The Best Parts Inventory Management Software

We reviewed the best parts inventory software for manufacturers and maintenance organizations. We based our rankings on features like real time stock tracking and automated reordering to help you optimize inventory distribution.

- Fast implementation times

- Affordable pricing for small businesses

- Responsive support

- Has a forever-free version

- Very easy to create and add new items

- Mobile accessibility

- Offline mode with work order syncing capabilities

- Customizable KPIs

- Strong international support: multi-currency, multilingual, multi-location, etc

Using our review methodology, we’ve evaluated the best spare parts inventory systems based on real-world usability, feature depth, and industry fit. Each tool below earned its place by excelling in specific areas like procurement, maintenance tracking, customization, or ease of use.

- Click Maint: Best for Education

- Fiix CMMS: Best Preventive Maintenance Tools

- eMaint CMMS: Best for Manufacturers

- Tractian CMMS: Best Automation Tools

- Zoho Inventory: Best Procurement Tools

- UpKeep: Very User-Friendly

- FMX: Strong Facility Management

- Sortly: Great Asset Tracking

- Fishbowl Inventory: Most Customizable Option

- Fleetio: Best for Fleet Maintenance

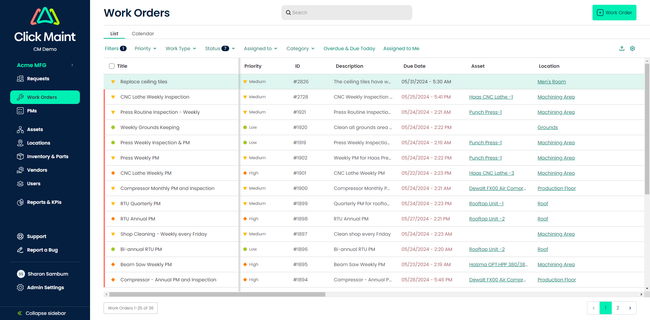

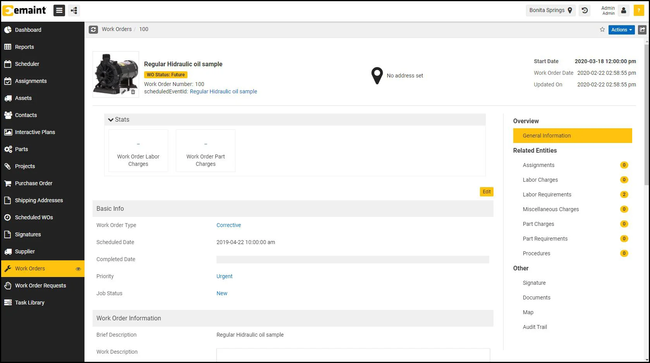

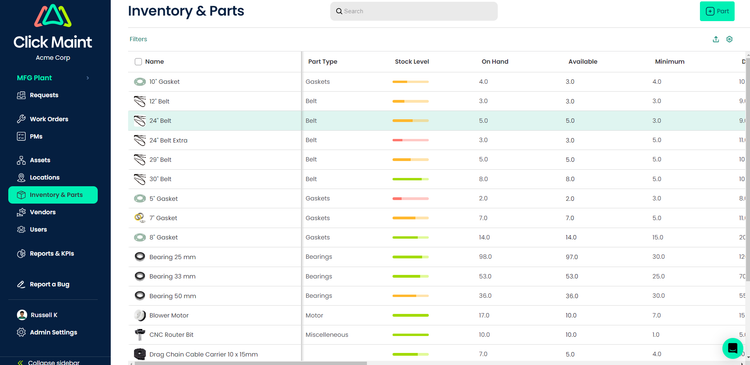

Click Maint - Best for Education

Click Maint’s inventory management module can help schools consolidate their inventory. It includes stock level tracking to ensure you maintain proper amounts. These can be for facility spare parts, like HVAC, plumbing, and electrical systems. This helps ensure maintenance departments can repair breakdowns and fix issues immediately without having to wait for a part reorder.

The module also includes barcode and QR Code scanning through the mobile app. Technicians can scan items to receive or issue them for work orders, which automatically adjust stock counts. This helps improve accuracy by reducing manual data entry. And when items pass the minimum threshold, it will instantly notify you to reorder.

