The Best Track and Trace Software

Track and trace software monitors and records the movement of products or materials throughout the supply chain. We evaluated several systems for various sectors, including food and beverage, cannabis, and pharmaceuticals.

- Adheres to ISA-95 and ISA-88

- Connected production data

- Low code/no code offerings

- End-to-end traceability

- Seamless integration

- Serialization capabilities

- Efficient tracking using RFID

- Real-time inventory management

- Compliance with state regulations

We’ve used our advanced review methodology to review a handful of systems and selected our favorites, including Sepasoft, Antares Vision Group Supply Chain Visibility, and Metrc.

- Sepasoft: Best for Food and Beverage

- Antares Vision Group Supply Chain Visibility (rfxcel): Best for Serialization

- Metrc: Best for Cannabis

- TrackRX by TrackTraceRX: Best for Pharmaceuticals

- TIBCO Track and Trace Accelerator: Best for Business Intelligence

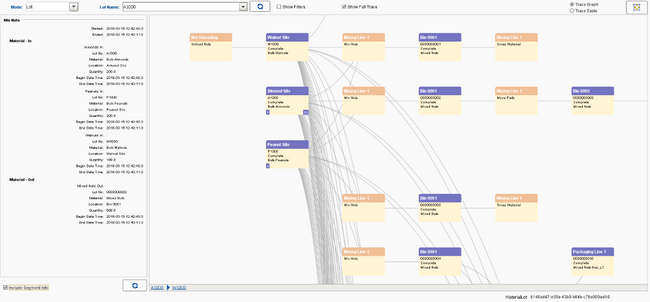

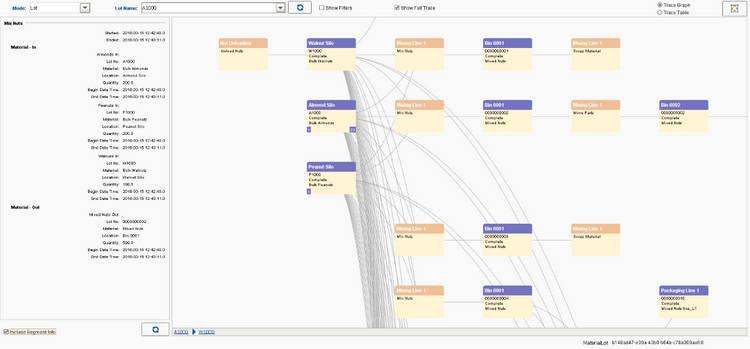

Sepasoft - Best for Food and Beverage

Sepasoft enables you to track allergens at the raw material or ingredient level, ensuring that all incoming ingredients are flagged with their specific properties. This advanced traceability ensures that no cross-contamination occurs during production.

For example, you might produce baked goods that contain nut allergies. Sepasoft will automatically log ingredients that contain nuts at the supplier stage and flag them as high-risk allergens. As the baked goods are processed, the software tracks the movements of these ingredients across the production line.

If a product with almonds, such as almond cookies, goes through production before a nut-free cookie, the system will alert you to perform a thorough cleaning after completing the almond batch. It will also monitor your cleaning procedures and help operators validate that no almond residue remains before switching to the allergen-friendly cookie batch.

If an audit occurs, the system will provide a detailed allergen traceability report demonstrating compliance with food safety regulations. However, Sepasoft starts at $2,750 per module, which could be pricey for smaller businesses.

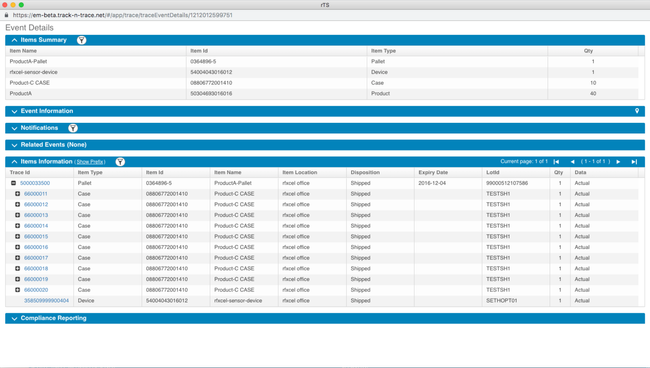

Antares Vision Group Supply Chain Visibility (rfxcel) - Best for Serialization

Antares Vision Group Supply Chain Visibility, previously known as rfxcel Track, offers end-to-end traceability. It allows companies to track their products from the moment they leave the manufacturing facility to the point of consumption.

The system offers serialization, which assigns a unique identifier to each product, allowing for complete traceability and accountability. Antares also has advanced encryption and authentication protocols to ensure the safety and privacy of sensitive data. This is crucial for pharmaceuticals, healthcare, and food industries, where data breaches can have serious consequences.

