The Best Cosmetic Manufacturing Software

We’ve evaluated and ranked the best cosmetic formulation software based on core functionalities, ease of use, pricing, and customization options.

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Advanced R&D/formulation tools

- Complies with regulations across over 55 countries

- Template-based reporting builder

- Recalls and mock recalls are easy to perform

- Greatly increases the ability to fill orders

- Wide variety of reports

Using our advanced review methodology, our team has carefully evaluated the top manufacturing ERP software. We found options for small and mid-sized companies, as well as those prioritizing research and development and lab management.

| Product | Software Tool | Pricing |

|---|---|---|

| Deacom | Lot Tracking Tool | Essentials: $500/month, Main Version: $5,000/month |

| Cosmetri Product Manager | Advanced R&D/Formulation Tools | Pricing not publicly listed, offers Essentials, Standard, and Professional plans |

| Mar-Kov | Batching and Packaging Tools | $159/month |

| BatchMaster ERP | Laboratory Management Module | Approx. $2,000/user (perpetual license) |

| Datacor ERP | Batch Production Module | Pricing not publicly listed |

| Katana Manufacturing ERP | Batch and Lot Tracking | Starter: $179/month, Standard: $359/month, Professional: $799/month |

| Aptean Ross Edition | Traceability Module | Average 3-year cost over $100,000 |

