The Best Factory Automation Software

Factory automation software can help manufacturers of all types and sizes optimize production and streamline workflows. We reviewed top options for core functionalities like advanced analytics and machine-to-machine communication.

- One-time fee for the main platform

- Applications are scalable

- Easy to configure and implement

- Allows for real-time communication among team members

- Users can attach files, videos, and operating procedures to tasks

- Includes Internet of Things (IoT) support

- Offers global, multi-site customer deployment

- On-premise and cloud-based scalability

We’ve evaluated various platforms for key features like frontline worker support, versatility, and IoT sensor data collection.

- Ignition by Inductive Automation: Best Overall

- Parsable: Best for Frontline Operations

- FactoryTalk: Best for Enterprises

Ignition by Inductive Automation - Best Overall

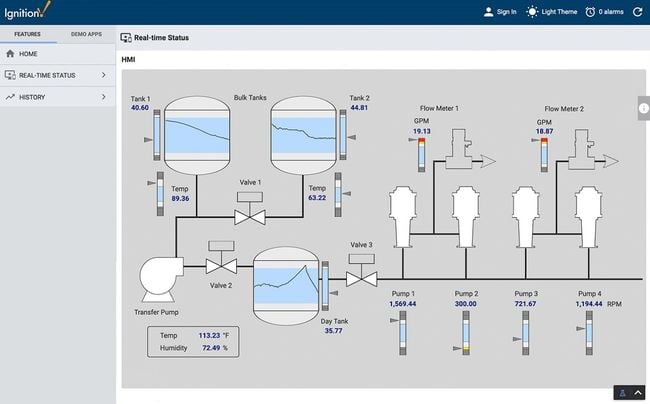

Ignition by Inductive Automation is an extremely versatile platform that combines custom HMI, SCADA, and MES functionalities into one system. It features a modular architecture, so you can add and remove features as needed without impacting performance. This helps you build the system to meet your needs, whether you’re manufacturing automotive components or producing food and beverages.

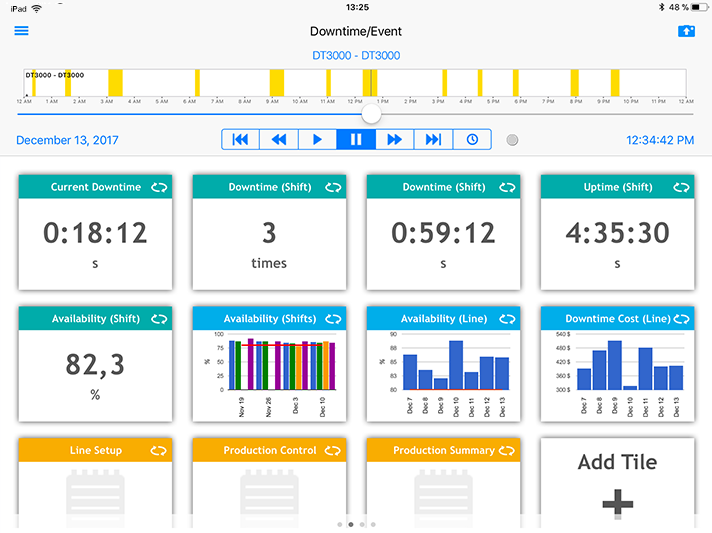

Specifically, its SCADA solution offers real time monitoring of your entire shop floor. The system allows you to see current tag values to see the status of your facility on any device. You can customize these on SCADA dashboards to analyze data points, letting you make adjustments to ensure operations are running smoothly.

Ignition offers modular pricing, so you only pay for what you need, with costs as low as $3,018 for a perpetual license. It also has prebuilt packages that include unlimited tags, designer clients, and SQL database connections. However, these are significantly higher in price, with the smallest plan costing $14,690.

See our Ignition by Inductive Automation product profile.