Click Maint is one of the more affordable systems on the list, with a starting price of $35/user/month. Its plan comes with every feature, as opposed to the tiered pricing plans found in other CMMS software like UpKeep.

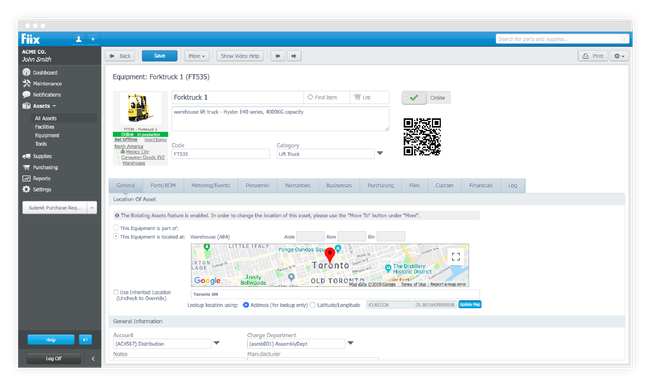

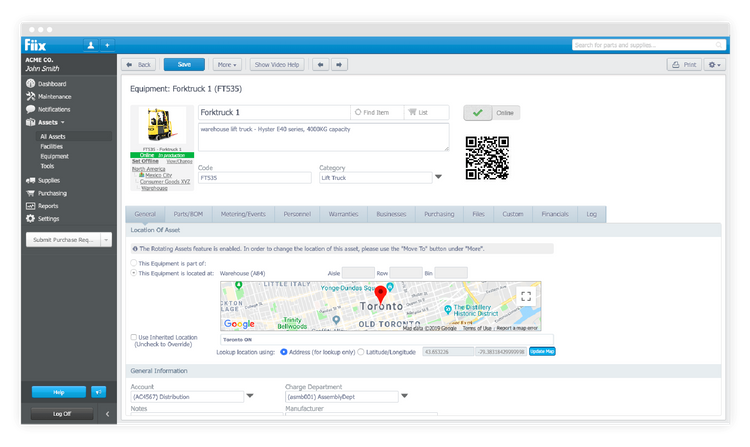

Fiix CMMS - Best Preventive Maintenance Tools

Fiix CMMS offers strong preventive maintenance tools that establish a framework for proactive maintenance management. In Fiix CMMS, you can set up schedules based on manufacturer recommendations, historical data, or usage patterns. The system will automatically generate work orders and send alerts to maintenance personnel, detailing what needs to be done and when. And if any spare parts are used, it automatically deducts them from your inventory, ensuring all stock is accurate.

As tasks are completed, your staff can log the work done, update inventory levels if parts were used, and provide feedback on equipment performance in the system. This data collection allows for reporting and trend analysis to inform future maintenance decisions.

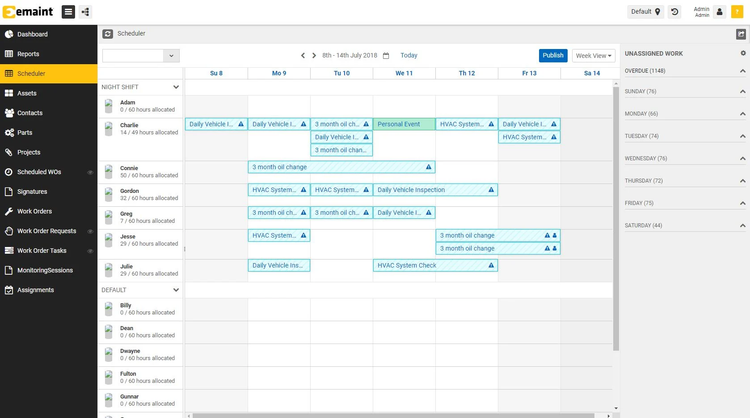

eMaint CMMS - Best for Manufacturers

eMaint CMMS is best for manufacturers because it offers tools to track assets, implement preventive maintenance, and optimize inventory. This makes it a valuable asset for manufacturers aiming to minimize costs related to parts management. eMaint’s proprietary sensors add an extra layer of functionality, beneficial for larger businesses in the manufacturing sector.

