The Best Plastics ERP Software

As the plastics manufacturing industry evolves, new challenges emerge in both production and operations. This ERP software can optimize your business, from recipe management to regulatory compliance.

- Built-in AI support

- Customizable and extensive reporting

- Integrates with apps like Excel

- Enhanced regulatory compliance

- Optimized supply chain management

- Offers tailored features like recipe and lab management

- Accounting module has detailed functionality

- Tracks employees and manufacturing data in one place

- Integrates with Salesforce, DemandCaster, financial systems, eCommerce, and more

Plastics ERP software streamlines polymer manufacturing and distribution operations, like production planning, inventory management, and quality control. We used our advanced review methodology to evaluate and rank the top education ERP software in today’s market.

- Epicor Kinetic: Best Overall

- Datacor ERP: Best Industry-Specific Features

- Plex ERP: Best for Traceability

- Dynamics 365 Business Central: Best for Mixed-Mode Manufacturing

- Acumatica: Best for Agile Manufacturing

- SYSPRO: Best QMS Tools

- Aptean ERP: Best Formula Management

- DELMIAWorks: Best Process Monitoring System

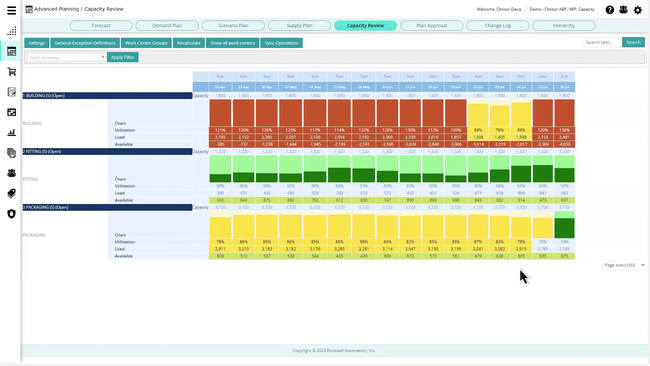

Epicor Kinetic - Best Overall

Epicor Kinetic includes an advanced inventory management module, ensuring compatibility and transparency in component tracking. The platform also includes a comprehensive toolkit for accurate estimates, quoting, scheduling, and monitoring.

Epicor Kinetic supports custom and on-demand production. Its simplicity and effectiveness extend to make-to-stock operations as well, making it flexible for a range of manufacturing techniques. In addition, its track-and-trace and quality control functionalities make it a vital asset for industries under stringent regulatory demands. Epicor’s specialized CMS for automotive plastics further underscores its tailored approach, providing a global ERP system for the rubber and plastics industry.

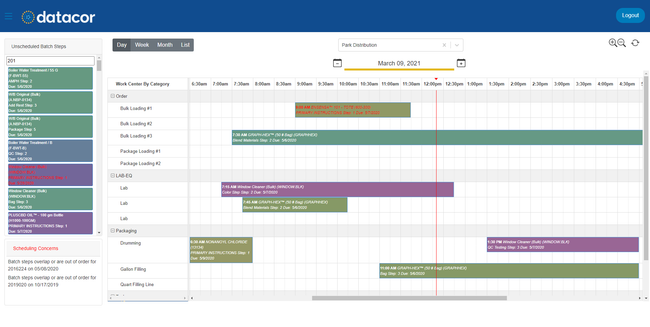

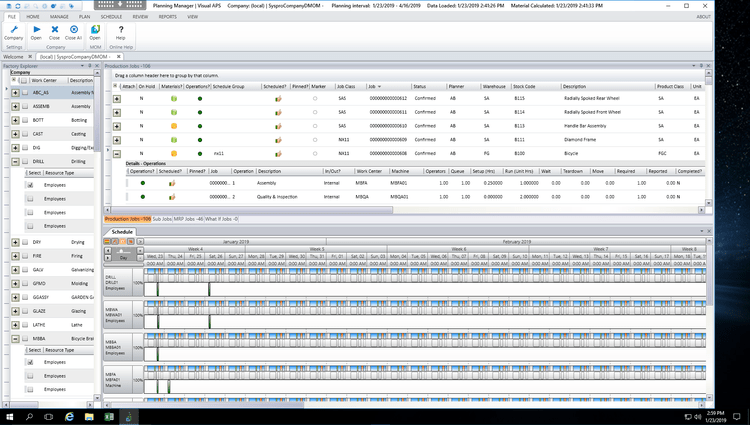

Datacor ERP - Best Industry-Specific Features

Datacor ERP is designed specifically for process manufacturers. This ERP system supports batch production, automating production scheduling and procurement. It also optimizes buying and production decisions and performs production cost and yield analysis. Datacor’s lab management features provide flexibility in managing complex formulas and production histories.

