The Best Order Fulfillment Software

Order fulfillment systems streamline workflows to ship the most amount of goods in the quickest amount of time. This guide reviews the top software for 3PLs, wholesalers, and eCommerce brands.

- Integrates with major eCommerce platforms

- International fulfillment services

- Facilitates batch order management

- Multi-warehouse inventory visibility

- Native warehousing mobile app

- Automated PO creation

- Simple interface

- iOS and Android apps

- Wide variety of add-ons

Whether you operate your own warehouse or use third-party logistics providers, these platforms help increase efficiency and automate your fulfillment process.

- ShipBob: Best for DTC eCommerce

- Extensiv: Best for 3PLs

- Zoho Inventory: Best for Wholesalers

- Acctivate: Best for QuickBooks Users

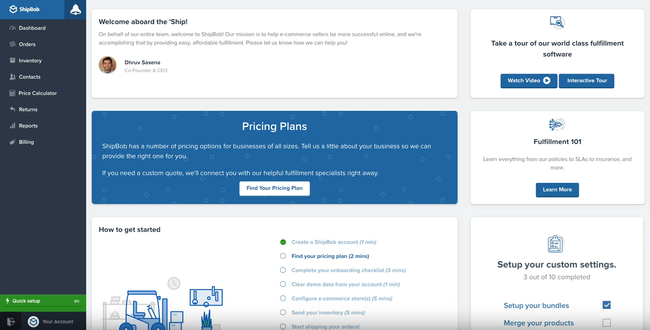

ShipBob - Best for DTC eCommerce

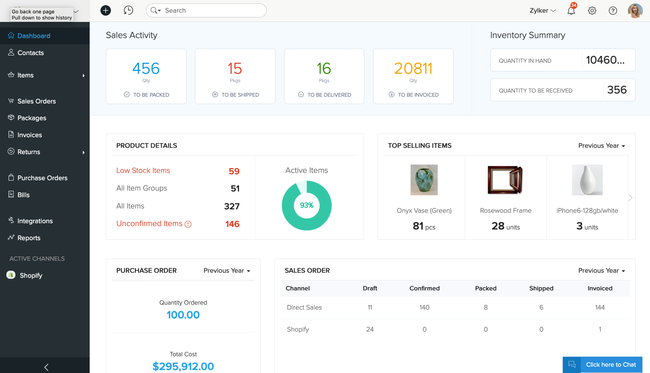

ShipBob offers growing brands with increased order volumes a distributed inventory feature, designed to speed up deliveries. The software allows you to store and monitor stock across multiple fulfillment centers with its extensive network. You’ll also receive reorder alerts to proactively manage slow-moving or out-of-stock items.

The software even evaluates customer order patterns to recommend how to best split inventory geographically. The system’s algorithm selects the nearest fulfillment center and most affordable carrier for that location. It then dynamically calculates shipping routes for both ground and air carriers.

This strategic placement means you can provide two-day express shipping across the continental US. This helps you minimize cart abandonment and increase order value, which is critical when you’re competing with giants like Amazon.

ShipBob now operates a quote-based model. However, they originally quoted receiving fees starting at $35 for the first two hours, monthly storage fees ($5 per bin, $10 per shelf, and $40 per pallet), and standard pick and pack services, with the first four picks per order for free. For initial implementation costs and exact pricing, you’ll need a custom quote.

See our full review of ShipBob for more details.

