The Best Production Scheduling Software

Production scheduling software streamlines shop floor operations with real-time progress tracking and automated production planning. Compare the options to find the right one for your business.

- Responsive customer support

- Intuitive scheduling features

- Highly customizable for small and large businesses

- Flexible and customizable work views

- iOS and Android mobile apps

- Visual and configurable interface

- Affordable, transparent pricing

- Real-time inventory tracking across locations

- Data-driven decision-making support

The best production scheduling software will streamline inventory management and optimize capacity planning for manufacturers. After examining over 20+ products across 7 metrics based on our review methodology, we’ve ranked our top picks in production scheduling software.

- PlanetTogether: Best for High-Mix Manufacturing

- Visual Planning: Best for Labor-Based Planning

- Katana: Best for Small Companies

- MRPeasy: Most Affordable

- Eyelit APS: Best for Constraint Scheduling

- Fulcrum: Best for Metal & Steel Manufacturing

- Digit: Strong User Interface

- FEDRA: Best for Contract Manufacturing

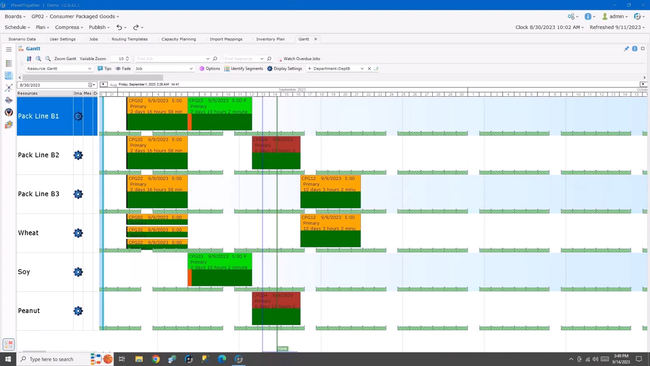

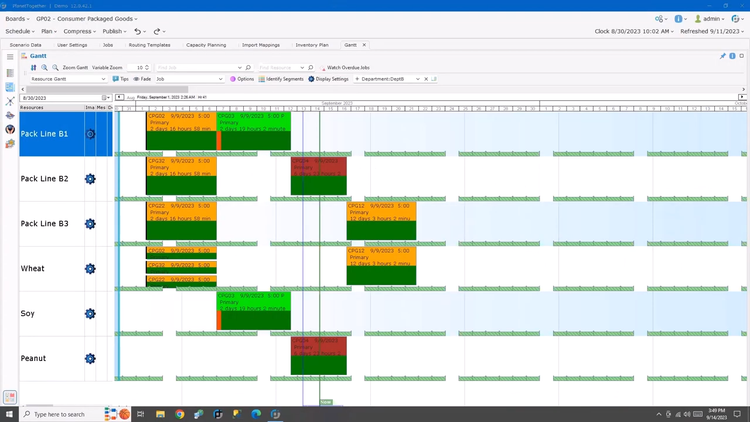

PlanetTogether - Best for High-Mix Manufacturing

PlanetTogether is best for manufacturers that produce a wide variety of products in batches, often with a high degree of customization. It’s a good choice for food processors and pharmaceutical companies. But it can also handle electronics, automotive, and chemicals, thanks to its strong capacity-constrained scheduling

PlanetTogether’s constraint management tool offers drag-and-drop functionality. We found it easy to move jobs, tasks, and resources around in the schedule. If a priority order comes in, it’s simple to adjust and prioritize it in the queue. Overall, the APS does a solid job of integrating labor shifts and material supply into your schedule.

While scheduling is intuitive, we’d like to see more streamlined dashboards in PlanetTogether. The interface can feel cluttered at times and lacks modern design elements. However, this is a common issue among APS systems, many of which still rely on legacy designs.

UI aside, PlanetTogether is a good pick for any high-mix manufacturer looking for an effective solution for finite capacity scheduling.