Quality control is another industry-specific feature, with Datacor ERP offering extensive capabilities to track the manufacturing process from start to finish. This includes producing Certificates of Analysis, collecting product specifications, and ensuring that each batch or lot meets the unique specifications of different customers.

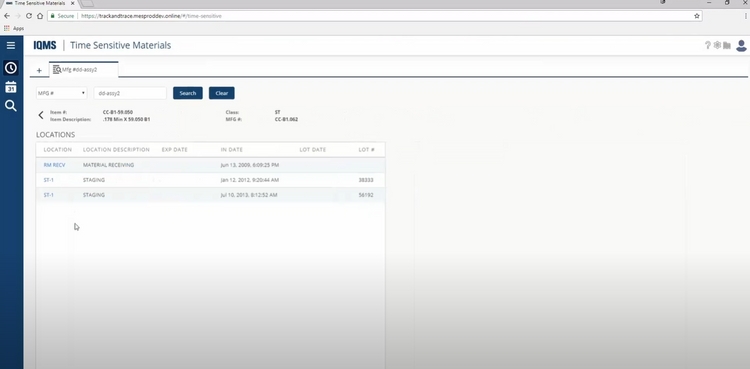

Plex ERP - Best for Traceability

Plex ERP provides end-to-end traceability of resin lots, from receipt through production and shipment. The system generates lot numbers instantly when you receive materials, allowing you to track finished goods back to the specific resin lots used. This allows you to perform detailed quality audits and makes recall scenarios faster.

Additionally, Plex allows you to trace regrind throughout production. When you generate regrind, the system maintains a genealogical link to the source resin lot(s), so you know exactly where it came from. It also logs the regrind percentage per batch or mold, even with multiple generations of material reuse. This helps reduce waste by reusing scrap plastic while still maintaining full traceability.

Plex ERP is an all-in-one solution, combining MES, finances, and quality management under one roof. Pricing starts at $3,000/month, but most businesses will have a much higher price. Final costs require a custom quote, depending on your company size and required modules.

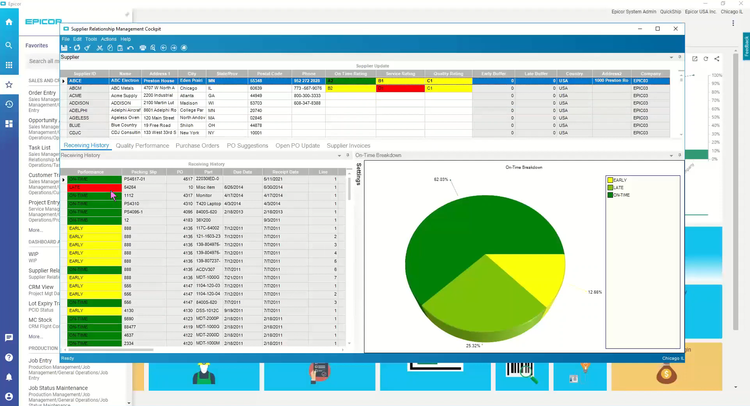

Dynamics 365 Business Central - Best for Mixed-Mode Manufacturing

Microsoft Dynamics 365 Business Central supports a range of manufacturing processes crucial for plastics, including discrete, process, lean, and mixed-mode manufacturing. This versatility allows plants to quickly adapt to new manufacturing methods and material innovations, maintaining a competitive edge.

We found the system’s planning worksheet and MRP engine quite useful, especially for advanced demand forecasting and production scheduling. This integration ensures that plastics manufacturers can anticipate material needs and adjust production schedules in near real-time, optimizing resource use.

