The Best Warehouse Order Picking Software

Picking and packing items can be a lengthy process that leads to mistakes in your inventory. We tested and ranked the best systems for eCommerce retailers, wholesale distributors, and manufacturers to help you find the best system that meets your needs.

- Integrates with major eCommerce platforms

- International fulfillment services

- Facilitates batch order management

- Integrates with QuickBooks to monitor supply chain and sales

- Automate inventory counts

- Multiple pricing plans

- Competitive pricing; does not require a subscription

- Integrates with QuickBooks

- Can function as a light MRP system

To help you choose the right solution for your business, we used our review methodology to rank the best software on the market today.

- ShipBob: Best for eCommerce Integration

- HandiFox: Best for QuickBooks Integration

- Fishbowl Inventory: Best for Inventory Management

- Cin7 Core: Best WMS Mobile App

- PickRight: Best for Hands-Free Scanning

- Finale Inventory: Most User-Friendly

- Veeqo: Best for Shipping

- ShipHero: Best for Packing

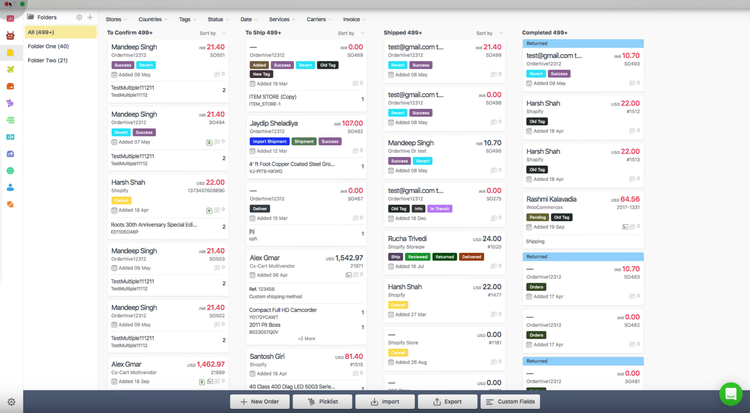

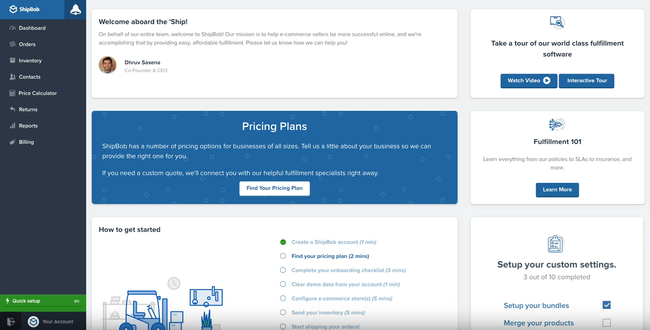

ShipBob - Best for eCommerce Integration

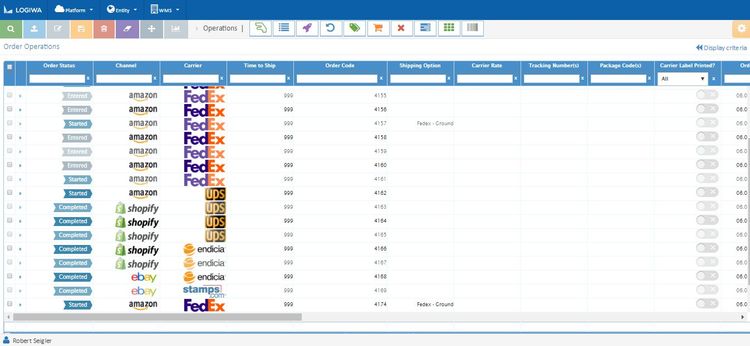

ShipBob’s offers several eCommerce integrations, connecting with popular platforms like Shopify, Amazon, and WooCommerce. This streamlines fulfillment by automatically transferring orders from your online store to ShipBob’s platform, reducing manual data entry and ensuring real-time updates on order statuses.

This integration consolidates orders from multiple eCommerce platforms into one consolidated dashboard, eliminating the need to check each platform individually. As orders come in, the system will create pick lists that can help your team with quick and efficient product retrieval. As you fulfill orders, ShipBob will automatically update stock levels across your integrated platforms, helping prevent stockouts or overselling.

When orders are packed and shipped, the system will send shipping confirmations directly to your customers. This level of automation helps reduce errors while speeding up order processing, helping you maintain a competitive advantage in the fast-paced eCommerce landscape.