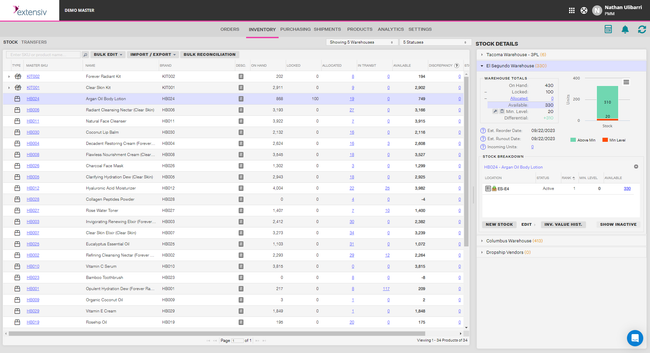

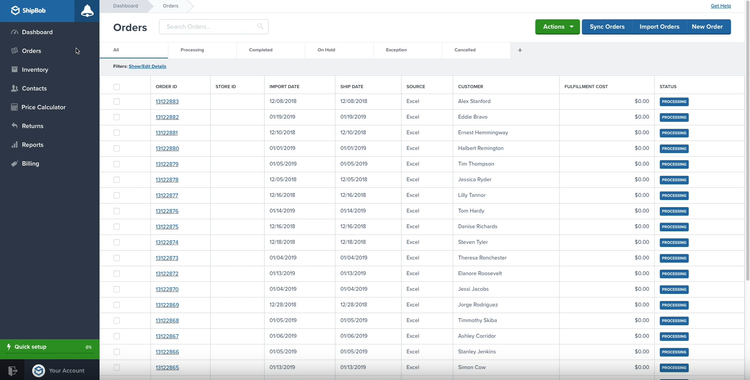

Extensiv - Best for 3PLs

Extensiv, formerly Skubana, is ideal for companies with multi-warehouse operations and diverse client portfolios. Its order routing and automation feature integrates with over 150 leading platforms, like Shopify and BigCommerce, to centralize order data. It then delivers live tracking through various phases like picking, packing, and shipping.

You can customize routing criteria by client priorities and preferred carriers, ideal for simplifying numerous fulfillment strategies. What’s more, Extensiv dynamically allocates orders to the best location based on stock levels, customer proximity, and shipping costs.

This system includes intuitive dashboards to depict fulfillment progress across several client accounts and locations so you can quickly pinpoint and address bottlenecks. Additionally, it combines inventory data across all warehouses to prevent duplicate orders and over-promised shipments. Low stock levels trigger notifications to reroute or split orders as needed. Once routed, orders auto-generate pick tickets and notify warehouse staff to begin processing, critical when you’re balancing high order volumes and diverse SKUs across multiple clients.

Pricing for Extensiv starts at $399/month, though it varies based on your user count, order volume, and specific business requirements.

View our Extensiv Order Management profile for pricing and key features.

Zoho Inventory - Best for Wholesalers

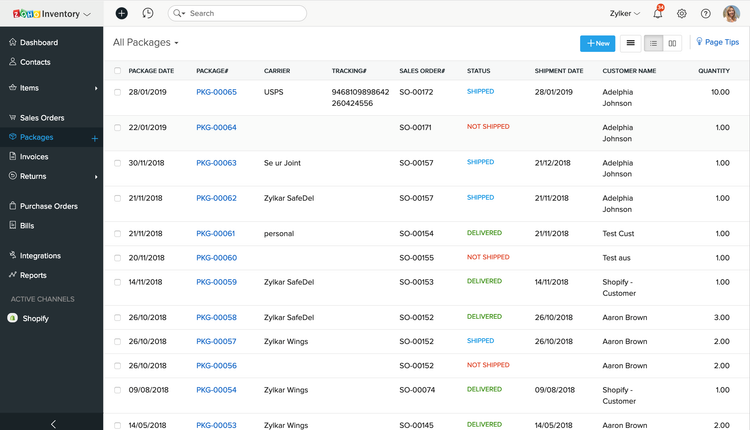

Zoho Inventory is ideal for businesses managing a high volume of shipments with diverse carrier needs. The system integrates with UPS, FedEx, and DHL for faster rate comparison and shipment generation. This saves you from having to log into different carrier systems, allowing you to choose the best option for each order based on cost, delivery time, or other priorities.

With a built-in verification system, Zoho Inventory ensures addresses are accurate before processing shipments, minimizing delivery errors and aligning with carrier requirements. Plus, you can consolidate orders into multi-package shipments or split them based on inventory availability, providing clear tracking regardless of the carrier you pick.

You can generate labels directly within the software and access flexible billing options. Easily assign shipping costs to your company, the customer, or a third party, ideal for B2B arrangements. While Zoho offers a free option, we recommend getting a paid plan starting at $29/month billed annually. This will give you access to multi-location warehousing, multi-user support, and integrated shipping labels for scaling wholesale operations.

