The Best Production Tracking Software

Whether you’re a small-scale manufacturer or managing a large facility, find a platform that supports your production tracking needs. We assessed factors like pricing and ease of use as well as capabilities like IoT integrations and traceability tools.

- Competitive pricing; does not require a subscription

- Integrates with QuickBooks

- Can function as a light MRP system

- Dynamic formula adjustment

- Automatically creates, links, schedules dependent batch jobs

- Includes inspection plans, nonconformance, and CAPA capabilities

- Gathers real-time shop floor data

- Great customer support

- Logical, intuitive UI

Using our in-depth software review method, we’ve identified and ranked the best production tracking software available today. Here are our top picks based on factors like value for money, performance, integration options, and key features like resource management and scheduling tools.

- Fishbowl Inventory: Best Overall

- BatchMaster ERP: Great for Process Manufacturing

- Hydra X: Advanced Tech Integrations

- Katana MRP: Best MRP

- SOS Inventory: Best Barcode & Lot Tracking Tools

- MRPEasy: Most User-Friendly Option

- FactoryFour: Most Customizable

- MachineMetrics: Best for OEE

- Eyelit APS: Best for Automotive Manufacturing

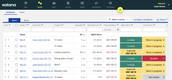

Fishbowl Inventory - Best Overall

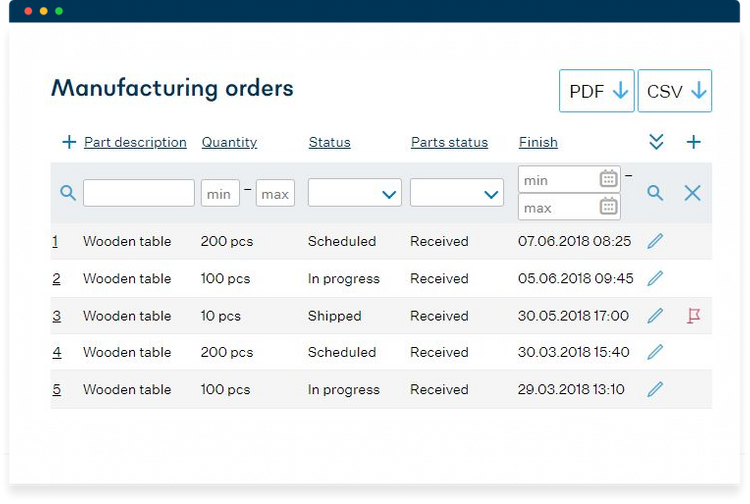

Fishbowl Inventory offers detailed part and product tracking within its manufacturing work orders module. You can easily add details like SKU or price. They can also choose the best tracking method and import data from spreadsheets for batch processing. When a sale is initiated, it automatically creates an order, helping you save time by eliminating manual processes.

Additionally, Fishbowl automatically generates serial numbers and offers lot number and expiration date fields. You can set minimum and maximum inventory thresholds to ensure parts remain at optimal levels without constantly checking. This helps process manufacturers have more control over their finished goods inventory after production. It even includes unlimited custom fields, enhancing tracking granularity and flexibility.

Fishbowl integrates with QuickBooks to help balance books after sales and adjust accounts following inventory audits. It’s best suited for small to midsize companies that need strong inventory management within their production tracking. If you already have an ERP in place, though, you may be better off with a more specialized system like HYDRA X MES.

See our full Fishbowl Inventory review.

