The Best Job Shop Software

Find the right platform for your shop’s specific challenges, whether that’s efficient job costing for your machine shop or CAD integration for custom fabrication. We assessed these systems for functionalities like multi-level BOM support and real-time machine monitoring.

- Detailed cost reports with access to historical data

- Enhanced job costing

- Logical database structure

- Support for 30 industries and more than 25 countries

- Windows and cloud deployment

- Mixed-mode manufacturing support

- Stores historical data on run descriptions, process dev, BOMs, etc.

- Supports cross-module and multi-level reports

We’ve ranked job shop manufacturing ERP based on how well platforms address common challenges faced by tool and die manufacturing, sheet metal fabrication, and prototype development. Additionally, we’ve factored in affordable pricing to support smaller teams and resource-constrained shops.

| Common Job Shop Challenge | Recommended Tool | Pricing |

|---|---|---|

| High Scrap Rates in Precision Machining | Cost Reporting Tools in JobBOSS² | $3,000 per year |

| Complex Custom Orders and Designs | CAD Integration in Global Shop Solutions | $1,500 per month for minimum of 10 users |

| Parallel Scheduling Bottlenecks | Parallel Machine Synchronization in ProShop | $715/user/month |

| Inconsistent Inventory Replenishment | Automated Reorder Points in Fishbowl | Min of $1,597.50 per user for SaaS |

| Frequent Design Changes in Prototyping | Dynamic BOM Management in MRPEasy | $49/user/month |

| Custom Work Order Management | Work Order Management in xTuple | $175/user/month |

| Material Shortages in Foundry Operations | Multi-Level BOM in Katana | $179/user/month |

| Real-Time Monitoring in Injection Molding | RealTime Process Monitoring in DELMIAWorks | Requires quote |

- JobBOSS²: Best for Machine Shops

- Global Shop Solutions: Best for Custom Fabrication

- ProShop: Best for Tool and Die

- Fishbowl: Best for Sheet Metal

- MRPEasy: Best for Prototyping

- xTuple: Best for Woodworking Shops

- DELMIAWorks: Best for Plastic Injection Molding

- Katana: Best for Casting and Foundry

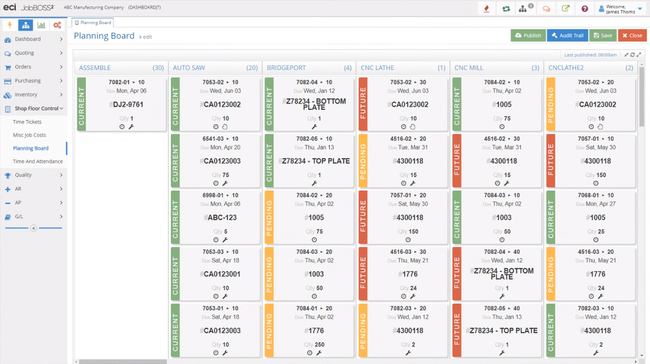

JobBOSS² - Best for Machine Shops

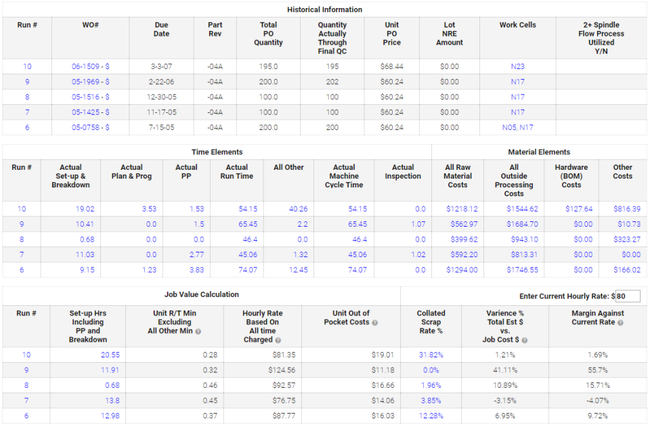

JobBOSS² offers job costing and scrap tracking through its cost reporting tools, letting you track labor, material costs, and scrap. For example, if you’re mid-run producing precise parts and notice higher scrap rates during a turning operation, you can recalibrate the process to avoid losses down the road.

