The Best Warehouse Management Software

We reviewed the best warehouse management system (WMS) software to help you track inventory and boost fulfillment–whether you’re a 3PL, high-volume fulfillment center, or general distributor.

- Integrates with WooCommerce, Amazin, Shopify, eBay, Walmart, and more

- Offers two-day and overnight delivery options

- Provides automatic notifications for stock replenishment and allows setting of reorder points

- Provides batch tools through the order manager to track process workflows

- Integrates directly with QuickBooks for easy data migration

- Can handle millions of SKUs for scalability

- Offers various picking methods such as wave and zone picking

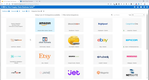

- Integrates with over 240 eCommerce, shipping, and accounting platforms

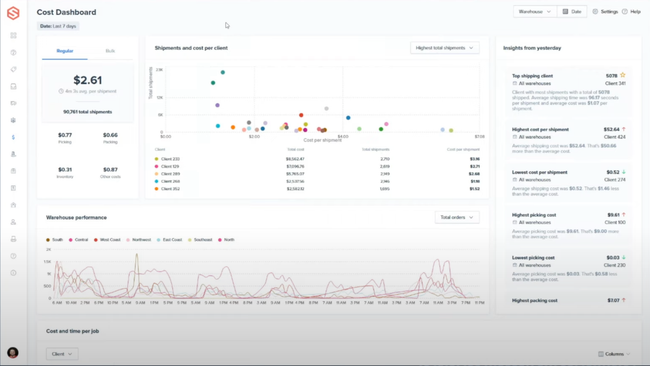

- Allows for real-time feedback on worker performance

We ranked the top WMS systems for different sectors, from general distributors and direct-to-consumer brands to 3PLs. We also compared each platform’s best industry fit and pricing.

- ShipHero: Best for General Distributors

- Acctivate: Best QuickBooks WMS Add-on

- Logiwa: Best for Direct-to-Consumer Brands

- NorthStar WMS: Best for Food Distribution

- Körber: Best for Omnichannel Retailers

- Blue Yonder Luminate: Best for Complex Warehouse Operations

- Da Vinci WMS: Best for Cartonization

- Fishbowl Inventory: Best for eCommerce

- 3PL Warehouse Manager: Best for 3PLs

- Infor WMS: Best 3D Visual Warehouse Tool

- Infoplus WMS: Best for Seasonal Fulfillment

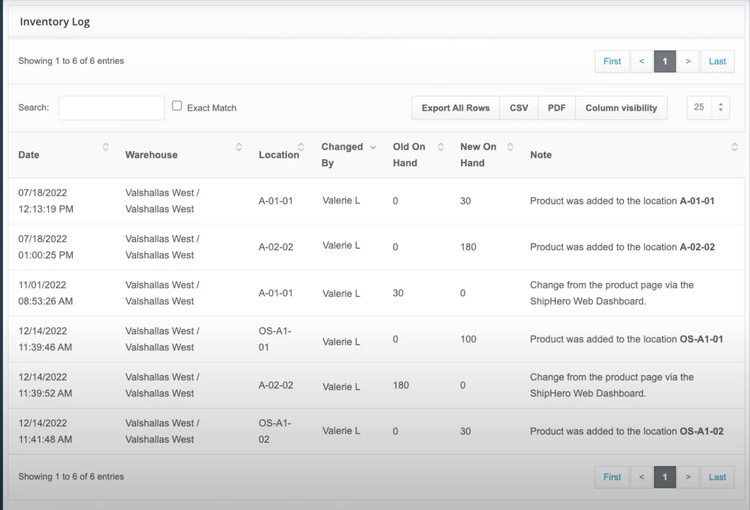

ShipHero - Best for General Distributors

If your team juggles tons of SKUs from multiple vendors, you’ll need visibility and control to stay on top of it all. ShipHero’s mobile replenishment app is a real standout, designed to help your warehouse staff check stock, manage inventory levels, and handle restocking tasks from anywhere.

With a quick glance at the app, your team can get an overview of low-stock items and outstanding tasks. You can prioritize these by urgency, ensuring high-demand products get restocked based on your specific criteria. This keeps your operations running and helps you avoid dreaded stockouts.

General distributors can also leverage:

- Detailed Tracking: See exactly when and where inventory moves, down to who handled it.

- Flexible Replenishment Options: Move one item to a shelf or consolidate multiple products onto a pallet.