Metrc - Best for Cannabis

Metrc is a system designed for government and state agencies. This database uses RFID technology for tracking and real-time inventory management, ensuring precise and efficient monitoring of cannabis products throughout their lifecycle. It can help businesses maintain compliance with state and federal regulations in the heavily regulated cannabis industry.

It can also integrate with other software systems that cover different stages of the marijuana industry, from cultivation to retail sales. This feature allows for continuous tracking of the entire lifespan of cannabis products.

TrackRX by TrackTraceRX - Best for Pharmaceuticals

TrackRX offers high security with advanced encryption and authentication protocols, making it an ideal solution for the pharmaceutical industry. Its ability to provide real-time VR-driven data, reducing capital investments and man-hour costs in drug traceability, further underscores its effectiveness as a traceability solution.

TIBCO Track and Trace Accelerator - Best for Business Intelligence

TIBCO Track and Trace Accelerator is part of TIBCO Spotfire, a complete business intelligence platform. This Accelerator uses event processing software for efficient and dynamic tracking of logistics processes. Its configuration-driven process allows for quick state modifications and rapid introduction of new logistics products, significantly reducing the time required for updates and adaptations.

The real-time dashboard feature is particularly beneficial for operations staff as it provides a comprehensive view of network health and highlights exceptions that require attention. This enables proactive management of logistics processes and improves operations efficiency.

What is Track and Trace Software?

Track and trace software provides companies, mainly manufacturers, with real-time product distribution and logistics updates through technology like radio-frequency identification (RFID) and barcoding. This type of supply chain software is primarily used to determine the location of merchandise or equipment and confirm the arrival of shipped packages.

Notable Features

- Inventory management: Tracks all information about items you build, buy, store, or sell

- RFID, QR code, and barcode tracking: Various methods of automated tracking based on scanning technology

- Visual trace graphing: Gain a visualized overview of where products are and where they have been; create custom links between tasks such as parent-child, bi-directional, and peer-to-peer

- Warehouse management system (WMS): Coordinate inventory movement and employee actions throughout a warehouse or distribution center

- Recall management: Create specified workflows for directing recalls or stock withdrawals

- Historical data analysis: Review past inventory data to identify trends and areas for improvement

Benefits

More Accurate Inventory

Track-and-trace software helps businesses monitor their various properties, from merchandise intended for sale to field equipment. This inventory traceability can assist manufacturers, suppliers, and distributors in understanding how their products move along the supply chain. Adopting tracking technology like barcode or QR code scanners increases inventory visibility.

It also provides paperless tracking, further streamlining the entire traceability process. Apps compatible with mobile devices allow access to traceability records from anywhere in the world.

Better Anticipate Customer Demands

Knowing your inventory levels in real time can help you anticipate and plan for customer demand. Reviewing historical data is one way to gain valuable insight into future buying decisions, leading to more accurate manufacturing requests when it’s time to restock.

Compliance with Local Safety Laws

Certain products cannot be shipped unless under strict safety and traceability regulations. For example, pharmaceuticals and explosive materials are tightly controlled to avoid possible accidents. Since different localities have their own safety regulations, it’s vital to track different compliance requirements based on where you do business.

An increase in inventory visibility provided by tracking and tracing tools saves significant time and money when dealing with local and international safety organizations. For instance, a delivery driver can use their mobile device to access track and trace software to prove compliance with traceability regulations while dealing with different government entities.

Easier Recall Management

In the event of a recall, every affected product must be accounted for to prevent possible injury or accidents among the public. Track and trace solutions make managing product recalls easier by containing records of all products that your company handled. This data can act as proof of compliance and help your company avoid the common risks of product recalls:

- Consumer safety endangerment

- Disruption to business continuity

- Financial penalties and fines

- Civil lawsuits

- Criminal charges prosecution

Industries Served

Several industries depend on track and trace solutions to control their supply chain:

- Manufacturers: As part of manufacturing execution systems (MES), manufacturers can see where any product is during the manufacturing process

- Distributors and repackagers: Since distributors are focused on moving merchandise en masse, it’s important to always know where items came from, where they are, and where they are going to avoid costly delivery errors

- Food service: Food traceability measures have to be compliant with requirements set by the Hazard Analysis and Critical Control Points (HACCP) and the Food Safety Modernization Act (FMSA)

- Pharmacies: Pharmaceutical distribution processes must be compliant with the U.S. Drug Supply Chain Security Act (DSCSA), Drug Enforcement Agency (DEA), and Food and Drug Administration (FDA), which requires detailed traceability measures for the transport and sale of all medications and controlled substances

- Dispensaries: Like pharmacies, dispensaries face strict regulations for distribution and need accurate track and trace methods to show compliance with all local safety requirements