The user-friendly interface is accessible to maintenance managers and teams, allowing them to visualize maintenance asset location data on floor plans, schematics, or site maps. Customization options make eMaint an ideal choice for mid-market and enterprise-level organizations seeking efficient spare parts management and overall maintenance optimization.

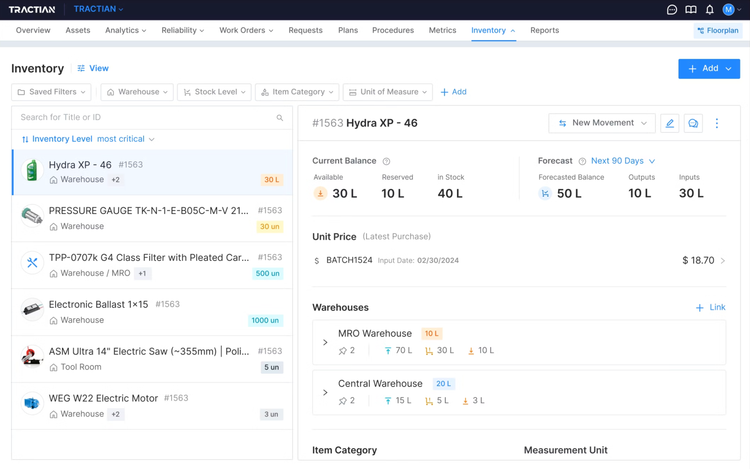

Tractian CMMS - Best Automation Tools

Tractian offers built-in automations that help you manage your parts inventory more easily. You can set minimum stock levels and reorder points for parts and supplies to stay ahead of shortages. This lets you avoid unplanned downtime caused by missing items or delayed shipments. And as inventory comes in, you can track each part from arrival to installation. The system shows you data like usage reports and cost tracking to ensure proper use and speed up stock audits.

Additionally, inventory is linked directly to work orders and usage history. This means in Tractian, reorder logic is based on actual demand and consumption instead of static spreadsheets. Even better, techs can request items straight from the work order. The system then auto-fills the purchase details, links to suppliers, and alerts team members to make the workflow as straightforward as possible.

While Tractian is great for most industries, it really stands out for industrial manufacturers that need to track hundreds or thousands of parts for their plants. It can integrate with your existing tech stack, whether it’s an ERP, WMS, or accounting platform. As for pricing, the Standard plan starts at $60/user/month for 5 users or more, billed annually.

Zoho Inventory - Best Procurement Tools

Zoho Inventory offers advanced procurement management and replenishment features that streamline acquiring spare parts and other inventory. These tools integrate with Zoho Inventory’s system modules, such as sales, inventory, and accounting.

The system maintains optimal stock levels by automating the ordering process. When stock items reach predefined reorder points, it automatically generates purchase orders and sends them to designated suppliers, reducing the risk of stockouts and production delays. It can also place orders for multiple items simultaneously, streamlining the procurement process and allowing you to save time and reduce manual errors.

The system easily creates and manages purchase orders, monitors their status, and receives notifications about supplier confirmations. This level of organization not only enhances communication with suppliers but also maintains detailed records of supplier information, including contact information, payment terms, and order history.

UpKeep - Very User-Friendly

UpKeep is a CMMS that offers a user-friendly interface for managing spare parts. With a mobile app that offers real-time work requests, preventive maintenance scheduling, and QR code functionality, UpKeep is well-suited for organizations aiming to streamline maintenance processes.

A key feature for parts management is streamlined communication with maintenance technicians. UpKeep provides companies that require real-time access to work orders a way to coordinate maintenance activities across multiple locations. The software’s compatibility with both iOS and Android devices ensures flexibility and accessibility for all team members. Additionally, the incorporation of QR codes for asset tracking simplifies maintenance check-ins and updates on-site, enhancing efficiency.

FMX - Strong Facility Management

FMX offers a compelling choice for businesses seeking spare parts management software within a facility management context. It provides a comprehensive solution for facilities managers, particularly in industries like manufacturing, property management, education, and more. The software’s low stock alerts, incoming shipment notifications, and custom alerts are valuable tools for ensuring timely reordering of supplies and monitoring inventory expirations.

