The Best Textile Software

Textile software helps streamline and automate production, inventory, and supply chain handling processes. We tested the best systems based on key features like raw material and product lifecycle management, and production planning.

- Open-source architecture

- Multilingual support

- Highly customizable

- Multi-channel sales and multi-warehouse inventory

- Offers integrated accounting

- PLM and CRM included

- Inventory & order management tools built for apparel

- Integrates with leading eCommerce and accounting platforms

- ERP designed specifically for apparel industry

We used our software review methodology to evaluate and rank the top systems on the market.

- ERPNext: Best Raw Material Management

- ApparelMagic: Best Product Lifecycle Management

- InStyle Software: Best for Apparel Manufacturers

- Datatex NOW: Best for Production Planning and Scheduling

- BlueCherry Enterprise: Best Shop Floor Control

- MRPeasy: Best for Small Manufacturers

- Infor MES: Best MES Option

- A2000: Best Warehouse Management System

ERPNext - Best Raw Material Management

ERPNext’s raw material management feature streamlines the procurement, tracking, and utilization of resources, giving you better control over your inventory. This can be particularly useful when dealing with diverse materials or fluctuating demands, enabling efficient production planning and reducing waste.

ERPNext links raw material inventory to each product’s BOM. When a production order is created, the system references the BOM to determine the required raw materials and quantities. The system will continuously update inventory levels as they’re procured, consumed in production, or moved between warehouses.

For example, maybe you’re a medium-sized textile manufacturer who struggles with frequent stockouts of cotton yarn and surplus dyes. This causes production delays and increased holding costs. With ERPNext, you can generate a raw material requirement plan based on upcoming production orders for fabric types, such as lightweight cotton and denim. The software automatically creates purchase orders for cotton yarn, thread, and dyes when inventory exceeds the predetermined reorder point, selecting the most cost-effective suppliers.

Upon delivery, the system triggers a quality inspection. Here, you can test your cotton yarn for tensile strength, and then the system will only add the approved batches into your inventory.

ERPNext is a fully open-source program, meaning it’s free to download the source code and customize it yourself. They also offer cloud-hosting services, starting at $5 per month for small businesses. Either way, it’s one of the most affordable ERPs out there.