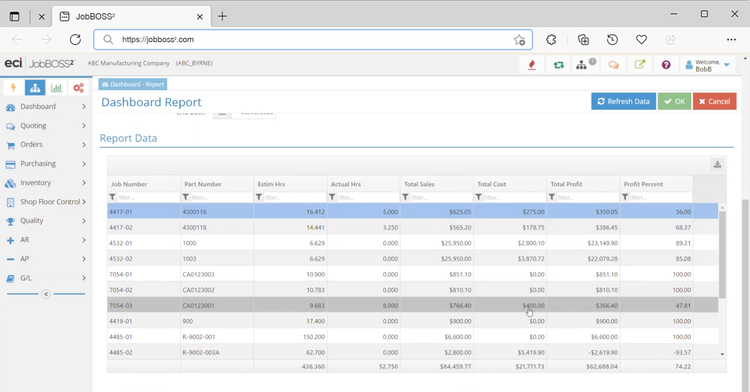

The system provides over a dozen job costing reports, filtered by customer code, job number, part number, and product and work code. If you’re producing medical device parts, you can filter reports by job or time frame to see your total sales, costs, and profits. That way, you can quickly identify problem areas where you’re overspending or undercharging.

Among these reports, the Job Cost Summary stands out, breaking down profits or losses on each job from labor hours to material costs. For example, in a CNC milling job, you can determine how labor hours, materials, and external costs like heat treating affect your bottom line. You can also compare estimated against actual costs incurred as the job progresses to catch discrepancies early.

Additional reports include:

- Margin Summary Report: Track job-level profit margins to compare estimated and actual costs, ideal for tight-margin jobs in the electronics or automotive sectors.

- Performance Summary Report: Review employee and machine performance against expected setup and cycle times so you can adjust your schedules or re-allocate labor.

For repeat jobs, this ERP retains part histories and profitability trends, making re-quoting easier and projecting future job profitability based on past data. That way, if you’re producing a part that consistently generates more scrap, you can adjust quotes for future orders. JobBOSS² offers these features at a starting price of approximately $3,000 per year, affordable for many small to mid-sized machine shops.

Read our full review of JobBOSS².

