The Best Warehouse Execution Systems (WES)

Get the best software for your business. Compare product reviews, pricing below.

What are Warehouse Execution Systems?

Warehouse execution systems (WES) are logistics software suites made for managing on-site product picking, distribution and storage. While this software is primarily used by distributors, manufacturers also use WES to automate product assembly processes and handle raw materials. WES works with warehouse management systems (WMS) to provide better warehouse operations.

Similar to a manufacturing execution system (MES), WES software provides vital logistics for on-site operations. However, WES is based around warehousing and distribution scheduling while MES is strictly for controlling manufacturing shop floors. Additionally, WES software can be used to supplement enterprise resource planning (ERP).

Features of Warehouse Execution Systems

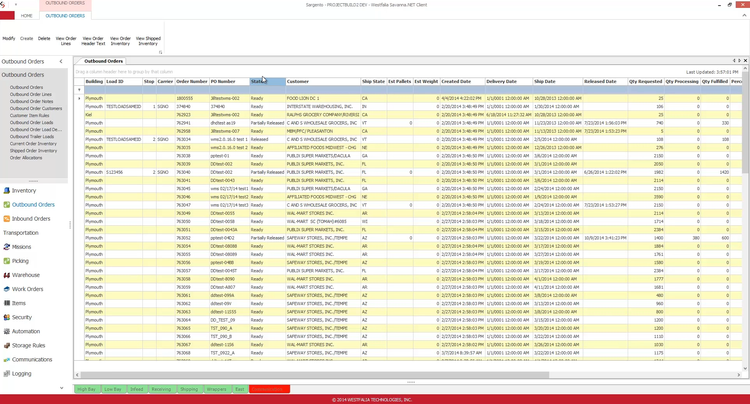

- Scheduling: Accurately schedule material and product arrivals with outgoing order distribution. Also coordinate wave picking schedules to ensure machines and personnel are operating at full capacity.

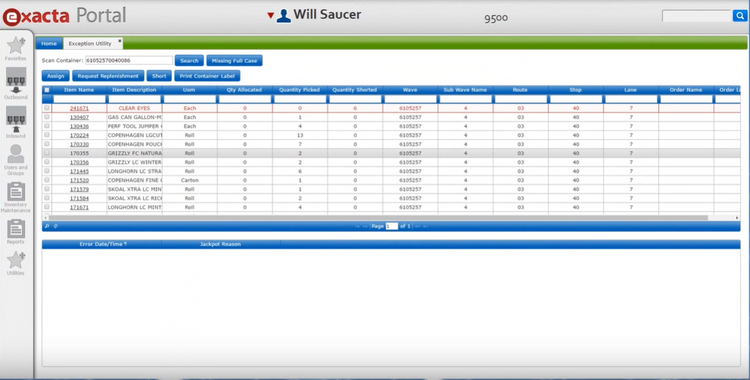

- Inventory traceability: Keep real-time data on inventory levels within the warehouse using barcodes, RFID, or other organizational systems. This also tracks damaged or recalled products.

- Automated storage and retrieval systems (AS/RS) compatibility: Products are moved through the warehouse by machinery through an automated system to cut down on retrieval times.

- Assembly automation: If your warehouse involves processing, use conveyor and machine control to automate product assembly to save time.

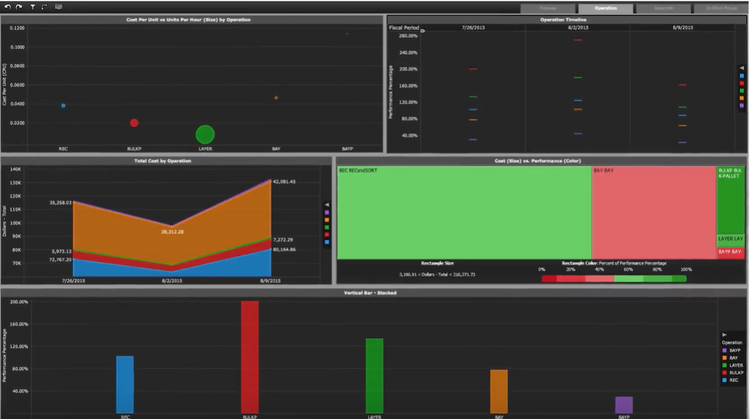

- Analytics reporting: Generate reports from real-time and forecast data to stay up-to-date on warehouse performance.

- WMS and WCS integration: WES software usually includes several warehouse management and control tools for controlling stock as it moves within the warehouse.

Warehouse Execution System Benefits

Using a warehouse execution system can save your business a lot of time and money. Learn about all the benefits of WES:

Better In-House Product Tracking

Many warehouses used to have sortation centers where sorters would manually organize ingoing and outgoing materials. Now, modern warehouse automation has changed that. As a logistics software, warehouse execution systems manage how products and raw materials flow through your facility. Using real-time tracking modules can show how efficiently products are moving into your warehouse.

By knowing your inventory levels in real-time, you can increase replenishment rates by predicting and preventing shortages. Whether you’re dealing with individual products or bulk cartons on pallets, a warehouse execution system keeps you informed of stock locations and levels.

Product tracking also lets you remove damaged or recalled stock from your inventory as needed.

More Efficient Processing

When WES is used for manufacturing operations, the features can improve the assembly process. By making it easier to track within the warehouse, you can organize the placement of each required piece to streamline the construction process.

Streamline your material handling system by using WES solutions. Know when new shipments of raw materials or components are coming in so you can ensure material handling equipment is available right away.

Improve Order Accuracy

Many warehouse execution systems are used to improve outgoing order accuracy by monitoring multiple areas of your facility. When an order is placed, WES tools communicate between various departments to ensure the right products are pulled in a timely fashion for distribution. Traceability measures like barcodes help your personnel and ASRS machinery find what each order needs by scanning, reducing human error when there are similar products in storage.

WES streamline order accuracy by finding the best picking locations for each product. For example, say one of your retail partners sells swimsuits and swim accessories. You notice that most orders for children’s swimsuits overwhelmingly include purchases of swim shoes and goggles. A WES software can identify these trends and suggest new picking locations in the warehouse so that it’s easier for your team to put swimsuits, shoes, and goggles together for the finished order.

Order management is particularly difficult when you work with omni-channel ecommerce retailers. Maintaining an accurate order system prevents delivery delays to your customers. Using the swimwear example, you can use WES tools to determine whether or not it’s faster to send out each product individually or combine them all into one package for delivery. The faster you provide order fulfillment, the more satisfied your customers will be.

Reactive Performance Analytics

There are WES tools which provide real-time analytics of your warehouse stock. If there is a change somewhere along the supply chain, say a raw material shortage or overstock at a retailer, you can use these updates to adapt your system. By adapting your warehouse functionality as soon as possible, you can avoid wasting time and money on reactive solutions.

Labor management also falls under WES functions. Using analytic tools, you can see when and where you should be scheduling staff throughout the warehouse.

WES vs WCS vs WMS

How is Warehouse Execution Different from Control or Management? There are a lot of different systems designed for streamlining warehouses and distribution center operations. WES has some overlap with two types in particular: management and control. Warehouse management systems (WMS) are different because it is designed for managing inventory itself. Warehouse control systems (WCS) are focused on real-time operations within the warehouse or distribution center and are designed to work with WMS applications.

Fortunately, WES can integrate with both WMS and WCS to fully optimize your warehouse operations, in addition to ERP. While there is some overlap, WES is intended to fill in any gaps from WMS and WCS software.