The Best Tool and Equipment Tracking Software

We evaluated the top tool-tracking systems based on key features, pricing, and functionality. In addition, we’ve identified the industry leaders in preventative maintenance and tool inventory management.

- Multi-language support

- Customizable dashboards & reporting

- Offers maintenance request portal

- Has integrated barcode scanning in the mobile app

- Plans include unlimited users

- No-code and customizable

- Picture capture and upload capabilities

- QR code scanning

- User-friendly mobile app

Tool-tracking software tracks parts inventory, equipment performance, and preventative maintenance scheduling. Computerized maintenance management software (CMMS) and enterprise asset management (EAM) systems make maintenance workflows more efficient and expand the lifespan of your tools and equipment.

- Eptura Asset: Best for Facilities Management

- Asset Panda: Best for Construction

- UpKeep: Best for Manufacturing

- eMaint CMMS: Best for Retail

- Limble CMMS: Best for Educational Institutions

Eptura Asset - Best for Facilities Management

User-friendly and streamlined, Eptura Asset is a cloud-based CMMS software featuring digital floorplan capabilities. These help facility maintenance staff quickly locate and track tools and equipment for efficient inventory management and maintenance planning. They can monitor the entire lifecycle of each piece of equipment, from acquisition to disposal. This includes tracking the cost history, upcoming maintenance, and repair schedules.

Eptura Asset provides a detailed breakdown of individual pieces of equipment, including open work orders, recently completed service, upcoming maintenance, and more. This feature allows for efficient monitoring and management of each tool and piece of equipment.

Key Features:

- Inventory Tracking

manages an up-to-date inventory of all equipment and tools. This feature ensures that all assets are accounted for and can be easily located when needed. - Preventive Maintenance Plans

The software allows for the creation of preventive maintenance plans. These plans can trigger work orders after a set amount of time or when a usage threshold is met, ensuring that tools and equipment are maintained regularly and reducing the likelihood of unexpected breakdowns. - Asset Reports

The software enables reporting on assets using various metrics. This can include information such as utilization rates, maintenance histories, and costs associated with each tool or piece of equipment. - Asset Utilization Tracking

The system includes functionality to track how assets are being used, helping to identify underutilized assets and optimize equipment allocation. - Maintenance Request Portal

End-users can submit maintenance requests for equipment and tools conveniently, allowing technicians to manage these requests effectively. - Parts Inventory

The software monitors stock levels, tracks usage patterns, and forecasts future needs to optimize inventory levels for equipment parts, helping to avoid stockouts or overstocking.

| Pros | Cons |

|---|---|

| Multi-language support | Pricing requires consultation call |

| Customizable dashboards & reporting | Limitations in task customization |

Bottom line: Eptura Asset helps extend the life cycle of your equipment through preventive maintenance software that helps you generate, schedule, delegate, and monitor PMs.

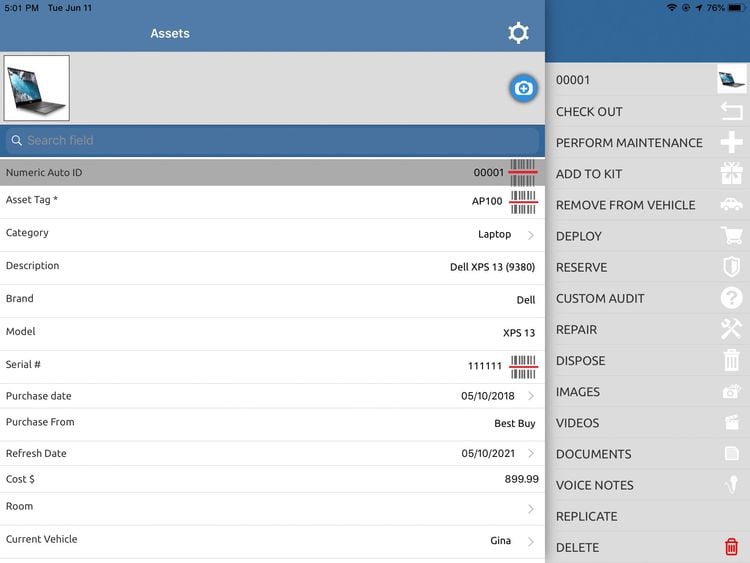

Asset Panda - Best for Construction

Asset Panda helps small, medium, and enterprise-level construction companies monitor their equipment throughout their life cycles. Cloud-based with mobile app capabilities, Asset Panda eliminates the need for bulky barcode scanners and spreadsheets, providing the same data set to unlimited users with iOS and Android devices. It offers custom configuration, mobile signature capture, and intuitive interface.