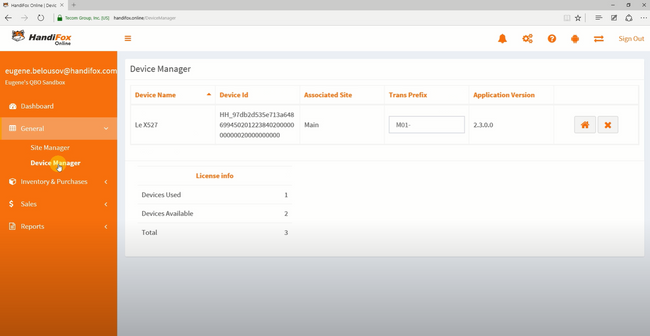

HandiFox - Best for QuickBooks Integration

HandiFox is an inventory management software with order picking functionality. It is particularly suited for those warehouses that rely on QuickBooks for accounting purposes, as HandiFox offers direct integration. This integration allows for effective management of inventory, sales orders, and invoices.

The HandiFox mobile platform facilitates inventory management on the go, making it convenient for businesses with remote sales teams or those needing to manage inventory across multiple locations. The app even syncs with QuickBooks to make real-time inventory management updates.

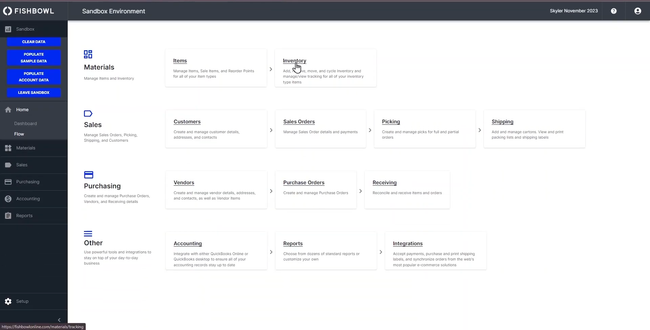

Fishbowl Inventory - Best for Inventory Management

Fishbowl Inventory is a scalable warehouse management software that is particularly well-suited for growing businesses requiring advanced inventory management capabilities. It offers a wide range of features tailored to various aspects of inventory management, including parts tracking and purchase order management. This makes it ideal for businesses with complex inventory needs such as those with FDA or USDA audit requirements for traceability.

Fishbowl’s extensive reporting options, covering aspects like accounting, purchase orders, sales orders, and bill of materials, are highly beneficial for businesses looking to analyze data and make process improvements. Its ability to export these reports in various formats like PDF and CSV adds to the convenience and flexibility of the platform.

Cin7 Core - Best WMS Mobile App

Cin7 Core includes a warehouse management system (WMS) mobile app that can help optimize your pick, pack, and ship operations. Your team can use Bluetooth scanners or iOS and Android devices to track stock locations and fulfill orders. Cin7 Core supports serial and batch tracking, which can help reduce errors and update inventory in real time.

The app also includes directed putaway, which automatically assigns storage locations based on predefined rules, like shelf space and demand frequency. Additionally, Cin7 Core prioritizes order fulfillment based on first in, first out (FIFO) or other predefined picking methods. This ensures you use older stock first, guiding pickers to the right batch or lot for a smooth inventory flow.

This WMS mobile app makes it easy to manage stock movements between different sites, so you can always ensure accurate allocation. With access to inventory tracking on the go, you can see your warehouse processes from anywhere. The WMS mobile app is available even in the lowest pricing tier at $349/month.

PickRight - Best for Hands-Free Scanning

PickRight by ProCat Distribution Technologies’ hands-free barcode scanning technology and user-friendly interface contribute to its standout features, making it a top pick amongst warehouse order picking solutions. One of the key strengths of PickRight is its ability to improve picking accuracy through an intuitive feedback system: correct picks are acknowledged with a chime, while incorrect picks trigger a buzz alert. This immediate feedback helps correct picking errors.

PickRight also has features like batch picking, team picking, zone picking, and real-time pick shift status reports. These tools provide valuable insights into the performance of individual employees and the overall picking process at each warehouse location.

Finale Inventory - Most User-Friendly

Finale Inventory is particularly well-suited for established retailers, wholesalers, distributors, and eCommerce sellers. This is due to its flexibility in handling items with serial numbers, and its compatibility with various systems and platforms to support barcoding, custom reports, and multi-channel eCommerce. Integration with platforms like ShipStation adds significant value for users who require real-time inventory updates.