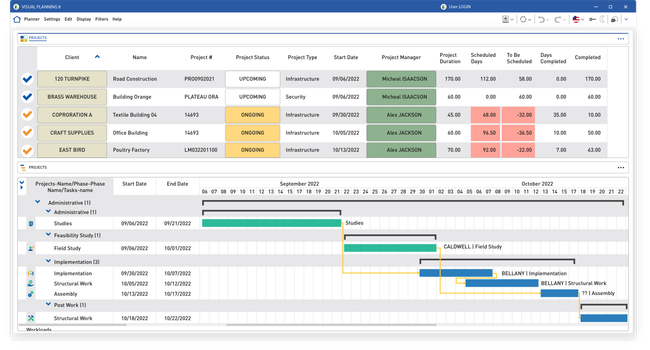

Visual Planning - Best for Labor-Based Planning

Visual Planning is a resource scheduling software designed to plan jobs, projects, and tasks. Its VPAutomation tool sequences tasks automatically based on employee availability and their specific skill sets.

VPAutomation can pinpoint the most skilled machine operators available for a certain production line. Each operator’s profile includes details like their experience levels and certifications. From there, you can define each production task with the skill requirements necessary for completion. VPAutomation uses an allocation algorithm to cross references these skill sets, then assigns your employees to shifts or scheduled events.

For more tailored workforce management, VPAutomation utilizes your custom HR rules, such as work-hour contracts (like 35-hour or 39-hour weeks) and mandatory breaks between shifts. Visual Planning assesses current capacity, availability, and cost factors to make the best staffing decisions.

This software can adapt to various uses, including HR, construction project management, manufacturing, and more. The software helps companies track crews, machines, processes, and supplies effectively. Functionalities include:

- Work orders

- Machine scheduling

- Inventory management

- Supplier management

- Delay alerts

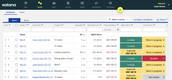

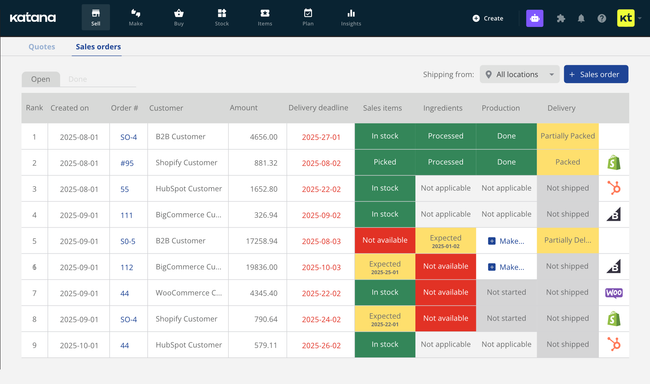

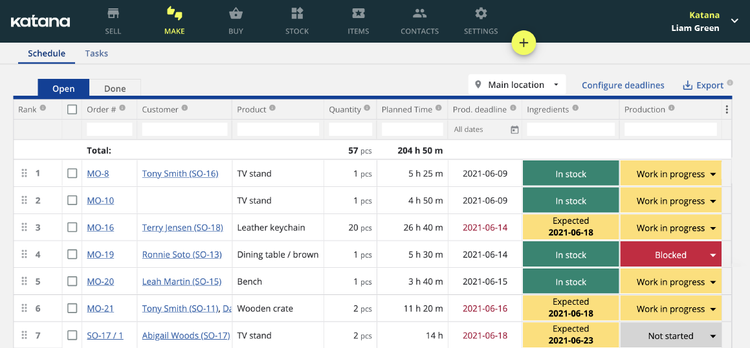

Katana - Best for Small Companies

Katana Manufacturing ERP offers user-friendly production scheduling that integrates with purchasing, warehousing, and sales, starting at $179/month for one inventory location. While a system like SAP S/4HANA might be better suited to enterprise-level operations with multi-stage processes, Katana is a solid option for smaller companies with 10 to 200 employees.

Katana offers a responsive, visual dashboard for intuitive scheduling. This means you’re spending less of your limited resources on employee training. Regardless of your team’s technical skills, they can access an easy-to-read table on the schedule screen.