Asset Panda offers custom pricing that scales with the number of assets tracked annually.

Asset Panda enables QR and barcode scanning through your employees’ smartphones or tablets. Their barcode scanner mobile solution is intuitive even for tech novices and customizable for your industry. Easily integrate Asset Panda with numerous applications already in your tech stack, including Google Workspace, Microsoft System Center, Zendesk, and more.

Key Features:

- Compliance Tracking

Stay in compliance with government, insurance, and warranty requirements by keeping detailed asset records. - Facilities Management

Improve safety and compliance, equipment management, and decision-making in your facility with up-to-date data on costs, replacement frequency, and repairs. - Fixed Asset Tracking

View historical asset records from purchase to disposal and manage checkouts and maintenance. - Maintenance Tracking

Keep complete calibration records for assets, extend the lifecycles of your equipment, and reduce downtime in your facility. - Mobile Audit

Schedule recurring audits and capture accurate records you can easily access through desktop and mobile devices. - Tool Tracking

Ensure your assets return at the end of a job with tool management software that specifies asset conditions, locations, and crew assignments.

| Pros | Cons |

|---|---|

| Easily upload photos and documents | Cumbersome setup for new users |

| User-friendly | Requires a demo to get a pricing quote |

Asset Panda offers a two-week free trial after demoing the software. Discounts are available for multi-year, education, and non-profit clients.

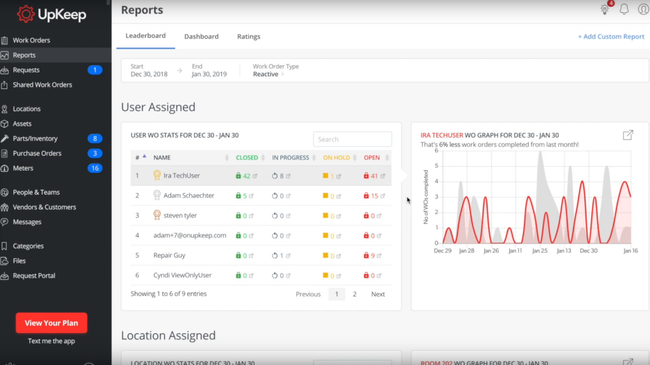

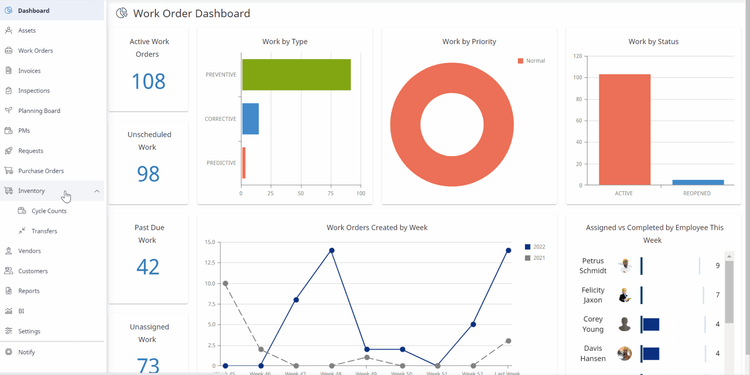

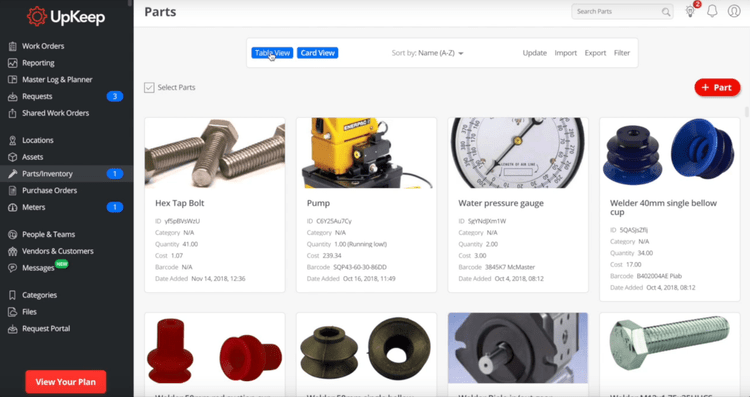

UpKeep - Best for Manufacturing

As a cloud-based CMMS software, UpKeep provides an asset operations management (AOM) platform and mobile app to help streamline work orders and PM scheduling for manufacturers. This way, regardless of employees’ location, everyone in your enterprise can gain an understanding of maintenance life cycles, asset utilization, and workflow processes. UpKeep is in our top four because it’s user-friendly and easy to integrate with your current tech stack.