| MRPeasy | Quality Control Module | $49/user/month |

- Deacom ERP: Best Overall

- Cosmetri: Advanced R&D/Formulation Tools

- Mar-Kov: Best Batching and Packaging Tools

- BatchMaster ERP: Best Laboratory Module

- Datacor ERP: Great Batch Production Module

- Katana: Great for Mid-Sized Manufacturers

- Aptean Ross Edition: Best Traceability Module

- MRPeasy: Great for Small Manufacturers

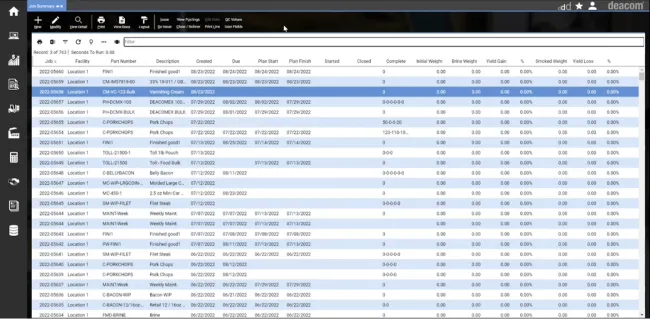

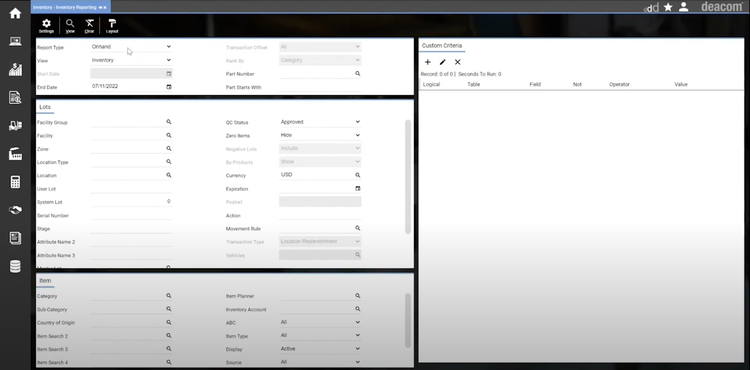

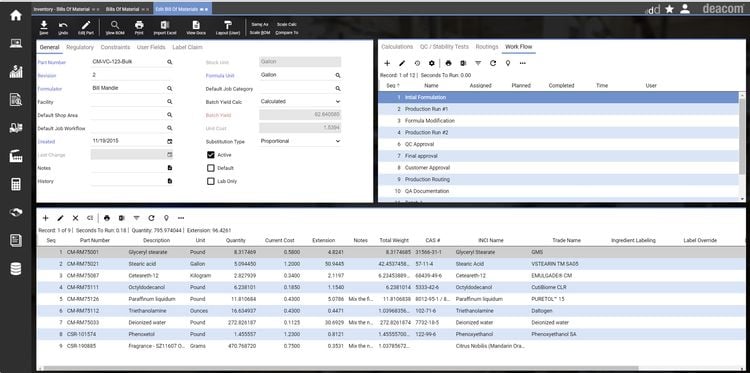

Deacom ERP - Best Overall

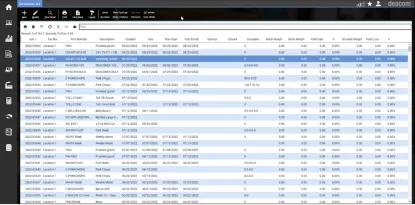

Deacom’s lot tracking tool lets you trace every ingredient, formula, and finished product by lot number. When pigments or emulsifiers first arrive at your plant, the system assigns each lot a unique identifier. This allows you to follow ingredients through multiple product lines for every batch of lipstick, moisturizer, or serum.

This cosmetic ERP software includes bidirectional traceability:

Forward Traceability: If a batch fails testing, you can trace the affected products back to the exact lot of raw materials used. Backward Traceability: If a supplier recalls a defective ingredient, you can isolate any batch containing those materials.

These capabilities make it much easier to comply with FDA, GMP, and EU regulations dictating ingredient sourcing and contamination prevention. It also helps all product batches meet label claims, like paraben-free, by allowing you to quickly confirm whether raw materials contain restricted ingredients.

For smaller manufacturers, we recommend the newly introduced Deacom Essentials, starting at $500 per month. For more advanced capabilities, choose the main version of Deacom, starting at $5,000 per month. This means the system can accommodate smaller operations as they grow, making it ideal for companies of all sizes.

Read our full profile on Deacom for more details.