Read our full Zoho Inventory to learn more.

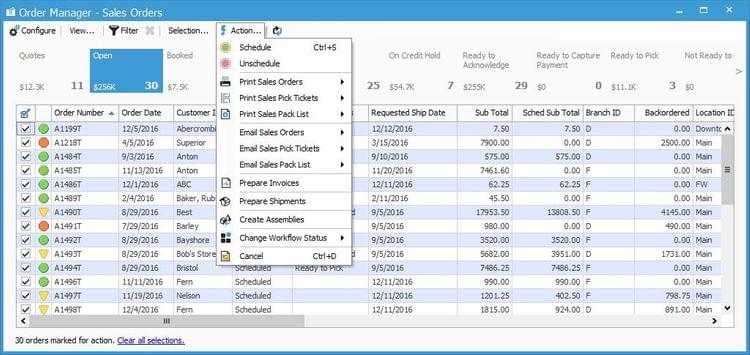

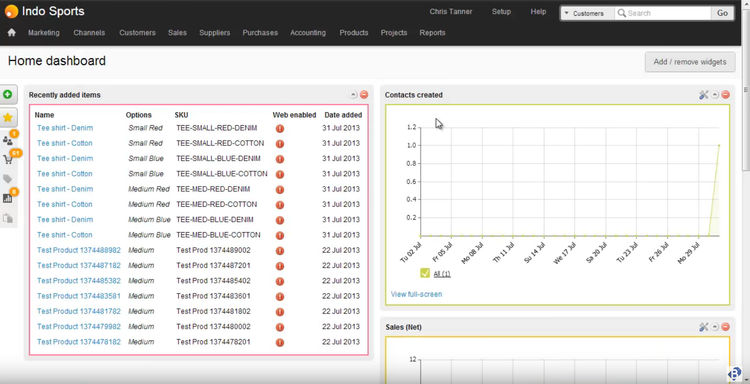

Acctivate - Best for QuickBooks Users

Acctivate is purpose-built for distributors and growing businesses that want to keep QuickBooks, but need stronger tools for managing inventory and fulfillment. It adds batch picking, barcode scanning, and backorder tracking, without requiring you to abandon your existing accounting setup.

Because Acctivate syncs directly with QuickBooks, it eliminates double entry for orders, sales, inventory, and customers. From a single dashboard, users can track order statuses, generate purchase orders, and set fulfilment priorities, ensuring high-value and time-sensitive orders ship first.

The platform also supports complex workflows like lot and serial tracking, kitting, and EDI, making it a scalable choice for distributors with evolving needs. For shipping, Acctivate integrates with UPS, FedEx, USPS, and even LTL carriers to automate rate shopping, label creation, and tracking updates.

Pricing starts at $5,995 for initial license and implementation, along with a $5,000/year support plan. The initial setup and ongoing costs increase for more advanced plans and complex setups.

Want to learn more? Read our full review on Acctivate

What Is Order Fulfillment Software?

Order fulfillment software helps automate and coordinate the steps between receiving a sales order and getting products into your customers’ hands. This includes managing inventory levels](/roundups/best-inventory-management-software/#buyers-guide), picking and packing items, printing shipping labels, and tracking deliveries. These systems use automation rules to streamline routine decisions, such as how orders are prioritized or which warehouse should fulfill them, so your team can operate efficiently at scale.

Most order fulfillment platforms integrate with your eCommerce systems, allowing you to sync incoming orders, create purchase orders, process returns, and track shipments from a single dashboard. Fulfillment tools may also be included within broader supply chain management software if you need capabilities like demand forecasting or advanced logistics.

Key Features

-

Order Management: Manages receiving, tracking, and fulfilling customer orders across multiple sales channels. Tracks all shipments and pushes tracking details to customers. Automates decision-making on approvals, backorders, and processing logic.

-

Inventory Control: Tracks stock levels in real time, triggers low-stock alerts, and links with purchase order systems to replenish goods. Supports UPCs, serial numbers, lot tracking, and barcoding for accurate inventory movement.

