The Best Automotive ERP Software

Automotive ERP software manages production planning, inventory control, and order tracking in the automobile industry. We tested various systems that cater to parts manufacturers, tiered suppliers, and aftermarket distributors.

- Open architecture for rapid integrations

- Multi-entity support

- Mobile accessibility

- Mostly straight-forward and user-friendly

- Built with over 40 years of manufacturer and distributor expertise

- Integration with AI, MI, IoT, and Cloud-hosting

- Reduced IT Dependency

- Continuous support and updates

- Industry specific to Automotive

We used our software review methodology to select the best systems, including Acumatica, SYSPRO, xTuple, and Epicor Vision.

- Acumatica: Best for Automotive Parts Manufacturers

- SYSPRO: Best for OEM Suppliers

- xTuple: Best for Small to Mid-sized Manufacturers

- Epicor Vision: Best for Aftermarket Distributors

- Infor CloudSuite Automotive: Best Specialty Vehicle Suppliers

- QAD ERP O³: Best for Tiered Suppliers

- DELMIAWorks: Strong Manufacturing Intelligence

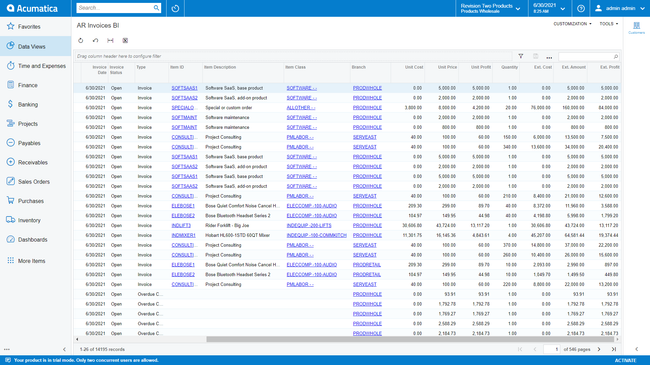

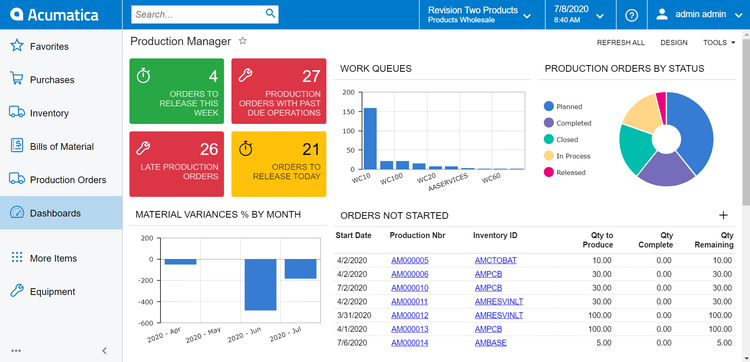

Acumatica - Best for Automotive Parts Manufacturers

Acumatica’s spare parts management can help streamline tracking, procurement, storage, and distribution. The system provides real-time visibility into parts inventory across multiple warehouses, giving you instant updates when components are moved, consumed, or restocked.

For example, you may specialize in producing and distributing parts such as brake pads, filters, and transmission components to B2B and B2C customers. Using Acumatica’s barcode scanning tool, you can log these items into your inventory as they arrive. Each part will be assigned a lot number and bin location for easy retrieval.

As your team consumes components for manufacturing or customer orders, the system will update inventory levels in real time. If stock levels fall below a predetermined threshold, Acumatica’s demand forecasting engine triggers an alert or automatically creates a purchase order to replenish the inventory.

Suppose a customer issues a recall on a batch of brake pads due to a suspected defect. In that case, you can use Acumatica’s lot tracking feature to identify all buyers who received the affected batch. The system flags any products with shelf life limitations, like brake fluids, when they near expiration. The software will prioritize these for shipping in upcoming orders, reducing waste while ensuring customer satisfaction.

Acumatica’s average pricing ranges from $2,800 to $6,500 per month This can be a bit pricier than systems like xTuple, which is $175/month, or SYSPRO, starting at $199/user/month.

For more information on Acumatica’, check out our review page.

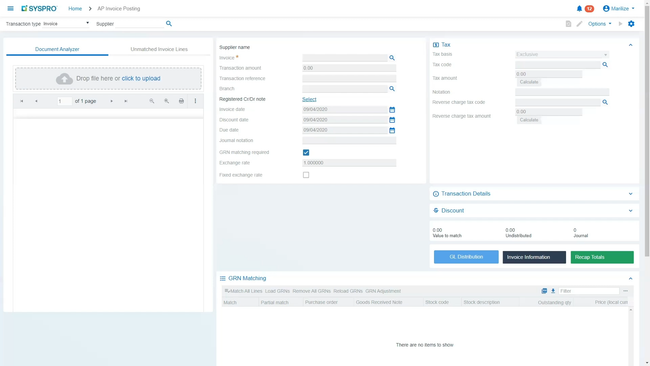

SYSPRO - Best for OEM Suppliers

SYSPRO’s engineering change control (ECC) feature allows you to track and manage engineering changes across a product’s lifecycle. It ensures that modifications to product designs, BOMs, and production processes are documented, approved, and implemented in a controlled manner.