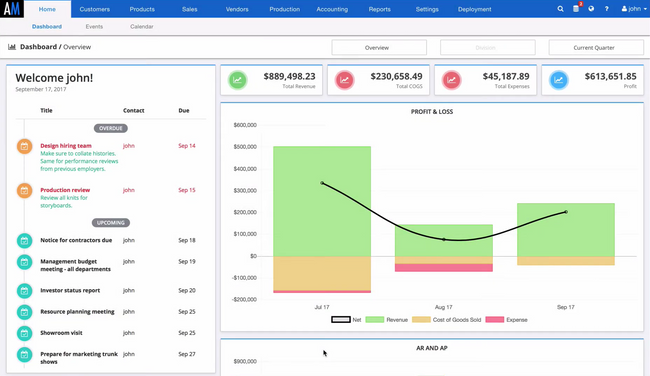

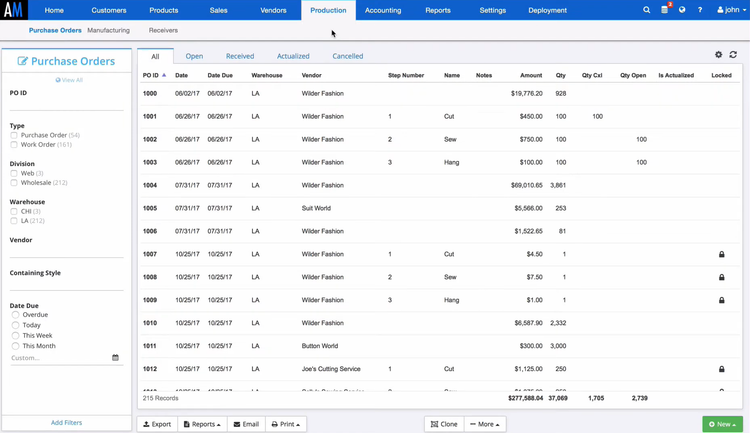

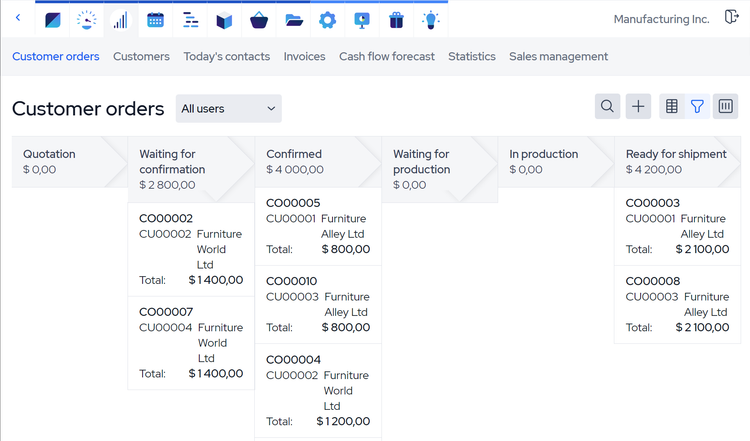

ApparelMagic - Best Product Lifecycle Management

ApparelMagic’s product lifecycle management feature is a central hub for managing aspects from ideation to final production. It connects departments such as design, production, and sales, ensuring everyone works with real-time information.

For example, you’re in the process of launching a new line of sustainable activewear. Your design team creates sketches for the new line and uploads them into ApparelMagic, along with specifications for sustainable fabrics like recycled polyester.

Your sourcing team can use the material library to identify fabrics already in stock or find alternative options that can reduce costs without compromising sustainability. The software also allows you to communicate with multiple suppliers to obtain samples and compare quotes.

Once you select the material, you can create prototypes of the activewear. Any feedback from quality control can be automatically logged into the system. Once you approve all changes, the PLM feature will notify the production team to begin planning the manufacturing process. The system will provide them with a finalized BOM and detailed instructions. Your sales team can use the finalized product details to prepare promotional materials and launch plans.

ApparelMagic’s pricing varies from $120/month to $1,250/month. The software has four pricing plans; however, if you’re a small business, you might want to consider a more affordable solution like ERPNext.