For teams managing large or complex spaces, this type of warehouse inventory software can reduce miscounts, misplaced items, or missed replenishment alerts. ShipHero starts at $1,995 per month with five user seats; it’s a solid pick if you deal with at least 500 orders per month.

For more information on ShipHero, read the full review.

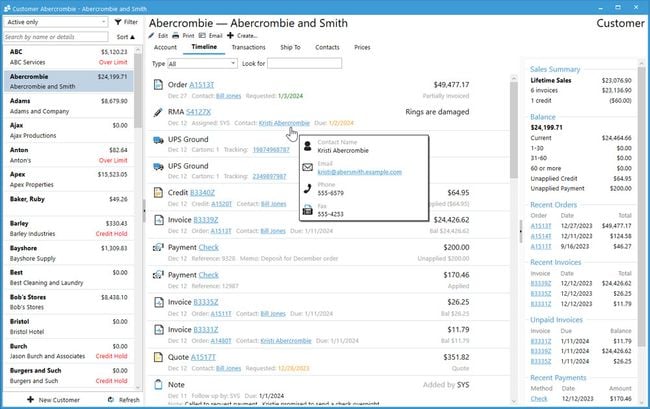

Acctivate - Best QuickBooks WMS Add-on

Acctivate is purpose-built for small to mid-sized businesses that rely on QuickBooks for accounting but need more robust inventory and warehouse capabilities. Instead of replacing your accounting platform, Acctivate extends QuickBooks functionality by adding tools for warehouse management, order processing, and inventory tracking.

Acctivate connects directly with your QuickBooks data to keep financials in sync while adding features like multi-warehouse tracking, mobile barcode scanning, and real-time inventory visibility. You can manage serialized or lot-controlled items, automate order routing, and eliminate manual double entry between systems. For businesses handling complex or multi-channel sales, Acctivate offers centralized order management, helping process orders quickly and without mistakes.

While Acctivate is one of the few WMS systems to offer bi-directional integrations with QuickBooks, it requires expensive customization for RFID tracking, so larger distributors needing fully automated warehouses may want to consider other systems. However, with pricing starting at $5,000 per year with an initial implementation fee, Acctivate is a solid QuickBooks add-on.

For more details on Acctivate, read our full review.

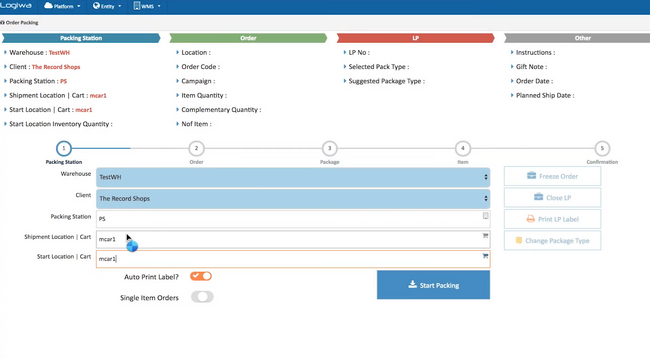

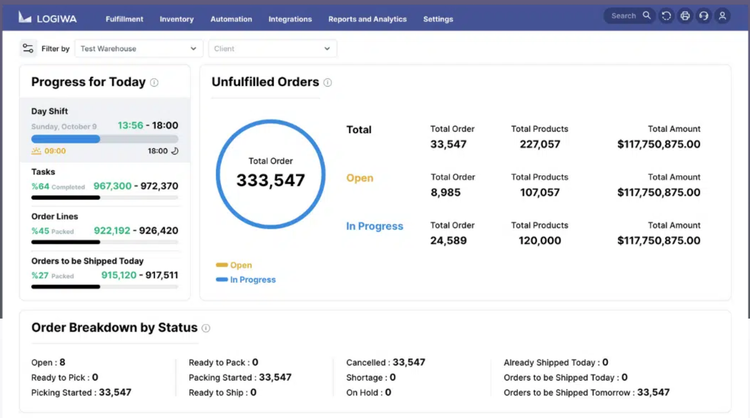

Logiwa - Best for Direct-to-Consumer Brands

Logiwa’s helps keep your shipping fast and your customers happy through its automated order routing tool. It takes the guesswork out of fulfillment, managing order flow based on your rules. So instead of manually checking which warehouse has stock or comparing shipping costs, this WMS software does it for you based on:

- Inventory location: Goes to the facility with the most stock.