For instance, you supply automotive components and produce a sub-assembly for an electric vehicle manufacturer. They request a design change to the sub-assembly that will improve overall energy efficiency, which involves replacing a part with a lighter material.

The EV manufacturer will send a change request, and your team can initiate an ECC process in SYSPRO to assess the modification. The system will evaluate your current inventory to determine if the new material is available and will calculate the cost of the impact of using the new material versus the existing one.

You can send the change request to the stakeholders for review and approval. The system documents any concerns in the workflow. After approval, the ECC feature automatically updates the BOM for the sub-assembly with the new material. SYSPRO adjusts inventory levels and generates procurement orders for the new component if needed. It also updates production schedules to reflect the change.

The system stores a detailed record of the change, including details on who approved it and when, ensuring compliance with industry standards and traceability. This way, you can successfully implement the design change without disrupting your production timelines.

To learn more about SYSPRO, read our full review.

xTuple - Best for Small to Mid-sized Manufacturers

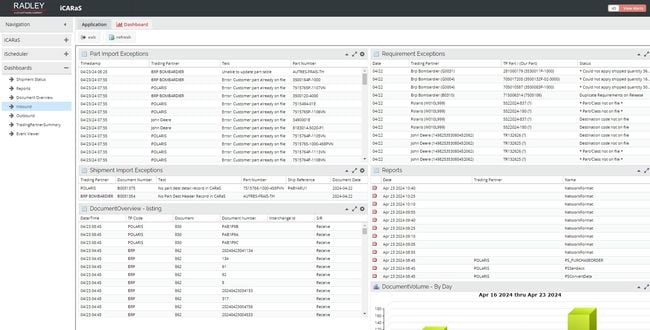

xTuple offers an EDI automotive-specific integration, iCARaS, designed to facilitate seamless communication and data exchange between automotive manufacturers and their supply chain partners.

This integration allows you to automatically send and exchange key documents, such as purchase orders, shipping notices, and invoices. It also supports ANSI X12 and EDIFACT standards, ensuring compatibility with global trading partners.

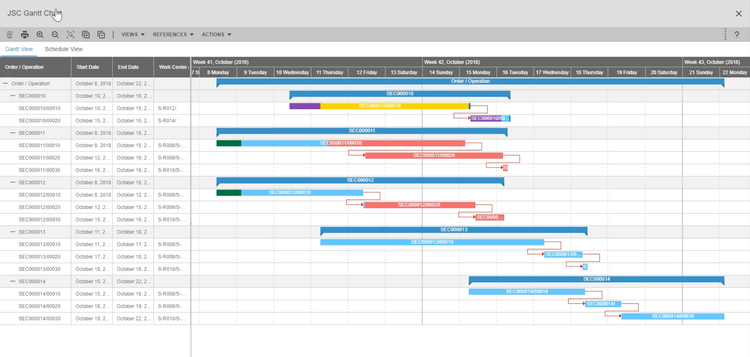

xTuple’s production scheduling feature supports the precision automotive manufacturers require to meet tight deadlines and manage complex supply chains. Its Gantt charts and calendars give you a clear view of production timelines, ensuring seamless coordination of tasks between multiple departments.

xTuple can integrate data from various departments, including inventory, sales, and procurement, to create a production plan. It will then analyze current orders, resource availability, and deadlines to create a detailed schedule that continuously updates as new information becomes available.

For example, you receive a rush order for custom brake assemblies. Your sales team will enter the order into xTuple, specifying the quantity and due date. The production scheduling tool will check the availability of raw materials, labor, and machine time. Since this is a high-priority order, the software will change the schedule to ensure that you complete this order on time. It will assign the necessary machines and workforce to the order and automatically notify the team’s leads of the change.

xTuple is our most affordable pick, starting at $175/user/month. This affordable price and manufacturing-specific features make it suitable for small to midsize manufacturers.

For more information on xTuple, visit our review page.