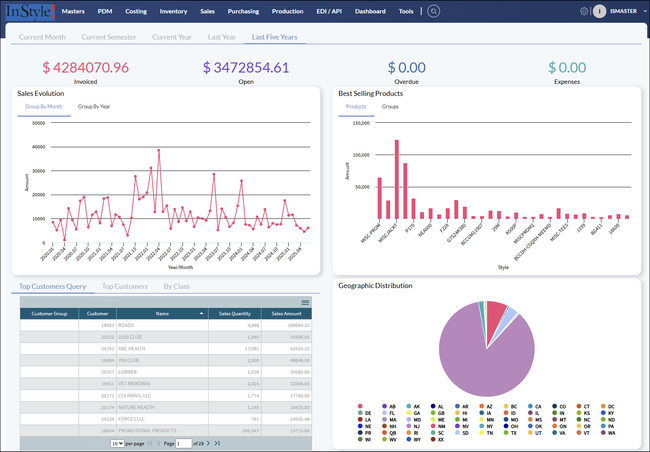

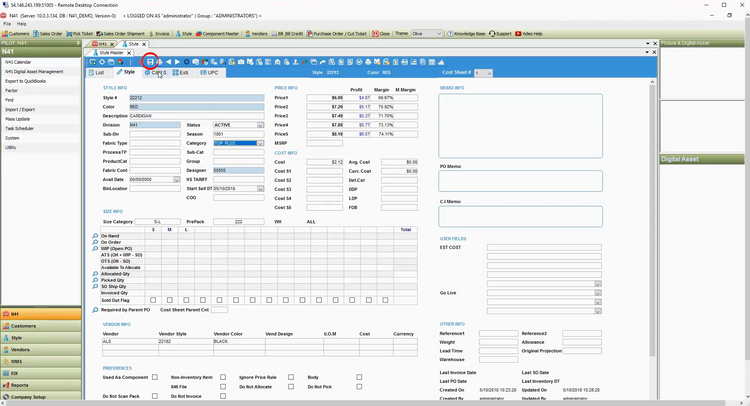

InStyle Software - Best for Apparel Manufacturers

InStyle Software’s production planning module helps apparel manufacturers adapt to style and season-driven demand. It supports products that have several variations, like size, color, and patterns that change quickly. The system combines MRP with design management, allowing you to tie your BOM data to your shop floor. That way, late changes, material substitutions, and shifting delivery dates won’t cause massive delays or cost overruns.

Additionally, InStyle’s MRP module is part of its end-to-end ERP suite that also includes purchasing, inventory, and order management. This allows manufacturers to keep cut-and-sew lines fed and finished goods shipping on time. The MRP module aligns fabrics, trims, and packaging with production schedules, ensuring you have the right materials to meet demand. It supports tighter coordination across the entire lifecycle—from a confirmed order all the way to fulfillment, without relying on spreadsheets or disconnected systems.

InStyle offers flexible pricing plans that fit both small and large businesses. The lowest plan starts at $199/month for one user and includes core modules like the style master and inventory management. It can also be deployed on-premises or in the cloud.

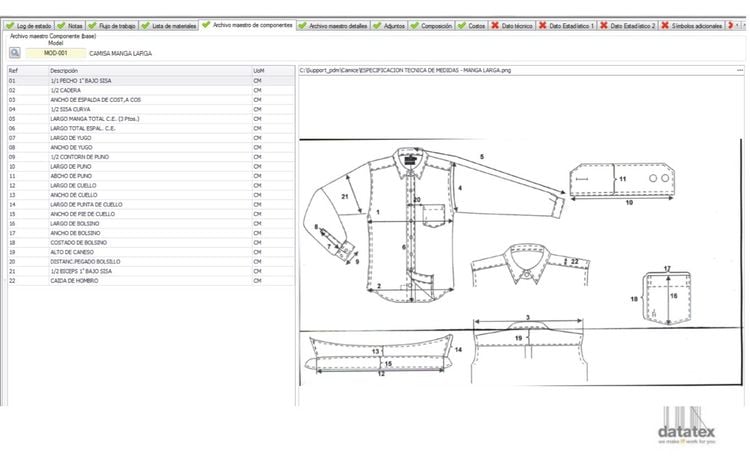

Datatex NOW - Best for Production Planning and Scheduling

Using its production planning and scheduling feature, Datatex NOW ERP streamlines and optimizes your manufacturing processes. It uses advanced algorithms to create a production schedule that minimizes downtime, avoids resource conflicts, and adheres to delivery timelines.

The system takes input such as customer orders, raw material availability, machine capacity, and workforce schedules. For example, maybe you’re a textile manufacturer who produces custom fabrics for apparel brands. Using Datatex NOW, you can evaluate the availability of dyeing machines, weaving looms, and skilled labor.

The software will schedule the production of the most urgent order first while ensuring that other orders proceed without resource conflicts. It will also ensure that each fabric’s specific yarns and dyes are procured and available when production begins.

Using Gantt charts, you can see if there are any potential delays in production, such as planned machine maintenance. The software automatically adjusts the schedule, shifting other tasks to underutilized resources. If there are any delays in production, such as a machine jam that slows the weaving process, Datatx NOW will immediately reschedule the remaining tasks and notify your maintenance team, minimizing the impact on overall timelines.

The production schedule will sync with your logistics partners, ensuring the finished fabrics are dispatched to customers promptly.

BlueCherry Enterprise - Best Shop Floor Control

BlueCherry Enterprise’s shop floor control provides real-time visibility, monitoring, and management of manufacturing processes.

This capability uses IoT-enabled devices and software integrations to capture real-time data from production lines. The data is shown through dashboards and reports, allowing you to identify inefficiencies, track performance metrics, and make informed decisions.