Business Central handles complex BOMs and detailed routings to help plastics manufacturers maintain precise control over production processes. This feature is essential for ensuring product quality and consistency, especially when dealing with complex products that require specific manufacturing steps and component ratios

Acumatica - Best for Agile Manufacturing

Acumatica is an agile solution for managing the varied facets of plastics production, such as injection molding, blow molding, resins, and plastic adhesives. This agility is crucial for adapting to rapid changes in development and managing a wide range of finished products.

Key features like advanced inventory management and precise production planning ensure that plastics manufacturers can efficiently align their stock levels with customer needs. Acumatica’s cloud-based ERP system seamlessly supports varied manufacturing modes by unifying data, systems, and processes. This cohesive approach facilitates timely MRP and finite scheduling, shortens cycle times, and elevates product quality.

SYSPRO - Best QMS Tools

SYSPRO has strong QMS tools, managing diverse product outputs and ensuring the quality of raw materials. It handles rigorous quality checks, including on chemical composition and hardness, with customizable inspection plans. SYSPRO’s traceability tools provide detailed tracking of materials from their arrival to final delivery, a key aspect for regulatory compliance and enhancement of operational practices.

The software is particularly effective in navigating the complexities of modern manufacturing trends such as Industry 4.0, offering tools for mass customization and integrating 3D printing processes. SYSPRO enhances supply chain operations with sophisticated forecasting and planning, ensuring supply meets demand efficiently. It also focuses on streamlining production to optimize capacity and reduce bottlenecks. Additionally, SYSPRO’s ability to integrate with external systems boosts overall operational efficiency, providing a competitive edge in the market.

Aptean ERP - Best Formula Management

Aptean Process Manufacturing ERP Ross Edition is ideal for formula management because it’s designed to handle the complexities of process manufacturing, enabling precise control over recipes. It covers ingredient variations, production processes, and quality control, ensuring consistent product output. For that reason, Aptean ERP is a good fit for the food and beverage, chemicals, pharmaceuticals, and biotech sectors.

Additionally, Aptean ERP lends transparency to key enterprise areas, including purchasing, inventory, manufacturing, and sales. Its inventory and warehouse management capabilities, mobile accessibility, and planning and financial control features. It is the official successor to Ross ERP, offering visibility and transparency into operations with customizable reports and inquiries.

DELMIAWorks - Best Process Monitoring System

DELMIAWorks gathers data from your injection molding machines and extrusion systems through its RealTime Process Monitoring System. Using machine-level sensors, this ERP monitors parameters like injection pressure and cooling times, alerting you if any deviations arise. For example, if mold temperature or pressure exceeds your set threshold, DELMIAWorks notifies you via email or SMS message so you can shut down machines and perform maintenance.

The software also includes a statistical process control module to help you maintain quality and precision in your operations. It provides:

- Data Filtering Options: Segment data using parameters like lot numbers, specific tooling used, or work order numbers to pinpoint the root cause of defects.

- Customizable Charts and Histograms: Generate X-bar and R charts, scatterplots, and histograms to analyze trends like cycle time consistency and machine performance and utilization.

- Reporting Tools: Export charts and statistical analyses to Microsoft Word and Excel for audit-ready reports.

Also, DELMIAWorks includes a shop floor layout visualization tool for an interactive map showing each machine’s real-time operational status. This tool lets you quickly see which machines are running, idle, or triggering alarms. If your equipment experiences any issues, DELMIAWorks flags this on the shop floor layout so you can start troubleshooting.

Though DELMIAWorks doesn’t list pricing publicly, it starts at around $250 per user per month, with a minimum of five users. Expect some initial investment in setup, especially if you’re installing sensors for legacy machinery.

Learn more about DELMIAWorks in our product profile.

The plastics industry, a subset of chemical manufacturing, is constantly growing and trying to find new ways to utilize polymer materials in goods and services. From new construction to advanced electronics, this fast-growing and ever-changing field is essential to almost every industry on Earth.

Plastics manufacturing as a whole has reached an all-time high in production and adaptation. Old formulas are being improved daily to create new, higher-quality products.

What is Plastics ERP Software?