It includes all essential details like job priority, planned time, production and delivery deadlines, and production status. Plus, it’s easy to rearrange tasks—simply drag and drop them to update the schedule. For example, if an urgent customer request comes in, you can bump up a high-priority order without issue.

When you move tasks, Katana automatically recalculates resource allocations and timelines. This means your production schedule always reflects the most recent changes, helping you avoid bottlenecks down the line. As your team uses raw materials during production, you can replenish your stock as needed and avoid costly shortages or overstock scenarios.

Katana also provides shop floor control via the tasks dashboard, which lets you quickly assign specific tasks for manufacturing orders to different operators. Filter each task by resource or workstation to see at a glance which resources are available and which are in use. This transparency supports real-time planning and performance monitoring so you can keep tabs on the progress of different tasks and orders.

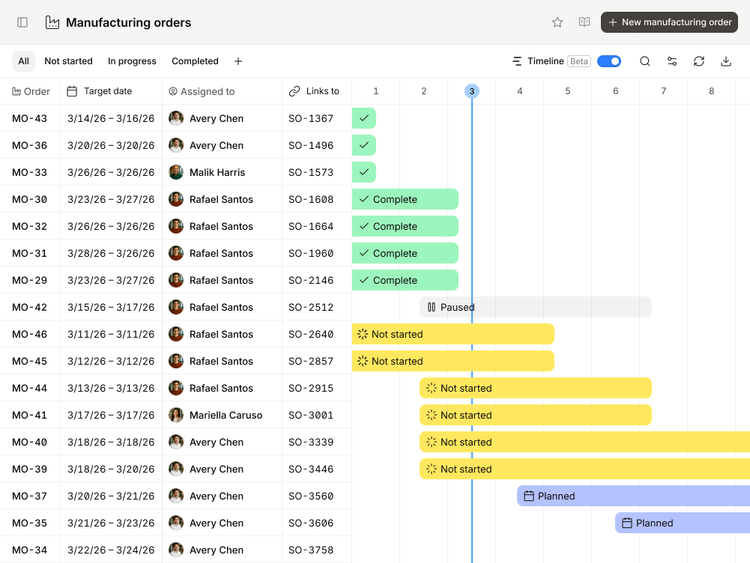

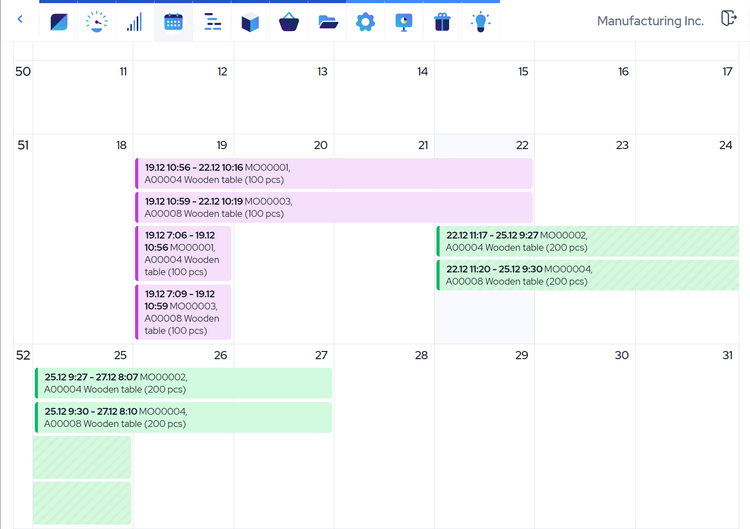

MRPeasy - Most Affordable

MRPeasy is a cloud-based material requirements planning (MRP) software. It starts at just $49/user/month for all of its main functions, including production planning and reporting, drag-and-drop rescheduling, and workforce management. It’s one of the most affordable systems on the market, providing strong features at a great value for small businesses.

Beyond its low price, MRPeasy offers an easy-to-use production planning module for a wide variety of manufacturers, including food and beverage, automotive, and industrial, among others. What really makes it stand out is its drag-and-drop scheduler that makes rescheduling easy. Orders are displayed on a Gantt chart, and you can just move them to another date if you’re running behind. The system accounts for workstation availability and only lets you move it to an open spot, preventing accidental double-bookings.

