The Best Small Business Manufacturing Software

The best manufacturing software for small businesses helps lighten the load as you move from spreadsheets and basic accounting tools to more complex operations. We’ve reviewed affordable options in sectors like food and beverage, plastics, and job shops.

- Infinite serialization levels for diverse requirements

- Integrated QC tests throughout product lifecycle

- Seamless regulatory compliance with ERP foundation

- Mostly straight-forward and user-friendly

- Built with over 40 years of manufacturer and distributor expertise

- Integration with AI, MI, IoT, and Cloud-hosting

- Streamlines manufacturing operations

- Real-time visibility into the manufacturing process

- Integration with other systems for improved efficiency and productivity

We’ve ranked the 10 best small business manufacturing software for various modes, from engineer-to-order (ETO) to made-to-stock (MTS) operations, and across industries, including job shops, textiles, and food and beverage production. These picks are ideal for small manufacturers with annual revenue under $15 million.

- Deacom: Best for Food and Beverage

- SYSPRO: Best for Most Manufacturers

- DELMIAWorks: Best for Plastics and Rubber

- MRPeasy: Best for Textiles

- Acumatica: Best for Mixed-Mode Environments

- JobBOSS²: Best for Job Shops

- xTuple: Most Affordable Option

- Katana: Best for Direct-to-Consumer

- Odoo: Most Customizable

- Cetec ERP: Best for Electronics

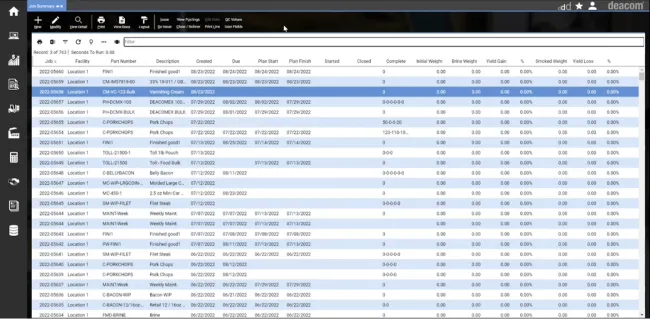

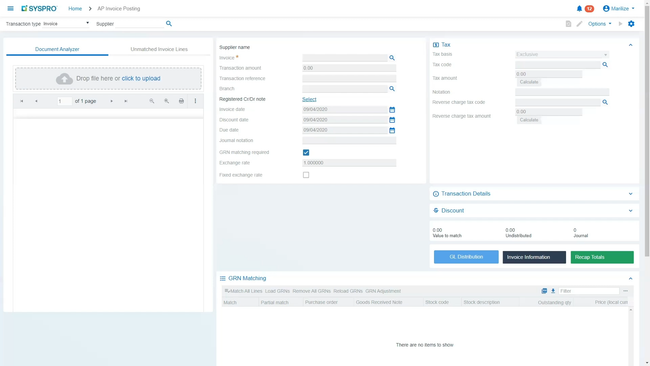

Deacom - Best for Food and Beverage

Deacom is an ideal food manufacturing ERP for small businesses. It offers lot control and traceability features that let you easily track raw materials through production to shipping. Using lot numbers and serialization data, Deacom records a detailed audit trail of every step, from when and where a lot was used to who handled it and its current status.

When raw materials are received, this manufacturing software solution auto-assigns lot numbers embedded in GS1-128 barcodes. During processes like receiving, job issuing, and sales reserving, operators scan these barcodes. The data from the scan, like lot number, quantity, and expiration date, then automatically updates in the ERP system.

Additionally, Deacom’s drill-down functionality lets you review details at any level of production. You can:

- Start from a raw material and trace it through production into any intermediate or finished goods.

- Reverse the process by starting from a finished good and identifying all raw materials used.

This provides bidirectional traceability, which is helpful for quickly identifying any issues. This food manufacturing software also integrates lot tracking directly into its recall management features, so you can quickly identify which customers received specific lots. You can use the built-in email functionality to notify them about recalls. Additionally, you can track on-hand inventory to quarantine affected lots before they go any further.

For smaller manufacturers, we recommend the newly introduced Deacom Essentials starting at $500 monthly. This version is designed specifically for companies with over ten employees and $5 million in revenue.

Learn more about Deacom and food manufacturing software for small businesses in our full review.