UpKeep starts at $45/month/user for iOS, Android, and web-based devices with the option for a free 7-day trial.

Maintain an intuitive, centralized data ecosystem through UpKeep’s mobile-first platform. According to UpKeep, businesses can increase asset and equipment lifetime up to 11% and decreases downtime up to 26%.

Key Features:

- Analytics & Reporting

Use pre-made or custom dashboards to capture your maintenance department’s top KPIs; generate reports for inventory levels, technician productivity, and work order completion rates. - Asset Management

Regulate the entire asset lifecycle through UpKeep’s mobile asset tracking software for everything from asset downtime to depreciation. - Integration

Align UpKeep CMMS with FreshBooks, Infor EAM, Azuga fleet management, and more applications. - Parts & Inventory

Enable notifications for parts managers when quantities are running low; allow front-line technicians to easily add spare parts to work orders by scanning QR codes using the mobile app. - Safety & Compliance

Protect your enterprise from failing audits by providing historical maintenance documentation and uploading safety and regulatory manuals. - Work Order Management

Optimize wrench time and filter work requests by priority level, asset, location, and assigned technician.

| Pros | Cons |

|---|---|

| Easily upload photos and documents | Limited customization of user permissions |

| User-friendly interface | Not able to save generated invoices |

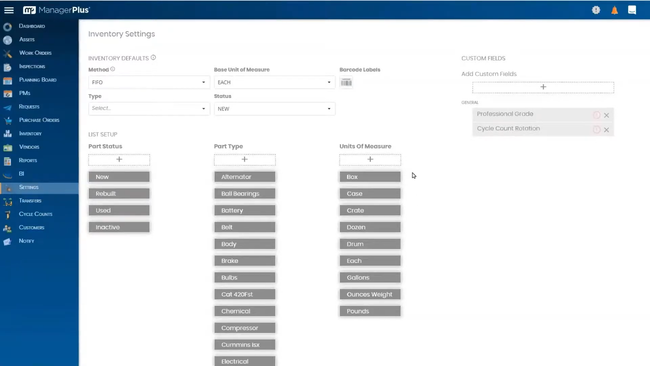

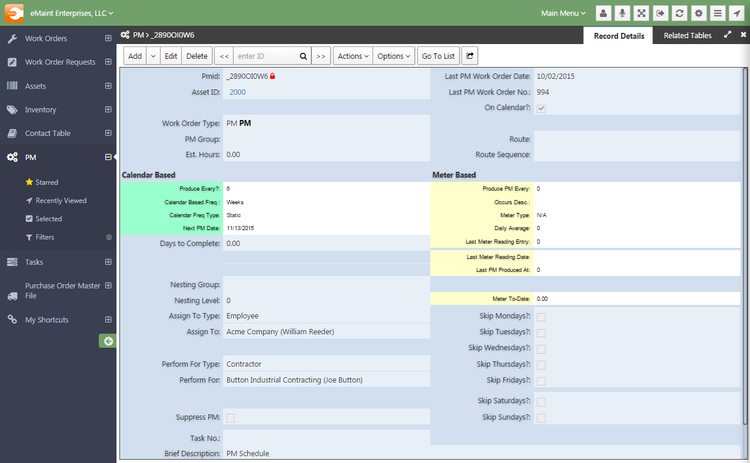

eMaint CMMS - Best for Retail

This software streamlines workflows across various sectors, especially retail. eMaint CMMS provides a high degree of customizability, so you can tailor filters, dashboards, field properties, and record displays to meet the exact specifications of your industry, from HVAC to transportation.

In retail, use filters to access location-specific data, set up dashboards to monitor KPIs like HVAC performance across stores, and customize field properties like asset location (e.g., front vs. back-of-store). This allows you to quickly pinpoint assets in need of attention at each of your stores and helps you address issues before they impact the customers experience.

