The Best Cloud Manufacturing Software

This guide highlights cloud ERP options that give you real-time visibility into live production metrics and adaptive demand forecasting. We assessed platforms for various manufacturers, from process-based to small businesses.

- Open architecture for rapid integrations

- Multi-entity support

- Mobile accessibility

- Built for manufacturers

- Collects real-time shop floor data

- Built-in artificial intelligence support

- Multi-site and multi-company support

- Built-in business intelligence

- Comprehensive supply chain management

We tested the most popular platforms for features like predictive maintenance and streamlined supply chain workflows. Whether you’re in food and beverage processing or aerospace, you’ll find a system that fits your operations while easing the demands on your in-house IT.

- BatchMaster ERP: Best for Process Manufacturing

- Epicor Kinetic: Best for Discrete Manufacturing

- CloudSuite Industrial: Best for Complex Manufacturing

- xTuple: Most Affordable Option

- SAP S/4HANA: Best for Industrial Manufacturers

- NetSuite: Best for Mid-Sized Manufacturers

- Acumatica: Industry-Specific Option

- SAP Business One: Best for SMBs

- Fishbowl Inventory: Extensive Integrations

- Odoo: Best Open-Source Option

- ECI M1: Best for Job Shops

BatchMaster ERP - Best for Process Manufacturing

BatchMaster ERP offers both on-premises and cloud-based deployment to process manufacturers, including those in pharmaceuticals, food and beverage, and chemicals. It’s particularly well-suited to formula-based production due to its dynamic formula management tools. You can scale batch sizes up or down to maintain the right proportions. You can also switch out ingredients based on their cost and availability, allowing you to tweak your formulas to meet different needs.

The formula management tool ties right into the costing feature, so you can track both current and potential costs. It supports fixed, tiered, and scalable costs and lets you apply fees based on production stages:

- Intermediates: Allocate costs for partially-completed products, like sauces or doughs; this helps with tracking costs within multi-stage production.

- Recipes: Track the cost of each ingredient and labor involved in a recipe to keep raw material expenses in check and even substitute ingredients as prices or availability fluctuate.

- Finished Goods: Aggregates all costs involved in creating the final product, from recipe expenses to any added costs specific to assembly, like packaging.

BatchMaster is available as a standalone ERP. Or, you can deploy it as an add-on to QuickBooks, SAP Business One, or Microsoft Dynamics. While the user interface might look a bit traditional, it syncs well with Microsoft products. That’s a plus if you already use one of those platforms.

Epicor Kinetic - Best for Discrete Manufacturing

Epicor Kinetic is well-suited for made-to-order and engineer-to-order work. It’s a tier-two ERP software with modular manufacturing and distribution capabilities. Its key features include compliance management, planning and scheduling, supply chain management, quality assurance, and maintenance management.

This cloud manufacturing ERP also delivers customizable reporting and the option for limited code adjustments, allowing companies to align the platform with their specific business workflows. Additionally, the software’s ability to collect real-time shop floor data and support AI adds value to manufacturing operations. Despite the learning curve associated with the software, its highly flexible nature makes it an ideal choice for businesses seeking an adaptable ERP system.

CloudSuite Industrial - Best for Complex Manufacturing

Infor CloudSuite Industrial is a cloud-based ERP solution tailored for companies managing intricate manufacturing and supply chain processes. It handles configure-to-order, make-to-order, and engineer-to-order processes.

Infor CloudSuite Industrial offers deep industry-specific functionality for sectors like automotive, industrial equipment, high tech, and aerospace and defense. Additionally, its cloud-native architecture ensures robust security and scalability, keeping pace with the evolving needs of complex manufacturing sectors.

xTuple - Most Affordable Option

xTuple starts at $175/user/month, with a five-user minimum for the manufacturing edition. It’s one of the more cost-effective cloud manufacturing ERPs on the market today, though exact pricing requires a custom quote.

xTuple’s work order management system is also a perk of the software, acting as a central hub that ties into every other tool. When you create a work order, this cloud manufacturing software pulls in the associated BOM. You can link all raw materials to specific routing steps to easily track what is consumed for each operation.