Parsable - Best for Frontline Operations

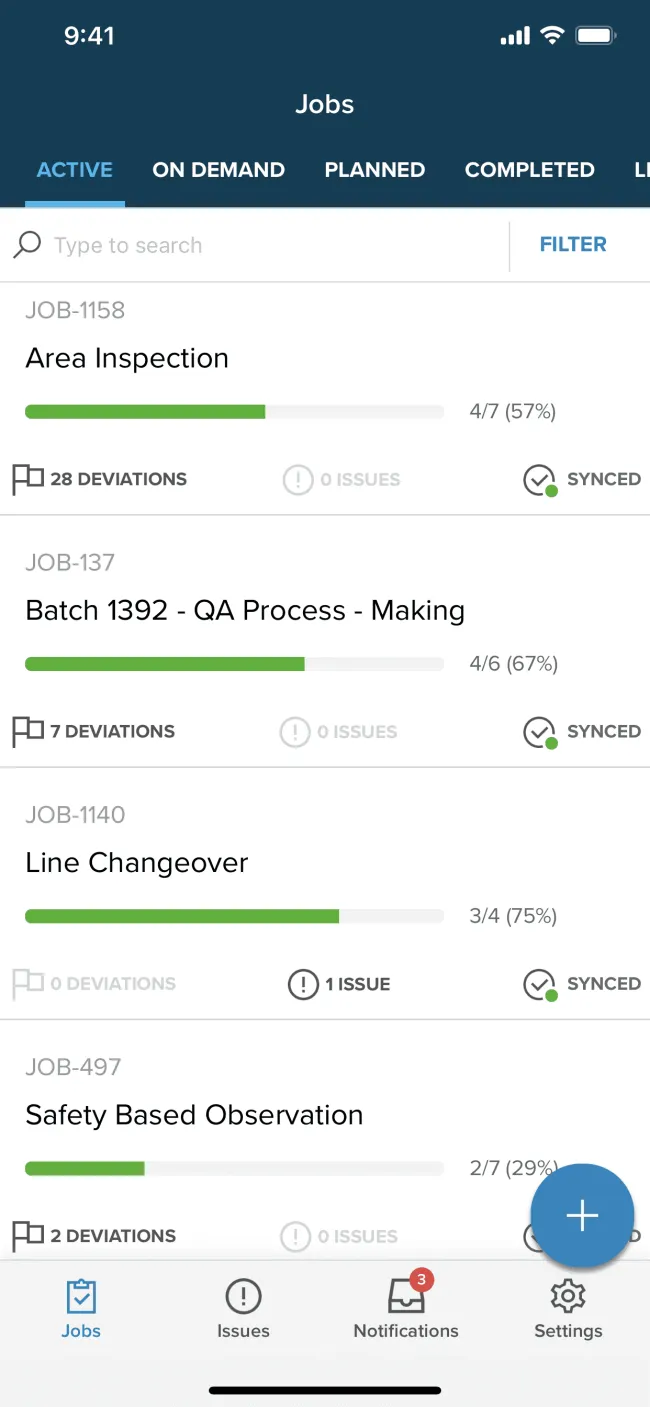

Parsable Connected Worker’s strong mobile app provides frontline workers access to digital analytics to increase plant productivity. Employees can collaborate with local or remote experts to troubleshoot problems and reduce delays. Users can even monitor their machine’s health through IoT sensor data from their phones. These mobile capabilities increase factory automation by empowering frontline workers with data and insights.

Additionally, Parsable includes AI-powered analytics that can help you automate your entire plant. Using live sensor data, the system lets you proactively detect anomalies in machine performance. Administrators can communicate this to operators for immediate intervention to minimize downtime. It also displays AI-suggested insights to help optimize your processes.

Parsable is a great fit for small manufacturers in multiple industries, including food & beverage, building materials, and consumer packaged goods. Pricing starts at an affordable $30/employee/month.