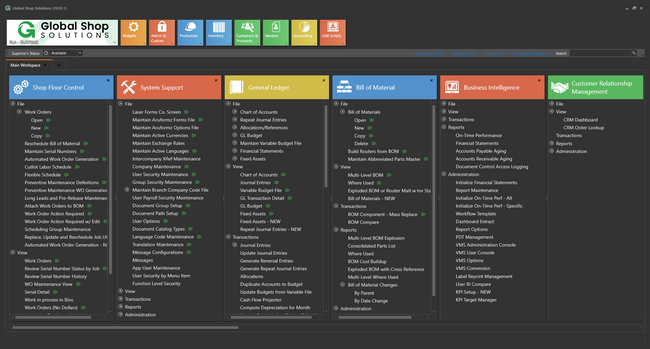

Global Shop Solutions - Best for Custom Fabrication

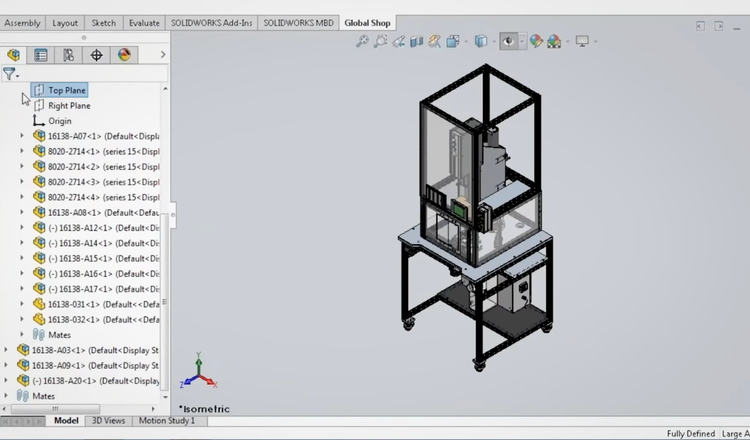

Global Shop Solutions’s CAD integration capabilities offer a decisive advantage for fabricators handling complex, highly customized parts across industries like aerospace, defense, and automotive. You can easily transfer designs from your favorite CAD software directly into this ERP system.

The bill of materials (BOM) attached to a design in your CAD software exports seamlessly into Global Shop Solutions. The ERP instantly compares the imported BOM with your existing inventory, instantly flagging any missing parts or materials before they impact production. For custom parts with multiple components, Global Shop Solutions supports multi-level BOMs, breaking down complex assemblies into their individual parts. The system then updates inventory in real-time, so you’re never at risk of shortages or over-ordering.

If you ever need to adjust designs–like when a client requests a special modification–Global Shop Solutions keeps it simple. You can update or revise part properties directly in the CAD program and auto-sync those changes within the ERP system. That way, your machinists are always working with the latest designs.

Supported CAD programs include:

- SOLIDWORKS

- PaletteCAD

- Solid Edge

- MADA

- Autodesk Inventor

- Lantek Expert

While it’s a powerful platform, Global Shop Solutions is on the pricier side at $1,500 per month for a minimum of 10 users. For smaller shops with fewer users, something like xTuple—which starts at around $175 per user per month—might be a more affordable option.

Learn more about pricing in our Global Shop Solutions review.

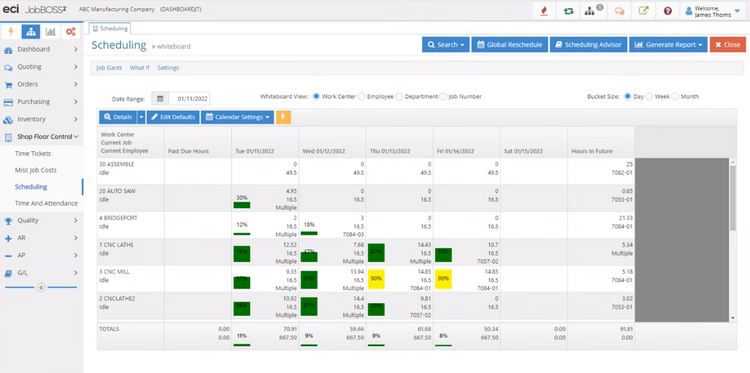

ProShop - Best for Tool and Die

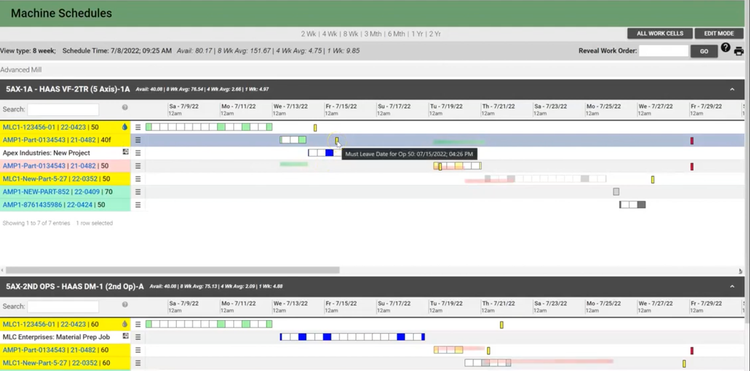

ProShop’s precision scheduling tool is designed for the high-complexity work that goes into tool and die job shops. It offers a Gantt chart view where you can monitor and tweak schedules at different levels – like individual work centers, employees, or machines. This means you’re getting a real-time look into multi-step operations such as EDM, grinding, or milling, ensuring everything stays on track.