-

Warehouse Management: Identifies the most efficient picking method based on your layout, inventory availability, and order load. Generates detailed pick lists with order numbers, SKUs, product locations, and item descriptions.

-

Kit Assembly: Combines multiple components into a finished kit for sale or distribution. Helps plan, track, and assemble items for bundling or promotional fulfillment.

-

Returns Management: Handles product returns, including restocking workflows, return shipping labels, and inventory adjustments. Ensures goods are routed to the correct warehouse or disposition site.

-

Shipping Label Creation: Generates compliant shipping labels with origin, destination, weight, and tracking info. Supports major carriers like UPS, FedEx, and USPS to streamline outbound shipping.

-

Fulfillment Rules: Sets logic to prioritize which orders ship first based on criteria like customer status, warehouse availability, product type, or delivery windows. Helps reduce bottlenecks and meet customer expectations.

-

Sales Channel Integration: Connects with platforms like Amazon, Shopify, and WooCommerce to sync orders, inventory, and tracking. Ensures you fulfill multichannel demand from a unified system.

Benefits

The best order fulfillment software will integrate order management, inventory control, and warehouse management to provide you with a complete fulfillment solution. Some of these basic benefits include lowering your operating costs, eliminating errors, finding new business easier, and more. These benefits can be prioritized however your business needs. Some of the top benefits of these systems include:

Maintain Inventory Accuracy

Order fulfillment software will help track every movement in your inventory. This provides an easy-to-discover audit trail, which internally can let you know which employees were involved with fulfilling orders and how efficient they have been. Externally, clients can keep track of your current and historical inventory levels.

These systems can also track inventory at multiple locations. Whether your inventory will be pulled from a storefront, a back office, ordered from a supplier, or picked directly from your warehouses, order fulfillment systems can help find the most optimal place to grab an item. They can also help transfer items between your physical locations.

Integrate With Your Marketplaces

When you sell items over multiple channels, you’ll need a multichannel sales management tool. Retailers and wholesalers who sell goods in various marketplace stores desire a centralized solution to manage their online sales. Selling your goods on a third-party marketplace can make it difficult to automatically track orders and stock counts.

Many order fulfillment software options will integrate with popular online marketplaces, such as Amazon, eBay, Shopify, and Etsy. This level of integration can provide the following benefits:

- Update stock levels on your selling platforms. This prevents you from having to manually update stock counts after every new order, which can become tedious when a business sells on multiple channels.

- Update your client database. Anytime a new customer purchases from you, their details can be imported into your client database, which can create a customer profile for this customer.

- Centralize all orders. Rather than having multiple marketplace ledgers to look into, centralize all of your daily, weekly, and monthly sales into one unified screen to better analyze and understand company profit.

For eCommerce businesses that strictly sell on one marketplace, you may be better off looking into a solution intended for that specific outlet, such as accounting software for Amazon sellers.

Track Shipments With Your Carriers

Order fulfillment software can integrate with shipping carriers and help manage your shipping via shipping label generation, real-time shipping cost shopping, tracking information, and post-shipment updates. These integrations can ensure the correct shipping method is used and that the correct postage and labeling are applied to all orders.

Communication can also be given to each customer to inform them of the carrier being used and any tracking details that will let them track their shipment. Internally, it can ensure that proper details on the item weight, value, and more are communicated to the shipping carrier so appropriate priority can be assigned.

Whether you use FedEx, USPS, UPS, DHL, or others, numerous order fulfillment and WMS options can help you calculate the best rates, track packages, receive address verification, and more.

Pricing

The price of cloud-based order fulfillment software starts as low as $9.99/month for a product such as ShipStation. For locally installed options, a simple order fulfillment solution such as Pomodo can be found as low as $119/month. For more advanced options, solutions can range as high as $135/month (Megaventory) or up to $1,995/month (ShipHero). These ranges don’t take into account the costs of any needed services, such as implementation and training.

The cost of order fulfillment software is typically based on the:

- Number of warehouses

- Number of needed users

- Number of orders processed each month

- The size of the inventory

Some solutions can take all of these variables into account and create unique pricing for your business model.