From there, xTuple uses the work order to generate the traveler, including:

- Pick lists

- Routing sheets

- Work order labels with barcode and part info

After you complete each step, xTuple can either backflush inventory or allow for manual issuing at each stage. It even updates WIP quantities in real time and logs operations against the work order, accumulating material costs, overhead, and labor expenses.

Overall, xTuple is best for smaller manufacturers with anywhere from 10 to 200 employees. It’s highly versatile and ideal for discrete and batch process production, contract manufacturing, and engineer-to-order and mixed-mode environments.

SAP S/4HANA - Best for Industrial Manufacturers

SAP S/4HANA lets you break down industrial products like construction machinery or power generation systems into detailed assemblies and sub-assemblies. Its multi-level bill of materials (BOM) capabilities give you clarity across your design, from hydraulics systems and mechanical linkages down to gaskets and fasteners.

Built-in change management tools capture design revisions without disrupting downstream operations. Any updates to components or assemblies trigger a structured approval process; audit trails let you easily view who made the request, what was changed, and how it impacts other BOM levels. This is particularly useful for meeting ISO standards like ISO 9001, so you can stay compliant while adapting to evolving regulatory standards.

You can also easily manage product variants, which is vital when customers order machines with different configurations, like engine options or control panels. You can compare these BOMs side-by-side in the ERP, pinpointing exactly where two equipment models differ. This reduces your risk of cross-contamination in your parts list or production schedule.

Subscription pricing for SAP S/4HANA Cloud starts at approximately $20,000 to over $100,000 per month. Your final costs will ultimately depend on factors like your user count and desired modules.

NetSuite - Best for Mid-Sized Manufacturers

NetSuite is well-suited to medium-sized companies expanding beyond basic software due to its out-of-the-box functionality. Many of NetSuite’s features are ready to use immediately upon installation, with no customization required. Its main strength lies in accounting, inventory control, order management, and supply chain management tools. This makes NetSuite a good fit for distribution and light manufacturing businesses. Moreover, being web-based ensures access anytime, anywhere.

However, it’s important to note that NetSuite may not be the right fit for smaller companies with fewer than 20 employees. Additionally, it’s not well-suited for process manufacturers due to its focus on discrete bills of materials rather than recipes and formulas.

Acumatica - Industry-Specific Option

Acumatica provides a cloud-based manufacturing edition that supports discrete, process, and make-to-order processes. The software’s adaptability and scalability make it particularly appealing, allowing users to select industry-specific modules and add more as their business grows.

It’s important to note that Acumatica’s learning curve can be steep, and customization may increase the total cost of ownership. Moreover, the pricing details require contacting Acumatica’s sales team directly.

SAP Business One - Best for SMBs

SAP Business One integrates finance, sales, supply chain management, and production processes into a single platform for small and medium-sized enterprises (SMEs). The software’s flexibility, customizable features, and wide array of add-on applications make it adaptable to evolving business requirements.

SAP Business One offers manufacturing resource planning (MRP), providing functionalities such as planning, demand forecasting, and material requirements optimization. The MRP Wizard streamlines these recommendations, allowing businesses to further optimize costs and efficiently manage manufacturing processes.

Fishbowl Inventory - Extensive Integrations

Fishbowl Inventory integrates with QuickBooks to enhance users’ inventory management capabilities or help them implement a light MRP system. It can also integrate with eCommerce platforms, including:

- Shopify

- Amazon

- eBay

- Magento

- Woocommerce

- Wayfair

Fishbowl is focused more on inventory management but also works in manufacturing settings. It’s particularly for small to midsize enterprises (SMEs) seeking powerful and scalable inventory management without a hefty price tag. This software is well-suited for manufacturers with stringent FDA or USDA audit requirements for traceability, making it a robust choice for businesses in regulated industries.

Odoo - Best Open-Source Option

Due to its open-source architecture, users can customize Odoo to their unique organizational workflows. Businesses can tailor the software’s code or implement third-party integrations to expand its functionality. While Odoo offers extensive customization options, deploying and maintaining the software may require technical expertise.

Specifically suited for businesses with up to 200 employees, Odoo stands out for its competitive pricing and seamless integration with third-party apps. This customizable ERP solution provides comprehensive functionality for companies looking to streamline manufacturing operations and grow with a flexible cloud-based system.