- Customer proximity: Routes to the nearest warehouse to minimize shipping times.

- Carrier costs: Integrates with UPS, FedEx, and others to pick the most cost-effective shipping option.

- Shipping Preferences: Chooses a facility that offers specific shipping methods like overnight delivery.

Logiwa even factors in order size, customer loyalty, or time sensitivity. It plays nicely with most major eCommerce platforms like BigCommerce, WooCommerce, and Shopify. However, some users say that integration with custom systems generally requires some extra setup through third-party assistance. That said, it’s still a solid pick for fast-moving brands with DTC or B2B models.

Read our full review for more details on Logiwa.

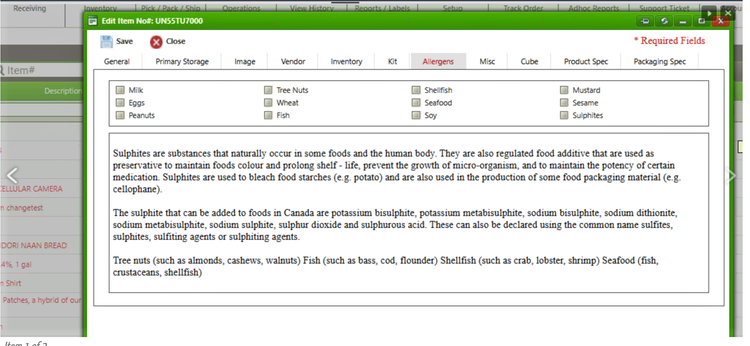

NorthStar WMS - Best for Food Distribution

NorthStar WMS’ allergen control feature helps you manage ingredients like nuts, gluten, dairy, and shellfish across your entire operation. As soon as you receive allergen-containing items, NorthStar flags them and directs your team on how to store them safely. This can help you avoid cross-contamination and comply with food safety standards like HACCP and FSMA.

The allergen control tool syncs with inventory tracking, auto-updating stock levels as products move through your warehouse. When picking orders for a large chain, the system alerts you if both allergen-free and allergen-containing products are included. This makes it much easier to tweak your picking list, so you can pack and label allergen-free goods separately. Best of all, after you process the order, NorthStar generates labels with all the relevant details.

This warehousing software is a solid pick if you’re meticulous about managing risks and building trust with your clients. Prices for NorthStar WMS start at $1,000/month, but depending on the number of users and features your company needs, they can increase up to $5,000/month.

Learn more about other Northstar WMS key features.

Körber - Best for Omnichannel Retailers

Körber WMS offers a last-mile delivery solution that gets orders to your customers quickly, no matter where they’re shopping. You can monitor your shipments in real time, with insights into status updates and any potential delays.

After processing an order, this warehouse manager software automatically selects the best delivery method based on cost, speed, and carrier availability. From there, it creates a shipping label, schedules a pickup, and sends the necessary details to the customer. This means better route planning, fewer failed deliveries, and a smoother overall experience for both sides.

As customers come to expect faster and faster shipping, Körber can help you stay ahead of the competition. While some users say it doesn’t send alerts when backorders remain unfulfilled—and the reporting tools could be more flexible—it’s still a solid pick for small to mid-sized retailers. Pricing is not publicly available, so you’ll need to request a quote to get an idea of the exact costs.

For more information on Körber, read the full review.

Blue Yonder Luminate - Best for Complex Warehouse Operations

If you’re dealing with a multi-location supply chain, Blue Yonder Luminate brings advanced forecasting tools to the table. Its multi-echelon inventory optimization (MEIO) feature looks at your entire network, including warehouses, distribution centers, and even stores, to find the prime location to place stock for the biggest impact.

Instead of treating each warehouse as a silo, the MEIO tool views your supply chain as a network of interconnected echelons. It works by leveraging:

- Data collection: Gathers inventory flow, demand variability, and capacity data

- AI forecasting: Interprets historical sales and seasonal trends

- Stock optimization: Recommending ideal inventory levels by location

If you operate an enterprise with multiple distribution centers or deal with a complex assortment of products, this can help you handle fluctuating demand. You can pre-stock high-demand items where they’re needed most, which is especially helpful during seasonal peaks. This also keeps you from overstocking at one site while running out at another. While pricing isn’t listed publicly, we generally recommend it for large-scale distribution companies needing stronger supply chain planning.