FactoryTalk - Best for Enterprises

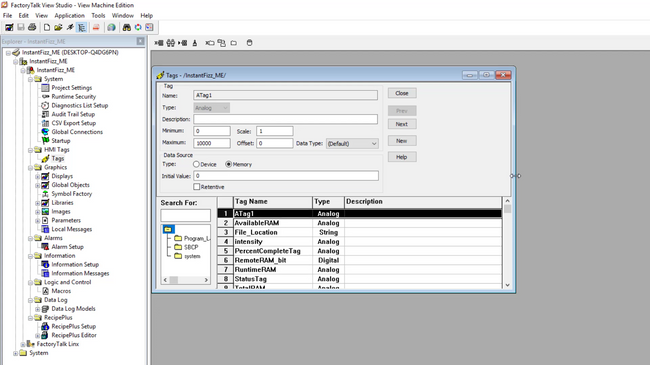

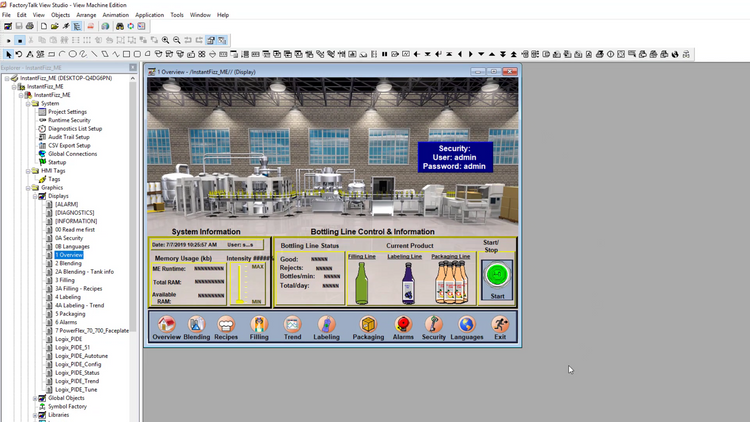

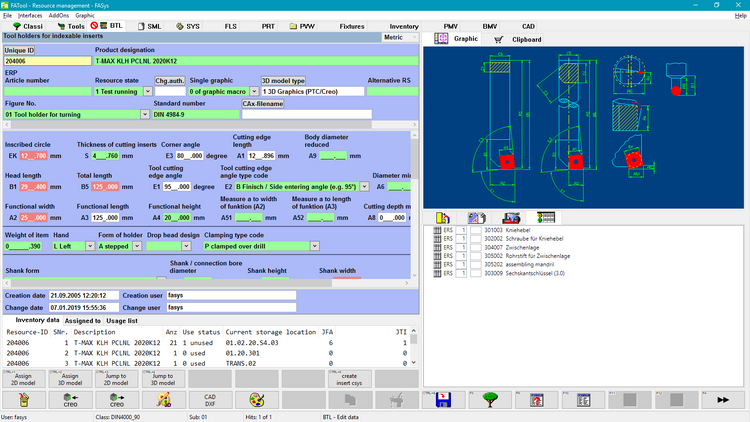

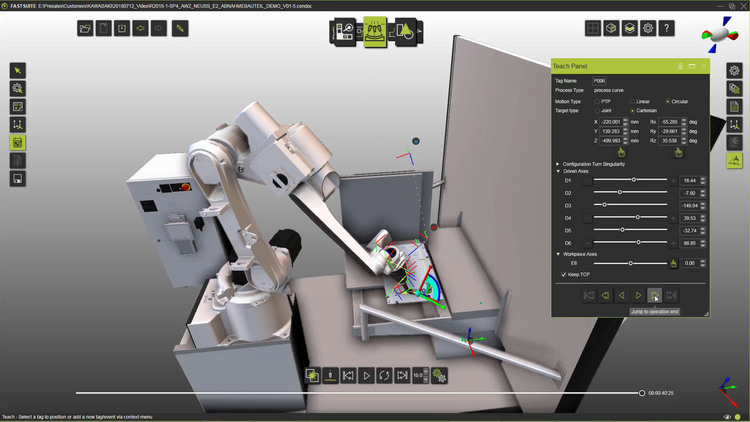

FactoryTalk is an MES that offers a suite of advanced applications for enterprise manufacturers, from design to innovation. Its built-in ThingWorx IIoT platform is crucial for data collection and remote monitoring. It consolidates data from existing production assets and ad hoc systems for one centralized view. Using the data, you can simulate processes in a virtual environment and test automation code to improve automation and efficiency.

Through the connected IIoT sensors, you can use the FactoryTalk Analytics module to leverage data. Monitor asset performance and track crucial KPIs like downtime, overall equipment effectiveness (OEE), and production counts. Drill down into energy usage to identify waste and root causes of quality issues. Process manufacturers can even optimize yield by applying corrective insights. These analytic capabilities allow enterprises to consolidate data from multiple shop floors and consistently optimize processes.

Unfortunately, FactoryTalk does not disclose its prices publicly, so you must contact them directly for a custom quote. That said, it requires significant investments due to its complex implementation and breadth of features. For a more streamlined setup, Ignition by Inductive Automations is a good alternative.

See our FactoryTalk product page for more info.

What is Factory Automation Software?

Factory automation software helps your organization achieve high availability of plants and machines through resource and cost optimized production. Also known as industrial automation software, the solutions connect to tooling and production resources through sensors and integrates equipment for better shop-floor data access.

This helps give manufacturers greater visibility and traceability in optimizing their production efficiency–as well as leading to lower costs, improved quality, and increased flexibility.

Sharing a close relationship with OEE software and MES software, factory automation software harnesses the power of Industrial IoT, or IIot, by utilizing smart sensors and programmable logic controllers (PLCs) to connect to manufacturing equipment in real-time.

This provides increased visibility on the performance of the manufacturing systems–allowing management to quickly reconfigure settings for changing production requirements, if needed.

The use of smart sensors in factory automation software can also be used for maintenance management. By collecting data for optimization and continuous improvement, you can also use that same data for predictive maintenance.

Machine learning algorithms can easily identify changes in manufacturing machine health, helping your business avoid failures in your production line.

Any manufacturing business with the wireless sensor network infrastructure has the ability to implement factory automation software in an IIoT environment:

- Add sensors to industrial equipment

- Send data over a wireless sensor network via Bluetooth, Wi-Fi, and more

- Connect the wireless sensor network to the cloud to update your central data repository

- Allow management to analyze the data or set up rules and triggers for increased automation and decision-making

Key Features

- Measure Data: Collect data from connected scales, calipers, thermometers, and sensors.