ProShop leverages a color-coded job status system to make it easier to spot problems at a glance. Whether it’s green for on track, yellow for at risk, or red for delayed, you can see looming bottlenecks long before they occur and course correct. There’s also a “must leave” date feature that calculates the exact deadline for each operation, critical for tool and die shops where one wrong misstep can create a domino effect of disruption.

Additionally, ProShop’s scheduling capabilities include managing parallel machine synchronization, allowing operations to run on multiple machines simultaneously without double-booking. For example, EDM and polishing operations can run in parallel, maximizing your efficiency without sacrificing precision. Finally, this ERP includes real-time scrap and rework tracking, so if parts fail inspection or need rework, the system instantly recalculates job progress and adjusts schedules accordingly.

ProShop starts at $715/user/month, or $7,800/user/year when billed annually. MRPEasy is a more affordable option for small shops at $49/user/month. However, ProShop is designed for businesses requiring highly integrated, precision-focused systems, while MRP is more of a scalable solution for small and mid-sized manufacturers.

Get more details on ProShop in our product page.

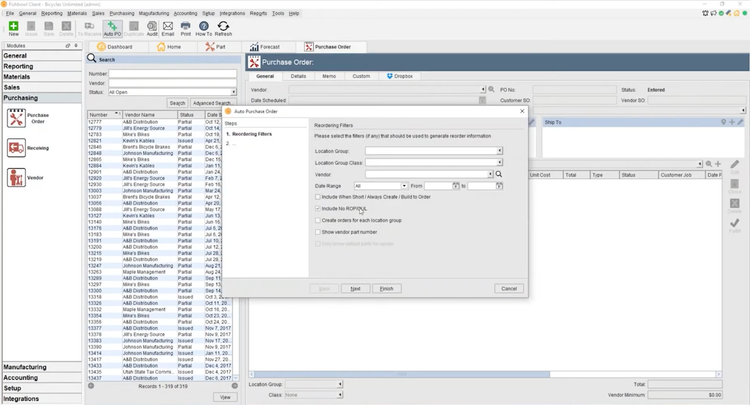

Fishbowl - Best for Sheet Metal

Fishbowl’s MRP tool helps you secure essential materials like sheet metal and fasteners right when you need them. The system tracks past usage data and vendor lead times, so you can set custom reorder points. You can also establish a safety stock level to cover delays or demand spikes, so you’ll never run out of materials, even during rush jobs.

Fishbowl continuously tracks your stock in real time as your shop uses up materials and receives new supplies. When levels hit your preset reorder point, the system triggers an automated purchase order. You can configure the software to send the PO directly to your supplier or set it up for approval first. This way, your shop always has the steel and aluminum it needs, keeping your fabrication processes running smoothly without delays.

Fishbowl’s capabilities extend beyond materials to other planning operations. Its MRP feature includes tool monitoring, allowing you to track the exact location of equipment, ensuring it’s easily found when starting new jobs. The system also monitors machinery and tool maintenance schedules so your CNC machines and laser cutters remain in optimal condition.

While many systems like ProShop include MRP tools, Fishbowl offers an affordable option to smaller job shops. It also has direct QuickBooks integration, a natural choice for shops that need to integrate inventory management and manufacturing functionalities without the cost of larger ERP solutions.

Read our comprehensive review of Fishbowl Inventory.

