Demand Planning software can leverage the power of AI and machine learning to help businesses forecast demand accurately, plan inventory effectively, and make informed decisions. We used our advanced review methodology to evaluate top solutions for small, medium, and enterprise-level businesses across all industries.

- Anaplan: Best Overall

- e2open: Best for Demand Sensing

- Kinaxis: Best “What-if” Scenario Planning

- Logility: Best for Manufacturing

- RELEX: Best for Retail

- Netstock: Best Integration Options

- SAP Integrated Business Planning: Best Product Ecosystem

- Avercast: Best Customization Options

- Intuendi: Cloud Deployment

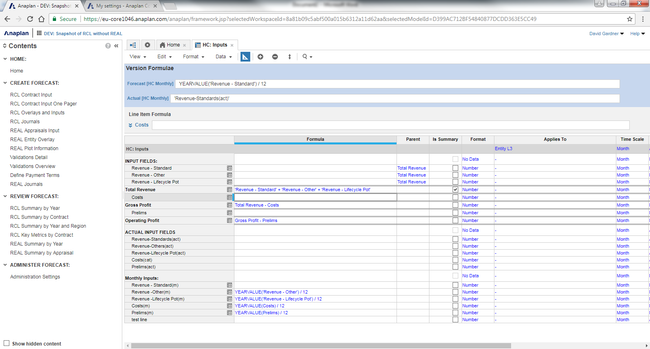

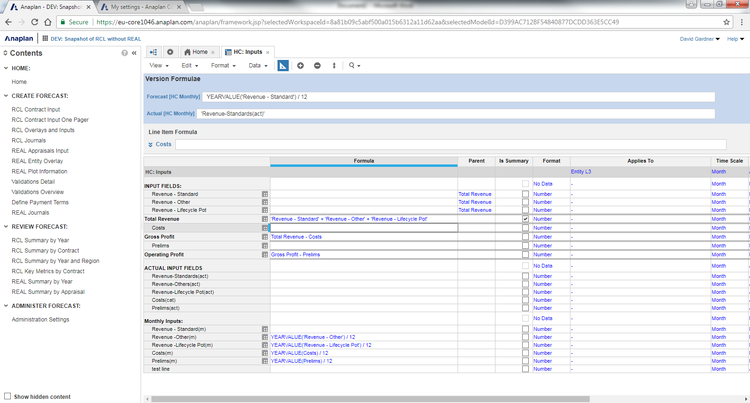

1 Anaplan - Best Overall

Why we chose it: Anaplan earned the top spot on our list for its proprietary Hyperblock Modeling technology. This calculation engine enables users to build and modify planning models using large, granular datasets. The Hyperblock technology offers scenario modeling, predictive capabilities, and advanced analytics, making it effective for consumer goods, financial services, manufacturing, and retail sectors.

We found Anaplan’s basic plan limited as you must subscribe to a premium plan for functionalities like third-party integrations. However, our experience has shown that even the most basic plan is a definite step up from Excel or other spreadsheet tools. It can handle large, complex datasets at scale and speed, making it a solid choice for enterprise-level planning.

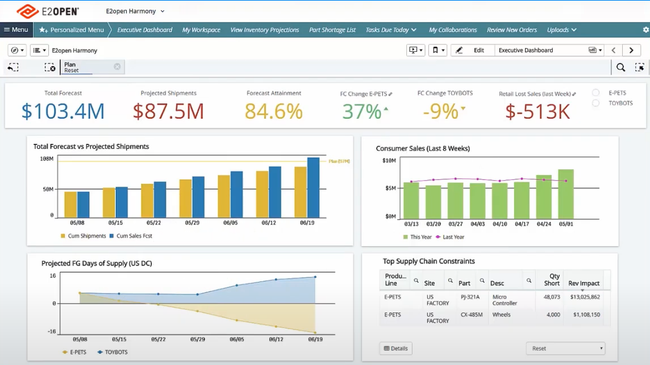

2 e2open - Best for Demand Sensing

Why we chose it: We found that the e2open platform excels in demand sensing, creating highly accurate short-term demand forecasts. It can measure multiple demand signals, including social media sentiment, stock levels, current sales, and competitor prices, to predict future trends. This enables businesses to leverage internal datasets with external data from suppliers and partners to analyze the current market and make changes as the market moves.

