The Best Shop Floor Management Software

Shop floor management software helps manufacturers streamline operations by tracking production, optimizing resources, and minimizing downtime. We tested and reviewed the top solutions that improve real-time visibility and boost shop floor productivity.

- Allows for real-time communication among team members

- Users can attach files, videos, and operating procedures to tasks

- Streamlines manufacturing operations

- Real-time visibility into the manufacturing process

- Integration with other systems for improved efficiency and productivity

- Affordable, transparent pricing

- Real-time inventory tracking across locations

- Data-driven decision-making support

We’ve used our in-depth software review methodology to test dozens of the top systems, helping you choose the perfect solution to boost productivity and meet business goals.

- Parsable: Best Digital Work Instructions

- DELMIAWorks: Best Real-Time Visibility

- Katana MRP: Best for Small Businesses

- MachineMetrics: Best for Predictive Analytics

- ShopVue MES: Best MES System

- MRPeasy: Most User Friendly

- QT9 ERP: Best for Health Sciences

- MasterControl: Best for Compliance

- Global Shop Solutions: Best Full Manufacturing ERP

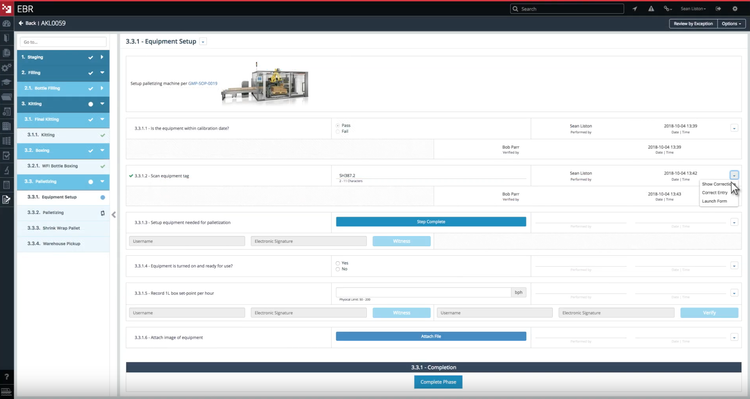

Parsable - Best Digital Work Instructions

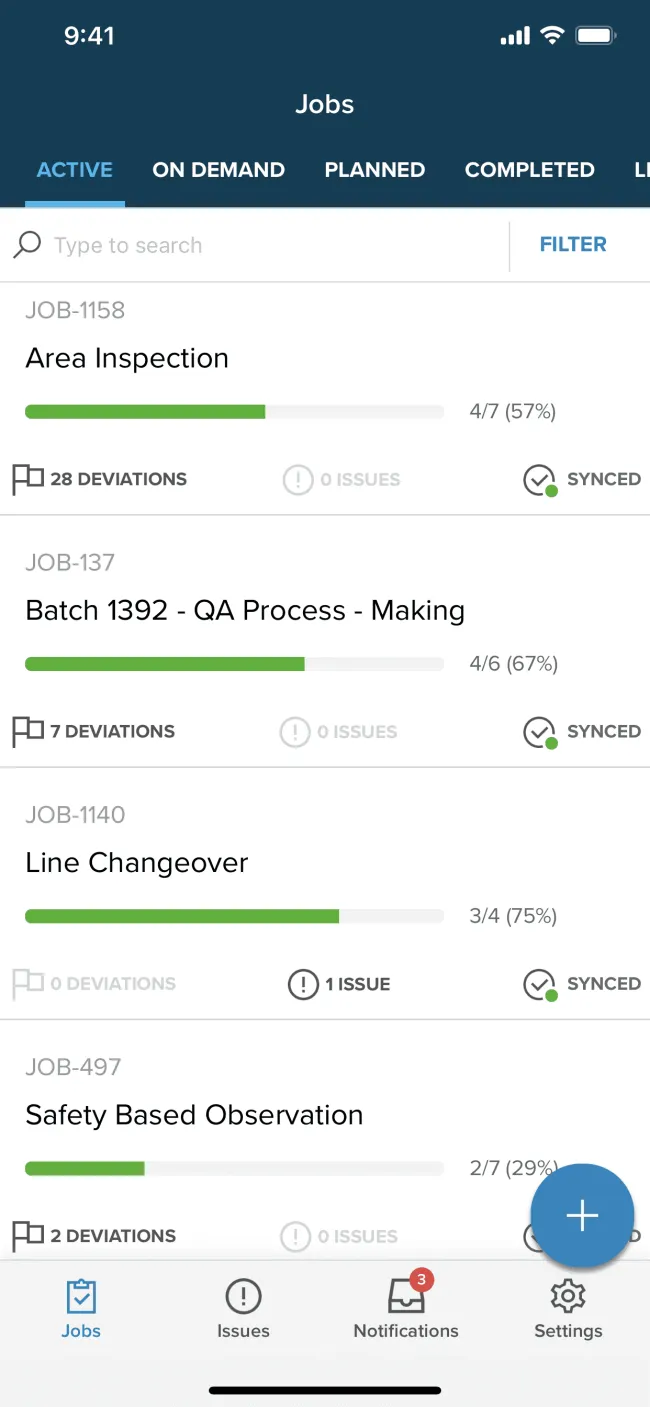

