What is MRO Inventory?

Maintenance, Repair, and Operations (MRO) inventory refers to all items necessary for maintenance work and day-to-day operations. Also known as stock control, MRO ensures accurate inventory counts of consumable materials to reduce maintenance downtime and related costs.

How Does MRO Inventory Work?

MRO inventory is all inventory related to daily operations, onsite repair work, and maintenance tasks. This can range from typical office supplies to highly specialized replacement parts. MRO inventory depends on timely procurement processes to ensure that enough material is ordered for continual operations.

MRO inventory can increase accuracy by letting businesses know which items are over/understocked and only ordering what is necessary. A well-stocked MRO inventory can increase productivity since maintenance teams won’t have to wait for replacement parts to arrive whenever repairs are needed. Instead, they can simply select from the available stock and get to work.

With a well-maintained MRO inventory, businesses can lower operating costs by only ordering materials when they are needed. Purchasing too many spare parts in advance can lead to overstock and overflowing storage spaces. It can also result in unnecessary expenses if the material never gets used. MRO uses continual counting to determine which items get used the most and which items need to be replaced most frequently.

Examples of MRO

Many materials can be considered MRO. It all depends on what the business needs during day-to-day operations. A few examples include:

- Cleaning supplies: Mops, brooms, cloths, chemical solutions

- Safety equipment: PPE (hard hats, masks, gloves), monitors, alarms

- Office supplies: Printer ink, notepads, pens, binders

- Spare parts: Battery, filters, belts, hoses, nuts, bolts

- Consumables: Oil, lubricants, adhesives

Each type of MRO is equally critical to the success of a business. For example, imagine a manufacturing plant. The raw materials needed for production are obviously vital to daily operations, but the ballpoint pens the managers use to sign contracts with suppliers are also important. MRO manages all these materials to prevent shortages and keep work moving.

4 MRO Best Practices

The success of MRO is possible with the streamlined management of business resources, from pens and paper to production machinery and raw materials. However, it can still be improved by following these best practices:

Identify Key Components

To establish MRO inventory, start by identifying which materials are the most important to operations and maintenance. The materials that are absolutely necessary for daily work processes should always be on hand. Then, less essential items should be prioritized down to the items that aren’t as critical to operations.

Perform Real-Time Counts

Continual stock counts provide a clear overview of what’s in stock, what’s low, and what’s out. It can also ensure that materials are kept in good condition and ready for immediate use. This applies more to repair materials and safety equipment than traditional office supplies, but it’s still helpful for MRO inventory.

Organize Storage Locations

Having an item in stock is useless if no one knows where it’s located. Warehouses, stockrooms, custodial closets, and other storage areas should be kept organized and clean. Misplaced materials can lead to unnecessary replenishment orders.

Item movement needs to be recorded as well. If someone takes material from the shared stock, it needs to be monitored in some way so that the items aren’t lost or misplaced. This could be as simple as utilizing a signout sheet or detailing item movement through spreadsheets and software.

Use Software to Manage MRO Inventory

MRO can be managed with several types of software, both specialized and those meant for standard inventory management. A few popular options include:

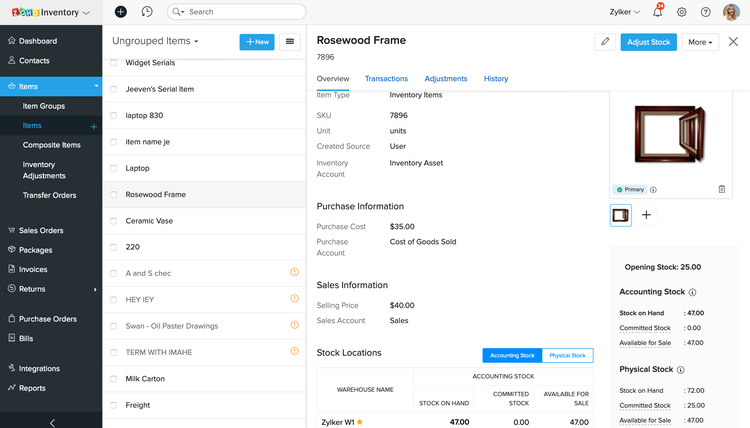

- Inventory Management Software: Regularly count stock levels of MRO parts to know when new replenishment orders are needed.

- Computerized Maintenance Management Software (CMMS): Schedule preventive maintenance based on corresponding inventory levels and equipment use.

- Procurement Software: Authorize and track orders for business consumables in advance or on an as-needed basis.

- Fleet Maintenance Software: Keep company vehicles running smoothly through scheduled maintenance.

- Aviation MRO: Automate maintenance tracking, inventory management, and flight operation functionalities in all aircraft maintenance and repair operations.

Some industry-specific solutions, like manufacturing software, also include tools for managing MRO inventory.

MRO KPIs

Knowing whether or not MRO is working depends on several key performance indicators (KPIs), such as:

- Inventory on-hand: How much inventory is on-hand on a day-to-day basis? There should be enough for at least one month to prevent disruptions to the consumer in an emergency.

- Shortages: Are spare parts missing from storage? Whether they are misplaced or out of stock, that shortage can delay repairs and bring business to a standstill.

- Expedited or rush orders: How often are shipments being rushed? Just like shortages, too many expedited deliveries can be a sign that MRO goods aren’t being ordered frequently enough, opening a business up to potential downtime.

- Procurement spending: How much is being spent on procurement? A working MRO should lead to more efficient spending, such as lower storage costs by reducing duplicate stock.

5 Common Challenges of MRO

The main challenges of maintaining MRO inventory include:

- Supplier shortages: MRO doesn’t change the dependence on suppliers for replenishment. Any delays on their end can lead to shortages.

- Duplicate supplies: Ordering too many spare parts can lead to an unnecessary (and expensive) stockpile. They also take up valuable storage space.

- Poor forecasting: Failure to forecast correctly can lead to understock/overstock situations, causing downtime when waiting on the delivery of parts to finish repairs.

- Worker satisfaction: Employees need to trust the MRO system for it to work. Many maintenance and repair technicians enjoy having their own stock on hand. However, this personal stash can lead to shortages of shared resources or important spare parts going “missing” when critical repairs are needed.

- Scalability: A lot of effort is needed for MRO to run smoothly. As described above, ideal conditions include monitoring the most important components, taking regular stock counts, and keeping storage locations organized. Some small businesses with low volume needs might want to skip MRO processes if they cannot meet these standards.

Following established MRO best practices can ease these challenges and help businesses manage inventory better.

Frequently Asked Questions

What does MRO stand for?

What are MRO materials?

MRO materials include any product used in maintenance, repair, or daily operations at a business. This ranges from typical office supplies to replacement parts of heavy machinery.

Any inventory that isn’t directly used in producing a good or service can be considered MRO.

What does MRO mean in procurement?

In procurement, MRO refers to all inventory that is not directly related to production. These are items procured for daily operations or maintenance, and they are known as indirect purchases.

For example, an office printer that is used for printing out purchase orders would be classified as MRO, as would the paper and ink. Procurement would be in charge of buying a new printer or reordering the related consumables.