Epicor Vision - Best for Aftermarket Distributors

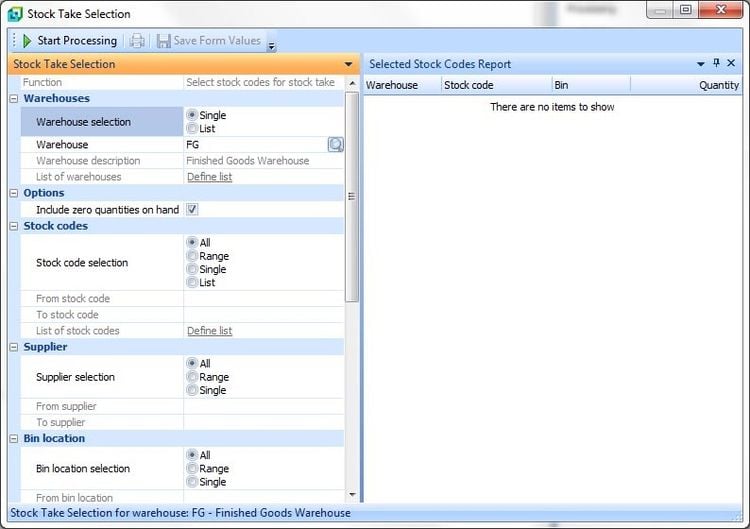

Epicor Vision’s multi-warehouse management feature allows you to manage inventory and operations efficiently. This capability can help you easily track stock availability, reducing overstock and stockouts.

Epicor’s data tools can help you stay ahead of fluctuating customer demand through its centralized visibility into replacement parts and accessories. You can use these dashboards to track your inventory levels across multiple locations and generate inter-warehouse transfers to rebalance your inventory. Epicor can also integrate demand forecasts and sales trends, helping you reduce stockouts and overstock situations that are common in fast-paced aftermarket sectors.

When a customer places an order, the system evaluates the most efficient warehouse for fulfilling the request. This evaluation includes stock availability, proximity to the customer, and delivery timelines. Once Epicor Vision chooses a warehouse, it’ll send the order details to the appropriate location for picking, packing, and shipping. You can also set replenishment triggers and transfer schedules to balance your inventory between your locations.

Infor CloudSuite Automotive - Best Specialty Vehicle Suppliers

Infor Cloudsuite Automotive’s Just-in-Time (JIT) manufacturing tool ensures that the parts you need are on hand to meet production demands. The JIT capability helps synchronize production schedules with demand forecasts and supplier deliveries, minimizing overstock and production delays.

Its JIT manufacturing functionality relies on real-time data and advanced scheduling tools to synchronize production activities with customer demand. The software will pull information from orders, production schedules, and supplier data to create a lean workflow where materials and components arrive just as they’re needed for assembly.

Let’s say you specialize in manufacturing custom ambulances, each requiring a unique configuration based on client requirements, such as layout design and medical equipment. A hospital places an order for five ambulances. The ERP will capture and translate the order into a detailed production plan.

The system will schedule the arrival of specific parts, such as medical-grade oxygen tanks and electrical wiring, that align with your production timeline. It will also communicate with your suppliers to ensure timely delivery.

Instead of holding excess stock, the materials will arrive exactly when assembly begins. If your client changes specifications midway, the software can update production schedules and adjust supplier orders in real time to accommodate the new requirements.

QAD ERP O³ - Best for Tiered Suppliers

QAD ERP O³’s supply chain planning feature uses historical data, market trends, and real-time analytics to optimize manufacturing schedules, inventory levels, and procurement plans. For tiered suppliers, accurate demand forecasting is vital, minimizing stockouts or overproduction that could disrupt multiple supply chain layers.

The software integrates with ERP modules to pull data on customer demand, inventory, production output, and supplier performance. QAD analyzes the statistics using AI-driven algorithms to anticipate material shortages and adjust capacity planning. The system will continuously provide updates based on real-time figures from suppliers, production facilities, and customers.

QAD also has supplier portals that allow seamless communication and help reduce lead times and errors. These are particularly valuable for tiered suppliers, allowing them to collaborate efficiently across complex supply chain networks. However, QAD is our priciest software choice, starting at $4,000/month. This price will vary depending on the number of users and your deployment option. If this is too steep for your budget, consider a more affordable alternative like DELMIAWorks.

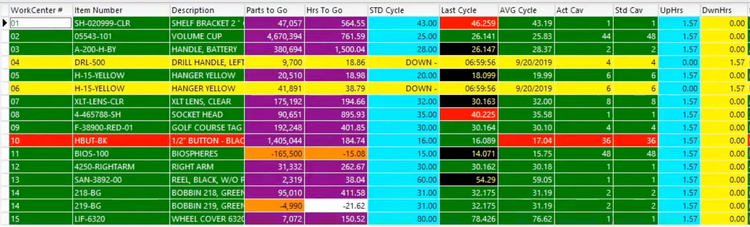

DELMIAWorks - Strong Manufacturing Intelligence

DELMIAworks’ OEE monitoring feature collects data directly from machines, sensors, and operators, ensuring accurate tracking of production metrics. This tool aggregates data from production machinery, IoT devices, and software inputs to measure three key components:

- Availability: Monitors uptime versus planned production time, identifying reasons for downtime, such as machine maintenance.