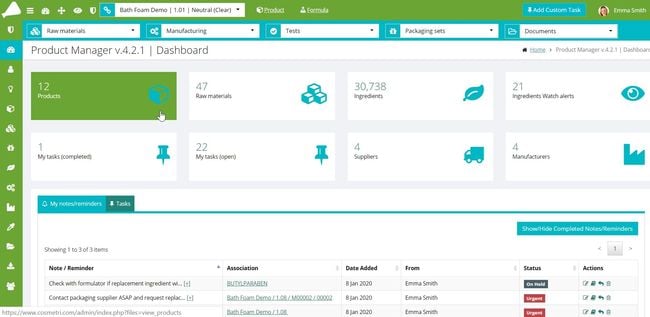

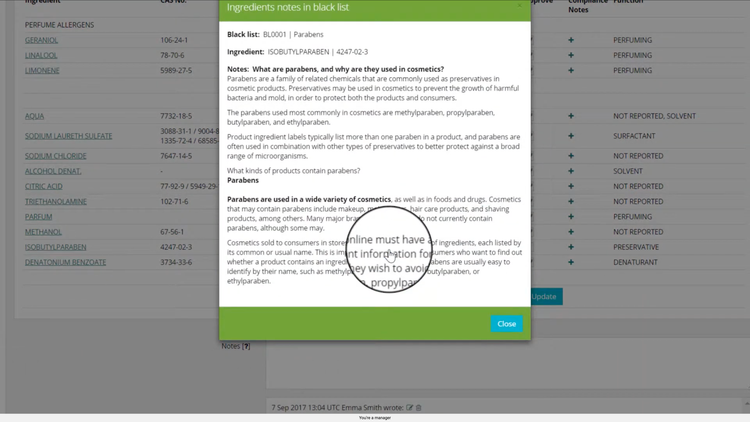

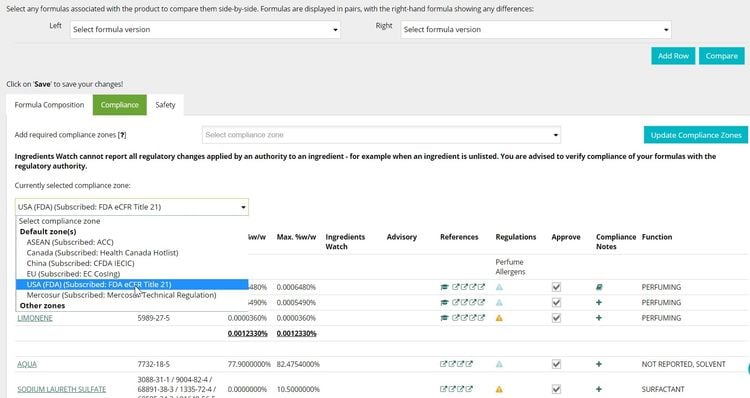

Cosmetri - Advanced R&D/Formulation Tools

Cosmetri Product Manager streamlines the research and development process. Start your initial concept by defining timelines and setting sample requirements. For the final formulation, choose from over 27,000 built-in cosmetic ingredients by searching International Nomenclature of Cosmetic Ingredients (INCI) or Chemical Abstracts Service (CAS) numbers. You can also import your own raw material data directly into the system to integrate existing suppliers or specialized ingredients.

The R&D and formulation tools also include ingredient management, where you can build custom blacklists based on certain clients or compliance zones. Easily clone formulas for multiple versions and even compare them side-by-side to highlight differences. This helps you balance performance and cost without compromising quality.

While Cosmetri doesn’t list public pricing, it offers three different plans. Essentials supports up to five users and 100 products. You’ll need to upgrade to the Standard plan for unlimited products and the Professional plan if you need to include over ten users.

Learn more about Cosmetri Product Manager.

