The Best Food Safety Software

Whether you’re in food manufacturing, distribution, or importing, finding the right food safety software is crucial to staying compliant with regulations like HACCP and FSMA. We’ve reviewed the top systems for functionalities like temperature monitoring and quality control.

- Covers international legislation including FSMA, USDA, CODEX, etc.

- Customizable reporting

- Offers auditing and management reviews

- Comprehensive inventory management

- Sales reporting and pricing capabilities

- Ability to track lots and attributes

- Experienced team that knows the fresh food space

- Lower costs for buyers and suppliers

- Combines food safety and procurement

Food safety is one of the most important aspects of food and beverage production. Food and beverage producers need an efficient way to stay ahead of changing compliance to avoid expensive government fines or product recalls.

Using our advanced review methodology, our team has carefully evaluated the top food safety software to find the best options for batch manufacturers across various industries.

- Safefood 360°: Best Overall

- Food Connex: Best for QuickBooks Users

- Procurant: Best for Retailers

- 3iVerify: Best for Importers

- Smart Food Safe: Best for Site-Based Pricing

- SafetyChain: Best HACCP Software

- FoodDocs: Best for International Compliance Documentation

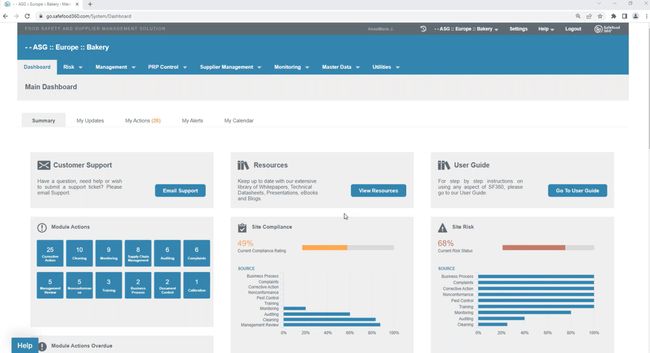

Safefood 360° - Best Overall

Safefood 360° is a user-friendly HACCP software for food safety management and supplier quality control; it offers full support for risk assessment, document control, process management, prerequisite programs, and monitoring.

Notable features for food safety include HACCP safety plans, auditing and management reviews, contamination control, customizable report generation, and supplier risk assessments. Safefood 360° complies with various international regulations such as FSMA, USDA, CODEX, EU, and Australian standards.

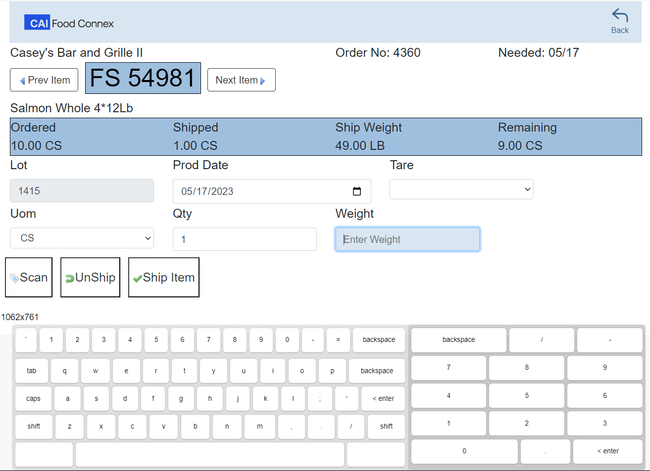

Food Connex - Best for QuickBooks Users

Food Connex is a food safety and ERP software for businesses transitioning from traditional spreadsheets and QuickBooks into more complete systems. It helps small to mid-sized food processors and distributors meet regulatory standards like SQF through built-in lot tracking, traceability, and mock recall tools. These features help maintain food safety and operational readiness.

The platform also supports variable-weight products, offering multiple units of measure and catch-weight handling. It integrates with QuickBooks Online and Desktop for a streamlined system that handles both accounting and business operations.

By positioning itself as an extension of QuickBooks, Food Connex offers an ideal middle ground for food businesses that need industry-specific functionality without abandoning their existing accounting setup. It allows teams to automate purchase orders and automatically sync inventory with QuickBooks. Essentially, provides ERP functionality without the price tag and time invested to complete a full ERP migration.

