The Best Maintenance Management Software

We reviewed the most popular maintenance management software for all industries, including fleet, aviation, and manufacturing. Whether you need IoT integrations for condition monitoring or a preventive maintenance scheduler, you can find a solution here.

- Automatic work order generation

- Easy-to-use mobile app

- Affordable for small businesses

- Set PMs based on multiple variables

- Can be used in most industries

- Automated work order generation and calendar

- Offers proprietary Fluke IoT sensors

- Condition-monitoring for production assets

- Effective for preventive and predictive maintenance

In this guide, we’ve ranked the top maintenance management software based on how effectively they perform different types of maintenance, like preventive, predictive, and corrective maintenance. We also included systems for specialized maintenance industries, like fleet and aviation MRO, to help you find a solution that aligns with your operations.

- MaintainX: Best for Corrective Maintenance

- Limble CMMS: Best for Preventive Maintenance

- IBM Maximo: Best for Predictive Maintenance

- eMaint CMMS: Best for Condition-Based Maintenance

- Samsara: Best for Fleet Maintenance

- MicroMain: Best for Equipment Maintenance

- Veryon: Best Aviation MRO System

- Click Maint: Best for Facilities Maintenance

- Equips: Best for Healthcare

- UpKeep: Best Mobile-First CMMS

- FieldMotion: Best for Field Service Crews

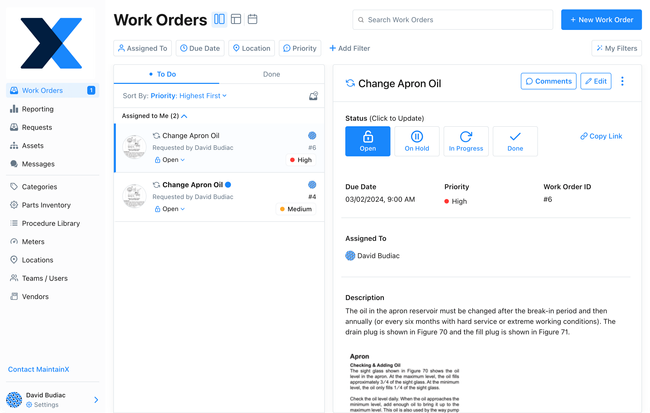

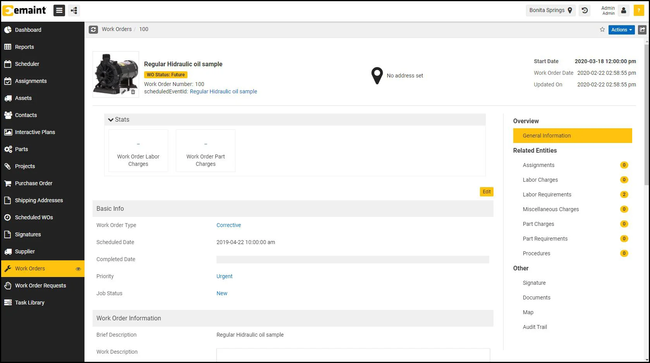

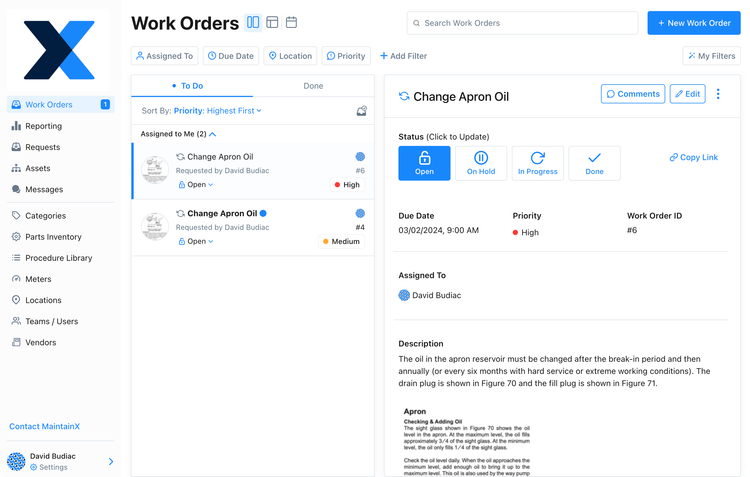

MaintainX - Best for Corrective Maintenance

MaintainX allows you to automatically generate a corrective action work order when an inspection is failed. For example, a machine safety inspection at a manufacturing plant discovers a faulty emergency stop button. The system will automatically create a work order for the broken button so technicians can take corrective action as soon as possible.