For instance, maybe you specialize in high-volume garment production and produce 5,000 shirts for a client. Using BlueCherry Enterprise, you can track the fabric as it moves through the cutting, stitching, and finishing stages, ensuring that none of the materials are lost or delayed.

During inspection, you identify a defect in one of the garment batches. With BlueCherry Enterprise, you can pinpoint which stitching line is responsible and immediately take action to prevent further deviations.

To meet the delivery deadline, the software reallocates tasks across lines to minimize bottlenecks and ensure a consistent production workflow. All production data is synced into the system to update inventory levels and notify shipping teams of completion.

MRPeasy - Best for Small Manufacturers

MRPeasy streamlines production management for small manufacturers, making it our top choice for this segment. It’s an AI-powered solution tailored for businesses with 10 to 200 employees. MRPeasy provides accurate production planning and reporting, ensuring apparel manufacturers can promise realistic lead times. Its real-time inventory overview helps prevent stock-outs and lower inventory levels, while also facilitating on-time deliveries.

MRPeasy’s integrated manufacturing software includes advanced tools for production planning, stock management, purchasing, and sales management through its CRM system. This is all underpinned by clear accounting insights to monitor business performance. Ultimately, MRPeasy is designed to replace spreadsheets and unify sales, production, warehousing, procurement, administration, and finance for smaller organizations.

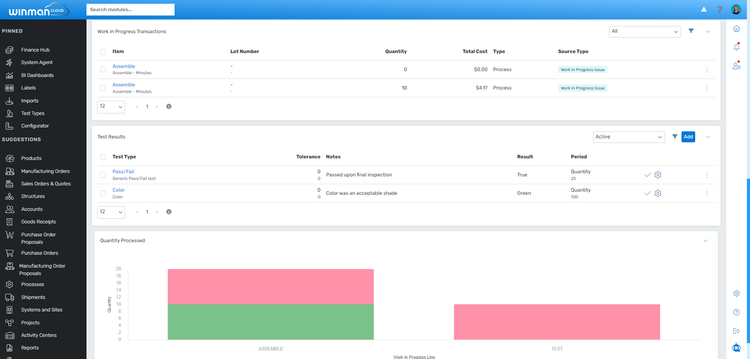

Infor MES - Best MES Option

Infor MES digitizes all manufacturing operations and integrates with ERP systems. This platform can connect to sensors and devices embedded in manufacturing equipment to collect data on machine performance, product quality, environmental conditions, etc. Additionally, Infor MES leverages the Internet of Things (IoT) technology to enhance further connectivity and data exchange between devices and the system.

We found that Infor MES can enhance quality control processes by providing real-time monitoring and analytics of production operations. For textiles, where fabric quality, dye consistency, and pattern accuracy are crucial, the system can identify deviations from standards immediately, allowing for quick corrective actions. Finally, Infor MES enables bi-directional traceability that is useful for compliance with regulations and standards, like those related to sustainable and ethical materials sourcing.

A2000 - Best Warehouse Management System

A2000’s WMS includes granular inventory, lot tracking, and multi-warehouse support for managing raw materials and unfinished rolls. Unlike most textile ERP, it delivers this tool natively, with no need for third-party integrations.

A2000 integrates with RFID readers and handheld scanners for live inventory capture, helping you follow dye lots, yarn cones, and woven bolts as they progress through your facilities. As your team scans items during receiving and production staging, this textile software creates a precise audit trail of all stock movements.

Additionally, A2000 supports precise location management. You can assign stock by dye lot, bin, shelf, or pallet, vital for picking specific fabric rolls or chemical batches that match your production specs exactly. Plus, your team can use their mobile devices to perform cycle counts with instance variance reporting. This helps you keep losses like fabric shrinkage and dye bleed to a minimum.

While exact pricing isn’t shared publicly, A2000 starts at around $200/month. Some users have mentioned that the financial management side of things could use some work, specifically that it doesn’t handle foreign currencies well. It’s up to the user to update the value of foreign cash in their local currency.

What is Textile Software?