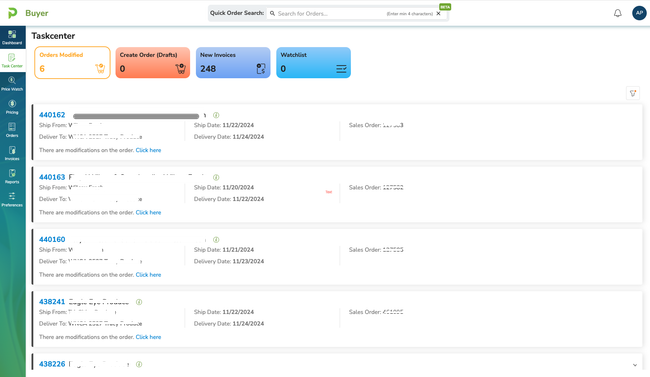

Procurant - Best for Retailers

Procurant’s food safety module streamlines operations for food retailers and wholesalers. You can perform daily opening and closing tasks using comprehensive checklists and create unique workflows to ensure your store adheres to safe food practices. This is ideal for retailers with delis, bakeries, and meat sections that require daily cleaning and opening and closing procedures.

Procurant’s food safety module also integrates with IoT sensors for remote temperature monitoring. The sensors can be installed in critical areas such as freezers, refrigerators, reach-in coolers, and storage rooms. When temperatures pass a certain threshold or power is disrupted, you’re instantly alerted to prevent spoilage and identify the cause.

Additionally, Procurant helps keep retailers compliant with critical regulations, including:

- HAACP: The system includes all steps for complying with HACCP, such as hazard analysis and critical control point (CCP) monitoring.

- FSMA: Keep traceability records and implement preventive measures like IoT temperature sensors.

3iVerify - Best for Importers

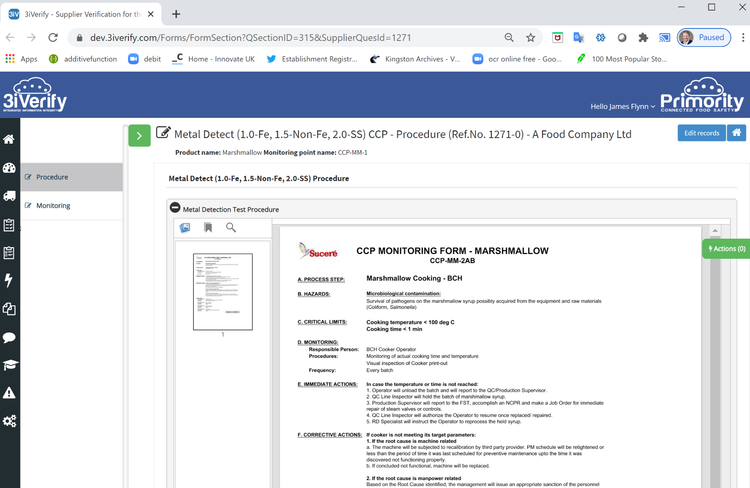

3iVerify is our top choice for importers, helping them evaluate their suppliers based on various standards while efficiently managing food safety and quality compliance requirements. This software is compatible with GFSI standards, has supplier and material approval procedures, and facilitates seamless integration with other systems through its API.

Key features encompass supplier management and approvals, document control, quality management, and traceability tools, all contributing to effective supplier oversight. Additionally, 3iVerify harnesses the power of artificial intelligence to actively monitor global food safety incidents, enhancing risk mitigation efforts.

Smart Food Safe - Best for Site-Based Pricing

We picked Smart Food Safe for its cost-effective approach, offering an annual subscription model per site with unlimited users and transactions. This can be a more budget-friendly option for businesses, particularly those with many users, as they aren’t charged on a per-user or per-transaction basis.

Furthermore, Smart Food Safe is considered a cost-efficient choice due to its inclusive range of modules. These encompass CAPA, supplier, audit, and document management. Smart Food Safe also handles digital record-keeping and product specifications, providing an integrated solution for food safety and compliance needs.