The new corrective work order keeps all data from the original inspection or scheduled maintenance work order. This gives the technician a better context for what failed while including other crucial information like repair priority, asset location, and spare parts needed to repair. The instant work order creation streamlines the detection-to-repair process, lessening total machine or equipment downtime.

While other systems like Limble and Fiix have similar functionality, MaintainX’s low cost and simple mobile interface make it a strong option for small to mid-size businesses. Its paid plans start at just $20/user/month when billed annually, which is one of the lowest prices on the market.

Read more about MaintainX in our full review.

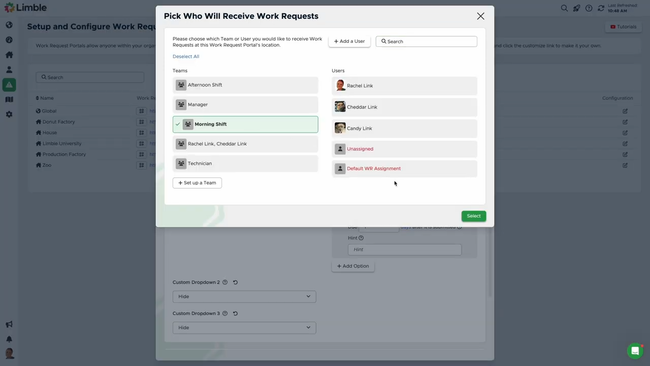

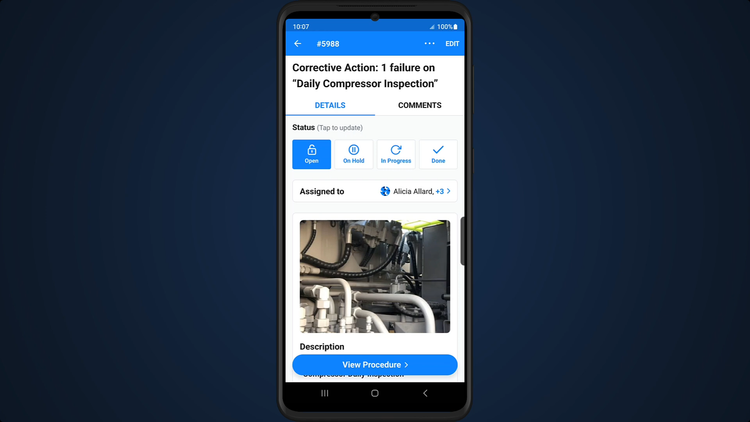

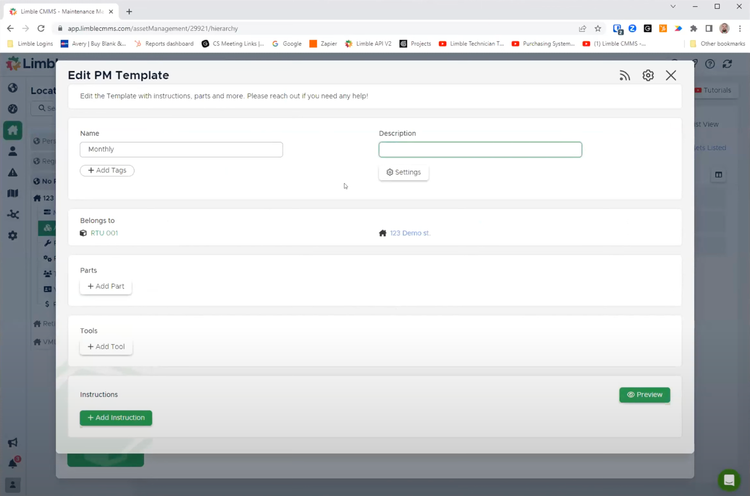

Limble CMMS - Best for Preventive Maintenance

Limble Cmms’s preventive maintenance (PM) creation tool allows you to efficiently generate PM templates for every machine or piece of equipment. You can set automatic recurrences based on time (daily, weekly, monthly, yearly), by meter reading, or threshold. For example, if a generator requires maintenance every 500 operating hours, the system will automatically create a work order once that threshold is reached.

Additional fields within a PM template include parts, tools, and instructions for more specificity. Through the integrated spare parts inventory module, you can quickly add the parts required for each PM schedule to the template. For instructions, you can add basic checklists, picture/file attachments, or text boxes. More advanced options include eSignatures, request approval, and linked work orders. These equip your technicians to arrive prepared with the right parts and detailed instructions in hand.

One way Limble’s PM creator stands out is its streamlined mobile experience. Technicians can perform all desktop functions through the mobile app. It organizes information logically to guide them step by step through the maintenance process for more efficient fieldwork. The app also lets technicians manually log any extra parts used, automatically deducting them from inventory.

