to ensure that stock levels are accurate across all sales channels. This is crucial for maintaining service levels and customer satisfaction in a competitive online market.

- Logistics and Supply Chain Firms: Companies specializing in logistics and supply chain management use these tools to track shipments, manage warehouse inventory, and optimize the movement of goods through various transportation modes.

- Third-party Logistics Providers (3PLs): 3PLs manage inventory and fulfill orders on behalf of other companies. They rely on stock management systems to handle complex logistics, including storage, picking, packing, and shipping operations.

Key Features

The core features of distribution inventory software include order management, inventory tracking, and warehouse management:

| Feature | Description |

|---|---|

| Inventory Tracking | Tracks inventory levels, locations, and status in real-time to prevent stockouts and overstock. |

| Order Management | Manages orders from placement through delivery, including processing, picking, and shipping. |

| Warehouse Management | Optimizes warehouse operations, including storage locations, picking processes, and routing. |

| Demand Forecasting | Uses historical data and analytical tools to predict future demand for better inventory planning. |

| Supply Chain Management | Manages the entire supply chain, from supplier to customer, ensuring efficiency and cost control. |

| Reporting and Analytics | Generates detailed reports and analytics to help in decision-making and operational improvements. |

| Barcode Scanning | Utilizes barcode scanning for quick inventory updates and accurate record-keeping. |

| Multi-Location Support | Manages inventory across multiple warehouses or storage sites. |

| Integration Capabilities | Integrates with other systems like ERP, accounting, or CRM software for streamlined operations. |

Benefits

Wholesale inventory management software enhances several processes, including stock level and supply chain management. Here are a few of the key benefits:

- Improved Inventory Accuracy: Reduces errors associated with manual counting and record-keeping, providing accurate real-time data.

- Optimized Storage: Analyzes sales trends and inventory levels to optimize product placement within the warehouse and improve the overall use of storage space.

- Reduced Costs: Minimizes costs associated with overstocking and holding unsold inventory; reduces stockout losses.

- Analytics and Reporting: Gives valuable insights into inventory trends, sales patterns, and customer preferences, enabling more informed decision-making.

- Supply Chain Visibility: Provides transparency in every stage of the distribution process, from order entry to delivery, helping to identify bottlenecks and inefficiencies.

- Regulatory Compliance: Maintains records compliant with industry regulations and standards for sectors like pharmaceuticals and food services.

Pricing Guide

Distribution inventory warehouse management systems can cost as little as $150/month to over $12,500/month. Prices will vary depending on the number of users and whether you require additional features.

- Entry-Level Software: $2,000-$10,000/year for up to 25 employees

- Mid-Tier Systems: $10,000-$50,000/year for up to 150 employees

- High-Tier Software: $50,000-$100,000/year for up to 500 employees

- Enterprise-Level Systems: Over $150,000/year for more than 500 employees

| Software | Best For | Deployment Options | Starting Price |

|---|---|---|---|

| Fishbowl Inventory | Consumer Goods | Cloud or On-Premise | $150-$200/user/month for cloud WMS |

| Cin7 Core | Retailers | Cloud | $349/month |

| SOS Inventory | Pharmaceuticals | Cloud | $64.95/month |

| Extensiv | 3PLs | Cloud | $599/month |

| Finale Inventory | Wholesalers | Cloud | $99/month |

| Infoplus | Building Materials | Cloud or On-Premise | $495/month |

| Acctivate | Food and Beverage | Cloud or On-Premise | $400/month |

| HandiFox | Mobile Option | Cloud or On-Premise | $39/month |

| Gofrugal | Restaurant Supplies | Cloud or On-Premise | N/A |