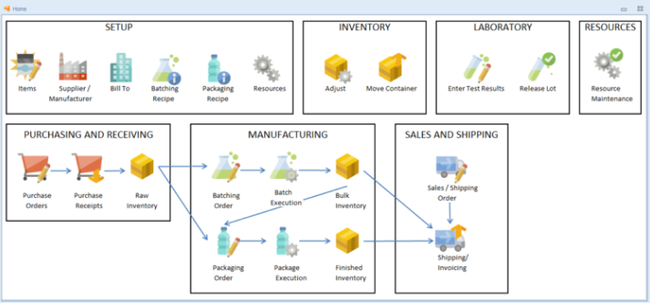

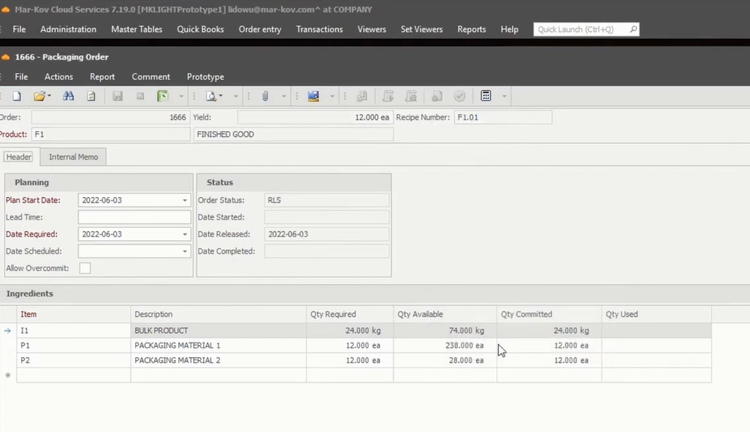

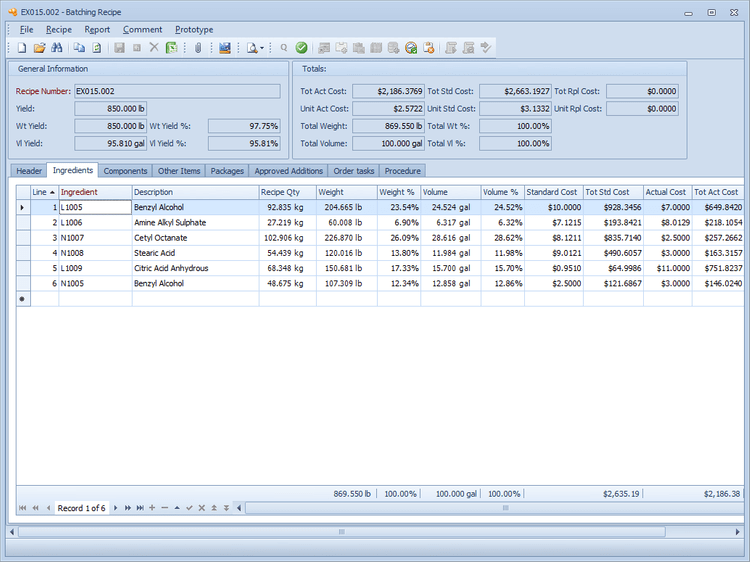

Mar-Kov - Best Batching and Packaging Tools

Mar-Kov includes a strong packaging and batching module that helps you control formulations and meet strict industry regulations. The process begins with a batching order that calculates the ingredient quantities needed based on your target field. If you adjust this–whether scaling up for a high-demand product or reducing batch size for limited runs–Mar-Kov recalculates material requirements instantly. Only published recipes can be used, reinforcing consistency and preventing any unauthorized changes to your formulas.

When you save the order, the system shows real-time ingredient stock levels to help catch shortages before production even begins. Your operators then follow step-by-step prompts to track ingredient usage and log any deviations. This level of precise control is essential for working with sensitive, often costly, materials like essential oils and pigments.

Mar-Kov integrates final testing into the process, generating sample sets directly from the batch. It requires you to log the testing results before packaging can proceed. This means every batch passes performance and stability checks, helping you prevent inconsistencies that could impact scent, texture, or effectiveness.

Packaging mirrors the batching process by only using approved recipes to match product specifications. Once packaging begins, the system tracks all material usage and yields automatically. The system locks the order after completion to preserve records for recalls or audits. This simplifies regulatory compliance and helps protect your brand’s reputation.

Mar-Kov starts at $159/month. Although it’s priced higher than tools like MRPEasy, its specialized features make it a good fit for cosmetics and fragrance manufacturers. It offers strong production controls that can scale as new product lines are added.

See our full profile on Mar-Kov for more details.

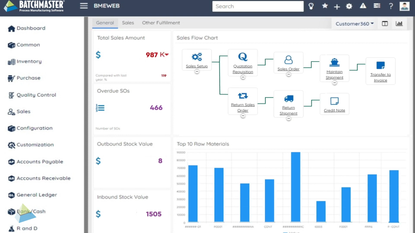

BatchMaster ERP - Best Laboratory Module

BatchMaster ERP’s laboratory management module makes it simpler to develop new products. It integrates formulation, batch sizing, and ingredient properties to minimize errors during research and development.

This ERP allows you to create formulas using percentage inputs rather than fixed quantities. This means you can scale production batches to meet bulk orders without recalculating entirely. You can also resize batches based on raw material availability to help reduce waste and lead times for last-minute adjustments.

Additionally, you can generate and compare multiple formula variations simultaneously. This lets you tweak compositions based on customer preferences, cost constraints, and market trends. You can prevent accidental overwrites and track all formulation changes for better compliance and intellectual property protection.

BatchMaster integrates Current Good Manufacturing Practices (CGMP) and FDA requirements directly into your processes. Formulations come with built-in checks for restrictions on certain chemicals governed by CFSAN, FDA, or international regulatory bodies. You can even embed special manufacturing instructions into the formula to ensure each batch meets safety protocols.