For more information on Blue Yonder, read the full review.

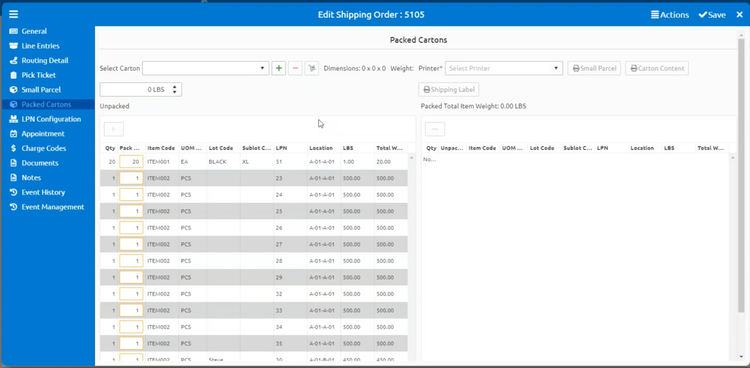

Da Vinci WMS - Best for Cartonization

Da Vinci WMS has an impressive cartonization feature specifically designed to optimize the packing process. When the warehouse management system receives an order, this tool pulls data on item weight, size, and handling needs. From there, it selects the best carton size from its database. This can save you from wasting time (and space) and help you adhere to weight limits.

Plus, this warehouse inventory control software even suggests how to arrange items in the carton, so you can cut down on shipping costs and damaged goods. It gives recommendations on padding and securing the items to prevent damage during transit. Then it automatically creates a shipping label and any necessary documentation.

As the cartons are packed, inventory levels update in real time. That way, you’re always working with accurate stock levels without running the risk of stockouts or overstocking. While the developer doesn’t list exact pricing details, this warehouse manager software best suits medium-sized to enterprise-level 3PLs, retailers, and wholesalers, especially in apparel and household goods.

For more information on Da Vinci WMS, read the full review.

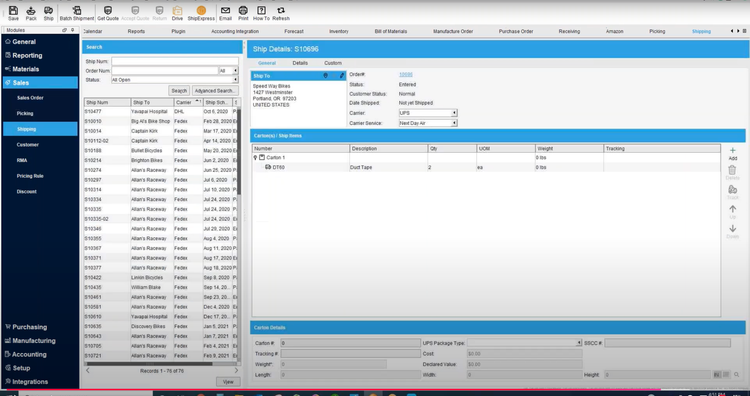

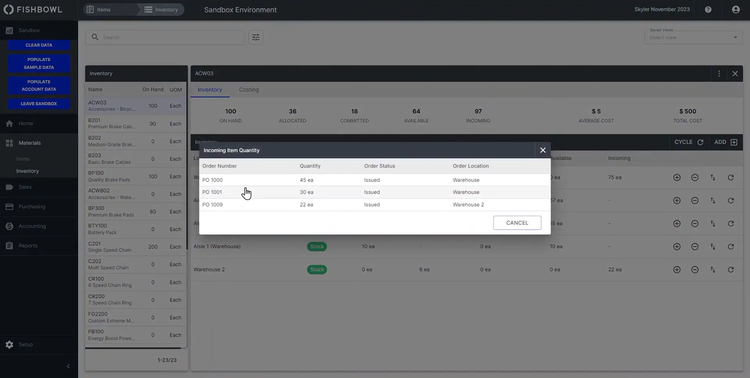

Fishbowl Inventory - Best for eCommerce

If you’re running a growing online store, Fishbowl’s warehouse management software can help you organize your orders without getting overwhelmed. Whether your customers buy through your website, a POS system, or marketplaces like Amazon, Fishbowl centralizes your order management.

The order management feature is relatively simple to use. It gives you a full roster of sales order statuses, allowing you to track them through quoting, picking, packing, and shipping. This means you can respond much faster to inquiries and keep your customers posted on their orders.

