The Best Capacity Planning Software

We’ve reviewed the best capacity planning software for different manufacturers like automotive and food and beverage. Whether you need demand forecasting or supply chain optimization, we’ll help you find a solution to optimize your production planning.

- Integrates with leading ERP systems

- Easy to navigate dashboard

- Automated classification of inventory items based on sales value and velocity

- Advanced AI analytics

- Strong advanced planning module

- AI and advanced analytics drive planning and optimization

- Designed for multi-echelon inventory optimization (MEIO)

- SaaS based platform

We assessed capacity planning systems for manufacturers in industries from automotive to food and beverage. We focused on functionalities that impact these businesses the most, like finite capacity planning and demand forecasting.

- NETSTOCK: Best for Aerospace and Defense

- ToolsGroup: Best for Automotive

- Logility: Best for Food and Beverage

- PlanetTogether: Best for Chemical

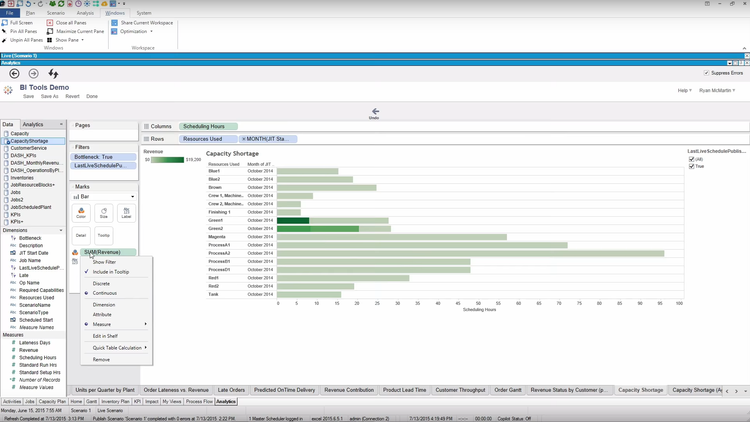

NETSTOCK - Best for Aerospace and Defense

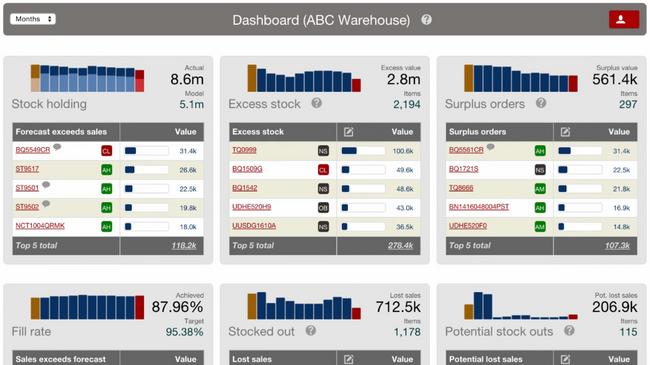

NETSTOCK’s finite capacity planning engine can help you find the optimal production plan for your company. You can simulate the effects of demand changes or supply variations to visualize different scenarios, allowing you to adjust production based on future variables. This helps avoid inventory surpluses on high-cost materials like titanium alloys due to poor planning.

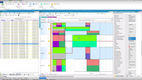

The tool lets you optimize production plans using specific time periods, from monthly to daily. It considers your resource constraints, such as labor or materials, and uses them to create production schedules. This allows you to generate realistic schedules and set strategic inventory levels.

NETSTOCK lets you visualize the plan it creates over the next 12 months on a rolling basis, showing planned replenishments and production schedules graphically. This allows you to easily spot bottlenecks, which is ideal for aerospace manufacturers dealing with long-term projects and tight deadlines.