Limble’s PM creator serves several different industries, including:

- Manufacturing: Schedule regular maintenance based on run time for assets like assembly lines and conveyor systems to reduce downtimes.

- Facilities: Schedule routine maintenance tasks for HVAC systems, lighting, or plumbing in educational or government facilities to ensure they are up to code.

- Healthcare: Ensure medical equipment is compliant with The Joint Commission (TJC) standards.

- Energy and Utilities: Include detailed instructions and file attachments to maintain more complex infrastructure like turbines, transformers, and pipelines.

Read more in our full Limble CMMS review.

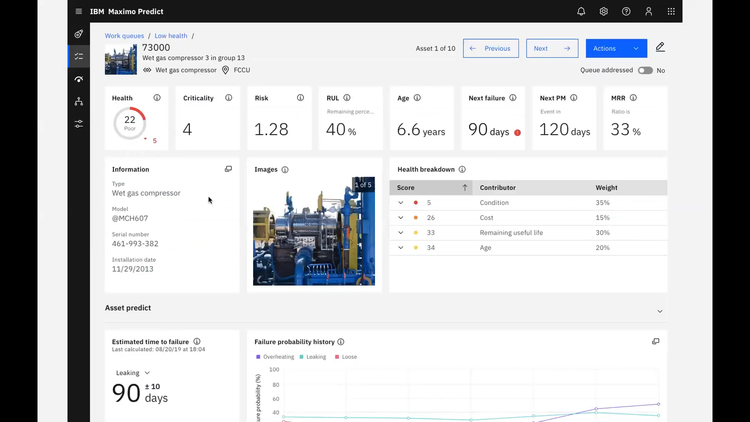

IBM Maximo - Best for Predictive Maintenance

IBM Maximo’s health and predict module integrates with IoT sensors and uses historical data to calculate and assign health scores for high-value assets to better predict upcoming maintenance. Health score valuations are customizable, so you can use a meter reading or incorporate several variables to determine an asset’s overall health. This is especially useful for energy and utility companies, as you can consider environmental factors and other asset dependencies when creating health valuations for energy grids or transformers.

You can view all assets with low health scores and drill down into each to view specific metrics to help predict maintenance. Maximo also includes a health breakdown that lists contributors to the overall health score and their weight within the formula. This helps you assess why an asset’s health score is low and determine if more frequent maintenance is required. For example, an energy company might find that temperature spikes drive low health scores in transformers, prompting more frequent maintenance that eventually reduces downtime.

Additionally, Maximo lets you add several customizable charts and graphs for further data analysis. These can include:

- Failure probability history: Shows percentages of causes of failure, like overheating, leaking, or loose parts to help with root cause analysis.

- Anomaly detection history: Instances where IoT sensors detect an anomaly in vibration, temperature, or voltage to spot possible trends.

- Asset timeline: Displays all events across a timeline for easy analysis. This includes failures, maintenance, completed work orders, and refurbishments.

IBM Maximo offers highly advanced functionality for evaluating asset health and predicting maintenance. Because of this, we recommend this system only for large to enterprise-level companies, as the system starts at just over $3,100/month. If your business requires more simple meter and condition monitoring for a lower cost, eMaint CMMS or UpKeep may be more suitable.