Fishbowl even lets you create picking lists to optimize routing in your warehouse, cutting down on your team’s travel time. Plus, you can generate shipping labels and track shipments directly within the order management system. You can even integrate with carriers like UPS and FedEx.

There’s a minimum of $6,795 for two users on a perpetual license and $1,597.50 per user for SaaS, billed on an annual basis. These costs go down with additional users, but it’s something to consider if you’re a very small business with a tight budget.

Get full pricing details on Fishbowl Inventory.

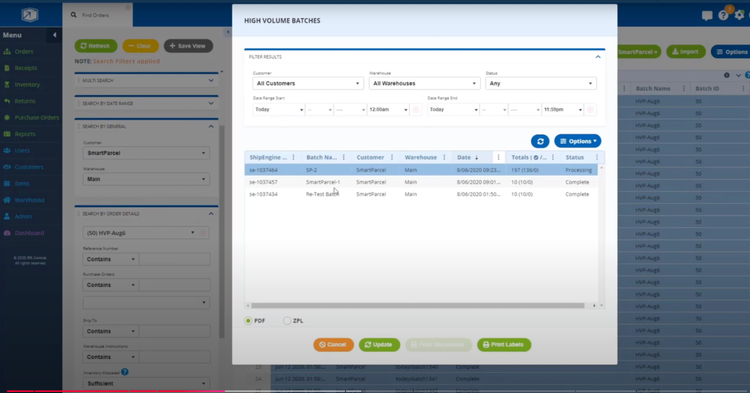

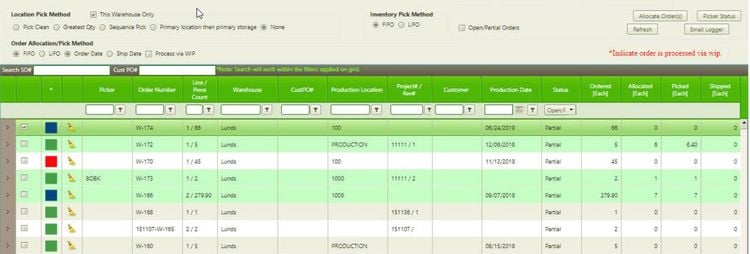

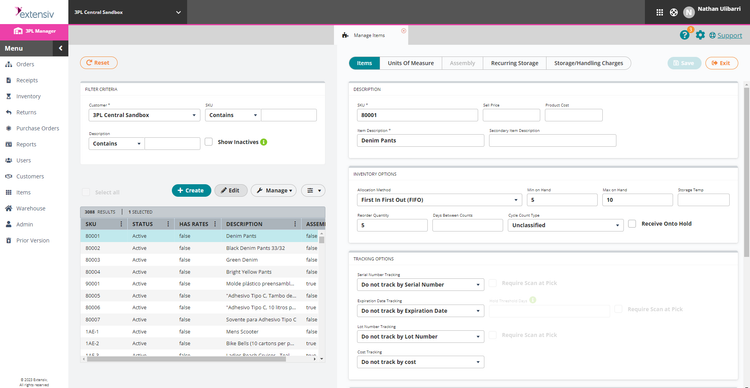

3PL Warehouse Manager - Best for 3PLs

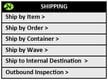

The volume batch processing feature in Extensiv 3PL Warehouse Manager is a great match if you’re constantly juggling high volumes of orders. It lets you create batches based on criteria like destination or shipping dates, so you can group similar orders together for faster fulfillment.

Once a batch is created, you can assign tasks to your staff. This approach allows one team to pick while the other team packs, improving workforce utilization and reducing downtime on the floor. Plus, with integrated tools like SmartParcel Suite and ShipEngine, you can simplify the process even further. These help you automate rate shopping, carrier selection, and even label printing within each batch.

After completing a batch, you can use this WMS software to generate a detailed report on the time taken for each processing phase. That way, you can assess your operational efficiency, identify any bottlenecks, and adjust batch strategies for the future. Starting at $599/month, Extensiv 3PL Warehouse Manager is best for small to mid-sized 3PLs.

For more information on 3PL Warehouse Manager, read the full review.