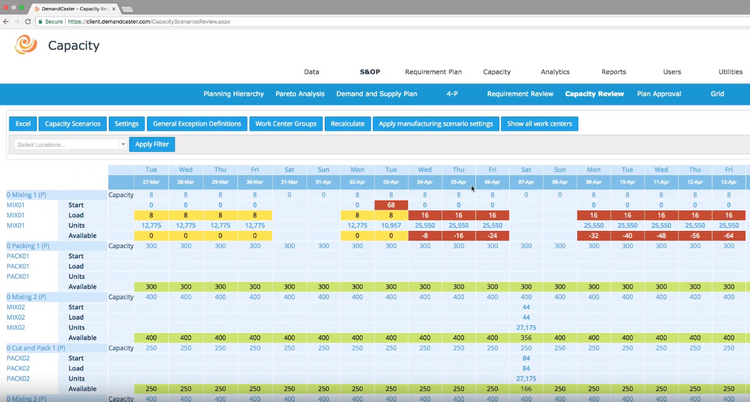

ToolsGroup - Best for Automotive

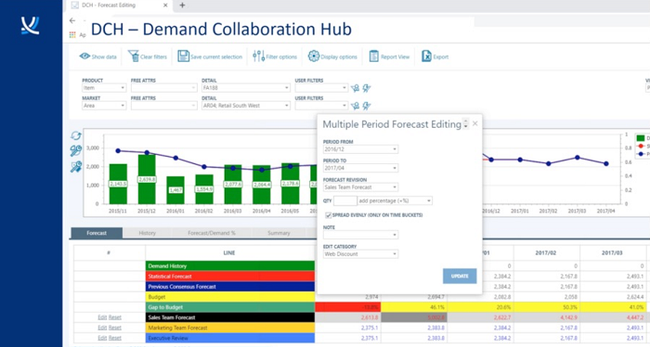

ToolsGroup’s demand planning module allows automotive manufacturers to determine optimal inventory levels within a complex supply chain. It uses probabilistic demand modeling, which provides a range of possible outcomes with the probability of their occurrence. This helps you evaluate multiple possibilities and determine which one is most likely, giving you flexibility.

The module supports both bottom-up and top-down planning to provide accurate forecasts for inventory optimization. It features a demand collaboration hub that utilizes demand and forecast data from multiple sources and allows all team members to work together when planning demand. This is ideal for automotive manufacturers, as several departments like sales and engineering, can add valuable input on seasonal cycles and market trends.

ToolsGroup also incorporates AI and machine learning into its demand planning system. One of its capabilities is performing what-if analyses for hypothetical scenarios. These can help plan for sudden shifts in consumer demand or supply chain disruptions, which can help you stay prepared for any significant market shift.

While ToolsGroup’s features are extensive, the software does come with a high price tag. Because of this, we only recommend this system for large automotive manufacturers that have outgrown their previous capacity planning system and require advanced functionality.

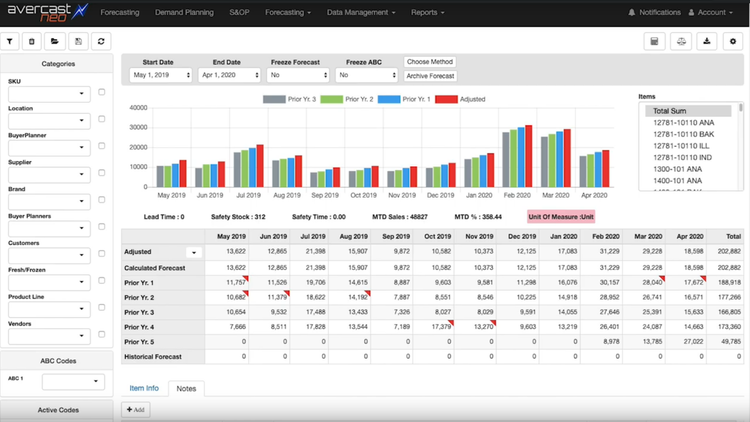

Logility - Best for Food and Beverage

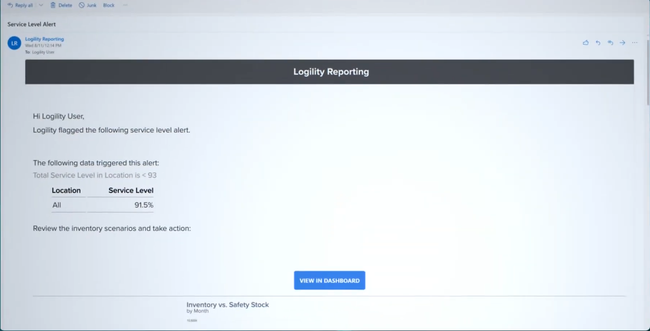

Logility’s advanced planning and scheduling module to help food and beverage manufacturers optimize their planning process. The system balances market demands with production efficiency, allowing you to adapt production levels to the appropriate demand. This is ideal for food and beverage companies that experience high market volatility and make fast production adjustments.