When you change an order’s production date, the update is instantly reflected in the system’s other charts and calendars. This allows you to be flexible without worrying about making multiple changes throughout the system. It’s great for industries like automotive, where market shifts, supply chain constraints, and consumer demands are highly volatile. With MRPeasy, you can adapt to these changes in real time without causing overruns or shortages.

Eyelit APS - Best for Constraint Scheduling

Eyelit Advanced Planning and Scheduling (formerly Optessa) is best for manufacturers that need to schedule around multiple, interdependent constraints. It’s especially useful for manufacturers in the automotive, industrial equipment, and electronic industries, where task sequences, machine limits, labor availability, and material timing are all critical factors in production.

At its core is Optessa’s optimization engine, which builds accurate and efficient schedules based on your real-world rules and constraints. It can prioritize tasks, minimize changeovers, and reduce idle times, all while accounting for the constant shifting availability of people, machines, and materials. Unlike drag-and-drop schedulers that surface conflicts after the fact, Optessa prevents them outright. Its algorithms generate production plans that are not just optimized but are fully executable.

However, with pricing starting at $5,000/month, Optessa is best for mid-sized and large organizations that can invest in a solution. Smaller manufacturers should consider other options like Katana MRP or MRPeasy.

Fulcrum - Best for Metal & Steel Manufacturing

Fulcrum Pro’s Auto Scheduler analyzes each job’s dependency chain for better task sequencing, factoring in aspects like job runtime, due dates, and priority levels. This approach helps reduce bottlenecks, especially when your production processes involve ordered steps like cutting, welding, and heat treatment.

The Auto Scheduler then factors in each machine’s current capacity and redistributes tasks based on their availability and job priority. You easily view this on Fulcrum’s visual interface, where each column represents a machine and each card shows a job’s details.

Just drag and drop the job card within a defined timeframe, typically 48 hours, for short-term adjustments that won’t derail future operations. This flexibility is useful in high-volume metal production, where preventing idle time is key to maximizing output.

Additionally, the Auto Scheduler stays current as new jobs come in or priorities shift. For urgent customer requests, operators can adjust the due date in the job’s settings. The scheduler then reprioritizes and reschedules operations to accommodate this change. This keeps custom order production moving efficiently and helps you avoid missing deadlines.

Digit - Strong User Interface

Digit offers a lightweight production scheduling software for small to midsize manufacturers. One of the system’s biggest strengths is its modern UI, and this is really apparent in the master production scheduler. It color codes each stage of the process, from planned to complete, along a logical Gantt timeline that makes it easy to spot bottlenecks and check statuses.

Additionally, Digit includes a strong capacity planning and resource allocation module. It consolidates your work orders and lets you filter them by status, work center, or team member. This helps you maintain stock levels, set priorities, and track performance. It’s a great way to keep jobs on track from one central location, instead of sifting through a spreadsheet.

While Digit is a newer system compared to more established vendors, the modern interface and ease of use make it a great option for small to midsize manufacturers. Pricing starts at $249/month for the Starter plan, making it more affordable than a larger APS system.

FEDRA - Best for Contract Manufacturing

FEDRA’s advanced scheduling and optimization module lets you synchronize orders, labor, and materials across shifting project demands, which is vital when you’re managing multiple customer jobs. FEDRA provides a live, adaptive map of your resources and machines, recalculating timelines as new data arrives from the MES or ERP. If a rush order is approved, FEDRA instantly simulates multiple alternative scenarios using its AI-driven reinforcement learning engine.

For contract manufacturers, FEDRA’s intelligence lies in its ability to learn from variability. It can analyze prior performance, including operator skill pairings and machine availability, to project which combinations will yield the shortest turnaround for each job mix. It can also weigh the trade-offs between giving one customer priority over another or split an order across machines to hit promised delivery times.

This means more predictable revenue and stronger customer retention, letting you pinpoint bottlenecks across work centers before they delay shipments. Overall, it’s a solid pick for mid-sized to large manufacturers with 200 to 2,000 employees.