Parsable offers comprehensive digital work instruction features designed to enhance shop floor management by providing accessible and clear guidance to frontline workers. Your employees can easily create and upload content, allowing for quick adaptation to evolving standard operating procedures and regulations.

You can include images, videos, and animations to enrich your instructions, making complex tasks more engaging and understandable to workers. You can also utilize clickable buttons, hyperlinks, and checklists to create dynamic content that facilitates user interaction and ensures thorough task completion.

These instructions are deployed to frontline workers’ mobile devices, providing real-time, step-by-step guidance. As shop floor staff perform tasks, the platform collects data on their execution, allowing you to monitor compliance and analyze performance metrics.

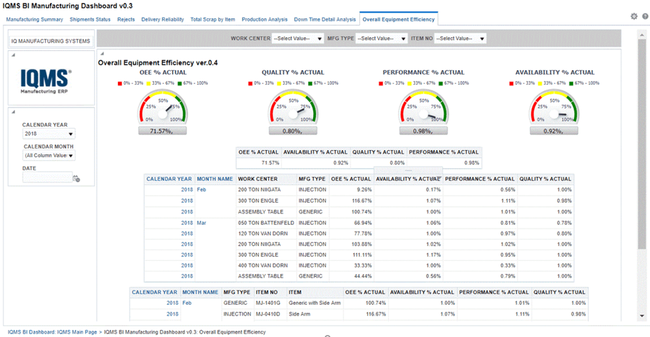

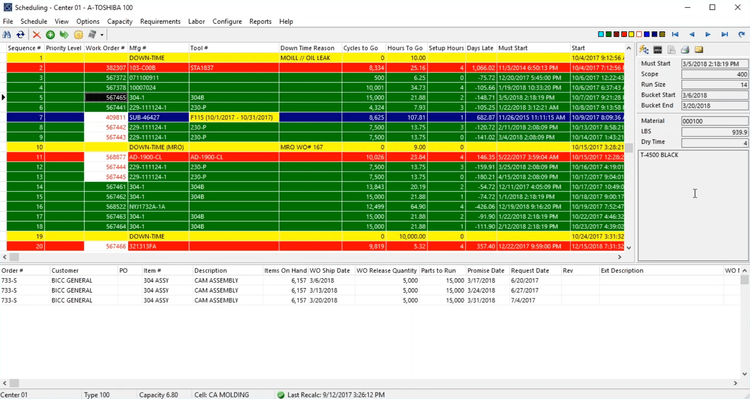

DELMIAWorks - Best Real-Time Visibility

DELMIAWorks is known for its efficiency-enhancing capabilities. As a manufacturing execution system (MES) developed by Dassault Systèmes, we found it offers a comprehensive range of features such as inventory barcoding, customizable reporting, and shop floor control. What sets DELMIAWorks apart is its ability to provide real-time visibility into the manufacturing process, enabling manufacturers to easily identify bottlenecks and optimize production for maximum efficiency.