While BatchMaster doesn’t list its pricing publicly, we estimate that it starts at $2,000/user for a perpetual license. It’s ideal for small to mid-sized companies in process manufacturing, including cosmetics and beauty products.

Get pricing details and more on our BatchMaster ERP profile.

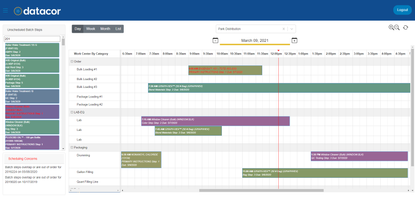

Datacor ERP - Great Batch Production Module

Datacor ERP simplifies the entire production lifecycle from order entry to batch creation. It integrates with materials requirement planning (MRP) to auto-generate batch tickets. Shop floor workers can access batch details directly within mobile tickets, meaning each step follows the right formula and meets quality standards – even as you scale up.

This ERP includes real-time dashboards for views into production statuses, allowing your managers to shift workflows based on demand. The system then balances demand planning with what you need to buy, so ingredients and packaging are ready when needed, avoiding delays. Its finite scheduling tool also makes it easy to make the best use of equipment, fitting smaller batches into larger schedules without disruption. This is ideal for cosmetics manufacturers dealing with many SKUs and different formulations.

Datacor also maintains granular batch and formula records from the first test to the finished product. This cradle-to-grave lot tracking means you can trace ingredients from start to finish, making recalls or troubleshooting much quicker. Additionally, the system automatically logs batch data and ingredient adjustments, so you always have a paper trail for regulatory needs and audits.

While Datacor covers many functionalities, some users mention that deeper customizations require assistance from the development team, which may add extra costs. However, the system can handle most production needs right out of the box. If you want an open-source ERP you can customize extensively, ERPNext and Odoo offer manufacturing capabilities.

See key features, benefits, and more in our profile on Datacor ERP.

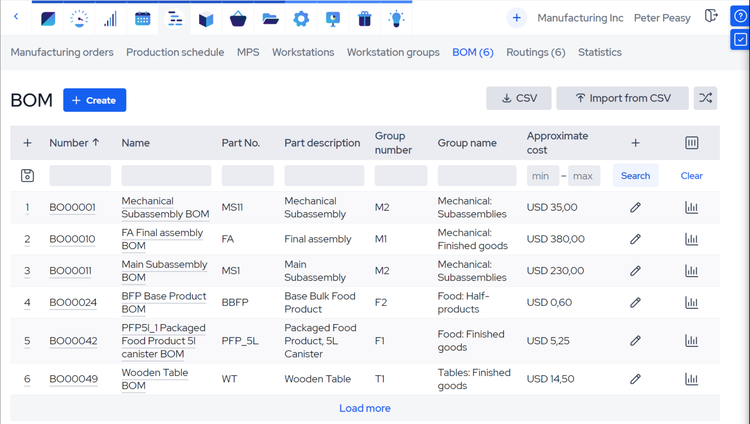

Katana - Great for Mid-Sized Manufacturers

Katana Manufacturing ERP balances advanced features with ease of use, supporting your growing operations without massive overhead. For example, medium-sized manufacturers require lot and batch traceability for compliance but often lack the resources for complex ERP implementations.

Fortunately, Katana is affordable and feature-rich, enabling batch and lot tracking whenever you create a new material or product. This means every item you receive, use, and sell automatically receives a specific batch or lot number. For better recall management, you can trace all items forward and backward through production to find affected products. Plus, expiration date management for materials like botanical extracts lessens the chances of using expired ingredients past their prime.

You can generate sub-batches for different formula lines, like developing several foundation shades from a single base. This helps keep everything organized and consistent, especially when you frequently release seasonal or limited-edition items. The bill of materials (BOMs) system in Katana also supports variant management through duplicating and modifying existing BOMs. This is a real time saver if you offer a wide range of SKUs.