Optimized to boost production while decreasing downtime, eMaint CMMS starts at $69/user/month for three users.

eMaint offers all you could want in an asset management solution: tracking parts usage processes, maintenance scheduling and history, and overall asset health. Cloud-based with a mobile app solution, this software offers access through any browser-based device, like desktops, smartphones, or tablets.

Key Features:

- Asset Management

Track assets through barcode labels, generate calendar- or meter-based PMs for planned maintenance and capture accurate material repair and labor costs for budgeting. - Inventory management

Auto-generate purchase orders for consumables and scan barcodes and QR codes to access parts records. - Preventive Maintenance Scheduling

Set a consistent PM schedule for each asset with task procedures and step-by-step guidelines. - Reports & Dashboards

Utilize 95 pre-loaded KPI reports or build your own to track employee productivity, work order completion rates, material usage, and equipment performance. - Work Orders

Automate scheduled and preventative maintenance work orders and maintenance and record-keeping for future audits. - Work Scheduling

Use the maintenance scheduler to assign work orders to internal technicians or outside contractors for specific days and time windows.

| Pros | Cons |

|---|---|

| Responsive customer support | Restricted formatting options |

| Customized workflows | Limited customizability for work and purchase orders |

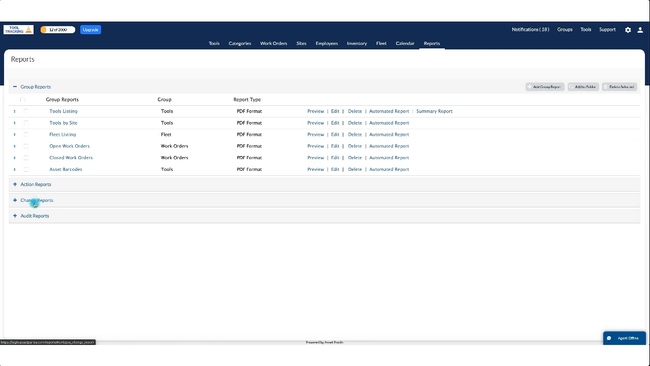

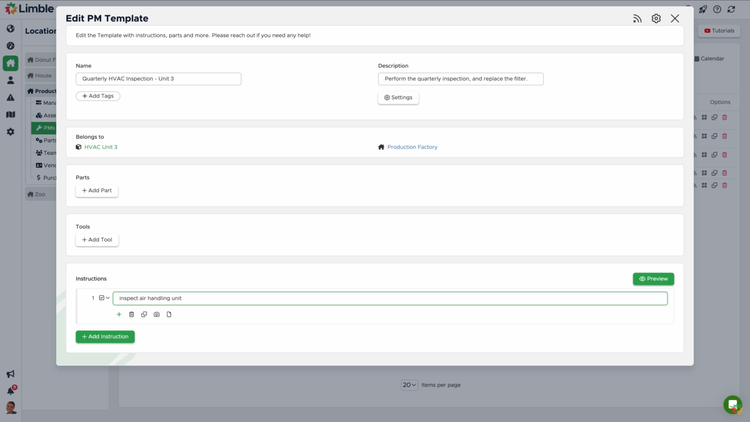

Limble CMMS - Best for Educational Institutions

Limble CMMS helps higher education facilities like universities and colleges operate campuses with extensive assets, including HVAC systems, lab equipment, and security cameras. The system allows you to create customizable PM templates for various assets, from lighting to kitchen appliances in dining halls.

Your team can start by assigning a specific asset to a PM. For example, in the “manage PMs” dashboard, you can select a particular HVAC unit. This opens the “edit PM template” screen. From there, you can customize the template to include instructions for inspecting the air handling unit and replacing the filter. Limble includes different instruction types, from basic checkboxes to advanced options like capturing a technician’s signature.

Limble’s conditional instruction tool lets you add granular steps that adjust based on inspection outcomes. For example, the option to clean the condensate pans appears only when inspecting the air handling unit. You can then click the “add parts” button to associate specific components, like an HVAC filter, with each PM. Then, you can schedule when each PM task occurs, whether on a particular day or recurring basis.