One of FMX’s notable features is its ability to track inventory and equipment histories, making it an ideal choice for businesses looking to manage spare parts efficiently. All this makes FMX an attractive solution for businesses seeking efficient spare parts management within the broader context of facility management.

Sortly - Great Asset Tracking

Sortly is a cloud-based inventory management software particularly well-suited for tracking assets such as tools, machinery, equipment, and vehicles. Its intuitive interface and features for customizing tags, generating QR codes and barcodes, and labeling items make it easy for users to get started with inventory management.

Sortly is especially recommended for small businesses and startups seeking straightforward inventory management solutions.

Fishbowl Inventory - Most Customizable Option

Fishbowl Inventory offers a customized platform for teams managing spare parts for equipment repairs, product assembly, or facility maintenance. Users can create custom tracking labels for each spare part, such as assigned serial numbers or job-specific usage tags, to better track what parts are used for.

Once labels are assigned, Fishbowl monitors how often parts are used, their costs, and current stock levels. This helps teams analyze usage trends, automate recording, and minimize inventory waste. Custom role-based dashboards also give purchasing and inventory teams different views from technicians using the parts, enabling them to focus on what tasks are most important to them.

Fishbowl’s modular design allows teams to start with basic inventory management and then expand into areas like manufacturing inventory, warehousing, or barcoding as needs evolve. One drawback is that the basic version only includes a limited amount of serial number tracking. So teams managing large volumes of serialized inventory may need to upgrade to the advanced plans. Pricing starts at around $3,200 per year for a limited user package.

Fleetio - Best for Fleet Maintenance

Fleetio is a fleet management system that includes a full spare auto parts inventory module. To avoid stockouts, you can configure low stock alerts for commonly used items like motor oil or filters. You can also get notified when a part is replaced that’s covered under warranty. This allows you to submit warranty claims for cost-saving opportunities.

Additionally, the Fleetio Parts mobile app supports barcode and QR code scanning to update your inventory levels. When you replenish items, just scan the barcode for easy stock updates. It also integrates directly with maintenance to easily assign parts to work orders, automatically updating quantities and costs once completed. It’s a great way to reduce manual data entry and keep stock accurate.

Fleetio’s spare parts module is integrated with the rest of the fleet management suite, which includes preventive maintenance, fuel tracking, and inspections. To get the full inventory functionality, though, you’ll need the highest cost Premium plan that’s $10/vehicle/month, billed annually only.

What is Parts Inventory Management Software?

Parts inventory management software, often shortened to parts management systems, helps businesses monitor and control the components they rely on for manufacturing, maintenance, and repair operations. These systems go beyond basic inventory tracking by supporting real-time stock visibility, automated reordering, and usage monitoring tied to specific assets or work orders. Spare parts modules are often included in CMMS systems (computerized maintenance management systems), or are standalone inventory management software.

You may need spare parts for:

- Product assembly

- Vehicle repair and maintenance

- Machine and equipment repairs

Whether your spare parts are for a warehouse or an auto repair garage, software can make it easier to optimize your inventory levels.

Key Features

- Parts profile: Store information on a part’s manufacturer, make, model, style, and other identifying features for future reference; record the part’s current location, minimum/maximum unit price, and available vendors

- Stock count tracking: Provides a record of the on-hand units for each SKU and helps maintain accurate stock levels through automated cycle counts

- Minimum stock quantities: Set an alert to automatically reorder when stock levels reach a predetermined minimum to avoid running low on parts; send email or push notifications when stock is low

- Inventory costing: Establish the cost value of assets for profitability tracking and tax accounting; potential cost methods include: FIFO, LIFO, and more

- Inventory receipts and tickets: Use receipts for inbound stock and ticketing for marking outbound parts

- Purchase orders and requests: Build a database with all your purchase orders

- Vendor tracking: Keep up-to-date records on vendors and suppliers of your business, along with their pricing data, to know who to contact for specific parts

- Work order records: Create a trackable document identifying what parts are needed for work that needs to be done from a Bill of Materials (BOM) and what parts are currently in stock