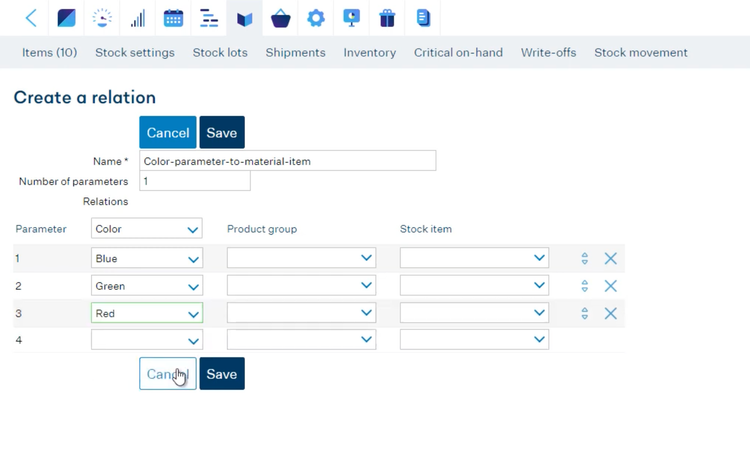

MRPEasy - Best for Prototyping

MRPEasy makes it easy to manage flexible BOMs using parameterized structures, allowing you to adjust materials and quantities dynamically as prototype designs or engineering needs change. You can set up parameters by material type, size, or any custom attribute that fits your project. For example, in electronics prototyping, you can switch between different wire gauges to meet specific performance requirements.

The system also supports multi-level BOMs with parametric sub-assemblies. This allows you to work with layered or modular designs, using different parts with shared attributes. Once your parameters are set, if the size or material of one part changes, these updates automatically apply to other related parts, passing down through the BOM hierarchy.

Additionally, MRPEasy’s system tracks all BOM variations separately in stock, which is useful when you’re working on small prototype runs with slight differences. This makes your inventory tracking more precise and helps you avoid material shortages, even during rapid design changes. Plus, when you adjust a parameter, MRPEasy automatically generates updated manufacturing orders, which keeps production aligned with your latest specs.

Read our full review of MRPEasy.

xTuple - Best for Woodworking Shops

xTuple’s work order management system supports custom orders, allowing you to easily input details for each project, whether it’s a one-off furniture design or a repeatable product. The work order captures all costs and instructions needed to complete each piece. For repeatable designs, xTuple auto-populates your BOM and routing steps once the work order is created. For custom projects, you can manually input this information to ensure accurate tracking of unique designs.

xTuple also handles complex, multi-part assemblies, which is useful for woodworking shops assembling custom builds or multi-piece furniture sets. For example, if you’re a cabinetmaker, you can track the different wood species, finishes, and hinges for each custom piece. This allows you to accurately track your material consumption and costs before production even begins.

For routing, you can assign different production steps to specific work centers, like cutting lumber, sanding, or staining. As each step is completed, the system backflushes inventory, automatically adjusting resource usage to give you precise control over expensive materials like hardwoods. The traveler, a printed document that accompanies the work order, includes routing steps and materials needed, along with barcodes for tracking and managing inventory.

Read our full review of xTuple.

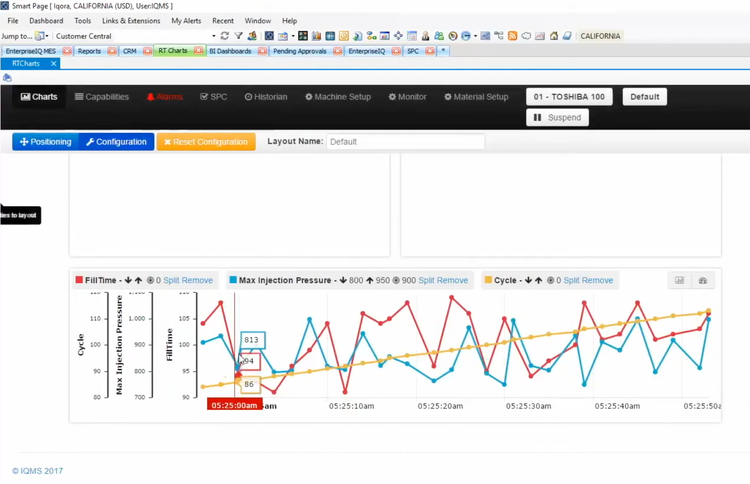

DELMIAWorks - Best for Plastic Injection Molding

The RealTime Process Monitoring System in DELMIAWorks gathers data from your injection molding machines using sensors and connectivity options, like a custom-built programmable logic controller for legacy equipment. This allows you to connect older machines to modern networks, ensuring you’re not limited by outdated technology.