Enterprise resource planning (ERP) software for the plastics industry consists of an integrated suite of popular business applications capable of automating and streamlining functions such as financials, sales, and operations. As a specific solution for plastics manufacturing, this software includes additional features to cover standard processes of plastics engineering. For instance, plastics ERP software can record specific polymer recipes and chemical blends vital to the continued development of new plastic commodities.

Since the plastics industry deals with so many facets of modern life, it is vital to have a custom ERP package that allows you to stay focused on future developments. Plastics ERP software can be highly customized to integrate the tools you need to streamline operations.

Note: Plastics ERP software generally covers both plastics and rubber production. It may also be referred to as manufacturing resource planning (MRP) software.

Features of Plastics ERP Software

- Accounting: Track all sources of revenue and expense through a general ledger which records accounts payable (AP), accounts receivable (AR), and employee payroll

- Budgeting and forecasting: Manage detailed financial plans to accurately predict future revenue and expenses; budget based on departments and workforce planning

- Bills of Materials (BOM): Keep records of all interrelated materials necessary for production from raw materials to finished goods

- Recipe and blend management: Store records of different plastic recipes, blends, and variations in one easily accessible location

- Regulatory compliance tracking: Traceability measures ensure your operations are within compliance throughout production, storage, and distribution

- Inventory management: Record information about the plastic commodities your company manufactures, assembles, or sells

- Supply chain management: Control the movement of goods and services between locations as efficiently and as cost-effectively as possible

- Human resources (HR): Manage current employees from the hiring and onboarding process through to time and attendance tracking

- Customer relationship management (CRM): Support customer outreach with contact management, lead tracking, order histories, and quote or invoice creation

Benefits

Incorporating plastics ERP software into your operations can provide many useful benefits, such as:

Streamline Back Office and Front End Operations

The first and foremost benefit of plastics ERP software is the ability to optimize operations across every department completely. Using different solutions for every task can quickly become inefficient and lead to miscommunication. In the plastics field, even more processes are necessary to operate.

Connecting once separate systems into a single plastics ERP solution adds overall efficiency. Share data between different departments without creating endless duplicates, which can clog up operations and lead to confusion. Through a singular database, basic accounting, budgeting, and forecasting can provide insight into your finances across the board.

Greater Workflow Visibility

ERP software can speed up internal processes while providing the mechanisms necessary to monitor them for continuous improvement. This additional transparency allows your organization to consider current processes more holistically.

For example, there are a lot of differences between manufacturing plastic commodities using extrusion and injection molding methods. ERP software lets you determine which method may provide the best ROI for your organization.

With cloud-based plastics ERP solutions, you can gain real-time visibility into all your processes, even those occurring in different countries worldwide. Since plastics are a global industry, this can provide a competitive advantage to your organization by keeping you up-to-date on the latest internal developments.

Increased Safety Compliance

Plastics and rubber production can harm worker safety and the environment. Mixing new chemicals, moving finished products, and storing raw materials all require strict compliance with local and international regulations. These safety laws are regularly updated, meaning you need a way to stay on top of the latest requirements.

Since regulation varies based on location, plastics ERP software helps you remain compliant no matter where you are. Recipe and blend management tools and a comprehensive Bill of Materials (BOM) can show exactly which chemical ingredients are used and in what quantities. This can prove compliance during an audit or if a batch is not up to standard. Track and trace features can show where raw materials came from, what they were used to produce, and where the finished products are.

Easier Decision Making

The above benefits add up to one more advantage: a more straightforward decision-making process. ERP software for plastic industries simplifies identifying opportunities for improvement by combining all the data you need into one accessible platform. With this data, decision-makers at every level of the company can gain greater insight into future decisions along every step of the supply chain.

Plastics Manufacturing Trends

In 2024, the plastics manufacturing industry has seen several changes. These range from changing production methods to COVID-19 safety adaptations. Here are just a few of the latest trends in the plastics industry:

- Automation through 3D printing

- Advances in polymer technology

- Rise in biodegradable plastics recipes and formulations

- Increase in production from recycled plastics

- Increase in making plastics that are easily recyclable

- A move towards lightweight plastics

- More demand for high-performance plastics, reaching $25.41 billion in 2024, according to a report by Smithers

By using plastics manufacturing software with ERP functionality, your company can more easily keep up with and adapt to these latest trends.