- Location tracking: Automate picking, packing, and shipping tasks related to inventory items by keeping real-time records on stock locations; Improve inventory loss prevention by keeping tabs on the movement of individual units

- Serial number, lot number, barcode, and RFID tracking: Identify particular units and track them using the preferred method of your facility, whether it’s scanning printed barcodes, QR codes, or using Radio Frequency Identification (RFID) readers to send radio waves and interpret the corresponding frequencies into inventory data

- Reporting: Use historical data on stock levels and usage rates to better inform your future decision-making when it comes to reordering spare parts

Top Benefits

Implementing software to manage your inventory can make your job easier in a lot of ways:

Real-Time Inventory Updates

Right now, you might be relying on Excel spreadsheets to track inventory. You might even have a physical checklist on a clipboard showing inventory levels. You deserve a better system, one capable of optimizing your asset management system.

Spare parts management software can do that, using real-time tracking tools such as custom QR codes and barcodes to count stock, set reorder points, and prevent overstock.

Along with real-time location data, you can look at the past of your assets as well. Movement histories can create a trail of how batches or individual parts move through your facility. This information can indicate exactly where each item should be and, more importantly, who was last in control of the missing parts.

Stay Ahead on Preventive Maintenance

Preventive maintenance can lead to a lot of cost savings for your business by reducing the likelihood of complete equipment breakdowns or extended downtime from waiting for replacement parts to arrive. Combined with parts management, you can streamline your maintenance operations by knowing exactly which assets are on hand and which ones are needed according to a bill of materials.

Knowing which spare parts you have in stock can allow your maintenance team to plan out their next repairs without running low on supplies. For example, a factory can use real-time inventory counts to see if anything is overstocked, and then begin using those excess spare parts to make preventive maintenance repairs.

Additionally, spare parts management systems can be paired with or included in computerized maintenance management software (CMMS) to streamline your maintenance department’s repair schedule.

Reduce Loss and Duplicates

Parts loss can happen for a variety of reasons. A piece might break and get thrown out without the system being updated. Employee theft can account for loss as well. Sometimes a part simply gets misplaced.

With a spare parts inventory control system, you can minimize theft and loss by increasing visibility of real-time stock counts to see exactly when parts go missing in the system.

Have you ever ordered an out-of-stock part only to find you still have a few units on hand? The cost of these duplicate reorders can add up, leaving you with extra stock and less storage space. And historical data gathered by cycle counts can reveal when certain assets tend to sell the most, allowing you to plan ahead.

Latest Trends

Parts inventory management has had many changes over the years. From handwritten notes to Excel spreadsheets, businesses of all sizes are always seeking ways to better track inventory. One recent advancement is the inclusion of mobile apps into inventory management systems.

Apps can be used on multiple mobile devices for increased freedom while tracking inventory. For instance, most warehouses rely on third-party hardware, such as handheld scanners or barcode readers, to scan items into the system. These pieces of hardware can be costly and require replacement every few years to stay up-to-date. With mobile apps, a warehouse manager with an iOS or Android smartphone can simply use their own phone to track inventory.

Pricing

Spare parts inventory software costs vary based on functionality, user count, and whether it’s part of a broader system like CMMS or ERP system. Systems focused only on part tracking and recording are more affordable, while platforms with maintenance automation, reporting, and integrations cost more.

For CMMS systems like eMaint or Click Maint, prices can range from $16-$120/user/month. These platforms are built primarily for maintenance management, and inventory tracking is found on advanced plans or as an add-on.

For full inventory management systems, which offer deeper tracking, forecasting, and automation tools, annual pricing generally ranges from:

- Low Range: $2,000 to $6,000 per year

- Mid Range: $10,000 to $30,000 per year

- High Range: $50,000 to $100,000 per year

- Enterprise Range: $150,000+ per year

Warehouse Management Software Costs

Some warehouse management applications include spare parts tracking alongside broader inventory and logistics features. These systems tend to be more expensive than standalone parts software and may be overkill if you’re only looking to manage internal stock and reorders.

Is There Free Software?

Free spare parts inventory management software is available, though it often limits users, features, and the number of tracked SKUs. Excel is always a free option but lacks integrations and automations with existing technology like WMS, CMMS, and ERP software.