However, some users have reported drawbacks with DELMIAWorks, such as its reliance on Microsoft Remote Desktop for application access and the lack of a web interface. Despite these minor cons, the software remains a top choice for businesses seeking a solution that streamlines manufacturing operations while providing real-time insights.

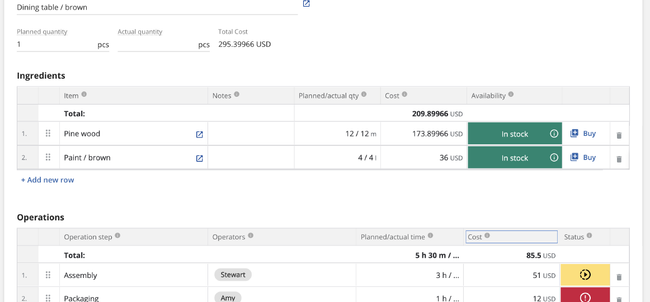

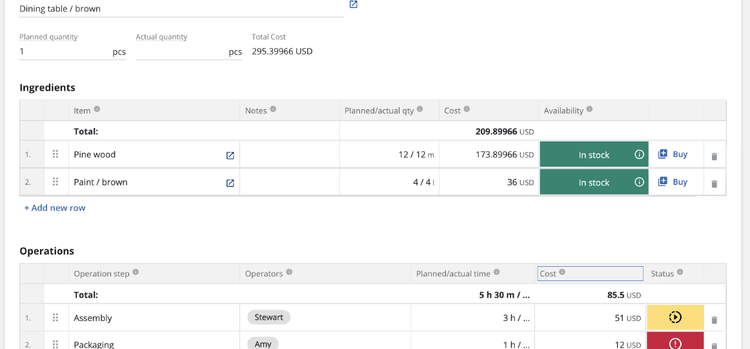

Katana MRP - Best for Small Businesses

Katana MRP offers real-time inventory management, production optimization, and data-driven insights to help businesses reduce manufacturing costs and improve efficiency.

One of the standout features of Katana MRP is its custom API integrations, which allow for seamless communication with various tools, including:

- E-commerce platforms

- Accounting software

- CRM systems

- Reporting tools

- Automation software

With its user-friendly interface and powerful features, Katana MRP is the top choice for small and medium-sized manufacturers looking to streamline their operations and make data-driven decisions.

MachineMetrics - Best for Predictive Analytics

MachineMetrics, a manufacturing analytics platform, provides real-time insights into machine performance, earning its place as a standout performer in shop floor management software. By collecting and analyzing machine data, including:

- Performance

- Health

- Breakdowns

- Changeovers

- Quality loss

- Downtime

MachineMetrics enables manufacturers to optimize their operations and reduce downtime.

The platform’s predictive analytics capabilities are particularly valuable, allowing manufacturers to anticipate maintenance needs and prevent costly breakdowns. While pricing information for MachineMetrics is not readily available, its impressive features and real-time data analysis make it a top choice for businesses seeking to optimize their manufacturing processes and stay ahead of the curve.

ShopVue MES - Best MES System

Shopvue MES offers a suite of modules that streamlines operations and gives you more control of the shop floor. Specifically, the direct machine interface (DMI) module automatically captures machine data for real time production monitoring. The unified architecture exchanges data between your controllers, machines, IoT devices, and monitoring apps, giving you a consolidated view on one dashboard. This eliminates the need to manually collect machine data like yield and scrap, which often leads to errors and write-offs.