Textile software can help streamline processes, improve efficiency, and manage the complexities of textile manufacturing and distribution. It provides tools for managing raw materials, production processes, inventory, sales, and supply chain operations.

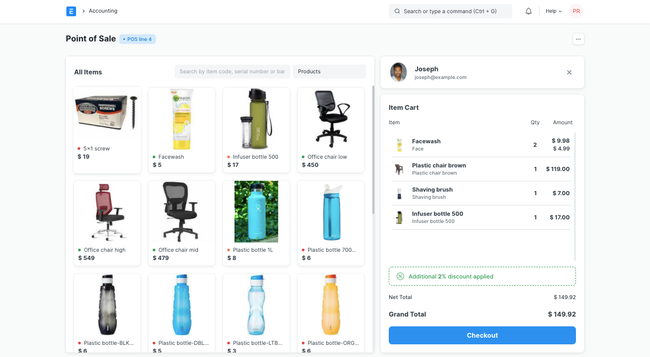

Other key features of the software include pattern making, product lifecycle management, computer-aided design (CAD), production scheduling and planning (manufacturing), and even point of sale (POS) for retail operations.

Key Features

- Design: Handles the image creation and editing involved in fabric designs. Includes repeats and separations, coloring, color-matching, presentation boards, engravings, tones, and more.

- Sales Order Management: Streamlines order processing by helping capture, track, and fulfill orders across multiple sales channels. Connects inventory and sales orders, creates shipping schedules, tracks fulfillment, and produces reports.

- Production Scheduling: Helps plan production on your shop floor by determining the need for materials and capacity to complete a production order. Creates a highly detailed production schedule that accounts for resource, staffing, and inventory needs.

- Inventory Management: Keeps track of all information about the items your company builds, buys, stores, or sells. It simplifies product pricing and helps maintain the most effective stock levels.

- Purchasing: Create financial documents for vendors when buying supplies or services. Includes information such as product type, quantity, and pricing.

- Maintenance Management: Creates work orders for maintenance activities (such as preventive maintenance tasks and predictive maintenance scheduling) to help limit machine and equipment downtime and lengthen the lifecycle of assets.

- Electronic Data Interchange (EDI): Helps exchange business documents in a standard electronic format. Examples include shipping statuses, invoices, purchase orders, inventory documents, and customs information.

Primary Benefits

Improve Your Supply Chain Through Business Intelligence

Many textile companies choose to use advanced planning and scheduling (APS) software functionality to meet their production needs. This process helps designate raw materials and production capacity to balance demand and plant capacity to their optimal fulfillment level.

In other words, it can plan and schedule production based on available materials, labor, and equipment–all while tracking the costs involved, the overall equipment effectiveness (OEE), and improving material requirements planning (MRP).

This is considered a high-level approach to making sustainable business decisions, as it utilizes business intelligence data to improve managerial control over your operations. Having analytics about your production process can help improve the quality control and flow of products through your production process.

One example may be when your business desires to minimize costs. Users of textile software can assign various weights to different parts of the cost function. This cost function is helpful when dealing with samples and providing detailed tracking of sampling costs. A textile business may want to schedule sampling on machines during set periods of downtime to ensure your operations (whether fiber, spinning, or cut and sew) are not interrupted.

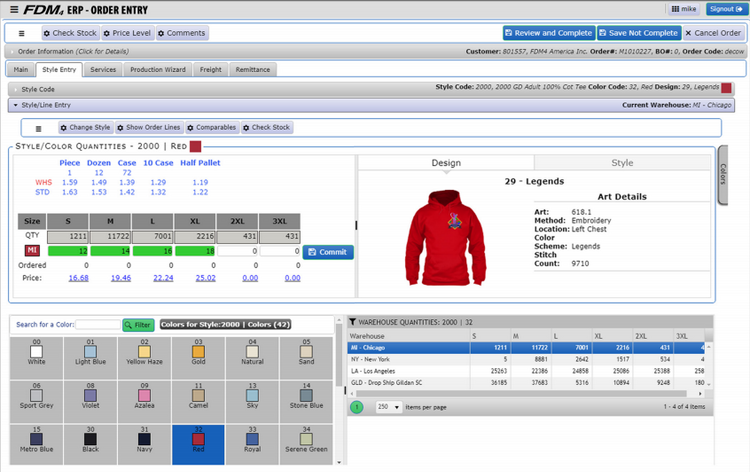

Manage Complex Merchandise Inventory

Something unique to inventory in the textile and apparel industry is a size and color matrix. A color/size matrix is an inventory database management feature that provides more efficient database management by minimizing the number of records required to track different product combinations that vary by color or size.