Designed for multi-building campuses, Limble streamlines large-scale maintenance that aligns with academic calendars. You can use the bulk PM import feature to set up multiple templates at once. This simplifies scheduling routine tasks across multiple assets, like classroom air conditioners. For facilities with extensive physical assets, Limble’s scalable setup is attractive, though its per-user pricing may be less suited to smaller budgets. It does however offer a free plan for smaller companies.

What Is Tool and Equipment Tracking Software?

An equipment and tool tracking system helps you monitor and manage machinery and other assets, including location, usage, availability, and maintenance needs. This software typically includes:

- Barcode scanning

- Inventory management

- RFID or GPS tracking

- Maintenance scheduling

- Asset utilization reporting

Sectors commonly leveraging this software includes construction, manufacturing, field services, facilities management, retail, healthcare, and educational institutions. These asset-heavy industries utilize tool management software to prevent loss and theft and schedule regular maintenance to extend equipment longevity.

Key Features & Benefits

Equipment management software helps you make better decisions about equipment investment and resource allocation:

| Feature | Description | Benefit to Companies |

|---|---|---|

| Asset Location Tracking | Tracks the real-time location of tools and equipment using GPS or RFID technology. | Reduces search time, minimizes loss, and ensures equipment availability. |

| Inventory Management | Monitors the quantity, availability, and asset condition in a centralized system. | Ensures resources are available as needed and prevents over-purchasing. |

| Maintenance Scheduling | Automates the scheduling of predictive maintenance based on condition monitoring and preventive maintenance based on usage or time intervals. | Lowers repair costs, reduces downtime, and extends equipment lifespan by preventing breakdowns. |

| Barcode/RFID Scanning | Uses barcode or RFID tags to simplify quick check-in and check-out of tools and equipment. | Enhances accountability and reduces unauthorized usage. |

| Reporting | Generates reports on tool and equipment usage patterns and frequency of use. | Helps support resource allocation decisions and identify under- or over-utilized assets. |

| Alerts and Notifications | Triggers automated alerts for maintenance, overdue returns, or upcoming inspections. | Minimizes downtime and prevents sporadic maintenance scheduling. |

| Compliance Tracking | Monitors compliance with industry standards, regulations, and safety inspections. | Reduces risk of regulatory fines, helps meet safety standards, supports audit readiness. |

What is The Difference Between CMMS and EAM?

Software providers sometimes use the terms CMMS and EAM interchangeably. Though both types of software strive to streamline maintenance workflows and asset management, there are some essential distinctions between the two:

CMMS

- Designed to schedule and dispatch maintenance work on assets after their purchase and installation

- Focused primarily on planning preventive maintenance processes

- Does not include the broader functionalities of EAM

- Ideal for a single location with a moderate number of users

EAM

- Designed to optimize the entire life cycle of an asset, starting with the initial purchase

- Focused on extensive predictive maintenance

- Exists as an extension of CMMS

- Ideal for multiple locations with a large number of users

Further Reading

Frequently Asked Questions

What basics should I look for in CMMS and EAM software?

CMMS and EAM automate equipment maintenance and increase the lifespan of your assets. If a tool-tracking solution is top of mind for you, the software you choose should offer modules in the following:

- Inventory management

- Preventative maintenance

- Asset and equipment tracking solutions

- Work order management

With asset tracking specifically, search for a program that can easily assign barcodes, asset tags, or even RFID (radio frequency identification) to your tools. That way you can follow their movement on the shop floor and beyond. Utilizing barcode scanners on mobile devices, front-line technicians can check in materials after completing work orders at your facility.

Which industries use CMMS and EAM?

Construction companies, educational institutions, healthcare facilities, and retail chains all benefit from the equipment and tool-tracking solutions provided by CMMS. Other industries include:

- IT

- Property Management

- Telecommunication

- Transportation

Any enterprise or organization that needs to track assets, supplies, equipment, facilities, and properties can utilize a CMMS platform.

Are CMMS and EAM Software as a Service (SaaS)?

Our top four recommendations exist in the SaaS model. This means you subscribe to the service monthly or annually. Your data is stored in the cloud, allowing you to access real-time maintenance metrics from your phone, tablet, and desktop.

On-premises CMMS and EAM are installed directly on the company’s server. This means more limited access to data, but users pay a one-time, upfront fee for perpetual licensing and hardware costs. On the other hand, this option affords more security and control over your information.