The DMI tool also converts critical data into easy-to-read statistics for quick monitoring. Track metrics and KPIs such as:

- Overall Equipment Effectiveness (OEE)

- On-Time Delivery (OTD)

- Overall Line Efficiency (OLE)

- Work In Progress (WIP)

Having easy access to all of these metrics allows you to identify potential inefficiencies or bottlenecks on the shop floor. From there, you can implement more efficient workflows to make your operation run smoothly.

Because ShopVue is a full MES system, it’s best for mid to large-sized companies that need total control over production and labor management. Prices range from $45,000 to $180,000/year, but you’ll need an exact quote based on factors like the number of terminals on your shop floor and required modules.

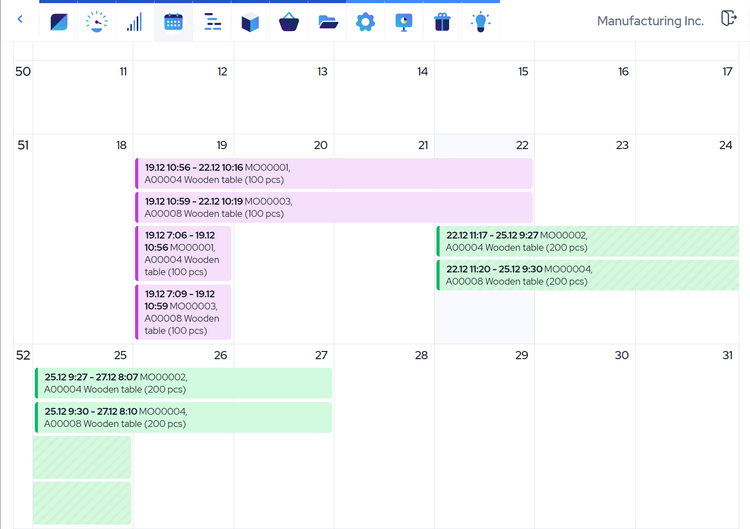

MRPeasy - Most User Friendly

MRPeasy provides small manufacturers with comprehensive functionality and a user-friendly interface. Some key features of MRPeasy include project management, production planning, inventory management, CRM, and procurement.

With these features, MRPeasy streamlines production processes, tracks manufacturing costs, and improves efficiency by effectively managing production data.

One of the standout features of MRPeasy is its seamless integration with popular accounting systems like Xero and Shopify, making it easy to manage all aspects of the manufacturing process and eliminate manual data entry. With its user-friendly design and powerful features, MRPeasy is an excellent choice for small businesses looking for a comprehensive manufacturing software solution.

QT9 ERP - Best for Health Sciences

QT9 ERP, a lesser-known entity in the shop floor management software market, offers a host of benefits and features waiting to be tapped into by businesses. Designed for life sciences, medical device manufacturers, pharmaceuticals, and biotech industries, QT9 ERP consolidates various business processes. It provides comprehensive features in inventory and supply chain management, sales management, and value-added services.

Although it may not be as well-known as some other options on our list, QT9 ERP is worth considering for businesses seeking a powerful and versatile shop floor management solution.

MasterControl - Best for Compliance

MasterControl, known for its focus on compliance, offers a top-tier Quality Management System (QMS) designed specifically for the Life Sciences industry, cementing its place in the shop floor management software market. With comprehensive features and tools, MasterControl helps organizations streamline their quality processes and ensure compliance with regulatory requirements.

One of the standout features of MasterControl is its seamless integration between the Documents and Training modules, allowing for efficient collaboration and ensuring that employees are properly trained and qualified. Although some users have reported issues with system upgrades and a lack of a complete training compliance report, MasterControl remains a top choice for businesses in the Life Sciences industry seeking a powerful and efficient QMS solution.