During the injection molding process, the system collects live data on KPIs like temperature and pressure. It also tracks process parameters like cooling durations and lets you set upper and lower limit thresholds for more precise monitoring. If a machine exceeds any of these thresholds, DELMIAWorks alerts you via email or SMS so you can shut it down or check for malfunctions.

Additionally, this ERP has a statistical process control module that allows you to take this collected data and create histograms, charts, and detailed analyses. You can easily drag and drop charts to explore how factors like temperature and pressure impact other metrics. Whether you’re producing packaging or custom parts, you can access control charts to see process variations over time and reduce defects.

That said, setting up the infrastructure for DELMIAWorks, like installing sensors, will require some technical expertise, especially if you use older or custom machinery. For that reason, it’s probably a better option for medium-sized job shops with more skilled labor and support staff.

Find out more about DELMIAWorks in our full review.

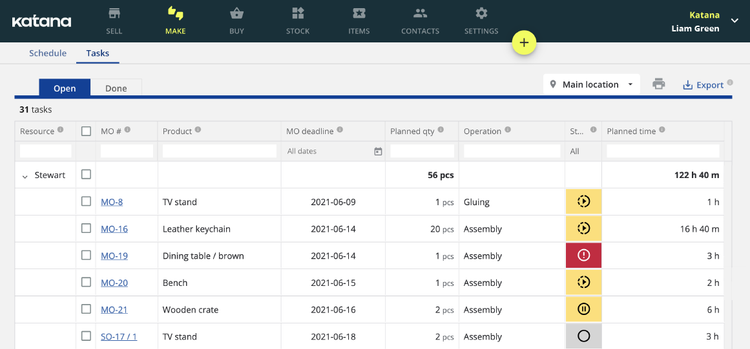

Katana - Best for Casting and Foundry

Katana’s multi-level BOMs make it easy to manage every production stage, from raw inputs like metals and alloys to consumables like binders or fluxes. Just enter these materials into your BOM and track their usage step by step for a real-time overview of stock levels. For example, if you’re producing precision aerospace parts, your BOM could look like this:

- Level 1: Model creation, including wax, wood, foam, plastics, and polymers.

- Level 2: Ceramic shell creation, tracking ceramic slurry and silica sand.

- Level 3: Metal casting, utilizing alloys like aluminum or titanium.

Each level links to the previous stage, ensuring you always have the right amount of materials on hand for each casting job. Additionally, Katana allows you to track variants of the same part. The BOM tool handles these by associating each variant with specific raw materials and process steps. If you’re casting an automotive part in aluminum or steel, you can set up BOM variants that automatically adjust for materials, melting points, and production steps.

Running out of an alloy or casting mold can result in significant downtime. Fortunately, Katana’s BOM tool integrates with its inventory management functionality. As you create and manage BOMs, the system auto-updates your stock levels in real time. When your supplies run too low, Katana can trigger reorder points to streamline procurement.

Find more details on Katana on our review page.

What is Job Shop Software?

Job shop software is a specialized manufacturing program designed for custom and batch production processes, resource scheduling, and complex job order tracking. While general manufacturing ERP includes many of these functionalities, you’ll better meet the unique needs of your job shop through specific software.

Job and machine shops differ from other manufacturing companies due to their unique production models, often make-to-order (MTO) or engineer-to-order (ETO). Because production is based on real-time customer demand, materials planning becomes more challenging. You’ll also need a system that can generate estimates and quotes for clients, predict labor requirements, and handle job costing to determine ROI.

Common Challenges

Job shops frequently encounter these difficulties, impacting both efficiency and profitability:

- Inaccurate Job Costing: Challenges in estimating and tracking costs for labor, materials, and overhead costs can lead to profitability issues; when you’re managing multiple projects simultaneously, this can make it difficult to see how profitable your overall operations are.