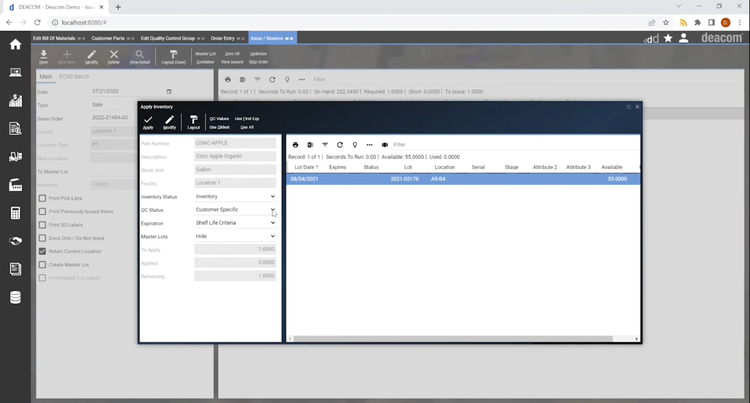

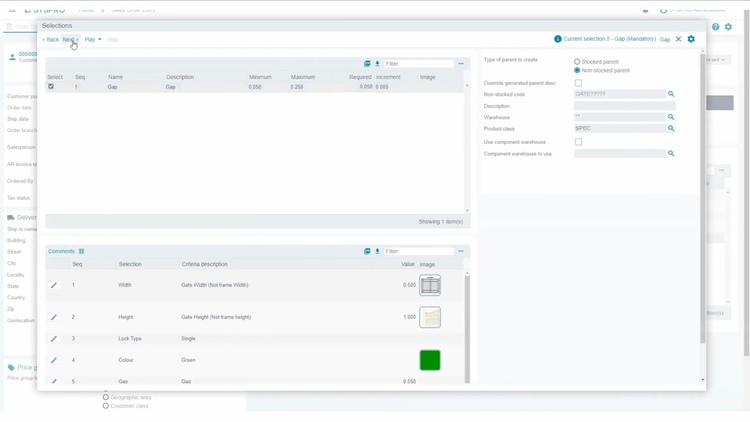

SYSPRO - Best for Most Manufacturers

SYSPRO can handle a variety of production methods, making it suitable for most small to mid-sized manufacturers. These include:

- Process Manufacturing: Supports complex formula and recipe management, allowing you to scale ingredients based on production batch sizes; provides traceability and compliance features for sectors like chemicals or food and beverage.

- Make-to-Stock (MTS): Forecasts demand based on past sales data and market trends; adjusts these forecasts dynamically based on incoming sales data, then calculates the required materials and scheduling orders to meet that demand.

- Engineer-to-Order (ETO): Offers a built-in project management module to create detailed plans with tasks and milestones; links jobs related to specific products to customer orders, material requirements, and production schedules.

- Make-to-Order (MTO): Includes a product configurator that streamlines the process of setting rules for customizable items. This makes it easier to manage customer-specific products from quoting to delivery.

It’s a popular manufacturing software for small businesses due to its support for various production approaches, making it ideal for mixed-mode environments as well. Its adaptability makes it a safe bet for most small and mid-sized companies with 10 to 500 employees in sectors ranging from electronics and furniture to chemicals and food processing.

Read our in-depth review of SYSPRO.

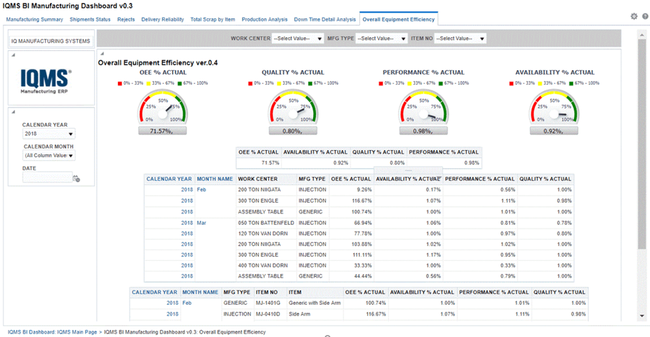

DELMIAWorks - Best for Plastics and Rubber

The RealTime Process Monitoring System in DELMIAWorks helps you stay on top of operations by gathering data from factory floor devices, controllers, and automation systems. It integrates directly with machines like injection molding and extrusion systems, using machine-level sensors and various connectivity options. For example, DELMIAWorks offers a custom-built programmable logic controller for connecting legacy equipment to modern networks using sensors and machine inputs/outputs.

The RealTime Process Monitoring System can collect live data on KPIs like cycle times, part counts, temperature, pressure, and mold conditions. It also tracks process parameters like injection pressure, screw speed, and cooling times. You can set specific parameters for monitoring and define upper and lower limits. If any of these go outside the acceptable range, the system will trigger an alert via SMS message or email, so you can quickly take action.

All information is stored in a database and can be integrated into the ERP system in real time or at set intervals. DELMIAWorks also offers a statistical process control module where you can create charts, histograms, and detailed statistical analyses based on this historical process data. Just drag and drop charts to explore how different factors, like temperature or pressure, impact other metrics.

Setting up the infrastructure for DELMIAWorks, like installing machine-level sensors, takes time and technical expertise, especially for older or highly customized machinery. For that reason, we would recommend this ERP for companies with 50-100 employees and $10-$20 million in annual revenue.

Find out more about DELMIAWorks’ features in our review.

MRPeasy - Best for Textiles

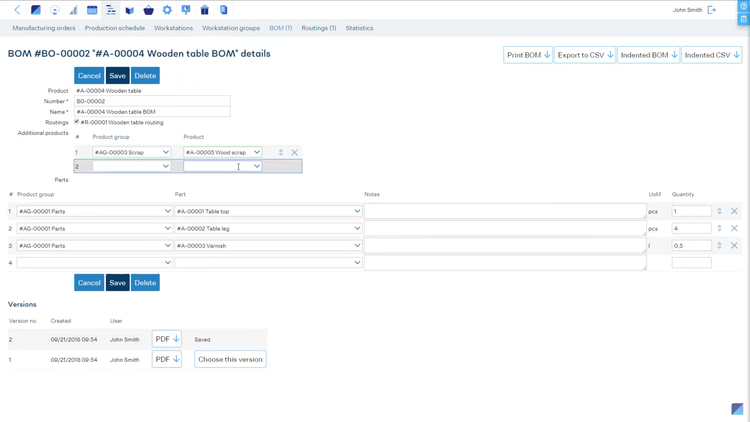

MRPeasy offers multi-level BOMs functionality with co-product functionality, ideal for managing the complex product structures common in textile and clothing production. You can easily track components like zippers, buttons, and fabric, as well as intermediate stages like assembling sleeves or linings. By giving you a clear picture of material requirements at each stage, MRPeasy helps you estimate fabric needs and even recycle scraps where possible.

The co-product BOM functionality makes managing scraps much easier. Whether it’s leftover fabric from cutting patterns or production defects, you can easily add these as scrap items in the “additional products” section of a BOM. This ensures all waste is properly tracked, offering more precise costing so nothing is overlooked when you calculate your total expenses.

What makes this manufacturing inventory software even more useful is the ability to designate scraps as valuable co-products. This helps you reuse materials in future production cycles. And by keeping tabs on inventory – whether it’s fabric, thread, or dyes – the co-product BOM tool helps you avoid shortages or overstock when working with seasonal fabrics or limited-edition designs.

Some users have mentioned challenges with customization, finding they need to adjust their workflows to fit MRPeasy’s structure. If your operations shift frequently across product lines or fabric types, you might find a customizable solution like Odoo more fitting, as it offers greater flexibility at a similar price.

Read our full MRPEasy review.

Acumatica - Best for Mixed-Mode Environments

Acumatica’s MRP with finite capacity scheduling is ideal for smaller manufacturers juggling make-to-stock items alongside custom assemblies or make-to-order jobs. It’s ideal if your plant doesn’t rely on one clean production model.

The system manages stocked products and custom jobs in the same planning cycle and translates that demand into production and purchasing plans. It then checks these against real capacity, so you’re not promising custom orders and stock builds off the same machines simultaneously.

Additionally, barcoded data collection and backflushing help keep your inventory, WIP, and costs accurate. That way, one production model doesn’t starve the other of capacity or materials. Drill-down reporting also gives you live insights into what to build for stock versus what to push for a customer order.

Acumatica’s small manufacturing package starts at $3,500 for ten or fewer users. The manufacturing edition is affordable and supports fabricated metal, electronics, industrial equipment, textiles, and even light process environments like food or batch production.

Find out more about Acumatica in our in-depth review.