Because e2open can pull data from sources such as an internal POS and current competitor promotions, businesses have seen an increase in the accuracy of demand forecasts by 30-40% compared to traditional methods. However, businesses looking for a more modern interface might find e2open lacking as users have found its archaic look and feel outdated.

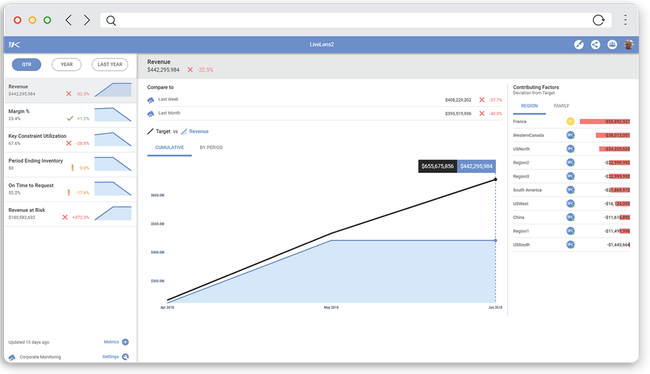

3 Kinaxis - Best “What-if” Scenario Planning

Why we chose it: One of the core strengths of Kinaxis RapidResponse is the platform’s ability to create and evaluate multiple scenarios for demand planning. We found that businesses can run multiple scenarios and evaluate their outcomes without waiting minutes for an answer. For example, users can take a concurrent planning approach by altering supply, demand, and other variables to see the impact instantly across their entire supply chain plan.

A key feature we found helpful is that Kinaxis can assign scorecards for specific scenarios so that demand planners can visualize the outcomes and results. The scorecards utilize weighted KPIs to provide comparisons of different scenarios’ impacts and tradeoffs. These include metrics like production, inventory, logistics, sustainability, and financial performance.

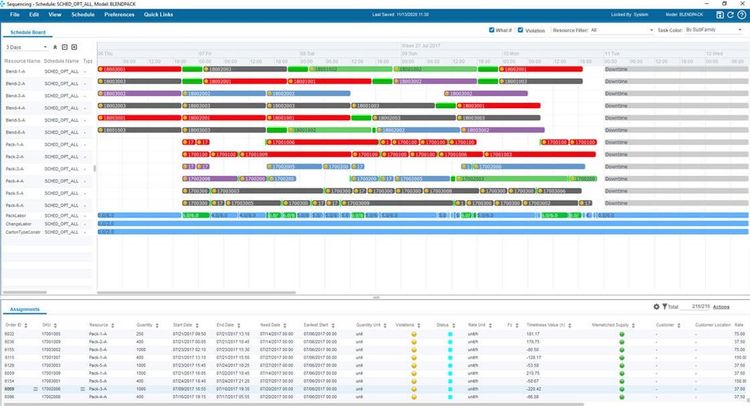

4 Logility - Best for Manufacturing

Why we chose it: Logility InventoryAI+ offers AI-assisted demand planning modules to help businesses manage manufacturing supply chains. Logility features planning and scheduling functionality integrated directly within their system, while other solutions require a third-party integration to capture those same features.

Logility’s InventoryAI+ module considers and plans for work-in-progress, raw materials, components, and subassemblies, which is helpful for complex manufacturing operations.