Finally, pricing grows with you, starting at $179/month for the Starter plan with one inventory location. If you need more, the Standard plan at $359/month covers three locations, and the Professional plan at $799/month supports ten. You’ll need the Professional plan for full traceability; otherwise, Katana offers it as an add-on at $199/month.

Learn more about Katana MRP, including pricing and integrations.

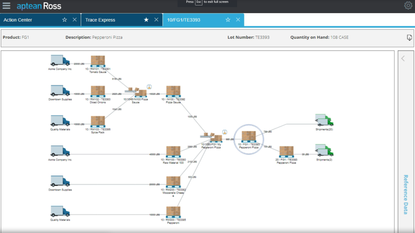

7 Aptean Ross Edition - Best Traceability Module

The Trace Express module in Aptean Process Manufacturing ERP Ross Edition allows you to track items across your entire supply chain, from raw materials to finished goods. Its graphical lot trace viewer lets you interact visually with lot transactions. You can zoom, drag, and customize certain layout elements to quickly pinpoint specific batches or ingredients. Plus, you can perform extensive searches based on lot points, job stages, and shipment history, which makes it easier to quickly respond to recalls or quality concerns.

Aptean Ross Edition uses Google Maps to help you track shipments and their destinations. This can also aid in more effective recall management, giving you a full geographic overview of affected products. With omni-directly traceability, you can perform forward and backward tracking, from ingredient sourcing to customer deliveries. This helps you maintain high production standards and minimize contamination risks or subpar ingredients in your formulations.

While Aptean does not provide pricing details for Ross Edition, the average total cost of ownership over three years is typically over $100,000. It excels in advanced traceability, but raw material management can present challenges due to the system’s complex interface and limited auto-population capabilities.

Review (/reviews/aptean-erp-ross/) in more detail, including pros, cons, and key features.

MRPeasy - Great for Small Manufacturers

MRPeasy includes a strong quality control module that helps smaller companies cut labor costs by automating inspections and keeping defective materials from clogging up stock space. This helps your business stay efficient and cost-effective while maintaining high product standards.

MRPeasy supports ingredient sensitivity and product safety by automatically holding incoming batches for inspection. By preventing contaminated or subpar materials from ever entering production, it reduces the risk of product recalls. A single defective batch can strain your resources when you operate with limited production lines and smaller batch sizes. Catching these issues early with the QC module helps you keep your manufacturing schedules on track.

The QC module also logs inspections and attaches documentation, creating detailed records for audits. If you don’t have a dedicated compliance team, this is a must. Plus, when you don’t have the bandwidth to track supplier quality over time, MRPeasy monitors rejection rates by vendor and gives you insights into which suppliers consistently deliver lower-quality goods. This can help improve your procurement strategies without additional staff or resources.

Affordable and efficient, MRPeasy brings critical quality control tools to smaller cosmetics manufacturers. It starts at $49/user/month, making it one of the more affordable platforms on our list. However, this can add up as your team grows. Katana is another low-cost option with a pricing model based on inventory locations rather than user count.

Get pricing details and more on our MRPeasy product page.

What is Cosmetic Manufacturing Software?

Cosmetic manufacturing software helps businesses produce high-quality personal care products like makeup, hair care, lotions, and perfume. These systems generally include tools like inventory tracking, lot traceability, and formula and compliance management.

Manufacturers must ensure their formulas are consistent and safe for human use. Cosmetics like lipstick and nail polish often come in various color options. Using the same formulations means each variation is consistent with every batch. Additionally, quality control testing ensures all products meet your standards.

Cosmetic formulation software also helps adhere to national and international regulatory requirements, including the Food, Drug, and Cosmetic Act, the Fair Packaging and Labelling Act, and ISO 22716:2007. These regulations prohibit using specific chemicals, outline storage requirements, and dictate label and packaging guidelines. Cosmetics ERP logs the ingredients used in each formulation, where the products are being distributed, and the packaging used.

