A Guide to Warehouse Inventory Management Processes

Warehouse inventory management is the process of tracking, storing, and managing inventory within a distribution center to ensure optimal stock levels, reduced storage costs, and fast order fulfillment. It includes:

- Receiving: Managing deliveries and unloading inventory; confirming stock quantities; barcoding and verifying product codes and SKUs.

- Storage: Organizing and placing items to use space efficiently; allocating space for single-load or mixed-load storage.

- Picking: Sending pick lists to warehouse workers with order details; printing shipping labels with tracking numbers; selecting and packaging items for shipping.

- Cycle Counting: Continuously auditing inventory by counting smaller sample batches; pinpointing and resolving stock discrepancies in real time.

- Cross-Docking: Routing incoming goods to outgoing orders; reducing storage time by fulfilling orders immediately.

- Lot and Serial Number Tracking: Tracking individual units or item batches; improving traceability for better quality control and regulatory compliance.

- Order Allocation: Prioritizing orders based on specific conditions or backorders; assigning picking and packing tasks to warehouse employees.

Inventory management refers to managing raw materials and finished goods directly related to production. The purpose of the warehouse inventory management process is to keep track of all inventory so that you never run out but also don’t have excess amounts sitting around unsold.

Having a streamlined warehouse management application for optimizing the picking, packing, and putaway of your organization’s inventory can save you time and money while keeping your company running smoothly.

Warehouse Management Systems (WMS)

Most businesses turn to a warehouse management system to manage stock stored in a warehouse or storage facility and track, audit, and manage items for order fulfillment. The best warehouse management systems will vary depending on your needs. Because every warehousing operation is different, it’s important to evaluate the features of different WMS platforms to determine the solution that best meets your needs.

Further Reading: Explore our picks of the best warehouse management software

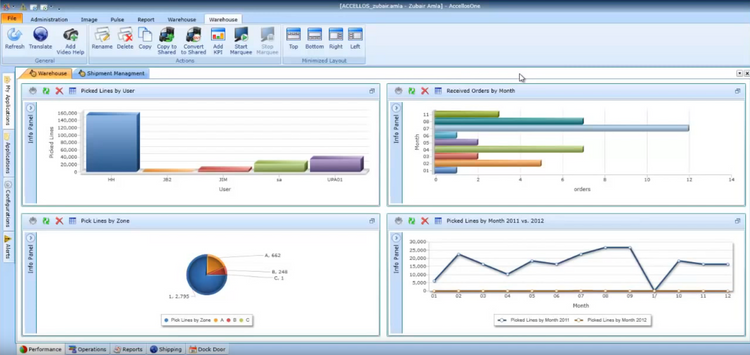

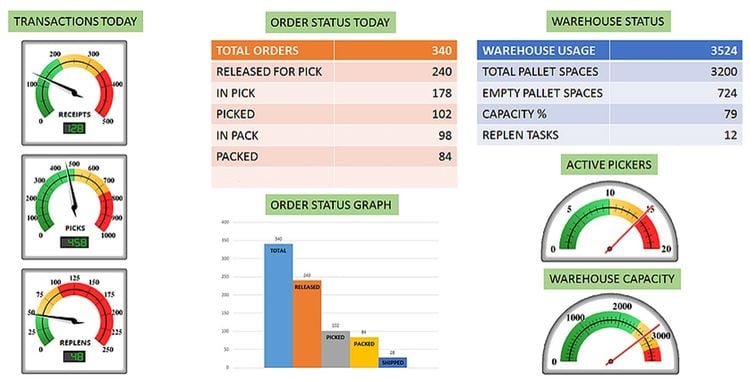

Warehouse management software (sometimes called WMS software) allows warehouse managers to manage and coordinate inventory and actions throughout a warehouse or distribution center. To oversee warehouse operations, WMS software gives managers powerful tools to design a warehouse’s workflow, control stock, schedule labor, generate bills, analyze reports, and coordinate with shipping yards and docks.

Sometimes warehouse inventory management functionality can be provided through a distribution ERP software or supply chain management software. The best warehouse inventory management software functionality makes it possible for a warehouse to operate at its maximum efficiency through:

- Higher accuracy of order fulfillment

- Optimized picking and shipping

- Faster delivery times

- Efficient labor management

- Increased visibility of an order’s status

- Optimized storage space

- Minimized inventory movement

- Improved yard and dock productivity

Challenges

Warehouse inventory control requires more than just organizing products–it helps create the right alignment of network strategy, technology systems, and engineering for improved inventory visibility and accuracy. Failure to face any of these common challenges can lead to inefficiency and reduced productivity.

Supply Disruptions

A supply disruption occurs when a disturbance or problem interrupts the supply chain events, activities, or processes. In other words, it’s a breakdown of the flow of goods to their ultimate resting point, which is delivery to the customer.

Companies can take steps to prepare against these disruptions with the right warehouse inventory management processes. For example, by evaluating where most of their customers are located, they can analyze which transportation methods are most effective for shipping goods to the customers. It can also guide decisions on where to place warehouses to minimize shipping costs and delivery times.

Market Volatility

Markets can fluctuate due to a number of factors, such as global competition and an increase in choices available to the customer. This volatile demand can create a ripple effect that makes it difficult to keep up. Modern warehousing technology prides itself on being demand-driven vs product-driven–meaning volatility can lead to overstocking, an increase in return rates, and more.

Companies can use warehouse inventory management processes to better prepare for market volatility by holding safety stock, leveraging technologies such as demand planning and predictive analytics, or diversifying their product and partner portfolio in the event that trade restrictions make it difficult to receive certain items or exchange goods with certain countries.