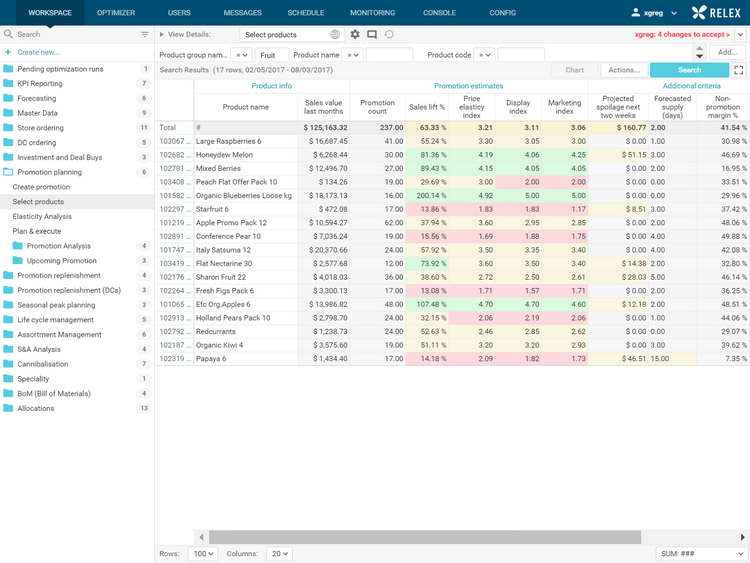

5 RELEX - Best for Retail

Why we chose it: We found RELEX adept in the retail environment as it helps retailers improve shelf space, reduce stockouts, and increase sales. One of the RELEX platform’s strengths is the ability to run locally optimized planograms across multiple store locations simultaneously. This helps match daily replenishment schedules and demand, ensuring more goods fit on the shelf and reducing excess stock in the backroom.

Additionally, RELEX has a history of experience working with retailers. In 2022, CORA France used RELEX to reduce its in-store inventory by 5% across 63 locations by automating the replenishment of their products.

6 Netstock - Best Integration Options

Why we chose it: Netstock makes our list because of its extensive list of ERP integrations. Out of the box, Netstock integrates a broad spectrum of ERP solutions such as NetSuite, Sage 300, Sage X3, SYSPRO, Acumatica, Microsoft Dynamics 365, and many others.

This allows manufacturers, distributors, and retail operations of any size to use the Netstock platform without disrupting existing processes.

7 SAP Integrated Business Planning - Best Product Ecosystem

Why we chose it: We found that SAP IBP provides an integrated demand planning platform for businesses using existing SAP products. It offers native integration with SAP S/4HANA and S4HANA Manufacturing to improve supply chain visibility and collaboration across departments.

However, businesses looking for an end-to-end solution or are not already using SAP, may run into integration issues or require the purchase of additional products such as the SAP Analytics Cloud.

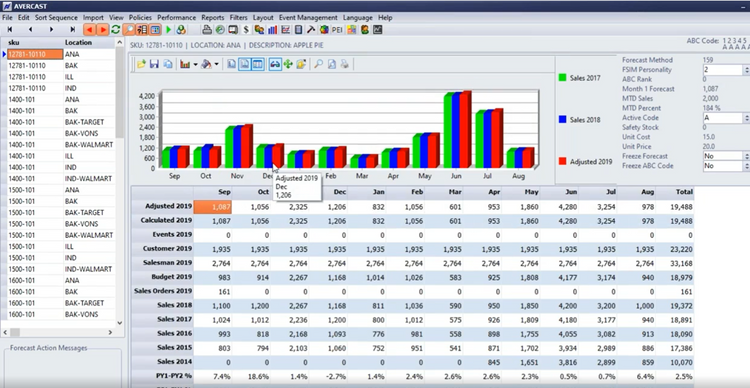

8 Avercast - Best Customization Options

Why we chose it: The Avercast platform is the best in terms of customization due to the 280+ custom AI-powered algorithms they have developed for their platform, each configured to a business’s unique needs. During our testing, we found that Avercast works one-on-one with every customer to tailor custom screens, workflows, and functions.

While Avercast is highly customizable for each customer’s individual needs, our research shows that upgrading to a newer version requires users to reconfigure their forecasts, and some have found the older SQL-style menus cumbersome.

9 Intuendi - Cloud Deployment

Why we chose it: We found Intuendi’s accessible cloud-based deployment allows small and medium-sized businesses to leverage the power of AI without too much legwork to get set up. Businesses in manufacturing, retail, and wholesale industries can create AI-assisted demand forecasts and optimize inventory quicker than traditional spreadsheet methods.

During our testing, we found that while Intuendi continually develops new features based on customer feedback, it still requires manual data uploads, which can be time-consuming for a business.

What Is Demand Planning Software?

Demand planning and forecasting software is a sales and operations planning (S&OP) technology that meets customer demand with the necessary supply level. This is accomplished by coordinating data from separate business units (primarily sales, marketing, and operations) to make more informed supply chain planning decisions that directly relate to inventory optimization.

Accurate demand planning involves collecting historical data on order volumes and inventory turns while mixing it with continually updated forecasts from your sales personnel.

Demand Planning Software vs. Business Intelligence Software

Demand planning solutions can be considered a business intelligence software specifically for supply chain analytics. The software can estimate future sales to improve inventory management and replenishment accuracy, plan purchases, and ensure proper stocking levels.

Demand planning software aims to manage your supply chain more effectively to increase inventory turns and fill rates beyond what your ERP suite or supply chain management software can do.

Features of Demand Planning Software

| Feature | Description |

|---|---|

| Sales and Operations Planning (S&OP) | The overall management of your sales plan and operations plan, which includes tracking sales per month by product family, demand management (such as new product promotions and special offers), production per month by product tracking, workforce and inventory level tracking, and backorder management |

| Demand Planning | Forecast demand for a product so it can be developed and shipped in as efficient as possible ways |

| Inventory Planning | Identify non-performing inventory SKUs and avoid overstocking. Scale for error to ensure under and over-forecasting situations even each other out. |

| Supplier Management | Helps strategically plan and manage interactions with any vendors or suppliers of goods. Set reminders for reorders and reduce risk in your supply chain. |

How Much Does Demand Planning Software Cost?

Demand planning software pricing can vary widely. The monthly subscription cost can range from $1,000 to over $4,000. The setup or implementation fees can vary even more widely, from $30,000 to over $100,000. The specific pricing may depend on factors such as organization size, the complexity of the demand planning processes, and the level of customization required.

Benefit #1: Improve Sales and Operations Planning

The sales and operations planning process helps companies create plans to maintain current business and take on new customers with new products through proper supply chain management. The process can help merge insight from all departments (such as sales, marketing, manufacturing, and more) to create an all-inclusive business plan to balance supply and demand. Execution between these departments centered around sales forecasts ensures that goods flowing through your supply chain are as optimized as possible.

A business will want to conduct the sales and operations planning process each month in various phases. This includes moving along the following processes:

- Sales forecasting: This is the generation of historical data (past sales) to analyze trends and create proper expectations (demand forecasts)

- Demand Planning: What are your current sales? What did your business forecast? Now, what did your business plan for? Demand planning in the sales and operations planning process is about validating your forecasts. Where does your demand typically come from? You’ll need to account for variability and adjust your inventory structure to account for it (if any).

- Supply Planning: Your business must ensure your production levels are as close as possible to what you previously planned for (via demand planning). This step is about assessing your ability to meet demand by reviewing available capacity and scheduling your production/output to the necessary level.

- Reconciliation of plans: This stage will help balance your demand and supply with any financial considerations and ensure that the previous steps have been accounted for.

- Finalize and link to the implementation: The execution stage of the process and the final step in the sales and operations planning process. Usually, for larger (global) companies, the process is put into place and funnels down to regional supplies (depending on if the operation produces items globally or sold and produced at a regional level)

Benefit #2: More Accurate Stock Data With Inventory Optimization

To ensure proper inventory levels are in place to meet your demand, you need proper inventory optimization. Inventory optimization software automates the analyses of your entire inventory cycle.