- Inefficient Scheduling: Poor job scheduling and resource allocation can lead to increased downtime and delays due to overlapping jobs, unexpected bottlenecks, and reactive adjustments for delays.

- Inventory Issues: Mismanaged stock levels can lead to overstock or stock shortages, causing production delays and higher costs due to a lack of raw materials and components.

- Poor Communication: Insufficient communication among your suppliers, employees, and clients can result in misunderstandings and production errors, ultimately disappointing customers.

Key Features and Benefits

Job shop software addresses common industry challenges by streamlining operations in the following ways:

| Feature | Functionality | Benefit |

|---|---|---|

| Quoting | Generates quotes for customers based on materials, labor, and equipment costs. | Creates accurate estimates to speed up quoting processes and land more work. |

| Job Costing | Calculates material, labor, and equipment expenses. | Enables better cost control and profitability monitoring by tracking all project costs. |

| Bill of Materials | Outline instructions on materials and assemblies required to manufacture a product. | Reduce production errors by listing detailed specifications and the exact quantity of materials needed. |

| Manufacturing Resource Planning | Calculates material requirements and coordinates personnel and machine workloads. | Reduces waste and boosts production efficiency by optimizing resource allocation. |

| Inventory Management | Tracks stock levels and parts on hand; triggers reorder points to replenish materials when needed. | Prevents overstock and stockouts by maintaining accurate records of material levels and upcoming production needs. |

| Work Order Management | Oversees production tasks and manages job assignments. | Reduces bottlenecks and delays through optimized job tracking. |

| Manufacturing Execution Systems | Monitor and control shop floor activities in real time; provide corrective action guidance for improved product quality and machine performance. | Improve shop floor efficiency and quality control, reducing production downtime and defects. |

| Production Scheduling | Plans and allocates time for production activities, coordinates workloads, sets deadlines | Aligns production activities with project timelines for timely completion and efficient resource allocation. |

How to Choose Software

Whether you need advanced production scheduling for producing automotive parts or better procurement for electronics components, choose an ERP that meets your sector-specific challenges:

| Subset | Market Cap (USD) | Key Features | Recommended Job Shop Software |

|---|---|---|---|

| Aerospace & Defense | ~$500 billion | CAD/CAM integration, compliance tools | Global Shop Solutions |

| Automotive Parts | ~$200 billion | Production scheduling, traceability | JobBOSS² |

| Precision Machining | ~$100 billion | Job costing, work order tracking | MRPEasy |

| Industrial Equipment | ~$150 billion | Predictive maintenance, asset management | Katana |

| Electronics & Components | ~$500 billion | Traceability, inventory control | Fishbowl Inventory |

| Fabrication & Welding | ~$50 billion | Project management, estimating tools | xTuple |

Pricing

Budget-friendly platforms like xTuple start at $175/user/month or $2,100 on an annual basis. Higher-end options like Global Shop Solutions can cost $1,500 per month for a minimum of 10 users.

Overall, annual software costs differ based on factors like features included, user counts, and type of deployment. Onboarding, customization, and integrations can also increase the total cost of ownership.

Small Job Shops

- $1,000 - $5,000 per year

- Includes entry-level solutions like MRPEasy or Fishbowl Inventory

Mid-sized to Large Job Shops

Frequently Asked Questions

Can QuickBooks be used as a job shop software?

QuickBooks Desktop Enterprise is popular with smaller job shops for managing accounts payable, accounts receivable, basic inventory, purchasing, and sales orders.

However, mid-sized to large job shops may find QuickBooks lacks vital features, like material requirements planning, equipment maintenance, engineering, and production management. In fact, many manufacturing companies eventually replace QuickBooks with another solution like a true ERP system.

What is the difference between MTO and ETO manufacturing?

ETO production involves designing and building products from scratch based on your client’s specifications. Examples include aerospace components or customized industrial equipment.

MTO production involves crafting items based on existing designs outlined in customer orders. These products might include furniture or automotive body kits.