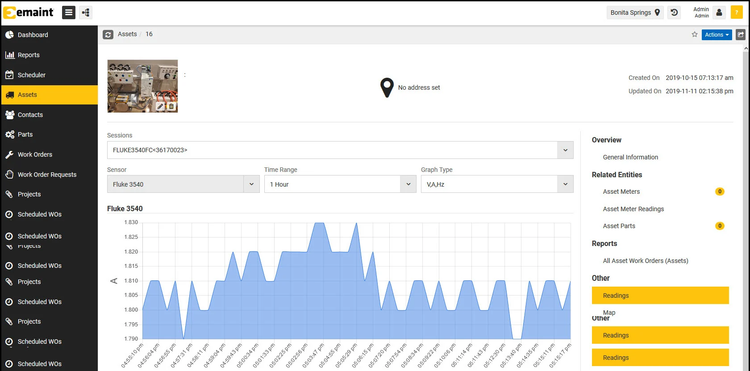

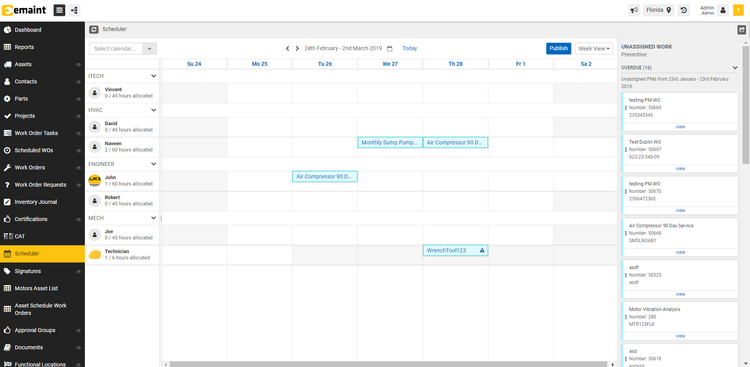

eMaint CMMS - Best for Condition-Based Maintenance

eMaint CMMS offers turnkey, proprietary Fluke IoT sensors to streamline integration for condition-based monitoring and maintenance. This simplifies a normally complex process, as you can purchase the sensors and CMMS system in one place instead of integrating with third-party devices. Popular systems offered include:

- Fluke 3563 analysis vibration sensors: Performs regular vibration monitoring and analysis for production-critical assets. For example, sensors installed on conveyor motors at a bottling plant can detect abnormal vibrations, signaling bearing failure.

- Fluke 3540 FC three-phase power monitor: Monitors key electrical variables in equipment, including current, voltage, and energy consumption. When a generator shows signs of power instability, maintenance teams can take action to ensure uninterrupted power during operations.

The condition-based monitoring module can be used as an advanced predictive maintenance method. Set upper and lower-bound danger limits for each asset and get alerted when those limits are passed. The system can also auto-generate work orders when these limits are exceeded. This lets you detect failures early before they lead to costly breakdowns and downtime and keeps workers safe.

Learn more in our full eMaint CMMS review.

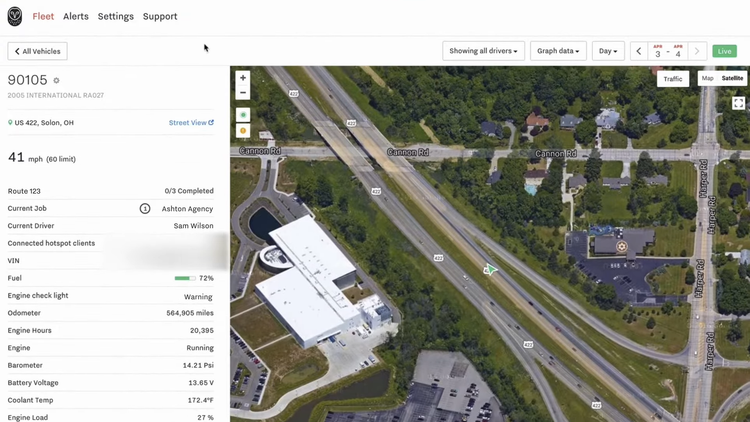

Samsara - Best for Fleet Maintenance

Samsara helps lower fleet maintenance costs by collecting vehicle diagnostics for real-time health monitoring. This is achieved through on-board diagnostic ports that collect data and relay it to the system so you can actively monitor drivers’ vehicles while they are on the road. Some data points include battery voltage, coolant temperature, and oil pressure.

The diagnostics data helps you proactively spot vehicle faults, such as engine overheating, exhaust leaks, ABS system malfunctions, and battery alternator failures. It lists the severity of the detected issue and how many times it occurred. This helps you catch vehicle problems early to prevent driver injuries and ensure quick, targeted repairs.

This feature integrates with the maintenance module to create streamlined work orders for vehicles with detected diagnostic faults. You can even create preventive maintenance schedules for each vehicle by setting up alerts when meters hit certain readings, like hours on the road or miles driven.

It’s important to note that Samsara is a fleet management system, so its maintenance capabilities don’t extend beyond fleets of vehicles. If you require both fleet and another form of maintenance like facility or equipment, you will need to purchase a separate maintenance management system and integrate it with Samsara.

Read more about Samsara on our product profile page.

See also our complete fleet management software roundup page for other leading systems.

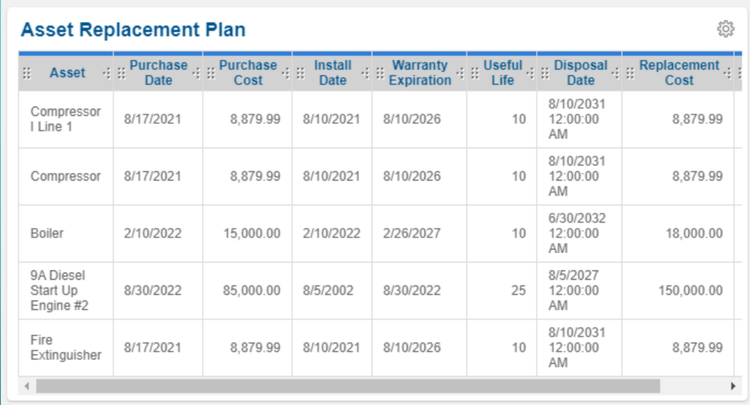

MicroMain - Best for Equipment Maintenance

MicroMain’s asset lifecycle management is ideal for the manufacturing and oil and gas industries that require comprehensive tracking of complex assets and equipment. The module manages the entire lifecycle, from procurement to disposal or replacement, so you know exactly how much you paid and how much it will cost to replace or repair it.

Specifically, MicroMain can calculate and track depreciation for high-value assets using acquisition cost and estimated useful life based on usage and condition. It supports common methods like straight-line, declining balance, or units of production. Knowing the asset’s value in real-time can help you allocate costs more accurately and ensure maintenance budgets stay on target. Knowing the current value also allows you to make more informed decisions about upgrade or replacement considerations.

For example, a critical production machine unexpectedly experiences an engine failure that will be expensive to repair. MicroMain can show you that the machine only has one year of useful life remaining, which helps your company decide to replace it completely instead of undergoing the costly repair and then replacing it a year later.

Read more in our MicroMain review.

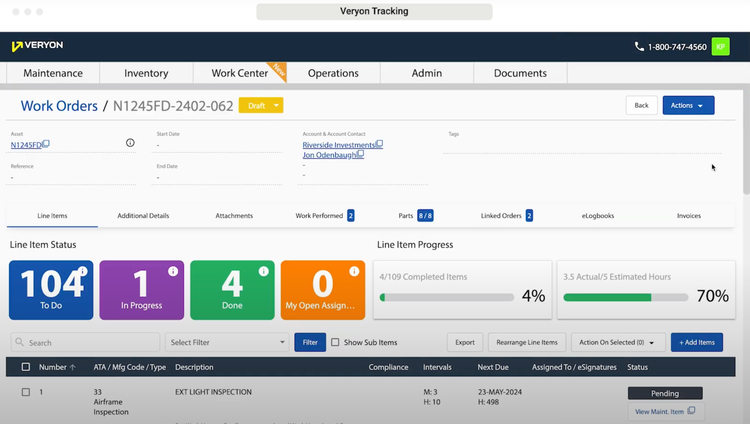

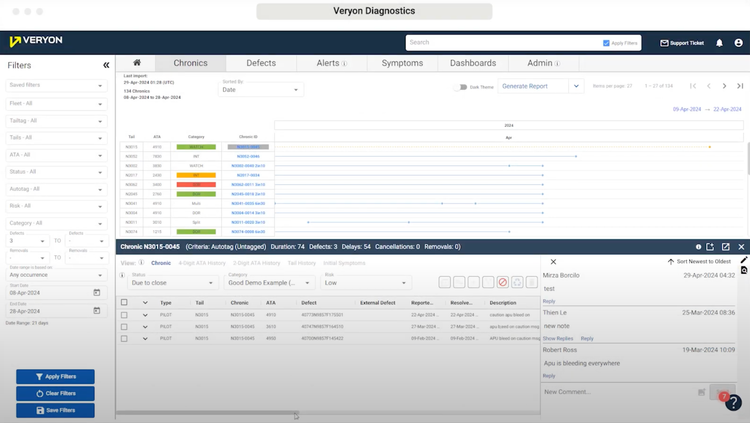

Veryon - Best Aviation MRO System

Veryon’s maintenance tracking module allows commercial airlines and MRO service providers to keep track of all repair tasks and aviation compliance. You can manage all work orders from one dashboard, making it easy to visualize what tasks need to be completed. It even sorts routine from non-routine maintenance, helping you isolate unexpected faults to diagnose the root cause.

To better understand each work order, you can drill down into more specific data, such as estimated maintenance cost vs. actual cost, reported hours, and landings. The status bar shows which work orders are on time or running behind, helping you prioritize tasks effectively.

Within the module, you can create electronic logbooks to record flight and maintenance data for each aircraft in your fleet. This includes flight hours, each maintenance task performed on the aircraft, and inspections completed. This helps you stay compliant with Federal Aviation Administration (FAA) regulations and ensures you stay audit-ready.

Read more about Veryon on our product profile page.

Also check out our best aviation MRO software page for more options.

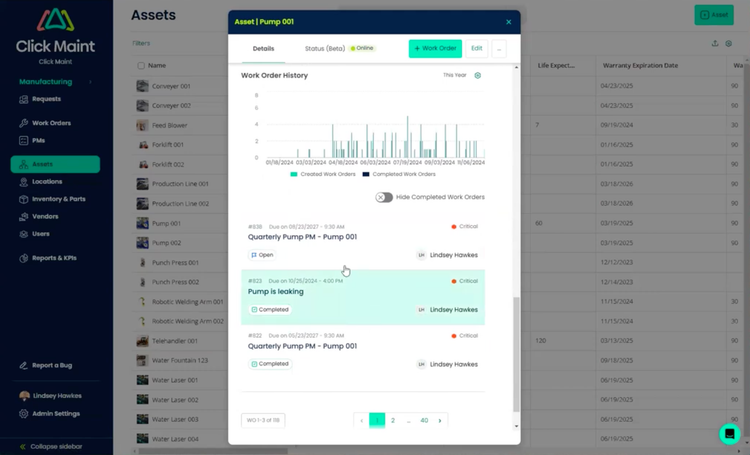

Click Maint - Best for Facilities Maintenance

Click Maint’s simple yet effective asset management module is a great option for small governments and educational institutions managing aging infrastructure. Oftentimes, buildings in these sectors have outdated equipment, whether it’s HVAC machines, electrical systems, or even plumbing. The module can help you track these by creating hierarchies to organize equipment across several facilities. This lets you easily reference maintenance histories to review lifecycles and spot assets that may need replacing.

While most maintenance management software has similar functionalities, Click Maint stands out with its easy-to-navigate interface. You can click on an asset from the filterable list, and it displays all relevant information, like purchase date, warranty, and building location. It even lets you create QR codes to print and attach to equipment so you can scan them with the mobile app to display their info. The easy navigation helps staff save time tracking asset lifecycles across every facility.

Click Maint offers an affordable all-in-one package that includes every feature it has to offer. At $35/user/month when billed annually, it’s best for small to midsize organizations looking to optimize their facility maintenance processes.

See our full Click Maint review to learn more.

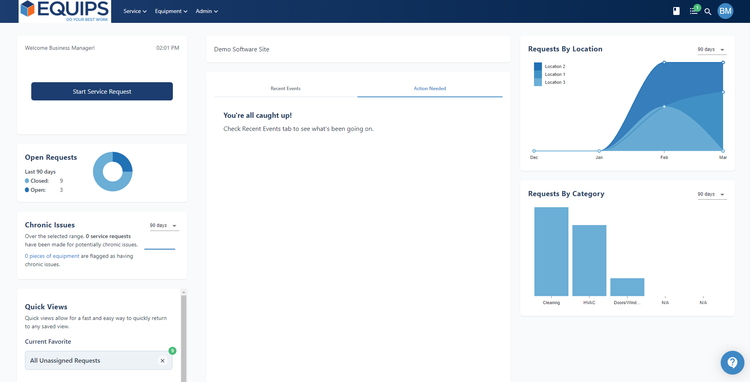

Equips - Best for Healthcare

Equips’s asset management module is a great tool for healthcare facilities handling critical patient equipment. You can create custom QR codes for building equipment, like HVAC units and generators, and devices like beds and CT scanners. That way, technicians can easily scan the code with the mobile app and have all the necessary information to fix any problems or perform routine PMs.

The module also enables asset lifecycle reporting. Just enter your purchase date, asset price, and depreciation method, and Equips will automatically track it. It also stores all performed service, maintenance, and downtime events for each piece of equipment to adjust useful life projections accordingly. This is crucial for hospitals or clinics to ensure equipment is safe for patient use.

Equips can be used by small to large businesses, catering to a wide range of companies. Other features include a vendor marketplace, PM schedules, and a pricing data tool for service contracts. Pricing starts at $50/user/month, with a minimum $1,500 one-time support fee. That said, you’ll need a custom plan to determine exact costs for your business.

See our Equips Review to explore standout features and user reviews.

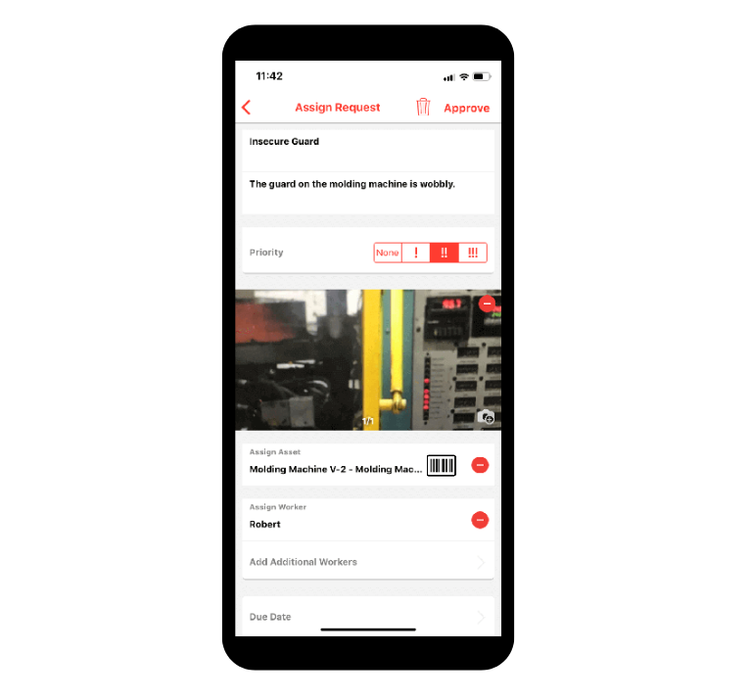

UpKeep - Best Mobile-First CMMS

UpKeep is a cloud-based CMMS designed for technicians managing maintenance in the field. It simplifies work order requests, asset tracking, and spare inventory management, which can all be controlled from an easy-to-use mobile app.

Its strength lies in its mobile-first design. Unlike many CMMS tools, where mobile apps play a supporting role, UpKeep’s mobile app serves as the primary interface. Technicians can manage work orders, scan QR codes for asset details, attach photos, log meter readings, and respond to requests right from their phones. They can also set up preventive maintenance schedules, track equipment history, update inventory, and submit purchase requests in the field, without needing to fall back to a desktop computer.

While UpKeeep includes an offline mode, which is helpful for intermittent connectivity, the mobile app is best utilized with an internet or cellular connection. With pricing starting at just $20/user/month for the essential plan, the system is a great fit for smaller to mid-sized teams that want a maintenance tool their staff can get up and using quickly and affordably.

Read more in our full UpKeep Mobile CMMS review.

FieldMotion - Best for Field Service Crews

FieldMotion’s asset management module makes it apt for maintenance-style field work. In a few clicks, your supervisors can quickly view asset quantities and locations. Live updates and mobile access mean your engineers can open the field app and immediately see what’s available. Low-stock email alerts remind you to correct shortages before a crew ever leaves the yard.

Because you can customize items into categories, it’s easy to find the right component and quickly assign it to a technician without having to hunt through spreadsheets. You can even allocate stock directly to jobs; this allows FieldMotion to track distribution to field workers and vehicles, so the parts needed for a planned maintenance visit are already staged before the truck rolls out.

In the field, your techs can use the mobile app to select or scan the asset and record usage. This maintenance tracking software then retains that asset history and, based on values captured in the mobile form, can auto-generate a follow-up for that asset. That way, next-step or recurring service work orders aren’t left to manual scheduling.

Asset management also syncs with quantities and values in accounting platforms like QuickBooks and Xero, so invoices accurately reflect what was allocated and consumed on a job. FieldMotion starts at $45/user/month with a minimum of three users. However, there is also a one-time setup fee starting at $1,000 based on your user count, though this includes full training, data uploading, and ongoing support.

Systems We Also Recommend

Tractian helps your team perform maintenance consistently; it uses an intelligent execution layer to put AI-generated instructions directly inside each work order. These guidelines are built from actual maintenance history, live asset data, and manuals, so your techs always have exactly what they need for the equipment and issue they’re tackling. When combined with real-time condition monitoring, this helps your team resolve problems faster and reduce downtime.

What is Maintenance Management Software?

Nearly synonymous with computerized maintenance management systems (CMMS), maintenance management software streamlines all maintenance activities for a company. This mainly includes creating work orders for different types of maintenance methods, like preventive, corrective, or predictive maintenance for high-value assets. It aims to lower maintenance costs, automate scheduling, provide real-time KPIs, and log all performed maintenance for your team.

Similarly to enterprise asset management software, these systems can track high-value assets like production machines, transformers, medical equipment, and wind turbines. They can also act as a type of facility management software and track equipment within educational or government facilities, like HVAC systems or generators.

Key Features and Benefits

- Work order management: Streamlines creation, tracking, and assignment of work orders. Ensures organization and prioritization of all maintenance tasks.

- Preventive maintenance scheduling: Schedule and manage preventive maintenance templates to minimize downtime and prolong equipment life.

- Reporting: Generate reports to analyze labor costs, average downtime, and preventive maintenance to analyze efficiency and effectiveness.

- Asset management: Stores information on all assets, such as maintenance cycles, acquired date, and locations, for easy reference.

- Compliance and safety: To stay compliant with industry regulations, keep historical records of all maintenance performed on critical equipment.

- IoT sensor integration: Optional integration with IoT sensors allows for real-time condition monitoring of production equipment and predictive maintenance.