For example, a solution such as Shipmonk will price their software based on:

- The type of fulfillment needed (eCommerce, retail, amazon, etc.). This will have the biggest effect on the item per order cost, as shipping different types of items will cost different prices.

- The number of orders processed per month. The first item pick fee is $2.50/order. If the order only has one item, this will be the only charge for that order. Additional items per order are picked at $.50/order. Promotional inserts are $.20/order.

- Any needed services. Software providers that also provide fulfillment services may charge you for storage (based on SKUs or according to size), shipping options provided, or additional one-off costs (packaging materials, unloading fees, and more).

What Does Your Business Need?

Depending on your size, your eCommerce fulfillment needs may be different.

Small Businesses

Startups and small operations should consider finding an eCommerce fulfillment option that will integrate with existing technology, such as any small business accounting software. Having a solution that can add to your existing infrastructure can help ease you into the world of fulfillment and provide a low-cost way of doing so.

Many cloud-based options have little to no upfront costs and can provide you with the same functionality many larger solutions offer (at a limited clip, such as being restricted as to how many orders you can fulfill each month).

Mid-Sized Operations

A growing business looking to become a more efficient supply chain operation will want to find a fully integrated option to meet its needs. At this size, you’ll want to ensure all incoming orders from all your channels are combined into one area, which will let you easily edit orders, manage returns, and communicate shipping updates.

Large Enterprises

Large businesses looking to automate their order fulfillment process will first want to ask themselves if what they truly need is an order fulfillment software or a supply chain management ERP software. Some may use the term synonymously, but many ERP-level options can be bought as order fulfillment software.

A large enterprise will want to ensure that any order fulfillment option includes advanced eCommerce capabilities for building a brand identity, processing a large volume of orders when operating at full capacity, and giving their customers a 24/7 portal for orders, updates, invoicing, and support.

Does QuickBooks Handle Order Fulfillment?

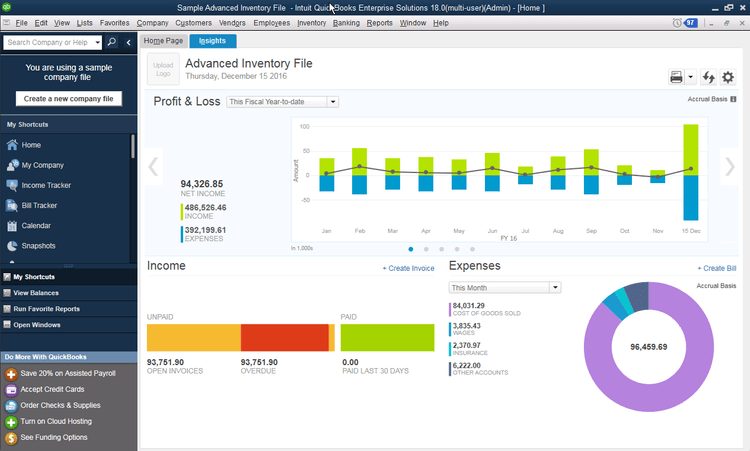

Newer versions of QuickBooks Enterprise (18.0 and later) have a sales order fulfillment worksheet, which helps create a workflow for efficient order fulfillment. This is only if you have enabled the Advanced Inventory preference. Users can manage and fulfill orders within the Customers menu. This newer feature works alongside the existing order entry, order update, and order tracking features already offered with varying levels of QuickBooks.

Even newer versions of QuickBooks Enterprise (19.0 and beyond) have access to the “Pick, Pack, and Ship” feature. This enhancement tool provides a dashboard intended to help increase speed and accuracy in your order fulfillment process. The pick tab can let you view and manage your pick lists. Once created, you can track their status in your warehouse with proper updates.

Outgrown QuickBooks?

Alternatively, there are many solutions that provide advanced inventory and order fulfillment capabilities that will integrate with the accounting side of QuickBooks. One example is Acctivate, which markets itself as “QuickBooks Inventory Management Software”. Core capabilities include inventory, order management, and purchasing. The appeal of these solutions is for businesses comfortable with QuickBooks as their primary accounting option but feel they’ve outgrown their distribution and fulfillment features.