- Image Capture: Record defects via images and videos with camera integrations

- Workflow management: Create digital workflows that combine work instructions and backend processes using logic

- Data and Analytics: Aggregate data from apps to create, update, and display records from apps, machines, and sensors. Filter data being shown in the analysis based on variables, records, machine output, and more.

- Connectors: Configure connectors to send data between APIs, SQL databases, and more. Build functions and logic to control how apps push and pull data from integrations.

Primary Benefits

Factory automation in a manufacturing environment leverages technologies to create a more complex system to increase outputs and efficiency while decreasing costs. This type of automation can also reduce risks that human operators may deal with when it comes to working with heavy machinery.

Improved Production Process Planning

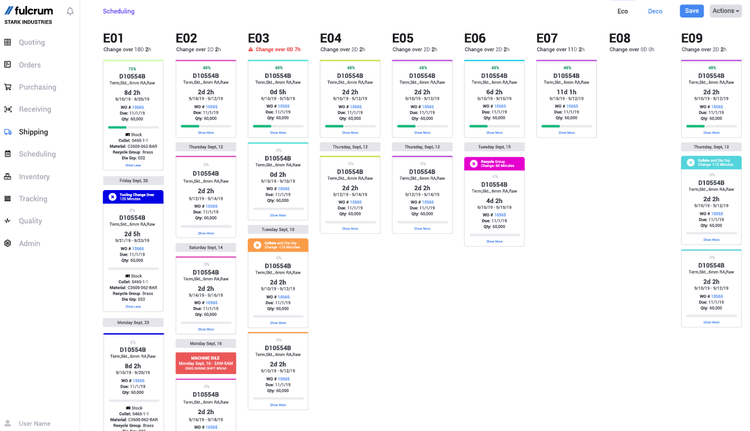

The use of factory automation software means manufacturers can improve planning and control by ensuring the right raw materials in the right quantities are available for planned production operations. It also ensures enough personnel are scheduled to work and the equipment required is available.

This combination of advanced planning and scheduling efforts ensures your manufacturing operations will go on as planned.

Additional benefits include:

- Enhanced performance and quality outcomes via consistent process planning

- Minimization of production run critical path time with routing optimization

- Decreased per job resources requirements via labor, energy, equipment, and rework management

Job Release and Resource Optimization

Manufacturers often have standards for how long a job should take. Usually this is determined during the design and engineering stage, but often this changes when the job comes to fruition on the shop floor.

Because these standards often dictate base pricing and scheduling, it can cause issues between expected vs actual job time. Examples of issues include:

- Unrealistic goals based on expected vs actual rates of production

- Difficult to meet delivery goals, leading to broken promises with customers

- Slimmer profit margins than quoted due to inaccurate quotes based on projected vs actual time spent on a job

Factory automation software will use actual performance data to drive expected job standards–all while updating them continuously via workflows. Connection with your manufacturing equipment can help contextualize the data and understand what your true production time really is.

Additional benefits include:

- Higher throughput via better resource utilization and load-to-availability ratios

- Minimization of planned downtime with intelligent equipment maintenance scheduling

- Increased ability to meet lead time obligations with job prioritization

Avoid Downtime With Production Workflow Management

Factory automation software provides visibility into production assets, such as what machines are available for a specific job at a given time. However, visibility on the plant floor can get cloudy with the large variety of systems and equipment being used on the plant floor.

Without careful planning, your business will end up being more reactive than proactive when it comes to scheduling jobs on your machines.

Workflow management offered by factory automation software helps guide your staff through their managed tasks. By being able to see asset availability, you’ll be able to configure assets to operate when available and avoid downtime. This avoids your factory line from experiencing any interruptions–as well as track response and recovery from incidents that may cause downtime.

This allows management to improve their problem-solving skills and speed up their response time when unavoidable incidents occur on the shop floor.

Additional benefits include:

- Improved internal and customer coordination with real-time job status visibility

- Reduced cycle times via timely communication of work order instructions

- Lower quality non-conformances via collection of machine sensor data and alerts and notifications

Quality and Data Management

Industry 4.0 (also known as smart manufacturing or digital transformation) refers to the new phase in the industrial revolution that focuses on interconnectivity, automation, machine learning, and real-time data. This concept relies heavily on IIoT concepts of connecting people, data, and machines as they relate to manufacturing

The core of this philosophy is plant data management. By collecting important data about your actual production, you’ll be able to:

- Cleanse data to eliminate future manufacturing error

- Normalize data as it relates to your average manufacturing processes

- Store data to make future decisions and improvements

- Ensure data doesn’t exist without context

Many of these functions are also offered in MES and product lifecycle management software options (PLM software).

Additional benefits include:

- Faster resolution of bottlenecks via process performance analysis

- Root-cause discovery of quality issues with statistical process control

- Enhanced ability to demonstrate regulatory compliance with full process traceability

- Satisfaction of regulatory compliance standards with production records