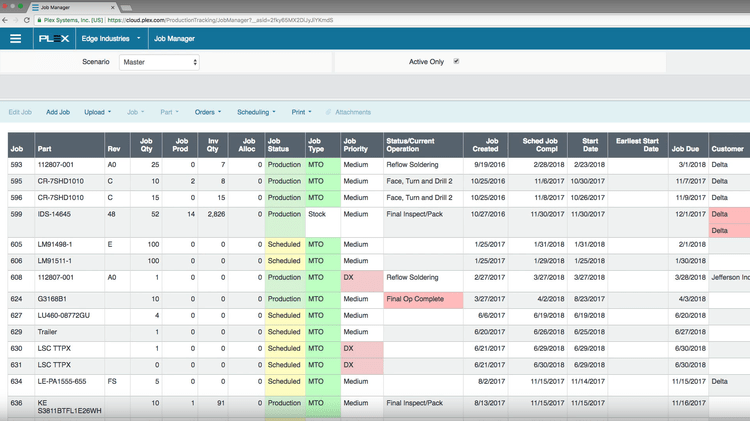

Global Shop Solutions - Best Full Manufacturing ERP

Global Shop Solutions is a great ERP solution for manufacturers looking for better shop floor control because it combines production, inventory, and accounting into a single, integrated platform. It is ideal for smaller to mid-sized manufacturers such as aerospace, automotive, and custom job shops that want to move away from disconnected systems or traditional spreadsheet methods.

With features like real-time production tracking, job costing, and integrated payroll, Global Shop Solutions helps manufacturers manage both their shop floor operations and finances without relying on third-party systems. This keeps your data consolidated, reduces manual entries, and reduces the risk of errors. Pricing for Global Shop Solutions starts at around $1,500 per month, making it a cost-effective option for manufacturers looking for an all-in-one shop floor ERP.

One drawback of Global Shop Solutions is that dealing with issues after upgrades can be a hassle. Given the complexity of the software and the fact that it is often customized for each user, issues tend to arise after updates, and support for older versions can be limited.

What is Shop Floor Management Software?

Shop floor management software is designed to prioritize, track, and report on production activities and ensure your manufacturing operations run smoothly. It plays a key role in managing the flow of materials, labor, machines, and production time within a manufacturing environment. This software provides real-time data on work order progress, machine usage, and inventory levels, allowing shop floor supervisors or business owners to make more informed decisions and maintain control over production schedules.

When integrated with other manufacturing systems, such as manufacturing execution systems (MES) or material resource planning (MRP) software, you will be able to stay more informed through real-time access to shop floor activities. Linking with MES software will help identify production inefficiencies and machine downtime reports and provide actionable insights into any bottlenecks. Integrations with MRP capabilities will allow you to optimize inventory management, ensuring that raw materials and components are available when needed while minimizing excess stock.

Shop floor management software enables you to identify and address potential issues in real-time before they escalate into major problems. By providing early insights, you can maintain better control over production efficiency, keep operations running on schedule, and ultimately improve overall productivity.

Key Features

- Production Monitoring: Monitor production performances and identify production inefficiencies. Define performance and measurement parameters for each item or tooling configuration. Receive job-specific statistics or entire work center performance efforts. Break down production feedback into total parts created, production time, downtime, scrap, rejects, parts remaining to be produced, and more.

- Production Planning: Plan production on your shop floor by determining the need for materials and capacity to complete a manufacturing production order. Create a highly detailed master production schedule that accounts for resource, staffing, and inventory needs to complete and optimize production.

- Inventory Management: Track finished goods and material availability by allocating raw materials to production or finished goods to sales orders. Move inventory to and from locations depending on need.

- Bill of Materials: Specifies the raw materials, parts, and sub-assemblies needed to manufacture each specific product. Make automatic inventory adjustments and help calculate manufacturing costs.

- Task Management: Create to-do lists and assign tasks to various departments or specific employees. Optimize time and resources by giving full visibility of the project lifecycle and who is responsible at each step within a manufacturing work order.

Benefits

Manage and Reduce Manufacturing Costs

Manufacturing production systems such as shop floor management software can only perform as well as the data entered into it.