This can sometimes be referred to as a “fashion matrix,” where manufacturers and retailers manage their product variants across a grid format to try and capture their product variants and align colors against sizes. This is appropriate when selling the same products in different sizes and colors.

Inventory in the textile industry can also be complex due to excessive or confusing inventory. As market demand fluctuates, so will your fulfillment dates, and these will need to be paired with your sales algorithms to maintain overall profit calculations.

As your variable costs change (such as manufacturing costs, overhead costs, and more), you should be able to easily change your matrix to help anticipate the risks and rewards of market fluctuations.

Finally, a solid inventory management functionality within textile software can help simplify purchasing and vendor management. You can record vendor details such as contact info, price lists, etc., which will let you grade your vendors based on their costs and performance.

Changing a purchase request into a purchase order quickly can help prevent procurement from exceeding any budget your business may be working with.

Provide Accessibility Through Mobile and Cloud Networks

Most ERP systems are online–eliminating the need to work at a single location. Employees can use web-based applications to access the system no matter where they are located–whether they are on a sales call, conducting quality checks at another location, etc.

Cloud solutions also help give you a leg up on your competition as they allow instant access to the newest updates offered by your software provider. As new businesses enter the market, you’ll want a solution to help you outlast your competitors.

Cloud-based ERP software also lets your employees access the solution from many devices, such as laptops, tablets, and smartphones. Allowing users to have real-time data access will enable managers to ensure that business operations are up to par at all times without any excuses for a delay in data entry.

Textile Software vs Apparel Software

Apparel ERP software is broad enough to handle the needs of both apparel manufacturers and retailers. This means the software can be used by clothing manufacturers, fashion designers, or high-end retailers.

Meanwhile, the textile industry is generally involved in designing, manufacturing, and distributing clothes. Still, it has less to do with a clothing retail operation looking to order more goods or manage their eCommerce store.

Given that the names of the software are often used interchangeably, most businesses will be fine using one or the other. However, it will be essential to ask your software provider what the intended market is for the software. If you were a textile retailer, you wouldn’t want a solution designed for manufacturers and vice-versa.

Pricing

The cost of textile ERP software falls somewhere between $10,000 and over $600,000 per year. Generally, exact pricing factors in your company size, desired features, and deployment complexity.

Entry-Level Textile Software: $10,000–$40,000/year

- Best for small textile companies with 1–50 employees

- Includes core functionalities like raw material tracking and production management

- Examples: ERPNext, Odoo with fashion add-ons

Mid-Tier Solutions: $40,000–$175,000/year

- Best for growing textile businesses with 50–250 employees

- Includes features like planning, costing, and vendor collaboration tools

- Examples: ApparelMagic Professional, FastReactPlan, BlueCherry Essentials.

High-Tier Systems: $175,000–$600,000/year

- Best for medium-sized to large manufacturers with 250 to 500 employees

- Supports deeper supply chain management, integration with MES/WMS, advanced reporting

- Examples: BlueCherry Enterprise, Infor CloudSuite Fashion, Aptean Apparel ERP

Enterprise-Grade Solutions: Over $600,000/year

- Best for global textile enterprises with over 500 employees

- Supports global sourcing and multi-site operations

- Examples: SAP S/4HANA for Fashion, Oracle Cloud SCM, and Microsoft Dynamics 365 Finance & Operations with apparel extensions

Your total cost of ownership will also factor in user count, deployment preference (cloud vs. on-premises), and needed customizations or integrations. Many vendors also charge additional fees for setup and training.