- Spare parts inventory management: Keep an accurate inventory of spare parts and add them to work orders to ensure your maintenance technician can have the right tools beforehand.

Maintenance Types

You can choose from several different types of maintenance to best care for your assets and equipment. Each method has a different intended use and outcome, and different features are used within maintenance management systems.

| Maintenance Type | Use | Important Features |

|---|---|---|

| Preventive | Aims to prevent failures before they occur by scheduling adjustments based on time intervals or usage patterns. | Automated scheduling, task management, asset tracking, reporting |

| Predictive | Uses real-time data and sensors to predict when maintenance should be performed. | Real-time monitoring, predictive analysis, historical data trend analysis |

| Corrective/Reactive | Performed after a defect or failure has been detected or after equipment has completely broken down. | Fault detection alerts, mobile access, work order management |

| Condition-Based | A type of predictive maintenance, this monitors the actual condition of equipment to decide whether maintenance should be performed. | IoT sensor integration, data collection, automated work order creation |

| Scheduled | A type of preventive maintenance, this is pre-planned based on a schedule, regardless of the equipment’s condition. | Calendar schedule, maintenance history, procedural work orders |

| Deferred | Postponed maintenance that is delayed due to factors like budget, resources, or time constraints | Cost estimation, risk assessment, task prioritization |

| Proactive | A type of preventive maintenance, this focuses on identifying and fixing the root causes of failure rather than just the symptoms. | Root cause analysis, asset condition monitoring, asset maintenance history |

| Emergency | A type of corrective maintenance required when an unexpected failure causes significant downtime, risks, and/or costs. | Remote monitoring, downtime tracking |

| Shutdown | Performed when equipment is deliberately shut down for a complete overhaul. This is typically planned in advance. | Resource allocation management, compliance, and safety management |

Industry-Specific Maintenance Systems

Some software options will be marketed and sold based on your industry or by the relevant asset/equipment:

- Fleet Maintenance Management Software: Maximizes your fleet vehicles’ uptime, efficiency, and life. Assets typically include cars, trucks, and trailers, but can also include construction equipment, machinery, and tools needed to maintain them. A unique feature module is fuel tracking. Samsara and Fleetio are a couple of leading products that are unique to fleet maintenance.

- Property Maintenance Management Software: Oversee the maintenance activities involved with the property you own and potentially lease out. Maintenance request portals give access to tenants rather than employees in your company. View maintenance activities on a per-unit basis and store important documents. This includes homes, apartment buildings, and hotels. A good example product is Appfolio, a popular property management system with a streamlined tenant portal for maintenance requests.

- Aircraft and Aviation Maintenance Management Software: Tracks maintenance, repair, and operations on aircraft and aviation vehicles. Also known as aviation MRO software, it handles aircraft airworthiness by ensuring compliance with maintenance activities, sourcing the right parts, and improving logistics controls. An example product is Veryon, built explicitly for aviation maintenance.

Pricing Guide

The pricing for maintenance management systems varies, as some systems offer free plans, like MaintainX and Fiix. However, these are only viable for freelancers or very small startups, as they are limited in functionality.

Paid plans for cloud-based systems typically range from $20-$200/user/month. The range is highly dependent on your business size and desired features. Usually, products offer tiered pricing options, with each tier offering more features at a higher price. There are also implementation and optional IoT sensor costs to consider.

There are some anomalies, like IBM Maximo, that cost anywhere from $200-$500+/user/month. This is considered an EAM system, and is specifically built for enterprise-level companies and offers more advanced features like a reliability strategies app and asset health analysis. Because of this, its price is much higher, starting at $3,150/month, with the standard plan starting at $7,200/month.

Here’s a breakdown of some expected costs and products based on your company size:

Low-Tier

- Company Size: 1-25 employees

- Cost Per User Per Month: $20-$80

- Average Yearly Cost: $1,000-$10,000 per year

- Examples: UpKeep, Limble CMMS, MaintainX, Click Maint

Mid-Tier

- Company Size: 25-100 employees

- Cost Per User Per Month: $50-$150

- Average Yearly Cost: $10,000-$50,000 per year

- Examples: eMaint, Fiix, Equips, MicroMain, Upkeep

High-Tier

- Company Size: 100-500 employees

- Cost Per User Per Month: $100-$250

- Average Yearly Cost: $50,000-$200,000 per year

- Product Examples: Eptura Asset, MicroMain (Enterprise), eMaint (Enterprise)

Enterprise

- Company Size: 500+ employees

- Cost Per User Per Month: $200-$500+

- Average Yearly Cost: $200,000+ per year

- Examples: IBM Maximo, SAP EAM, Infor EAM