What is Production Scheduling Software?

Production scheduling software helps plan production on your shop floor by determining the need for materials and capacity to complete a manufacturing production order. It also enables manufacturers to create a highly detailed master production schedule that accounts for resource, staffing, and inventory needs to complete and optimize production.

Production scheduling software helps you convert customer orders into manufacturing orders. It will look at the bill of materials, purchase orders, and current stock to ensure you have the proper items reserved or the purchase order generated to complete the order.

Also known as advanced planning and scheduling software (APS), production scheduling software for job shops is used in situations where traditional methods of demand forecasting and production planning (such as MRP software) have fallen short.

How We Selected the Top Products

We personally review software to help you find the best software on the market. Here is our review methodology for production scheduling:

1 Features

We tested features such as real-time progress tracking and automated production planning to better determine the top options on the market today. The top commonalities we found amongst the best products included capacity planning and the ability to prioritize different jobs. In particular, Gantt charts are very popular for easily visualizing different tasks.

2 Price

Second on our list was pricing options for this type of software. During our review, we found prices range from $50 per user per month up to $5,000 per month. There are also forever-free options to consider.

3 Performance

Last, we tested the software ourselves to judge performance first-hand. We tried our best to see how intuitive the user interface was, how easy it was to reach support, and what the ideal conditions for operating the software were.

Key Features

- Gantt charts: Create bar charts that show a project schedule, illustrating the dependency relations between pending and ongoing jobs and the employees scheduled to work during those times.

- "What-if" analysis: Test out various production schedules by moving orders to different time slots via drag-and-drop functionality. Find the best production window for your business by syncing resource availability and any constraints.

- Drag-and-drop capabilities: instantly move orders to different time slots throughout your schedule to see if your production team can fit the manufacturing job at that time or what possible effects it may have on your bottom line.

- Capacity planning: Determine the production capacity needed to meet your products’ demand. Adjust schedules in real time when unexpected bottlenecks occur.

- Priority scheduling: Calculate the profitability of each manufacturing job in order to establish priority levels and work on the most important jobs first.

Benefits

- On-time delivery: Ensure customers receive products when promised by optimizing your production so there are no interruptions and that new orders don’t bottleneck your production line.

- Optimized use of resources: Check the availability of workstations, monitor what materials are available, and let the software do the scheduling for you. Prioritize using machinery that is cheaper to operate to increase profitability over the long term.

- Reduced cycle times: Lower the time it takes to perform manufacturing processes and push out more manufacturing orders.

Pricing

Production scheduling software costs typically rise with headcount, scheduling complexity, and integrations with other systems. The table below summarizes typical annual spend by company size and software complexity.

| Tier / Company Size | Annual Cost | Example Solutions |

|---|---|---|

| Low-Tier (1–25 employees) | $5,000 – $25,000/year | Katana, MRPeasy, Statii, TACTIC |

| Mid-Tier (25–150 employees) | $25,000 – $100,000/year | PlanetTogether, Eyelit APS (Optessa), Simio, Asprova, Siemens Opcenter APS |

| High-Tier (150–500 employees) | $100,000 – $250,000/year | DELMIA Quintiq, Preactor (Siemens), AIMMS SC Navigator, AspenTech, Dassault Systèmes |

| Enterprise (500+ employees) | $250,000+/year | SAP IBP, Kinaxis RapidResponse, Oracle APS, Blue Yonder (JDA), OMP APS |

Free Options

Free production scheduling software can be hard to find since there are so few truly free options. Many vendors offer a free trial of their solution to get started, but only for a 7-day or 30-day trial. While free trials are great for testing the ins and outs of a program before making the commitment, many businesses still want free software when moving away from their reliance on spreadsheets.

DYNAMIC 3i Production Planning

DYNAMIC 3i from System Dynamics Corporation is a free ERP/MRP software that provides master scheduling, rough-cut capacity planning, and links with other functionalities your business may be using, such as inventory, MRP, and order processing. The solution can help you forecast sales and production levels while making updates to your master schedule whenever necessary. The free version of DYNAMIC 3i provides access for up to 2 users.