Finale Inventory offers an accessible cloud-based interface that can be used from a web browser or Android-compatible mobile devices. This ensures that users have a consistent view of inventory records from any location. Additionally, we found the system easy to learn and use, with free training demos and a dedicated help center available to guide new users through various processes.

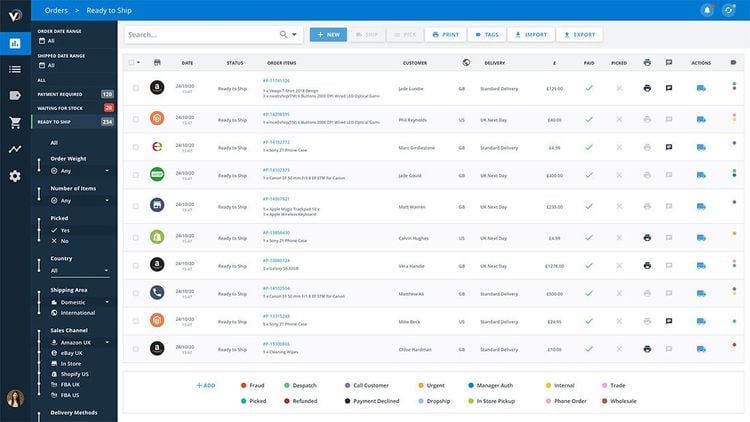

Veeqo - Best for Shipping

Veeqo is divided into two primary functionalities: inventory and shipping. The inventory side offers control over inventory management, including purchasing, product management, inventory insights, and automation. It also supports the use of a barcode scanner and app for enhanced inventory tracking.

The shipping side facilitates efficient order shipping across multiple sales channels, providing features like shipping labels, order management, tracking and returns, and shipping automation. The Veeqo platform is notably efficient in finding the low USPS shipping rates to keep shipping costs down.

ShipHero - Best for Packing

ShipHero warehouse management software includes direct-to-consumer supply chain and eCommerce logistics. Features like inventory management, order management, mobile pick and pack, returns management, and insightful reports, contribute to its suitability for businesses looking to optimize their warehouse operations. And its cloud-based nature allows for real-time syncing of different sales channels.

ShipHero uses AI to provide better packing recommendations and gamifies packing stations to speed up packing tasks. A Hero Board shows the exact number of orders for picking, packing, and shipping each hour so workers can stay focused on what needs to be done.

What is Warehouse Order Picking Software?

Warehouse order picking software expedites and optimizes the product selection process for distributors along the multi-echelon supply chain. Combining warehouse management tools with inventory control and order fulfillment, this standalone software finds, selects, and prepares products for shipping to retailers or directly to consumers.

Sometimes just referred to as an order or picking solution, this distribution software is specifically designed for use in warehouse settings. It accounts for common factors along the supply chain, such as the increasing switch over from traditional static picking methods to automated storage and retrieval systems (ASRS). By using warehouse order picking software, you can adapt your distribution system to fit modern needs.

Features of Warehouse Order Picking Software

- Inventory management and control: Track products stored at your warehouse in real-time to maintain an accurate stock count

- Order management: Receive, track, and fulfill all inbound orders across multiple sales channels

- Barcode tracking: Track item and lot movement throughout the warehouse via barcodes marked with UPCs and serial numbers

- Warehouse management: Create an efficient warehouse picking method to maximize fulfillment speed while optimizing storage space

- Automated pick lists: Send pick lists to warehouse pickers that contain customer info, date and time of order, order number, product location, product SKU, and a description or photo of the item

- Automated notifications: Set custom alarms and notifications for low stock counts in order to restock goods in a timely manner

- Shipping label creation: Print out carrier-compliant shipping labels detailing origin, weight, shipping class, and tracking numbers or barcode details along with destination and return address

- Shipment tracking: Track all shipments and push tracking details to customers

Benefits

By optimizing the order picking process, software helps traditional and eCommerce distributors in a variety of ways:

Create an Organized Warehouse Environment

Misplacing products in a warehouse can lead to lost revenue and unfulfilled orders. Between product racks and staging areas, it’s easy for one item to wind up mixed with the wrong order. Know where products are at all times through tracking tools like barcodes and radio frequency ID (RFID) offered by an order picking system.

Analyzing picking patterns can reveal internal bottlenecks that slow down the entire process. In some warehouses, it may increase productivity to limit travel through certain areas by making one-way picking paths. This can decrease retrieval time while increasing potential storage space.