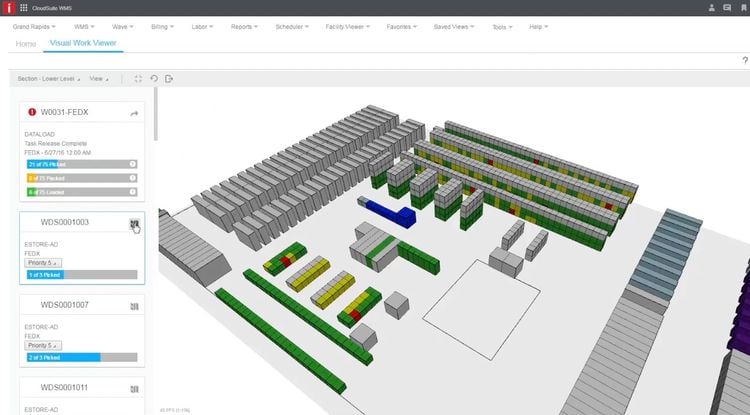

Infor WMS - Best 3D Visual Warehouse Tool

Infor WMS provides warehouse managers with a live view of their facility. This is perfect if you work with space-intensive inventory typical in automotive, industrial equipment, and manufacturing support operations. Overall, the 3D visual warehouse tool offers a clear, graphical interface for checking exact stock and shelf locations.

The warehousing software includes simulation functionalities that let you test different layouts, long before you make any physical changes. This is a big plus when you’re accommodating new inventory or adapting to demand shifts. You can test out storage configurations without disrupting your daily operations.

The 3D visualization tool also displays the most efficient routes for restocking and picking items. This improves your team’s efficiency, cutting down on unnecessary travel time and improving picking and packing accuracy. Your managers can also use this feature to validate and adjust routes.

While some users report that the 3D visual feature can cause slow performance, Infor WMS offers advanced features for managing stock across different locations. This makes it a good fit for mid-sized to large companies across manufacturing, distribution, and retail.

Learn more about Infor WMS.

Infoplus WMS - Best for Seasonal Fulfillment

Seasonal spikes can be a logistical nightmare, especially if you’re still processing orders one at a time. Infplus WMS created a wave planning feature that helps you stay ahead of the rush, letting you group and prioritize similar orders for faster picking and packing.

Infoplus wave planning works like this:

- Step 1: Assess the order queue - Breaks down orders by size, urgency, and shipping region

- Step 2: Create waves - Groups orders into batches based on common attributes

- Step 3: Assign tasks - Sends staff targeted picking instructions for each wave

- Step 4: Optimize routes - Reduces travel time and streamlines fulfillment

As you fulfill orders, the WMS tracks your progress live, so you can closely monitor wave completion and make any necessary adjustments. This makes it much easier to maintain workflow efficiency during busy stretches. Afterward, Infoplus can generate performance reports, offering insights into picking speed, accuracy, and areas for improvement. That way, you can prep for future holidays or major promo periods, where order volume jumps and every second counts.

Other Systems We Like

Finale Inventory is an inventory management software that has solid warehouse management features for small to midsize eCommerce businesses. It helps keep all of your SKUs aligned across multiple locations. You can also conduct inventory audits, create item kits, and label barcodes for further inventory control.

What is Warehouse Management Software?

Warehouse management systems (WMS) software helps you organize, track, and control the movement of goods within a warehouse or distribution center. This includes tracking inventory levels, directing pick-and-pack workflows, and coordinating outbound shipments.

To stay competitive, you can use WMS to automate activities like storing items, shipping, and reporting. Overall, these systems boost fulfillment efficiency, cut labor costs, and ensure timely deliveries at the lowest possible price.

Key Features

- Inventory Management: Track items by lot, batch, and serial number, create stock level alerts, cycle counts, and manage stock in real time.

- Order Fulfillment: Process sales and purchase orders and handle backorders and returns to easily complete customer orders.

- Picking and Packing: Streamline your picking and packing workflows with various methods, such as wave and zone picking, to ensure orders are fulfilled on time.

- Barcode Scanning: Efficiently track inventory, receive shipments, and track stock by scanning barcodes and using RFID tags.

- Location and Space Management: Manage bins, shelves, and zones while optimizing slotting. Configure location assignments using custom parameters for efficient distribution.

- System Integrations: Integrate with various other systems like ERP, accounting, TMS, EDI, and eCommerce platforms for two-way data sync.

Benefits of Using WMS

- Increased Inventory Accuracy: Track real-time inventory levels, locations, and movements to ensure accurate counts and minimize stockouts or overstocks.