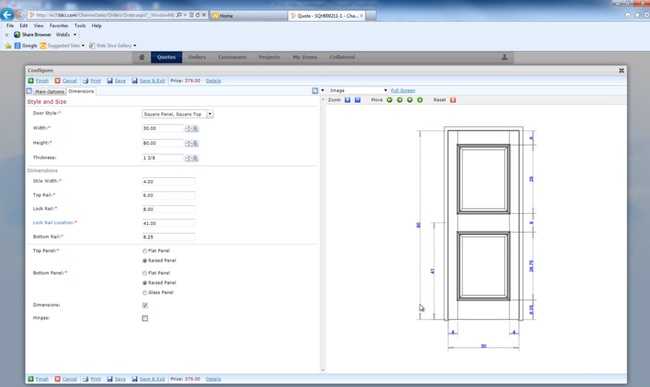

ECI M1 - Best for Job Shops

ECI M1 has comprehensive tools designed specifically for small to medium-sized job shops and made-to-order manufacturers. The software excels in streamlining complex job tracking, quoting, scheduling, and real-time job costing, ensuring maximum efficiency in production management.

ECI M1 integrates with various accounting systems and offers strong reporting and analytics tools. Its scalable architecture allows businesses to add more modules as they grow, making it a versatile solution for dynamic manufacturing environments.

What Is Cloud Manufacturing Software?

Cloud manufacturing software gives manufacturers full control over inventory control, sales order management, quality control, and material requirements planning from anywhere and with any device connected to the Internet. These cloud-based systems won’t be installed on your own computers, so you’ll save time on implementation, updates, and IT support. Since these systems are web-based, you can also access the system from any operating system, whether you have Windows or Mac or are looking to access it with a mobile iOS or Android device.

Manufacturers may also choose a cloud solution for the lower upfront costs compared to an on-premise solution that’s purchased outright. The subscription-based pricing allows manufacturers to pay a smaller fee over time. According to McKinsey’s 2021 survey, 64% of industrial companies report actively using cloud solutions.

Key Features

- Material Requirements Planning (MRP): Gives manufacturing companies visibility into the order-to-cash process. Features of MRP include shop floor control, purchase planning, demand forecasting, and equipment maintenance scheduling. Ties in with other functionalities, including accounting and order processing.

- Sales Order Management: Convert sales orders into work orders. Create and send invoices.

- Manufacturing Inventory Control: Track quantities, prices, variations, and locations of raw materials and finished products. Automate purchase orders for low-stock items.

- Bill of Material (BOM): A list of raw materials and assemblies used in the production process.

- Quality Management: Track defects for finished products and raw materials and manage corrective actions.

Benefits

Some of the advantages of cloud manufacturing software include:

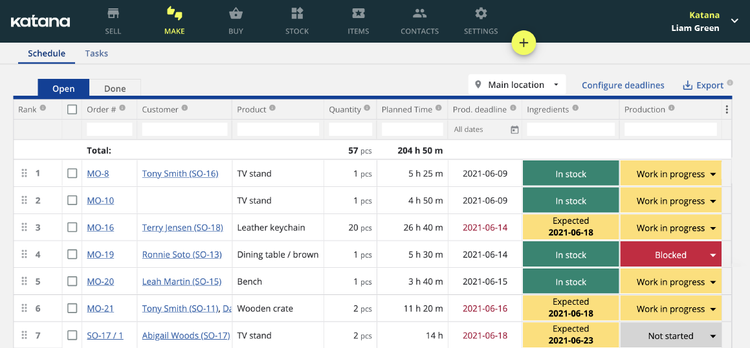

Streamlined Production Processes

Manufacturing resource planning within cloud manufacturing software streamlines production processes with production scheduling, purchase planning, demand forecasting, inventory control, and more. The system ensures your business keeps up with customer demand by calculating material requirements, coordinating workloads for personnel and equipment, and planning purchasing.

Accurately estimating the quantity and cost of labor, raw materials, and equipment needed to manufacture finished products is an important aspect of manufacturing software. This allows manufacturers to ensure they’re making the right amount of products while maximizing their ROI.MRP also helps ensure equipment is properly maintained to reduce machine downtime. The system will track preventive maintenance schedules and maintenance tasks.

With a cloud-based manufacturing system, operators and shop floor personnel can monitor the status of work-in-progress orders, equipment maintenance deadlines, and inventory levels from anywhere.

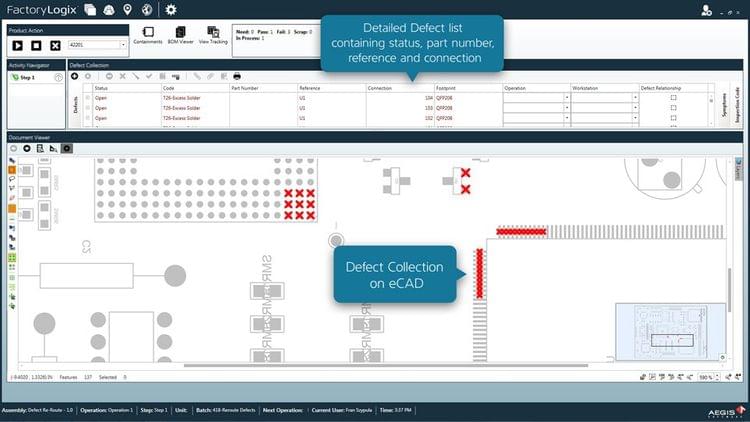

Improved Product Quality

Cloud manufacturing software ensures finished products are up to the standards of your business and regulatory agencies. Quality planning is one of the first steps manufacturers need to take–the system will help you define your quality standards and set dimensions like scrap and waste percentages, defect rate, deviations in measurement, and more.

Manufacturing software also helps manufacturers predict and take action when quality errors occur. Risk analysis predicts failure rates and potential costs associated with the issue, allowing you to take steps to prevent issues before they occur. Corrective Action/Preventive Action tools allow you to assign actions to the right personnel and monitor the status of the corrective or preventive action.

Quality control within the cloud manufacturing software helps maintain regulatory compliance. The system keeps detailed documentation and reports, ensuring adherence to strict regulatory standards. Compliance control is an important feature for many industries, including manufacturers of medical devices, food and beverage products, chemicals, pharmaceuticals, and more.

What Does Your Business Need?

The right software solution for your business depends on your unique needs, the size of your business, and the industry space you’re in. The most important factors to consider when choosing a cloud-based manufacturing system are your budget and software functionality.

- Small businesses generally look for a manufacturing cloud platform due to the lower upfront costs than on-premise solutions. Multi-module, cloud-based software makes it easy for small manufacturers to pay for only the functionality they need. As the business grows, more modules can be added easily.

- Medium-sized manufacturers find manual data entry or solutions meant for small businesses too limiting and often look for a system that automates more processes for a growing business. The system needs to be able to keep up with growing inventory and sales orders.

- Large businesses often look for a solution that will handle manufacturing operations and day-to-day business processes all in one system. Full enterprise resource planning software (ERP software) handles manufacturing processes like quality control, inventory management, and resource planning in addition to financials, sales, and production management. Warehouse management can also be included for stock control and picking/packing improvements.

- Direct-to-consumer companies that take orders, manufacture, and then ship directly to customers often sell their products online. Finding a cloud-based manufacturing system that integrates with your eCommerce system is important for real-time inventory tracking and credit card payment processing.

- Industry-specific solutions are used if your business deals primarily with discrete or process manufacturing only. Depending on your business needs, the system can handle lot and serial number tracking, regulatory compliance management, recipe and formula management, and more.

Pricing

Cloud-based ERP for manufacturing ranges from $10,000 to over $150,000 per year. Pricing can vary widely based on your company size, the licensing model, and the level of complexity you need.

- Entry-level systems start around $10,000 to $30,000 per year.

- Mid-tier systems, the most common category, range from $40,000 to $110,000 per year.

- High-end platforms cost over $150,000 per year, best for enterprise manufacturers with multiple facilities.

Expect implementation costs to be double your first-year investment. For example, if your annual subscription is $60,000, your total costs could be $120,000 or more after factoring in onboarding, training, data migration, and system configuration.