Easy Integration with Picking Systems

More than ever before, warehouses are turning to automated, robotic picking systems to speed up product retrieval and order fulfillment. Warehouse order picking software is compatible with multiple styles of picking methods. Some of these methods include:

- Order-based picking or discrete order picking: Picks are only performed for a single order at a time, selecting each item and immediately preparing it for delivery

- Cluster picking: Picks are made between multiple orders simultaneously to reduce trips to different pick locations

- Batch picking: Picks are not performed until there are multiple orders for similar products made which can be fulfilled together

- Wave picking: Similar to batch-picking, except performed based on timing throughout the day

- Zone picking: The warehouse is divided into zones, with pickers operating based on which zone each product is located in

Each method has its own advantages and drawbacks. For instance, batch-picking is useful for continually retrieving products which are popular sellers. However, larger facilities may benefit from cluster picking in order to cut down on time repeatedly moving between different areas of the warehouse.

Incorporate Automated Storage and Retrieval Systems (ASRS)

By utilizing a warehouse order picking software, you can incorporate an automated storage and retrieval system (ASRS) into your warehouse processes as well. ASRS uses everything from robotic arms to self-driving vehicles to fully automate as much of the picking process as possible. With order picking software, ASRS can be combined with the above picking methods to best fit your warehouse needs.

For example, if you prefer batch-picking, lift trucks may be necessary to move multiple orders at once. Order-picking software can automate the process of directing the trucks where they need to be to retrieve each product as efficiently as possible. Or, for order-based picking, optimize the route personnel take when retrieving individual items for faster overall fulfillment.

Fewer Delivery Mistakes

Shipping errors can be costly in several ways. First, the wrong order going to a retailer or consumer requires a lengthy returns process. Second, repeated delivery mistakes can lead to reduced trust from previously loyal customers. Finally, the wear and tear of making extra shipments to correct errors can take a toll on your fleet.

Warehouse order picking software assists with deliveries to prevent these errors from occurring. Automated picking processes ensure the right products are collected for each order. Then, custom shipping labels and barcodes accompany the outgoing order through its warehouse journey, from collection to delivery.

A Streamlined Supply Chain

Getting all of these different elements working together can balance the entire multi-echelon supply chain. Using warehouse order picking software to automate your distribution can streamline operations for everyone. Knowing your current inventory means you can keep manufacturers informed of when you are low on stock. In turn, you can let retailers know when to expect shipments.

If your warehouse works with third-party logistics (3PL), an order-picking system can benefit everyone by keeping everyone on the same page. Additionally, you won’t need to hire additional labor when utilizing a seamless, automated system for picking orders.

Common Challenges

Order picking is fairly labor-intensive and error-prone. The right software can minimize order errors, stock misplacement, and shipping inaccuracies.

1 Order Errors & Shipping Inaccuracies

Picking and packing errors can spike return rates and lead to frustrated customers. Barcode scanning and automated picking recommendations help guide your staff to the right items each time.

2 Poor Inventory Visibility

Stock misplacement results in delayed fulfillment, which can introduce bottlenecks to your workflows. Live inventory tracking and directed putaway help your team pinpoint items instantly, reducing unnecessary search time.

3 Inefficient Picking Methods

Approaches like picking one order at a time can also slow fulfillment. Software supporting batch picking, wave picking, and zone picking can optimize movement and reduce travel times between facilities.

4 Limited Employee Training

New employees may struggle to learn manual order picking processes. Cloud-based warehouse software offers a user-friendly interface and guided workflows to help improve picker performance.

5 Lack of Real-Time Data

Without real-time data, warehouse teams work in silos, which can result in miscommunication. This software allows users to access the most up-to-date stock levels, picking assignments, and live reports on productivity and fulfillment speed.

Software and Hardware for Order Picking

Warehouse order picking software is just one element of optimizing your distribution system. Both software and hardware components need to work together to ensure your warehouse operates as efficiently as possible. Physical components for warehouse picking automation systems include:

- Handheld or hands-free barcode scanners

- Voice-picking headsets

- Mobile devices

- Open- and closed-sided shelving

- Horizontal and vertical carousels

- Automatic guided vehicles (AGVs) and autonomous mobile robots (AMRs)

- Vertical Lift Modules (VLMs)

- Robotic shuttles

- Pallet racks and jacks

- Lift trucks

Utilizing automatic and autonomous vehicles can also reduce employee injuries, particularly if your warehouse stores products which are large, heavy, or awkwardly-shaped. Robotic arms can do the heavy lifting, letting personnel stay out of harm’s way. Integrating order picking software with your existing hardware can make your warehouse safe and efficient.