Key Features

| Feature | Description |

|---|---|

| Compliance Management | Ensures ingredients are stored, labeled, and procured compliant with national and international standards, including the FDA, ISO, and GMP. |

| Production Scheduling | Schedules the required raw materials, labor, and other resources needed to manufacture each cosmetic product. |

| Quality Control | Tests samples from product batches throughout the manufacturing process to ensure pre-specified parameters are met. Automatically flag batches that don’t meet requirements. |

| Inventory Management | Tracks details on raw materials and finished products, including expiration dates, inventory levels, and storage locations. Manages your manufacturing process’s inputs, outputs, intermediates, and byproducts. |

| Lot Traceability and Recall Management | Tracks where each ingredient came from and how it is used throughout the manufacturing process. Batch traceability makes it easy to identify which product is contaminated and where they were sold to effectively recall the products. |

| Product Development | Records and manages the progress of test formulations while calculating the cost of material inputs, processing, and byproduct disposal. |

| Production Scaling | Determines production capacity based on the availability of machines, labor, and materials. Calculate reserves of finished cosmetic products that will be necessary to respond to uncertain order volumes. Achieves JIT production. |

| Cost Control | Tracks expenses and risks while identifying sources of revenue loss. |

| Supply Chain Management | Monitors and ensures the integrity of your supply chain to maintain quality and regulatory compliance. |

| Formula Management | Keeps track of the ingredients and quantities used to keep products consistent and scale batches as needed. |

Benefits

Inventory Control

Cosmetic industry software tracks the location and inventory levels of chemicals and other ingredients, as well as on-hand finished stock. The software allows you to scan barcodes for each product to give you real-time information on product quantities and storage locations.

Another important feature of cosmetic manufacturing software is automating purchase orders. When chemicals or other materials run low, the system automatically places a purchase order with your preferred vendor. This prevents unnecessary downtime during the manufacturing process and helps ensure customer demand is being met.

Lot Tracking

These systems provide complete traceability of each batch. The system records the ingredients used, as well as the equipment and labor used to make each product. Detailed records of each QC test are also recorded within the system to ensure the product’s quality from start to finish.

The software helps cosmetic manufacturers track and trace batches throughout the supply chain, from manufacturing to packaging and distribution. You can easily see which retailers sell products associated with a specific lot number. Knowing where products from each batch were sold is important in the event of a recall. This allows you to notify affected retailers and reduce the risk of recalling more products than needed.

Formula Management

Cosmetic manufacturing software is a type of process manufacturing software, so it stores formulas for each product and variation you manufacture. This ensures your products are consistent among each batch, not only in quality but also in color. For example, some lipstick products have a number associated with them to designate a particular shade. The software will store the formula associated with the shade to ensure the product is always the same color.

The software also stores conversions for batch scaling. The number of cosmetic products can be scaled up or down, and the calculations will be calculated automatically. Batches can be scaled based on the availability of raw materials you have on hand.

What Regulations Apply to Cosmetics?

Beauty industry software helps businesses comply with all national and international regulatory compliance mandates. Certain cosmetics and personal care products must list the ingredients and potential allergens on the packaging and include a tamper-resistant seal. The system will keep lists of each ingredient used and manage what type of packaging needs to be used with each product.

Specific chemicals are prohibited or heavily restricted in other countries. For example, lead is banned in Canada and restricted to a maximum level of contamination of 10 parts per million in the US for externally applied cosmetics like eye shadow, powders, and lotions. The software will flag products containing specific chemicals that are meant for sale in a country with restrictions against them.