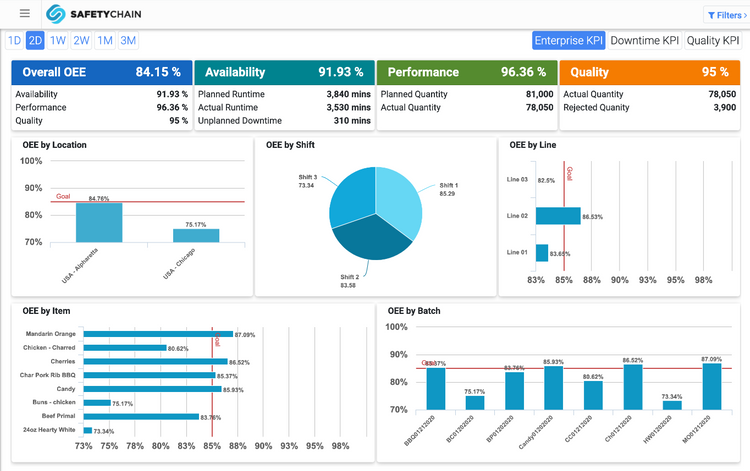

SafetyChain - Best HACCP Software

SafetyChain Compliance Manager is one of our top picks because of its deep feature set. It provides HACCP support, a GFSI code library, food safety checks, and IA (Internal Audit) plans. This platform caters to process manufacturers, focusing on food safety, quality control, and compliance management. Some notable features include real-time specification verification, automated audits to meet regulatory and customer demands, and a seamless paperless quality assurance process.

FoodDocs - Best for International Compliance Documentation

FoodDocs made our list because of its adaptability to various international food safety standards, making it a versatile choice for various food-related businesses. FoodDocs excels at capturing crucial information necessary for effective product traceability, including supplier and manufacturer details, product specifics, involved operations, staff responsibilities, corrective actions, and records related to delivery or disposal.

Moreover, FoodDocs boasts an AI-powered HACCP plan builder. This software offers a customizable and editable HACCP Plan template that automates the creation of essential documentation such as Prerequisite Programs, Hazard Analysis, Critical Control Points, and more. This functionality simplifies the compliance process with food safety standards and regulatory requirements.

What is Food Safety Software?

Food safety software is a digital solution designed to help food-related businesses ensure compliance with safety and quality standards to prevent foodborne illnesses and maintain product integrity.

With food safety software acting as an industry-specific quality management system (QMS), companies can adhere to compliance requirements set by different government agencies around the world. These systems help automate your compliance practices by digitizing all your logbooks and checklists for fast responses to regulatory changes. Keeping up with evolving regulations allows you to keep your production and distribution on schedule without safety violations.

Key Features

- Digital logbooks and checklists: Record all necessary information for the safe production and storage of food and beverage products.

- Document management: Keep track of all compliance documentation in one easily accessible space.

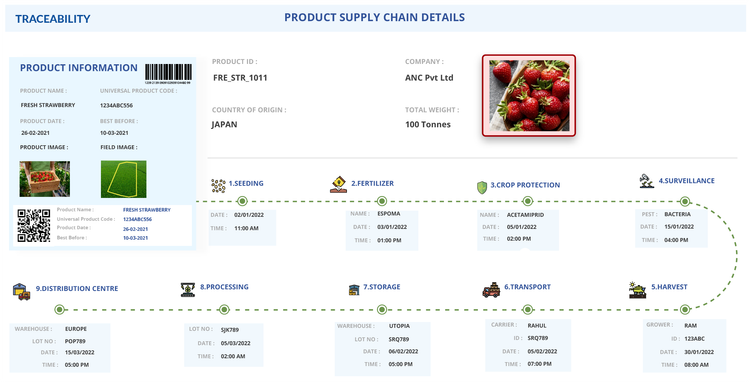

- Food traceability: Use barcodes, RFID, and other methods to track food products through production, storage, distribution, and consumption.

- Recipe management: Keep track of all ingredients necessary for preparing certain food and beverage products.

- Quality control: Follow stringent testing criteria when prepping food to ensure it meets company and legal quality standards.

- Temperature monitoring: Get real-time updates on food temperatures to prevent spoiling during storage, transportation, and distribution.

- Real-time analytics: Review manufacturing and distribution metrics from along the entire supply chain to analyze possible improvements or changes.

- Recall management: Set up processes for handling food and beverage recalls at every level of the supply chain.

Benefits

Food safety software benefits your business by keeping your company compliant with all sorts of regulations. Use this system to:

Remain Compliant with Local and International Regulations

The United States Department of Agriculture (USDA) alone has thousands of different safety protocols for handling food. The Food and Drug Administration (FDA) uses the Food Safety Modernization Act (FSMA) and the international Hazard Analysis Critical Control Point (HACCP) management system to analyze and control food safety practices. And these two agencies are just within the United States.

There are many international entities as well, such as the Global Food Safety Initiative (GFSI) and the British Retail Consortium (BRC), which have their own standards of food safety certification. If your company engages in international distribution or has foreign partners abroad, you’ll need to know the safety requirements of those countries as well.

For example, COVID-19 has caused many new and modified regulations to go into effect worldwide, including food production, to prevent foodborne illnesses from spreading. Keeping up with these sudden changes can take a toll on your business. Food safety software allows you to continually monitor different regulatory agencies for FSMA and HACCP compliance updates.

Reduce Product Recalls

Increased automation in food manufacturing has led to more scenarios for missed safety checks. By tightly controlling food while it’s in production, you can greatly reduce the chance of problems leading to recalls. Food safety compliance software streamlines the process by compiling regulatory information from different regions all in one place. For example, if your company produces food in the United States but distributes it to the rest of North America, you can use this system to check compliance with those other countries before shipping begins.

If a recall is necessary, food safety software provides traceability information that tracks where all products originate from along with where they are stored and sold. If a single batch is contaminated, you can issue a highly targeted recall for the exact products affected rather than a mass recall. This reduces the amount of lost inventory and saves incalculable time and money.

Increase Consumer Trust

Consumers don’t want to constantly worry about the safety of their food. With fewer recalls or safety violations, your customers will trust your brand more and more to provide high quality food and beverage products. Increased consumer confidence can lead to more sales and better ROI performance in the long term for your business.

If you ever do need to perform a product recall, a buildup of goodwill with your customers now can be helpful as you perform corrective actions. A fast and efficient recall shows your company knows how to protect consumers, mitigating possible damage to your overall reputation.

Access Information on the Go

With so many moving pieces in play simultaneously, the multi-echelon supply chain creates many opportunities for food and beverage products to be exposed to potential harm. Temperature checks are necessary when transporting frozen food to prevent spoilage, yet refrigerated truck drivers can’t constantly stop to manually check themselves. Overstocked warehouses can lead to distributors turning away new shipments. All of this contributes to food waste.

Fortunately, food safety management systems are compatible with mobile devices operating with iOS and Android. Everyone along the supply chain can check regulations in real time as the food and beverage products are moved to new locations. Automated temperature alerts can notify drivers when refrigerators are no longer working. Updated inventory tracking can show distributors how much space is available before new products arrive. And food safety software helps everyone remain compliant with local and federal regulations.

Types of Food Software

Since food safety is so important, there are other food-based software options available to increase accountability:

- Food manufacturing: Track the raw materials required to make products to ensure you keep the right production schedule and ingredients on hand to meet demand

- Food distribution: ERP-style programs lessen the costs associated with food distribution by automating operational and accounting processes

- Food traceability: Track and manage information on the food products they produce, stock, distribute, and sell

- Food service management: Learn how to manage the final stage of the food production supply chain

- Fresh produce software: Prepare for recalls and track complex produce inventories.

All of these different types of software can work together to improve your food safety compliance from source to table.

Pricing Guide

Food safety software pricing varies based on business size, industry (eg. manufacturing, distribution, food services), deployment type (cloud vs. on-premise), and feature scope. Most solutions are cloud-based and sold via subscription, but some legacy systems and larger enterprise options offer perpetual licenses.

Typical Pricing Models

Per User, Per Month

Common for cloud-based platforms.

- Small teams(1-25 users): $100 to $500/month

- Larger operations(50+ users): $1,000 to $5,000/month (Depending on users/modules)

Per Facility or Site

Often used in manufacturing and multi-site operations

- Starts around $2,000/year per site

- Can exceed $10,000/year for large facilities

Flat Rate or Tiered Plans

Useful for startups or smaller operations

- Entry-level plans: $100 to $300/month

- Premium or enterprise tiers: Custom quotes

Perpetual License (One-Time Fee + Annual Maintenance)

Less common; used by larger organizations

- Small teams: $10,000 to $25,000 upfront

- Large teams: $25,000 to $50,000 upfront

- Maintenance: 10-20% annually

Additional Costs to Consider

Beyond subscription or license fees, food safety software may have additional costs for implementation, training, and support. Implementation services can range from a few hundred to several thousand dollars, depending on the complexity. Some systems may charge extra for advanced modules like IoT sensors, audit management, or supplier portals. Also, consider potential fees for integrations with ERP or inventory systems.