The system also helps optimize for changeover constraints, which are common in the food and beverage industry. These changes, such as an allergen cleanse or a new packaging configuration, are challenging to perform while maintaining optimal production time and capacity. Logility accounts for this constraint when planning and helps you optimize product sequencing to reduce the impact of changeovers.

The module also uses demand forecasting to better plan production for the constantly changing food and beverage market. Logility leverages AI and machine-learning algorithms to more accurately predict demand, leading to better production planning and execution. This is effective for food and beverage manufacturers that handle seasonal variations, perishable inventories, and promotional spikes in demand to allocate the correct resources to avoid spoilage or shortages.

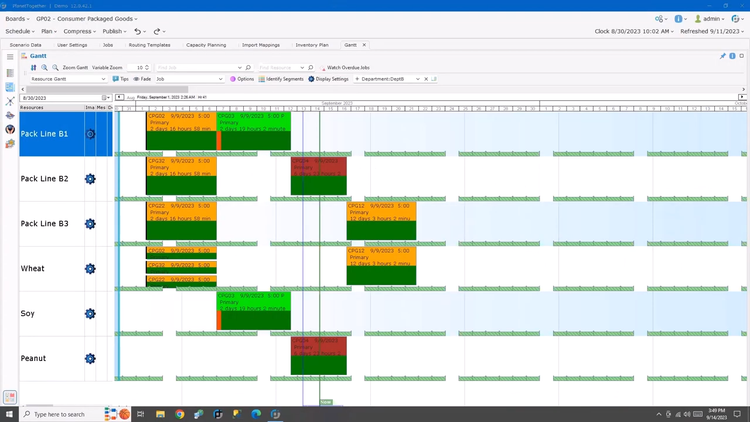

PlanetTogether - Best for Chemical

PlanetTogether’s advanced scheduling helps chemical manufacturers produce more accurately. The module includes smart batch scheduling, built for long multi-stage process times. It also helps optimize tank usage by coordinating cleaning times, reducing delays between batches, and having efficient timing for higher or lower volume production. This can really cut down on cleaning in place (CIP) cycles while still keeping the same product quality and compliance.

Additionally, PlanetTogether manages strict chemical production requirements, like expiration dates, allergens, and changeovers. This allows you to build your schedule to minimize raw material waste or adjust as needed. You can drag and drop orders in the Gantt chart, so if demand suddenly increases, you can adapt to meet inventory requirements while still maintaining safety and production compliance.

PlanetTogether is best for mid to large-sized manufacturers in high-mix, low-volume environments like chemical, food and beverage, and aerospace. It’s designed to integrate with your existing ERP, giving you better advanced planning for your entire supply chain. You’ll need a custom quote for pricing, but expect to pay anywhere between $10,000-$50,000 across your first three years of ownership.

What is Capacity Planning Software?

Capacity planning software is a supply chain solution that helps manufacturers and distributors compare production loads against available capacity. Also known as design capacity, this management software provides resource capacity data in real-time to help eliminate production bottlenecks.

Essentially, finite capacity is determined by calculating efficiency by the number of workers and shifts. Capacity planning software determines if any resources are being underutilized. By doing so, companies can eliminate discrepancies between customer demand and production capacity. While capacity planning tools have similarities to manufacturing resource planning (MRP), they cover more of the supply chain from raw materials to the finished product distribution.

Note: Capacity planning is sometimes used to describe IT capacity management or planning, a way of increasing software and hardware storage.