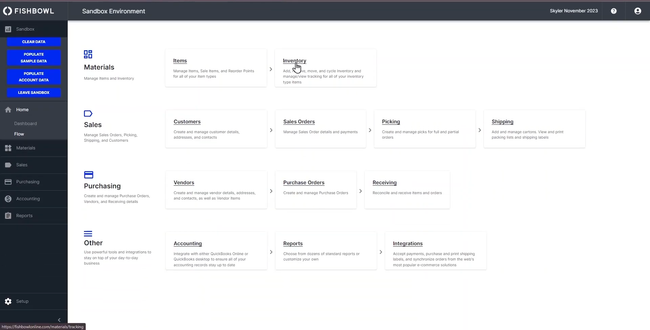

BatchMaster ERP - Great for Process Manufacturing

BatchMaster ERP excels in batch processing. It enables dynamic formula adjustment to meet specific physical or nutritional characteristics. You can also perform cost analyses of your recipes by comparing the price of ingredients, labor, and other miscellaneous expenses. This helps you accurately track the real cost of production for every formula.

It also automatically creates, links, and schedules dependent batch jobs, which is essential for a manufacturing tracking system. When creating your schedule plans, you can account for seasonal demand, helping you optimize costs and supply when the market shifts for each season.

BatchMaster ERP includes compliance with a wide range of regulations, such as food safety standards, recall, and traceability. The system also has a nutritional labeling feature, so you can easily generate product labels from one place. It even has graphical bi-directional traceability, ensuring you comply with strict FDA guidelines.

The food manufacturing modules can integrate with your existing financial systems, such as QuickBooks, SAP Business One, or Sage 100 & 300. You can install them on-premise or in the cloud, giving you the flexibility to choose which deployment method works best for you.

Read more on our BatchMaster ERP product profile.

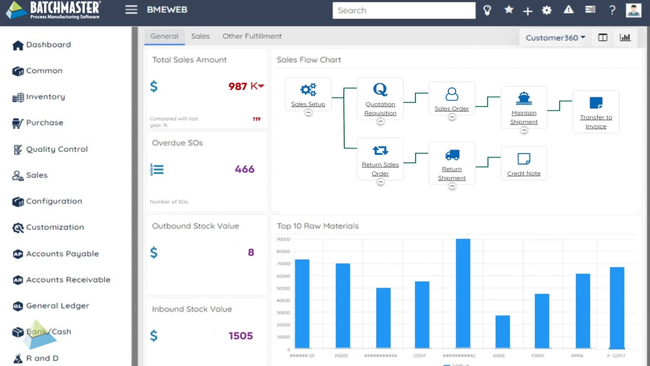

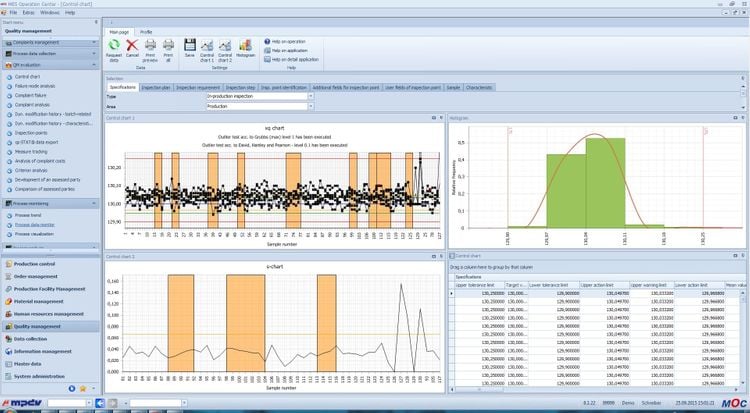

Hydra X - Advanced Tech Integrations

HYDRA X MES includes an AI suite that provides production analysis out of the box. The platform can leverage AI algorithms to analyze data, predict maintenance needs, and optimize production schedules. It uses your existing data from your ERP and shop floor to help you make more analysis-driven insights for your production.

Additionally, Hydra X fully supports IIoT integrations for smart manufacturing environments. It uses REST APIs and OPC UA, which allows it to be hardware agnostic and connect with sensors directly on your shop floor. These devices can measure anything from performance standards, like vibration and temperature, or environmental conditions like energy efficiency and power consumption.

Hydra X is best for mid to large-sized companies looking for a full MES system. It has native integrations with Oracle and SAP ERPs to combine planning and shop floor data to display real-time production metrics. Because of the advanced tech, the system has a higher cost than more basic MRP or OEE systems.

Visit our Hydra X product page to read user reviews and more key features.

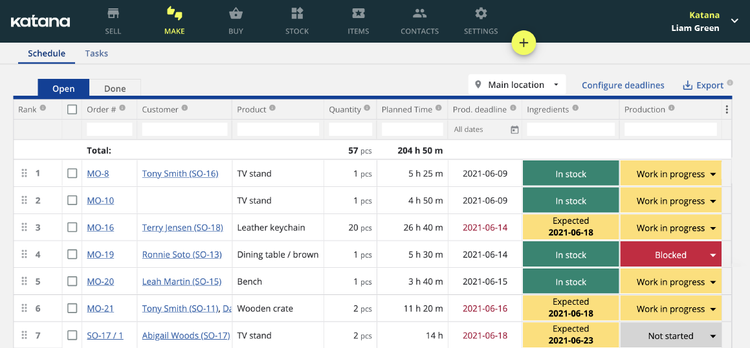

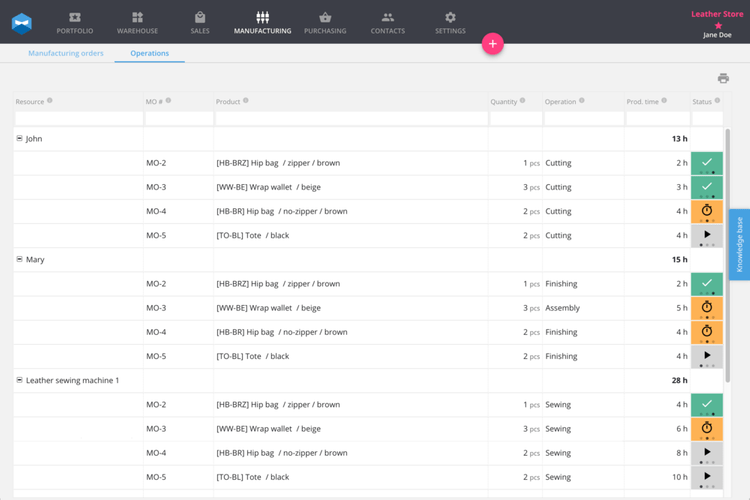

Katana MRP - Best MRP

Katana MRP is a decent choice for small to medium-sized manufacturers. It has affordable and transparent pricing, making it more accessible for SMBs with limited budgets. At the same time, it delivers a dense feature set, including real-time master planning, shop floor control, end-to-end traceability, and more. Last, we appreciate that it integrates with popular platforms many SMBs already use; Shopify, WooCommerce, Xero, and QuickBooks Online all integrate with Katana.

SOS Inventory - Best Barcode & Lot Tracking Tools

SOS Inventory makes tracking production in your plant much easier with built-in barcode generation and scanning. This system creates unique barcodes for raw materials and finished products, embedding details like colors, sizes, and expiration dates.

Your team can use mobile device scanning from any location for accurate inventory counts across the platform. By verifying each item’s status and location in the manufacturing cycle, you can streamline material issuing, production staging, and even quality inspections without manually searching your records.

Additionally, each barcode scan records information like the item’s origin, batch, or lot number. This provides forward and backward traceability through batch and lot tracking capabilities. That means you can monitor each batch of materials and products throughout different manufacturing stages.

-

Forward Traceability: Tracking the journey of materials or components from origin to final destination; uses lot numbers and barcode scans to record data about progress.

-

Backward Traceability: Tracing a product or material back to its origin to identify root causes of issues, like the supplier or manufacturing batch; uses lot numbers for origin identification and tracking histories.

SOS Inventory starts at $64.95/month for the Companion plan, which includes two users. Each additional user adds a $25 fee, which could become costly depending on your team’s size.

MRPEasy - Most User-Friendly Option

MRPEasy is a production management software that delivers a user-centric interface and intuitive design, lowering the learning curve for new users. For example, the platform consolidates multiple functions into a single screen. Receiving and purchasing tasks are all integrated into one purchasing section, making it easier to manage processes without navigating multiple screens. In addition, MRPeasy delivers multilingual support and responsive customer service, supporting users in international markets in their preferred languages.

FactoryFour - Most Customizable

FactoryFour allows users to tailor workflows to their specific production processes. It also allows them to personalize dashboards and analytics reports. Additionally, employees can view work orders by task, work center, product type, status, and operator. Last, FactoryFour’s public API allows manufacturers to customize the software easily and build integrations with existing systems.

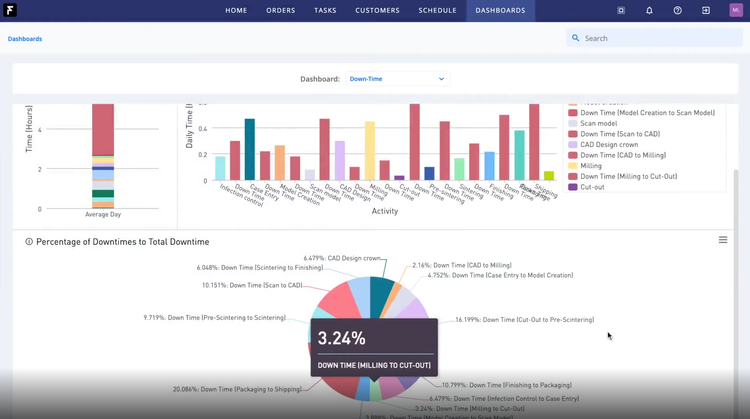

MachineMetrics - Best for OEE

MachineMetrics is a highly effective production tracking software, particularly for manufacturing companies looking to leverage IoT technology for enhanced productivity. The platform provides real-time production visibility and seamless integration with ERP and MES systems.

MachineMetrics features machine downtime tracking, real-time factory floor dashboards, operator-view tablets, alerts, notifications, and detailed analytics. These all enhance its suitability for modern manufacturing environments. Other strengths lie in its ability to offer customized dashboards for monitoring manufacturing assets and its capability for predictive maintenance by monitoring equipment health.

Eyelit APS - Best for Automotive Manufacturing

Eyelit APS, formerly Optessa, has a dynamic scheduling and sequence optimization module that enhances production sequences for automotive manufacturers. Using these, the system helps align capacity planning and resource allocation to reduce bottlenecks and increase output. This is essential for the automotive industry, which deals with complex vehicle components and a volatile demand market.

Additionally, the tool features complete forward and reverse traceability functionality. This gives you more quality control during production, with visibility into processes and outputs. For automakers, it’s great for handling part quarantines and recalls, which ultimately maintains your brand reputation.

Eyelit APS is best suited for large automotive and industrial manufacturers, with pricing starting at $5,000/month. The system is modular, so you only pay for features you need. Still, smaller manufacturers may want to look at a more affordable solution like Katana MRP or Fishbowl Inventory.

What is Production Tracking Software?

Production tracking software makes planning and assigning manufacturing tasks easier based on real-time data. Often part of manufacturing ERP, it provides suppliers with tools designed to provide regular updates on the manufacturing lifecycle so you can stay informed about any changes in the production schedule. The process begins with the order submission until the finished product is distributed to its end location.

Similar to manufacturing resource planning (MRP), tracking solutions help you manage resources, update your supply chain partners, and stay ahead of demand. Keep a real-time overview of every work order using production tracking software.

How to Choose Software

1 Assess Your Manufacturing Needs

- Feature Set: List specific needs such as inventory management, real-time tracking, quality control, and compliance management. Determine whether the software needs to cater to small-, medium-, or large-scale manufacturing.

- Process Compatibility: Assess the complexity of your manufacturing processes, including the number of products, variants, and production steps. Ensure the software supports your specific operations, like batch processing, continuous flow, or job shop.

- Regulatory Compliance: The software should facilitate compliance with industry-specific regulations (e.g., FDA for pharmaceuticals, ISO standards for manufacturing).

2 Define Functional Requirements

- Process Customization: Determine the level of customization required to match your specific manufacturing operations.

- Scalable Solutions: Ensure the software can scale up as your operations grow in complexity and volume.

- Integrations: Evaluate how the software will integrate with your current systems, like ERP, CRM, or SCM software.

3 Technology Integration

- Machine and IoT Integration: Assess the software’s ability to integrate with machinery and IoT devices for automated data collection and machine monitoring.

- Advanced Technologies: Consider how the software incorporates advanced technologies like AI, machine learning, and predictive analytics for process optimization.

4 Reporting and Analytics

- Custom Reporting: The software should offer customizable reporting features tailored to manufacturing metrics and KPIs.

- Predictive Maintenance: Evaluate if the software can analyze data to predict equipment failures and schedule maintenance proactively.

5 Material and Supply Chain Management

- Supply Chain Integration: The software should integrate seamlessly with supply chain management, especially for just-in-time (JIT) manufacturing models.

- Material Requirements Planning (MRP): Evaluate the software’s capabilities in MRP to ensure efficient material utilization and minimize waste.

6 Quality Control and Assurance

- In-Process Quality Checks: The software should facilitate real-time quality checks during the manufacturing process.

- Traceability: Ensure the software offers traceability for raw materials and finished products, which is crucial for quality assurance and recall management.

Key Features

- Resource Management: Determine how to best source and use raw materials for production.

- Scheduling: Arrange timelines for project orders based on material and staff availability. Based on the work order, set milestones, benchmarks, due dates, and deadlines.

- Share Production Updates: Provide production schedule updates to partners along the supply chain.

- Coordinate Team Communication: Manage digital and in-person communications between your team members to reduce downtime.

- Job Costing: Stay within budget by getting regular updates on orders and all associated job costs.

- Inventory Traceability: As orders are completed, use barcodes or RFID systems to improve inventory management.

- Warehouse Optimization Tools: If you store finished orders at a warehouse before they go to a distribution center, you can organize your space to maximize storage.

- KPI Data Collection: Set your key performance indicators (KPIs) to ensure you meet your production goals.

Benefits

There are many benefits to using production tracking software at your workplace. These are just a few:

Real-Time Production Updates

The best benefit of a manufacturing tracking system is that it can provide real-time updates on the manufacturing lifecycle. From one convenient software package, you can access the workings of your entire shop floor and see if everything is moving smoothly or if there are production issues.

Real-time shop floor data shows you all possible causes of manufacturing delays. Is a piece of equipment out of commission? Are holidays causing worker shortages? Account for these delays by adjusting your production schedule.

If you have multiple production lines working at once, production tracking will help you manage all of them.

Better Manage Resources

A significant source of loss for producers is outdated manufacturing processes that waste time, money, or both. As you track your production processes, you may find opportunities to better use your current resources. This may vary from sourcing raw materials to scheduling your workers.

Prioritize your resources so you can focus on the orders that matter most. Enterprise resource planning (ERP) software and production management systems help you optimize the manufacturing process so you get the most value out of each material. Tracking software can drastically reduce your bill of materials.

Set Realistic Minimums

You can track your team’s daily, weekly, or monthly minimum goals by monitoring production. When you get real-time data, you can compare it against your projected results to see if you will meet those goals. If you fall behind, you can adjust your production planning to compensate.

Another way to set accurate production benchmarks is to collect historical data. Based on this information, adjust your production targets to anticipate seasonal slowdowns and other annual manufacturing trends. Even better, the longer you’ve been manufacturing, the more production data you’ll have to use!

Anticipate Supply Chain Demands

Want to increase productivity? Streamline the production process by using tracking software from start to finish. Once you have a handle on the production process, you can increase or decrease output to better suit capacity.

When working along the supply chain, retailers might request more inventory based on forecasting data. Plan your production in advance to get ahead of your retail partners.

Additionally, there are many potential delays in the supply chain. Anything from severe weather to holidays can bring production to a halt. While some delays are unexpected, you can account for others by planning.

Provide Quality Assurance

Overall equipment effectiveness (OEE) depends on several factors, including part quality. Accurate production tracking tools let you find potential shortcomings and vulnerabilities within the production process. Quality management is necessary to avoid production errors, which may lead to costly recalls. Check over WIP products to ensure they meet all your quality standards at every stage of the manufacturing process.

Whether from barcodes or other systems, traceability automates tracking at an individual or batch level. If defects are found within one lot, you can begin to recall procedures for the rest of the affected products.

How is Production Tracking Different from Scheduling?

Production tracking has some similarities with production scheduling. However, while both are recommended for streamlined production, they serve distinct purposes. For starters, production scheduling software focuses on generating the timeline necessary for getting resources, staffing, and inventory in production. Production tracking is about comparing this schedule to reality to ensure you are on time throughout the manufacturing lifecycle.

Production tracking primarily measures overall equipment effectiveness (OEE), giving you more control over manufacturing quality, performance, and availability.

Medical Device Compliance Tracking

In the United States, medical devices must be tracked through the manufacturing process, per the Food and Drug Administration (FDA). Production tracking software gives you the tools for staying compliant with medical requirements. The FDA requires tracking for any device that may cause health consequences in the event of device failure. This includes:

- Pacemakers

- Defibrillators

- Heart valves

- Prostheses and implants

- Ventilators and monitors

Pricing Guide

Production tracking software prices depend on whether you have a single manufacturing plant or multiple manufacturing facilities. One-time perpetual license solutions start at $2,000 and increase to $50,000. Software-as-a-service (Saas) prices begin at $48 per month per user and can go over $2,000 per month. Here’s a general breakdown of what you can expect to pay based on your company size:

Entry-Level Tier

- Company Size: 1–20 employees

- Average Yearly Cost: $1,000–$8,000 per year

- Examples: Katana, Fusion Operations by AutoDesk (ProdSmart), Fishbowl Starter, Fulcrum Basic

Mid-Tier

- Company Size: 20–100 employees

- Average Yearly Cost: $10,000–$40,000 per year

- Examples: MRPeasy, JobBOSS², ProShop ERP, Statii

High-Tier

- Company Size: 100–500 employees

- Average Yearly Cost: $40,000–$120,000 per year

- Examples: Plex by Rockwell Automation, DELMIAWorks, Cetec ERP, Aptean Industrial Manufacturing ERP

Enterprise Tier

- Company Size: 500+ employees

- Average Cost: $120,000–$500,000+ per year

- Examples: SAP Digital Manufacturing Cloud, Oracle Fusion Cloud SCM, Siemens Opcenter, Infor CloudSuite Industrial(SyteLine)

Challenges

Without production tracking, you may encounter the following problems:

Higher Bill of Material Costs

If you haven’t updated your production methods in years, you might miss out on more effective practices. If you’re wasting raw resources, you’ll be stuck with a higher bill of materials. Lower your overall operating costs by using ERP modules of production tracking to find opportunities to save money along the manufacturing lifecycle.

Product Shortfalls

Shortfalls occur whenever you don’t meet retailer demand. Don’t let down your supply chain partners. Use production management software to stay on top of your work orders and anticipate demand.

Slower Manufacturing

Related to the above, outdated manufacturing may slow your production capabilities. You don’t want to fall behind your competitors. Use production tracking and scheduling tools to increase your production capacity.