Some of the most common regulations for the cosmetic industry include:

| Regulation: | Regulatory Agency: | Purpose: |

|---|---|---|

| Food, Drug, and Cosmetic (FD&C) Act | FDA | Restricts unsafe ingredients from being used in cosmetics manufacturing and bans mislabeled products from being marketed. Restricted and prohibited ingredients include bithionol, mercury, vinyl chloride, and chlorofluorocarbon propellants. |

| Fair Packaging and Labeling Act (FPLA) | FTC and FDA | Regulates labeling of cosmetic products - labels cannot be misleading, a list of ingredients must be included, and safe-use directions and warning/allergen statements must also be included. Many cosmetic and personal care products also require tamper-resistant packaging. |

| ISO 22716:2007 | ISO | It provides guidelines that are accepted under the Good Manufacturing Practices (GMP) for production processes, shipment, and storage. |

How to Choose Software

User-Friendly Interface

- Ease of Use: Prioritize cosmetic manufacturing software that is intuitive and easy to navigate, with cloud-based options for easier access.

- Scalability and Updates: Ensure the software can adapt to the cosmetic industry’s evolving needs, including accommodating new trends, product lines, and regulatory changes.

Features and Integrations

- Core Functionalities: Look for software with modules essential for cosmetic manufacturing, such as advanced formula management, batch tracking, allergen management, inventory tracking, and quality control.

- Integration Options: Choose software that integrates seamlessly with PLM, QMS, and SCM software and supports functionalities critical to cosmetics, like color matching, stability testing, and packaging design.

Industry-Specific Specializations

- Regulatory Compliance: Select software specifically designed to meet the cosmetic industry’s regulatory requirements, including compliance with FDA, EU regulations, and other global cosmetic standards.

- Customizations: Ensure the software can be tailored for specific cosmetic manufacturing processes, like varying batch sizes, seasonal product variations, and strict ingredient control.

Cost-Effective Solutions:

- Flexible Pricing Models: Consider systems with pricing plans suitable for cosmetic manufacturers of various sizes, from boutique brands to large-scale production facilities.

- Transparent Pricing: Emphasize the importance of clear, upfront pricing, a critical aspect of budgeting in the cosmetic sector.

Accessible Customer Support

- Support Availability: Ensure the software provider offers comprehensive customer support, ideally with expertise in cosmetic manufacturing.

- Dedicated Assistance: Prioritize providers that offer dedicated account managers who are knowledgeable about the cosmetic industry’s specific needs.

Evaluation and Trials:

- Software Demos: Request demonstrations focused on manufacturing scenarios to evaluate the software’s capabilities in handling formulation, compliance, and product development.

- Hands-On Trials: Use trial periods to test the software in your environment, focusing on regulatory adherence and product testing.

Pricing

Cosmetic manufacturing software pricing varies based on your company size and operational complexity. Here’s a breakdown of typical annual costs by tier:

| Company Size | Annual Spend | Examples |

|---|---|---|

| Entry-Level (1–20 employees) | $3,000–$8,000/year | Katana, Fishbowl, Cosmetri GMP |

| Mid-Tier (20–100 employees) | $10,000–$30,000/year | Mar-Kov, BatchMaster ERP, xTuple |

| High-Tier (100–500 employees) | $30,000–$120,000/year | Datacor ERP, Aptean Ross Edition, Deacom |

| Enterprise (500+ employees) | $120,000–$500,000+ | SAP S/4HANA, Oracle ERP Cloud, Infor CloudSuite Process |

What is a Cosmetic ERP

Many systems tailored to cosmetic manufacturing businesses are complete ERP solutions. These solutions manage manufacturing and other business processes like accounting, human resources, and customer relationship management. Cosmetic manufacturers that sell directly to consumers can also have an ERP solution with eCommerce functionality.

ERP systems typically include manufacturing resource planning (MRP) to help streamline manufacturing processes with advanced production scheduling and inventory control. MRP helps cosmetic manufacturers calculate the chemicals and raw materials needed to manufacture products, coordinate workloads, and plan purchasing.

Below are the leading ERP systems tailored towards the cosmetics industry. Compare features and request demos: