The Best Manufacturing Project Management Software

Find project-based manufacturing software for managing resources, scheduling tasks, and tracking progress. Our picks will help ensure every phase, from design to delivery, stays on schedule.

- Integrates with 400+ apps, including Miro, Jotform, Teams, Google Drive, and SAML

- Offers a free option to individuals and small teams

- Provides various dashboard views like Gantt charts, Kanban boards, and calendars

- Free trial and version available

- Issue tracking and workflow

- User-friendly task management

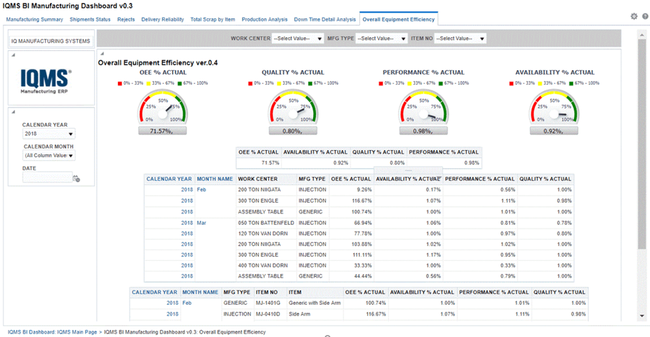

- Streamlines manufacturing operations

- Real-time visibility into the manufacturing process

- Integration with other systems for improved efficiency and productivity

We reviewed the best manufacturing project management solutions on the market, including Wrike, Smartsheet, and Zoho Project, to help businesses find the right software for their needs.

- Wrike: Best Overall

- Zoho Projects: Best for Small Companies

- DELMIAWorks: Best for Tooling and Mold Manufacturers

- Smartsheet: Spreadsheet-Style Interface

- Monday: Best Free Option

- TACTIC: Best Production Scheduling Tools

1 Wrike - Best Overall

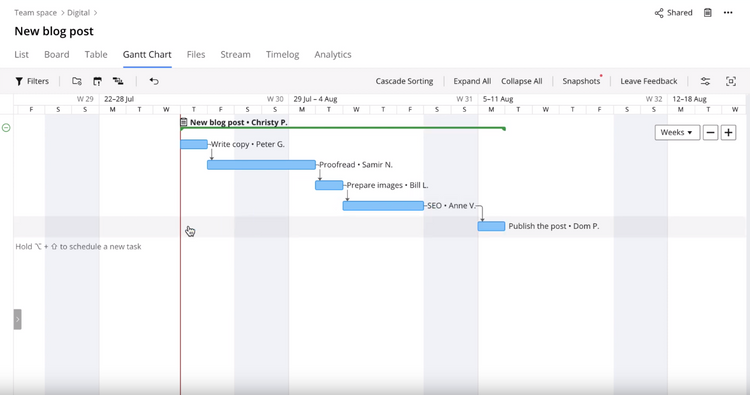

Wrike’s Gantt charts use a dual-panel format to help you visualize manufacturing projects. These charts combine a dynamic timeline on the right with a task table on the left. This helps you organize intricate workflows and manage dependencies from raw material procurement to final assembly.

Add production phases like design, fabrication, assembly, and quality control to the task table. You can further break these down into subtasks, such as CNC machining and welding, and hierarchies to reflect multi-level manufacturing stages. Wrike even lets you set dependencies to ensure downstream steps, like product testing, only happen once earlier phases are complete. If delays occur, Wrike automatically reschedules affected items, giving you an opportunity to shift resources or priorities.

For just-in-time manufacturing environments, Wrike includes critical path management, which immediately triggers alerts if any deviations threaten to disrupt your schedule. When conflicts arise, the platform flags these issues using visual indicators. This helps you take quick corrective action to minimize downtime and allocate resources more efficiently.

Wrike offers a free plan that includes basic project tools, including board and table views. However, for unlimited projects and interactive Gantt charts, you’ll need the Team plan at $9.80 user/month for teams of two to 25 users.

Zoho Projects - Best for Small Companies

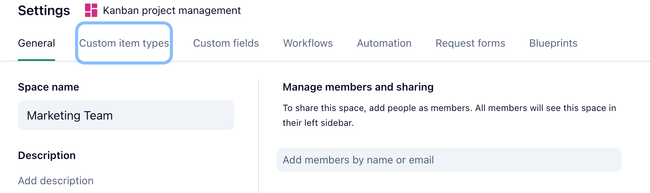

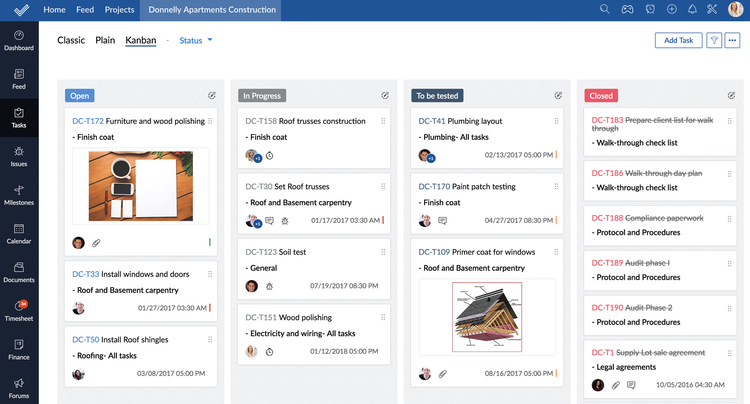

Zoho Projects is ideal for smaller manufacturing businesses. It offers a wide array of features, such as task management with dependencies, milestones, and Kanban boards. These capabilities align well with the intricate and detail-oriented nature of manufacturing projects. This software allows you to break down projects into manageable tasks and subtasks so that every aspect of production is carefully planned and executed.

With multiple pricing options and a free version available, Zoho Projects is a cost-effective solution for manufacturing businesses of varying sizes. It enables them to streamline their project management processes, enhance collaboration, and ultimately improve their manufacturing operations.

DELMIAWorks - Best for Tooling and Mold Manufacturers

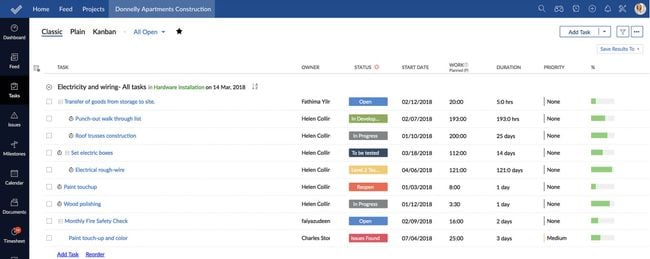

Tooling projects involve dozens of steps, from core design and cavity milling to EDM and final assembly. DELMIAWorks’ project manager module lets you break each mold build into hierarchical tasks with assigned materials, labor, and deadlines. Progress and costs roll up automatically to parent phases like machining, showing the cumulative expenses for subtasks such as rough mill and EDM work.

DELMIAWorks lets you directly pull materials, including P20 steel and copper electrodes, from inventory and assign them to specific tooling operators. It also makes it easier to track labor-heavy processes such as polishing. Your team can use manual timecard entry or barcode time collection to record their work at the task level. This links to the time and attendance module for more accurate job costing. From there, drill into each tooling project to compare actual vs. standard costs, material consumption, labor allocation, and profit margins.

The project cloning feature allows you to copy your past tooling projects, such as recurring mold types. From there, you can easily reuse task structures, cost data, and material lists to save time and ensure consistency for repeat builds. Though DELMIAWorks does not list public pricing, we estimate it costs around $250 per user per month, with a minimum of five users.

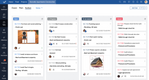

Smartsheet - Spreadsheet-Style Interface

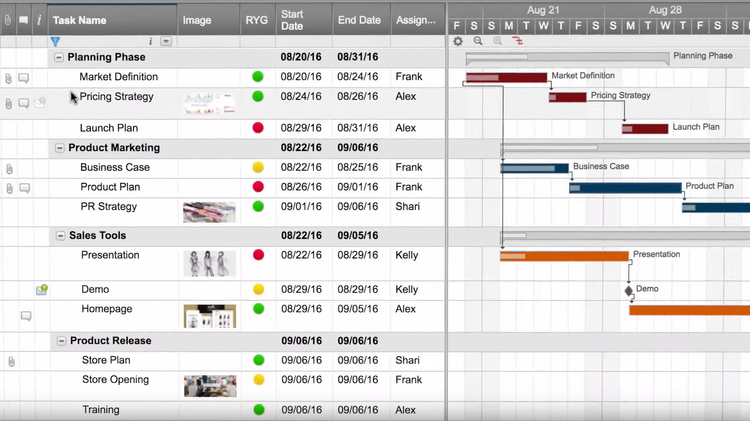

Smartsheet is a good choice for manufacturing businesses that prefer a spreadsheet-style project management approach. Its adaptability and process optimization features are well-suited for dynamic manufacturing workflows, allowing teams to streamline tasks and improve efficiency. Smartsheet is a scalable solution, making it suitable for projects that evolve into larger programs and portfolios.

With project planning tools like Gantt charts and Kanban boards, Smartsheet empowers manufacturing teams to meticulously plan and execute tasks, ensuring projects stay on track. Resource management and budget tracking capabilities are essential for manufacturing, and Smartsheet simplifies resource allocation and cost monitoring.

Monday - Best Free Option

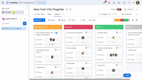

Monday offers a free plan with up to three boards and over 200 customizable project templates. These allow teams to tailor their processes, ensuring manufacturing projects are managed in the way that best suits their specific needs. With visual dashboards and various views, Monday provides real-time insights and progress tracking, crucial for manufacturing project management.

Custom views include:

- Calendar View

- Chart View

- Files View

- Kanban View

- Map View

- Timeline View

The software’s versatility is highlighted by its ability to streamline workflow, boost productivity, and provide valuable structure to its operations. Monday offers a flexible and adaptable solution. Its intuitive interface and interactive views make it a valuable tool for managing tasks, projects, and goals in manufacturing by helping teams prioritize and stay organized efficiently.

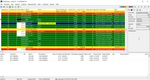

TACTIC - Best Production Scheduling Tools

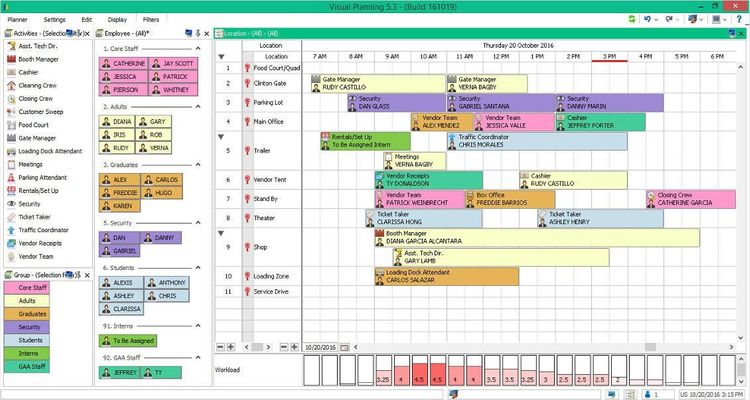

TACTIC by Waterloo Manufacturing Software offers dual functionality as both production scheduling software and advanced planning and scheduling software. Moreover, TACTIC’s ability to manage multiple locations in the supply chain makes it a comprehensive solution for manufacturing project management and supply chain optimization.

As production scheduling software, TACTIC allows manufacturing teams to generate precise dispatch lists that consider the finite capacity constraints of various resources, ensuring optimal allocation of labor and machines. This capability is invaluable for prioritizing production orders, managing overtime, and identifying potential delays. TACTIC excels at managing short-term scheduling needs, making it a crucial tool for manufacturing operations.

What Is Manufacturing Project Management Software?

Project-based manufacturing software is a program that helps manufacturers plan multi-phase operations by coordinating resources, timelines, and costs across departments. Key capabilities include planning production, scheduling your staff, and showing real-time equipment and staff availability visual methods such as Gantt charts and Kanban boards.

This special type of manufacturing ERP software helps managers control costs and hit deadlines across entire projects by helping them plan, organize, and manage all the resources needed to create estimates, provide quotes, schedule jobs, and track their production status from beginning to end. This is important for manufacturers that want to increase margins and profitability.

Businesses with complex supply chains may realize they are lost without the proper project status tracking, scheduling, and planning capabilities that an integrated project management tool provides. This is because many manufacturers may do business across multiple locations.

For example, a design team may create plans in one location but send them to a warehouse to be manufactured. They may also contract out their distribution process, meaning the finished goods need to be sent to a different location. This interconnected web of employees, equipment, and facilities requires a strong manufacturing project portfolio management solution to ensure all departments are kept on the same page.

Project management solutions for manufacturers can be locally installed, web-based, or accessed via mobile devices such as Apple iPhones (iOS) or Android devices. User permissions can allow all staff members to access only the appropriate part of the software.

Key Features

- Project planning: Plan and subsequently report project progress. Establish the steps and tasks required to define your objectives. Create new tasks, set due dates, assign people to tasks, and get plan updates.

- Project calendar: View your team’s availability or specific employees. Manage customer orders based on market conditions, other projects’ production schedules, and staff availability.

- Gantt charts: A type of bar chart that illustrates a project schedule. Helps visualize and plan tasks to stay on schedule. Drag and drop interfaces can let you shuffle tasks and subtasks, allowing you to organize your manufacturing project most efficiently for your employees. Can highlight dependencies to ensure work is completed in the correct order.

- Kanban boards: Visually depict work at various stages of a process using cards to represent work items and columns to represent each stage of the process. They divide your manufacturing process into stages, from ideation through manufacturing, packaging, and delivery.

- Time tracking: Track and analyze time worked on manufacturing projects to help decrease project timelines and deliver more stable, profitable projects. Add timesheets, set time estimates, and create time reports. The information gathered can be used for payroll, client billing, estimation, tracking, and time management.

- Task lists: View, manage & prioritize work in personal and team task lists. Identify and avoid capacity bottlenecks with task dependencies. Create lists based on how much capacity your employees, machines, and resources have throughout your project. See what tasks are due today company-wide or view a personal task list for each employee. Filter by the due date, owner, and project.

- Team collaboration: Includes tools such as team chat, discussion boards, and task comments. Manage your team’s workload and shorten the communication chain by connecting all members of your organization together. Includes integrations with programs such as Slack and Salesforce.

- Document management: Store, manage, and track electronic documents and images captured with a scanner. Upload documents to a specific project or task. Design documents, proposals, and signed contracts are examples of documents used. Access files and documents uploaded on third-party apps such as Google Drive, OneDrive, and DropBox

Benefits

The top benefits of manufacturing project management software include:

Visualize Timelines and Map Out Complex Projects

These systems tighten project timelines while delivering a more stable, profitable project. Project management software for manufacturing helps visualize all products your business is assembling, shows resource allocation (such as machinery or raw materials from inventory), and all staff members involved in the process.

Each software may include a different set of information, depending on whether you are creating a work plan, a timeline, or a Gantt chart. Sometimes, these terms can be used interchangeably.

- Work plan: Shows the start and end date of the project, responsibilities involved, and the budget.

- Timeline: Shows start and end date of the project, as well as milestones.

- Gantt chart: Shows the start and end date of the project, responsibilities, and dependencies of tasks.

With the right manufacturing project management software, all three of these maps can be combined to show the data you need. Because most manufacturing projects use different people and resources, it can be hard for them to keep tabs on one another. Gantt charts will help illustrate your project schedules company-wide, providing a single unified view of how one project will impact the raw materials and staff availability of another.

Know The Exact Production Status Of Every Manufacturing Project

Now that you have a visual project planning tool, you can load production schedules and put those Gantt charts to use. In the event of unexpected delays, a manufacturing project scheduling software will be able to send management the appropriate alerts to make adjustments. If you want to test out “what-if” scenarios involving postponing or delaying certain manufacturing jobs or rescheduling them to different times of the day, you’ll be able to see the proposed impact on other jobs, if any, depending on the personnel and equipment that would be affected.

Having complete insight into the product status of your manufacturing projects will help you avoid bottlenecks, leading to improved cycle times and increased employee productivity. In the long term, this should also help reduce waste and better understand your production costs.

Better Communicate and Collaborate With Your Manufacturing Team

Like any industry that may be using a project management system, manufacturers have their own deadlines to worry about, in addition to any natural fluctuation of customer orders and market conditions. Manufacturing project management calendars can let staff view what tasks they need to complete today. Project managers can view their own schedule and monitor their team’s productivity to ensure everyone is completing the work assigned to them that day.

An intuitive and visual solution will encourage all employees to use it as frequently as possible. This leads to better communication and lets people manage their work more proactively. For example, a manufacturing project management system will let the design team chat directly with the production team to ensure there are no surprises. Document management features will let each team upload appropriate paperwork and ensure everyone is aware of any project expectations.

Pricing Guide

| Tier | Employees | Adjusted Project-Based TCO Range |

|---|---|---|

| Low | 1–25 | $5,000 to $50,000/year |

| Mid | 25–150 | $50,000 to $150,000/year |

| High | 150–500 | $150,000 to $300,000/year |

| Enterprise | 500+ | $300,000 to over $1 million/year |

The cost of project-based manufacturing software will depend most on:

- The number of users

- The number of modules included

- Any integrations needed with any MRP software or accounting software.

Some systems require a minimum number of users to subscribe, making their advertised price appear much lower than the real monthly price.

Some software developers may offer free manufacturing project management software, but they are usually slimmed-down versions of their paid versions. These options let you manage one project with a limited number of users, and they are best used as free trials of the programs.