- Improved Efficiency: Streamline warehouse processes like picking, packing, and shipping to reduce time spent on tasks. Having these automated workflows can improve employee productivity and reduce operational costs.

- Better Space Utilization: Optimize warehouse space and storage using tools like slotting. This can help maximize the available space and make it easier to access high-demand items.

- Enhanced Order Fulfillment: Improve your order fulfillment process by ensuring that orders are picked, packed, and shipped quickly and correctly. This can lead to faster delivery times and increased customer satisfaction.

- Cost Reduction: Minimize errors and optimize warehouse operations to significantly reduce operating costs. Efficient inventory management can also reduce excess stock and holding costs.

How Do I Choose a WMS?

Choosing the right WMS software depends on the size and structure of your warehouse operations. First, get a handle on your exact warehousing and supply chain management needs:

- Startups and small businesses generally need cloud WMS software that centralizes tasks within a broader supply chain solution. For growing businesses, you can tailor web-based platforms to match your evolving workflows—think adding users, integrating with sales platforms, or even just modifying how orders are picked and packed.

- Medium-sized businesses often outgrow spreadsheets or more basic tools, requiring standalone WMS software. These systems often include barcode scanning, real-time inventory tracking, and rule-based picking to support growing order volumes.

- Large warehouses will need more detailed inventory tracking, like lot and serial number management, and retail compliance features like advanced labeling and ASN generation. If you’re dealing with transportation management software (TMS) or enterprise resource management tools, make sure your WMS can fully integrate with those systems.

- Different industries require sector-specific capabilities. For example, in aerospace and defense, choose a WMS with advanced traceability and quality inspection workflows to comply with FAA or DoD standards. For healthcare, prioritize warehouse inventory software with temperature control monitoring and expiration tracking to meet FDA or cGMP requirements. In industrial manufacturing, find a system that integrates with manufacturing execution systems (MES) to enhance your production workflows.

With the right WMS software, you’ll improve operational efficiency, shorten delivery times, and boost customer satisfaction. If cost is a concern, you don’t necessarily need to buy WMS software on its own. Many of the same features, like order or inventory management, can be found within broader systems like distribution software or supply chain management systems. If you’re outsourcing your warehousing to a 3PL, standalone 3PL software can connect with systems that third-party warehouses use, even if you don’t directly manage those facilities.

Pricing Guide

Pricing for warehouse management systems can vary based on several factors, including the deployment method (on-premise versus cloud-based), number of users, level of support included, and any additional services the vendor provides.

WMS for Small Businesses

- Approximately $5,000-$20,000 annually

- Best for 1-2 warehouses, up to 25 employees

- Examples: Fishbowl Inventory, Zoho Inventory, Acctivate, SOS Inventory

WMS for Mid-Sized Companies

- Approximately $20,000-$100,000 annually

- Best for 3-10 warehouses, 25-100 employees

- Examples: ShipHero, InfoPlus WMS, 3PL Warehouse Manager, NorthStar WMS, Logiwa, Royal 4 WISE WMS

WMS for Large Businesses

- Approximately $100,000-$250,000 annually

- Best for 10-50 warehouses, 150-500 employees

- Examples: Körber WMS, Tecsys WMS, Manhattan Active WMS

Enterprise WMS

- Over $250,000 per year

- Best for over 50 warehouses, more than 500 employees

- Examples: Blue Yonder Luminate, Deposco, SAP Extended Warehouse Management

| Software | Best For | Deployment Options | Subscription Pricing per Month |

|---|---|---|---|

| ShipHero | General Distributors | Cloud or On-Premise | $1,995/month |

| Fishbowl Inventory | eCommerce | Cloud or On-Premise | $150-$200/user/month for cloud WMS |

| Logiwa | Direct-to-Consumer Brands | Cloud | N/A |

| Northstar WMS | Food Distribution | Cloud or On-Premise | $1,000+/month |

| Körber | Omnichannel Retailers | Cloud | N/A |

| Blue Yonder Luminate | Complex and Large Scale Operations | Cloud | N/A |

| Da Vinci WMS | Cartonization | Cloud or On-Premise | N/A |

| 3PL Warehouse Manager | 3PLs | Cloud | $599/month |

| Infoplus WMS | Seasonal or High Volume Fulfillment Centers | Cloud | $495/month |

| Infor WMS | 3D Warehouse Mapping | Cloud | N/A |