- Performance: Compares the current output to the optimal production speed, detecting issues like bottlenecks and slow cycle times.

- Quality: Tracks the ratio of suitable units produced to the total output, pinpointing issues like high defect rates.

You can view this data through dashboards, allowing you to spot inefficiencies and implement corrective actions quickly. For instance, you decide to track the performance of your CNC machines and notice that one is performing at 80% due to worn tooling.

Your maintenance team can then schedule preventative maintenance based on these insights to ensure reduced downtime. Engineers can recalibrate the problematic production line to improve product quality and reduce scrap rates.

DELMIAWorks pricing starts at around $250/user/month with a minimum of five users, making it an affordable solution compared to QAD and Acumatica.

For more insights on DELMIAworks, read our full review.

What is Automotive ERP Software?

Automotive ERP software is a business management solution designed specifically for companies in the automotive industry, including parts manufacturers, tiered suppliers, OEMs, distributors, and retailers. These systems integrate and streamline various processes across departments, like manufacturing, supply chain, inventory management, sales, finance, and customer service.

This type of software can enhance productivity, improve visibility, and ensure compliance with industry standards. Key factors specific to this sector include production planning, quality management, demand forecasting, and product lifecycle management.

Common Challenges

- Supply Chain Disruptions: The automotive industry relies heavily on a global supply chain, susceptible to delays and shortages. An ERP system can provide real-time visibility, enabling you to identify potential disruptions early on, optimize procurement, and maintain safe stock levels.

- Quality Control and Compliance: Ensuring product quality is crucial, especially with strict regulations like IAFT 16949, ISO 9001, and environmental standards. Having a system with compliance tracking can ensure you stay within regulatory requirements and provide visibility into defective parts and their origins.

- Demand Planning: Demand can fluctuate due to seasonal factors, consumer preferences, and economic changes. An ERP software uses historical data and analytics to help you accurately predict future market behavior and avoid overproduction or shortages.

- Cost Control: Rising material and labor costs make it challenging to maintain profitability. ERP solutions provide detailed cost tracking, allowing you to analyze production expenses, identify inefficiencies, and optimize resource allocation.

Key Features and Benefits

- Production Scheduling: Offers just-in-time (JIT) and just-in-sequence (JIS) capabilities for efficient production and reduced inventory costs. Provides visibility of manufacturing processes, labor tracking, and machine utilization.

- Supply Chain Collaboration: Features real-time collaboration tools for communicating with suppliers, OEMs, and Tier 1/2/3 partners.

- Traceability and Lot Tracking: Provides end-to-end traceability for raw materials, components, and finished goods. Tracks lot and serial numbers throughout production to manage recalls efficiently.

- Quality Management: Offers features for automated inspections, tracking non-conformance, and ensuring compliance with industry standards like ISO/TS 16949 or IATF 16949.

- Bill of Materials (BOM) Management: Supports multi-level and dynamic BOMs, like variant and model-specific, to handle complex automotive components and configurations.

- Aftermarket Support: Manages aftermarket parts, warranties, and repairs. Integrates with CRM systems for customer service and warranty claims.

- Global Operations Support: Supports multi-currency, multi-location, and multi-language capabilities for global operations.

Pricing Guide

| Software | Best For | Deployment Options | Starting Price |

|---|---|---|---|

| Acumatica | Automotive Parts Manufacturers | Cloud, On-Premise | $2,800/month |

| SYSPRO | OEM Suppliers | Cloud, On-Premise | $199/user/month |

| xTuple | Vendor and Supplier Management | Cloud, On-Premise | $175/user/month |

| Epicor Vision | Aftermarket Distributors | Cloud, On-Premise | N/A |

| Infor Cloudsuite Automotive | Specialty Vehicle Suppliers | Cloud | N/A |

| QAD | Tiered Suppliers | Cloud, On-Premise | $4,000/month |

| DELMIAWorks | Manufacturing Intelligence | Cloud, On-Premise | $250/user/month |

Automotive ERP software can cost between $170 and $6,500 a month. xTuple is our most affordable solution, starting at $175/user/month, and SYSPRO is similar in price, beginning at $199/user/month. On the other hand, Acumatica and QAD are our most costly choices, with prices ranging from $2,800 to $6,500/month.

It’s important to remember that these are ballpark pricing estimates, and some developers will not provide exact estimates on their websites. Pricing can vary depending on the number of users, deployment options, and if you require any additional capabilities.