Key Features

- Demand Forecasting: Gives real-time updates on capacity as it relates to your inventory and production schedule.

- Manufacturing Resource Planning: Streamlines the manufacturing process by calculating material requirements.

- Product Lifecycle Forecasting: Anticipates and meets market demands for products.

- Warehouse Optimization: Coordinates inventory once it has arrived at your warehouse or distribution center. This uses a lot of the same tools as warehouse management applications.

- Supply Chain Coordination: Oversees the flow of products between each echelon of the supply chain, starting with manufacturers up to retailers.

- Workflow Audits: Generate a process map to locate likely sources of production bottlenecks.

Benefits

There are many benefits to using a capacity planning software for your business:

Fewer Bottlenecks in the Supply Chain

Multi-echelon supply chains are not easy to manage without comprehensive management software. All it takes is one step of the chain to fall behind to set your entire business back. It could be as simple as a delivery vehicle breaking down or an accident on the shop floor. If a resource is unavailable or a manufacturer is falling behind, capacity planning software can help.

First, you have to identify the type of bottleneck. Is it short-term or long-term? A short-term bottleneck may be the result of being short on labor due to worker illness. A long-term delay could be the result of seasonal resources being out of stock. Legal issues from changing regulations can also cause delays. Planning software makes it easy to accommodate for both scenarios by process mapping the workflow to find these potential bottlenecks so you can plan ahead.

Shorter Production Lead Times

Once you’ve identified possible bottlenecks, you can plan around them in order to shorten production lead times. This will let you maintain or increase your production schedule. Manufacturing resource planning modules, along with advanced planning and scheduling, make it easy to coordinate your distribution schedule from raw materials to finished product. You should have a plan for resource shortages, employee absences, and other common supply chain disruptors.

Using a capacity planner may reveal extra steps in your current production workflow. Find these weak points in the supply chain and start working to remove them. Then enjoy even shorter lead times and faster product turnarounds!

Streamline Inventory Replenishing

Think you can replenish your stock based solely on previous product performance? Think again. All sorts of tiny changes to the market can affect the current demand. Capacity planning once a year is not enough. Demand forecasting can provide real-time data so you can continually update your capacity and accurately replenish your inventory.

When you use a capacity planning software, you can find out exactly how much you’re capable of producing without going over capacity. Use a forecasting application to accurately predict your on-premise safety stock needs so you’re prepared for possible bottlenecks in the future.

A Faster Supply Chain

The faster your supply chain, the faster you can satisfy customer demand. From the moment the manufacturer accepts raw materials, you should be planning how you can get the finished product to suppliers and retailers. However, you don’t want to overproduce and flood your warehouse with overstock.

Plan every step with capacity planning software. Scheduling applications help you control inventory arrivals and distribution. Inventory optimization applications are your solution for making sure your warehouse efficiently takes in and redistributes products.

Long-Term vs Short-Term Capacity Planning

Just like production bottlenecks, capacity forecasting is divided into short-term and long-term. The terminology can vary based on the scale of your operations. Short-term planning can go by day, week, or month. Long-term capacity planning can cover multiple years. Depending on your business, you might also have medium-term capacity, which is between the other two at quarters or a fiscal year. If you are running a small startup,

Capacity planning software lets you account for both long-term and short-term demand forecasting. Use your short-term planning to better plan out for the rest of the year. And use long-term planning to get ready for the future.

Experiencing a short-term bottleneck? See how it will change your long-term planning. Then adjust your product schedule to make up for potential losses and see if you need to start using your safety stock.

Pain Points

Common issues that occur without capacity planning software include:

Alternating Overstock and Product Shortages

Even with the best planning solutions, you can still encounter production bottlenecks. If you don’t use any sort of capacity planning, you’re more likely to encounter issues with understocking and overstocking. A basic ERP system may assist with some resource planning but a capacity-specific program is designed for handling this exact situation.

Supply Chain Communication Failures

When you use capacity planning software to get real-time updates on production, you can keep your entire supply chain informed. For multi-echelon enterprises, you’ll need to ensure everyone is on the same page to avoid shortages or overproduction.