An optimized inventory optimization solution will examine the differences between demand forecasts and historical sales data to determine appropriate stocking levels. An incorrect forecast can lead to your business being unable to meet demand, which leads to products sitting idle, or even worse, you can’t fulfill sales orders on time.

Effective demand planning software will lead to your inventory being at its most optimal level by creating multiple what-if scenarios. This includes analyzing all parts of your supply chain, such as sourcing, production, warehousing, and transportation.

How does one change affect the other? What sort of impact does each change have on various types of inventory? Since inventory optimization can be seen as a form of predictive analytics, demand planning systems will accurately predict the amount and type of stock to carry.

Benefit #3: Optimize Labor Management

Demand planning software can also plan for labor demand rather than inventory optimization. This type of demand planning will accurately determine the number of workers available, which can influence costs and the quality of service provided to customers. The end goal of labor management via demand planning software will be to drive employee engagement and performance to enhance business results.

Workload analysis capabilities allow decision-makers to determine the standard time to produce a unit. This is opposed to a traditional and more subjective method of estimating the number of employees required for upcoming production periods.

By using workload analysis, you can determine the estimated number of workers by dividing the estimated number of hours needed to meet annual production by the workability of your workers.

Workers can also be incentivized for good job performance. Establishing benchmarks can maximize workforce potential by recognizing good performances. Conversely, it gives you visibility into completed tasks and any employee downtime.

Benefit #4: Integrated Cash Flow Management

By including financials in your sales and operations planning processes, your entire organization will better understand the data and how it can help plan and shape your financial goals. This includes planning capital projects effectively and scheduling maintenance repairs efficiently—all while knowing how it affects your bottom line.

Demand planning software can also improve cash flow by providing insight into how current inventory impacts finance. Too much inventory can disrupt cash flow–leaving you unable to meet demand.

By forecasting financials along with demand, you’ll be able to have a more sophisticated budgeting process. Depending on how far ahead into the future you forecast, you’ll be able to use financial projections based on projected demand when creating budgets or speaking to executives and decision-makers–giving you increased credibility with stakeholders.

Types of Demand Forecasting Methods

Demand is the biggest factor in creating sales forecasts, so you’ll want to make sure you use the most appropriate type of demand forecasting for the products you manufacture, the market you’re involved with, the staff you have on hand, and more.

Most demand planning and scheduling software will use predictive analytics capabilities to determine how scheduling, production, inventory, and staffing should be allocated for production. However, there are other methods of demand planning to consider:

Delphi Method

Known as one of the more time-consuming demand planning methods, the Delphi Method surveys experts anonymously. The surveys are administered in multiple rounds of questions, each new question being generated based on the summary of results received thus far.

The Delphi Method aims to get these experts to arrive at a consensus opinion. In the supply chain process, this consensus opinion is used in development to ideate new products, which can affect the inventory kept on hand.

Conjoint Analysis

This survey-based statistical technique considers perceived value and relies heavily on asking customers what they want. This is more of a judgemental approach to demand planning, as the survey planners (the forecasters) will ask the participants to make trade-offs when conflicts arise.

If customers want product A, will they take product B with similar benefits/features? In a supply chain, conjoin analysis helps businesses determine the importance of a product’s attributes and price. This can let businesses shift the features offered or adjust pricing to hit certain benchmarks in their overall sales. It can also let them know when a customer may consider buying a competitor’s product over theirs.

Demand Planning vs Supply Planning

The difference between demand and supply planning is that demand planning forecasts customer demand, while supply planning manages inventory to meet this demand.

Demand planners use extensive data, including past sales, to produce both constrained and unconstrained demand forecasts, indicating potential demand with and without limitations. These forecasts help businesses manage orders efficiently and reduce inventory costs.

Supply planning aims to efficiently fulfill demand forecasts, focusing on manufacturing lead times, order quantities, production leveling, and safety stocks. It operates based on the demand plan, which generates a master production schedule. The supply plan then assesses capacity and resource impact, making necessary adjustments.

Read more: Demand Planning vs Supply Planning: What are the Differences?