- Older systems required a hefty amount of manual data entry–meaning the solution would only be as beneficial to your business as quickly as you could key in data. And there’s plenty of paperwork and spreadsheets.

- Newer systems tend to alleviate these production costs through automation tools–meaning your workers are spending less time entering data and identifying areas where productivity needs improvement. Digitizing records allows for paperless operations, further decreasing on-the-job waste.

Run “What If” Analysis Scenarios

What-if scenarios let manufacturing managers analyze key performance indicators (KPIs), visualize production scheduling outcomes, and look for potential disruptions.

Examples of disruptions include a lack of supply, meaning the scenarios examine inventory management, facility capacity, and your overall supply chain. When production schedules can be visualized before being implemented, you can test out different variables and choose the best production scheduling method.

Accurate demand planning in shop floor management is beneficial for short-term and long-term planning, as it helps visualize and locate disruptions in production and offers cost-effective methods to complete processes. This involves collecting historical data on metrics like order volumes and inventory turns while mixing it with continually updated forecasts from your sales personnel.

Maintain Shipment Dates

Shop floor control systems allow you to identify your projected ship dates for manufacturing orders quickly. This is a huge asset when taking new orders–giving you a date you can quote to a customer and a promise you can live by.

With late shipments come paying overtime to employees to meet deadlines or breaking promises to customers with late shipments–which could negatively impact future business.

Real-time production data tracking can release WIP orders by knowing when they will be complete. When bottlenecks occur in production (which at times are inevitable), adjustments can be made to your production schedule and some jobs can be routed to available resources. Also known as constraint management, this covers activities that are delayed due to resource capacity and/or material availability limits.

Integrate with ERP Systems

Shop floor management systems are a great addition to your existing manufacturing ERP software environments. Integration wizards are included in a few shop floor control solutions and may aid with data collection for other systems, such as CRM software.

Alternatively, an SFM software vendor may specialize in integrating their solution with a specific ERP or MES. The biggest benefit of complete integration with other business management systems is having a complete view of your operations.

Businesses want to avoid duplicate entries or data transfers from one system to another whenever they receive new sales orders, hire new workers, or purchase new machines. They want a system that seamlessly transfers data from the planning and scheduling phase into their ERP solution.

Pricing Guide

Small Business Systems

Small business shop floor management software generally costs between $1,000 and $10,000 per year. These systems offer basic features for work order and inventory tracking and real-time data reporting with minimal integrations. Cloud systems are common at this level, making it more affordable for smaller manufacturers.

Mid-Tier Systems

These systems typically start at around $10,000 per year and can cost upwards of $40,000 annually. Mid-tier options offer more advanced features, including customizable dashboards, enhanced reporting, and integration with ERP/MES systems. They are best suited for growing manufacturers who need greater scalability and functionality.

High-Tier Systems

For larger businesses, the total cost can range from $50,000 to $100,000 annually. These systems include predictive analytics and machine integration and can support multiple sites, which is ideal for manufacturers with complex production or many locations.

Enterprise

For global enterprises with multiple manufacturing facilities, expect costs to start around $150,000 annually and go up from there. These programs will offer full customization, AI-driven analytics, and robust integrations with ERP/MES solutions. The annual cost will cover both the purchase and the support and customization of the software.

How to Choose

Examining various solutions’ features, pricing, and user reviews will help you pinpoint the best software for your business, paving the way for a seamless production process.

When selecting a shop floor management software, it is important to consider aspects such as:

- Functionality

- Real-time data

- Integration

- User-based permissions

- Scalability

- Cost

Each software option listed above offers unique advantages and features that cater to different manufacturing needs. By comparing these options and considering your specific requirements, you can make an informed decision and invest in a software solution to help your business grow and thrive.

By meticulously assessing your business needs, comparing features, pricing, and user reviews, and contemplating the unique advantages of each software solution, you can zero in on the ideal shop floor control software.

A shop floor management system will help streamline manufacturing processes, enhance efficiency, and boost profit margins by effectively utilizing shop floor data.