Inventory Loss

Losing inventory is a far more frequent occurrence than one would expect. Inventory shrinkage can include loss, theft, miscounting, or damage to goods in the warehouse. While moving and organizing space in a warehouse, it’s common for stock levels to be affected by this–ultimately increasing the total cost of goods.

Warehouse inventory management processes can better plan for capacity, keep warehouse space plans updated with products for quick retrieval, improve the visibility of product labeling, manage provisions for losses, and train staff in safe handling practices.

Common Functionalities

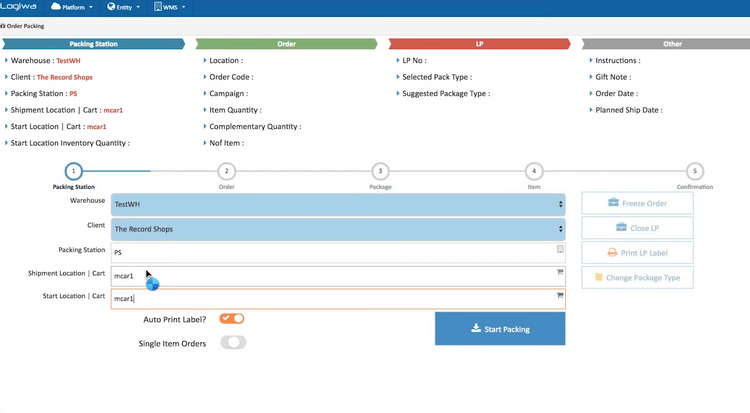

- Picking: Expedites and optimizes the product selection process. Finds, selects, and prepares products for shipping to retailers or directly to consumers. Send pick lists to warehouse pickers that contain customer info, date and time of order, order number, product location, product SKU, and a description/photo of item. Print out carrier-compliant shipping labels detailing origin, weight, shipping class, and tracking numbers or barcode details. Further reading: What is Order Picking? And What Are The Best Methods?

- Receiving: Manage deliveries, unloading, and storage of inventory within the warehouse or fulfillment center. Create proper documentation for pre-receiving tasks and attach it to each shipment with a visible barcode. Receive and unload stock based on the delivery schedule. Count and confirm inventory, including quantity and integrity of seals, and verify product codes/SKUs.

- Storage: Store received goods in a single-load or mixed-load option. Process delivered goods and allocate warehouse space for them.

- Cycle counting: Continuously track inventory levels and speed up the auditing process by breaking it down into smaller sample batches. These audit counts can be made without a shutdown of production or fulfillment, as opposed to a more traditional physical inventory count. It helps reduce inventory errors by identifying problems in the process. Further reading: What Is Cycle Counting?

- Cross-docking: Route goods being received to fulfill existing orders and use them before they take up space on your inventory shelves.

- Serial number and lot tracking: Allows for identification of a particular unit or group of inventory that can not be easily tracked as individual units.

- Order allocation: Input orders from various sources and create an order list to fill. Assign picking and packing tasks to employees and prioritize based on varying characteristics, such as fulfilling back-orders.

Importance

The right warehouse inventory management system can improve sales and increase profits by speeding up the processes that occur after a sale. By shortening shipping times, your company will be able to process more orders at a faster rate, leading to higher overall company productivity.

A warehouse management system becomes a vital part of any warehouse by improving inventory records, optimizing logistics, ensuring product accuracy via real-time updates, and offering better customer service. A WMS system also adds efficiency and consistency to your overall quality control processes, meaning that at every stage in your fulfillment process, workers will be able to pick and putaway more items in less time because they have the right tools guiding them.

WMS can also integrate with existing business management processes, such as ERP software. A full ERP suite will typically handle accounting processes such as income and expenses, purchasing, and general inventory costing.

Warehouse vs. Inventory Management

There are many ways to manage your company’s inventory. Detailed inventory management systems are often used alongside warehouse management systems (WMS). In fact, some people refer to these management systems interchangeably. While there are undeniable overlaps between inventory and warehouse management, there are key differences you need to be aware of before implementing one or the other at your business.

The key differences between inventory management systems and warehouse management systems are:

- Inventory tracking can be utilized by any business with inventory, regardless of whether it has a warehouse or distribution center. It can be something as minor as a single-store retail location keeping track of items on its product floor.

- Warehouse management tends to be a more complex process that focuses more on managing and coordinating inventory and actions throughout a warehouse or distribution center. The goal of WMS software is to better control a warehouse’s workflow via controlled stock locations, picking and packing optimization, labor scheduling, and coordination with shipping yards and docks.

Automation and the Future

A new trend in warehousing is warehouse automation, or the process of replacing human workers with robots, vehicles, and other automated technologies. Warehouse automation systems work by streamlining warehouse operations through automated means such as conveyor systems, scanning hardware at checkpoints, storage, and retrieval via robotics systems.

Warehouse automation systems, such as some of the newer warehouse inventory management systems, offer:

- More accurate order picking through traceability tools and AS/RS systems to cut down on human error or RFID tools for more streamlined tracking of managing inventory

- Streamlined multi-echelon supply chain operations to better sync income and outgoing processes to maintain storage equilibrium.

- Reduced maintenance and downtime for repairs through preventative maintenance software features that can plan routine maintenance prior to mechanical breakdowns

- Create a safer workplace environment by avoiding product expirations

Other types of WMS systems exist, such as warehouse execution systems (WES), which are logistics software suites for managing on-site product picking, distribution, and storage. While this software is primarily used by distributors, manufacturers also use WES to automate product assembly processes and handle raw materials.