JobBOSS² - Best for Job Shops

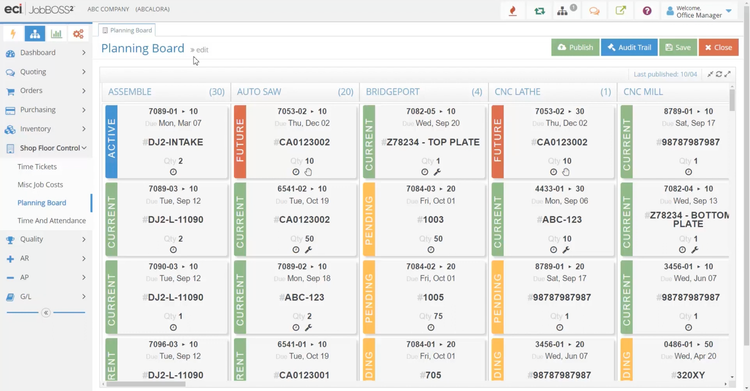

JobBOSS² is an effective manufacturing ERP for small job shops. It gives you strong production control through its shop floor scheduling tools. It supports multiple approaches depending on your needs, from simple prioritization to more detailed machine-specific scheduling.

This manufacturing industry software offers a planning board schedule, with a simple drag-and-drop interface that lets you prioritize jobs and assign them to machines or workers. Users can drag job “tiles” to arrange them in the order they should be completed. This allows you to visually organize work based on criteria like urgency, due dates, or available resources. You can move jobs up or down the list to reflect changes in priority.

Assign jobs to specific machines by dragging job tiles onto the appropriate machine slot on the board. This helps you balance workloads and optimize machine usage. Additionally, you can click on a job tile for a more detailed view. This includes required materials, production steps, and deadlines. Overall, the planning board is simplified for quick use so employees know at a glance what tasks come first, second, and third.

If you need a more advanced tool, this ERP also includes a scheduling whiteboard that factors in machine capabilities. It helps users plan jobs according to available resources. Additionally, it highlights any looming problems, like overdue jobs, through visual indicators like color-coded alerts. This makes scheduling dynamic and responsive to your changing shop floor conditions.

JobBOSS² simplifies complex scheduling processes, letting you maintain control without added complexity. Though there are some areas for improvement–such as more uniform color coding across browser and mobile versions–the scheduling system remains intuitive and operationally-focused.

Learn more about JobBOSS²’s capabilities in our detailed review.

xTuple - Most Affordable Option

xTuple starts at $175/user/month, making it an affordable small business manufacturing software. It performs well in discrete, process, and ETO/MTO environments. It’s a good fit for a variety of industries, from food processing to metal fabrication, and best serves companies with 10-200 employees. While you’ll need to schedule a consultation to get exact pricing, overall cost factors include:

- Software licenses

- Cloud or on-premises hosting

- Maintenance and support

- Training

- Accelerated onboarding (typically completed in about 90 days)

xTuple’s flexibility on user count is ideal for small businesses or startups with fewer employees. Pricing is based on named users, or how many users access the system at the same time, with a five-user minimum for the manufacturing edition.

While it’s highly affordable, some users have found the workflows restrictive and the Windows interface a little cumbersome to navigate. Unlabeled toolbar icons may also add to the initial learning curve. To help with this, opt for xTuple’s Basic Training or the EssentialsPLUS plan, which offers additional post-onboarding training.

Learn more about xTuple’s capabilities in our review.

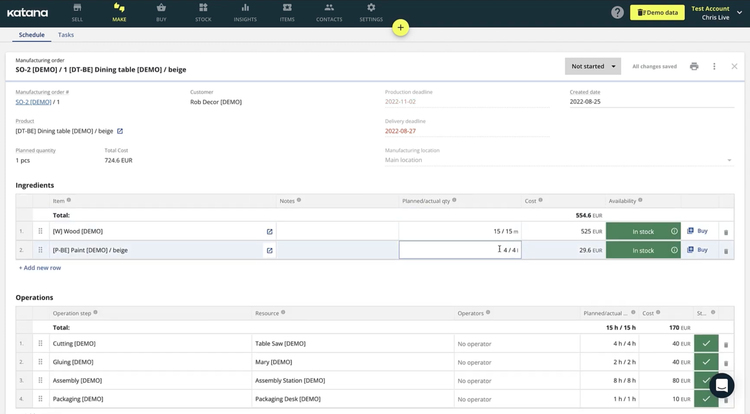

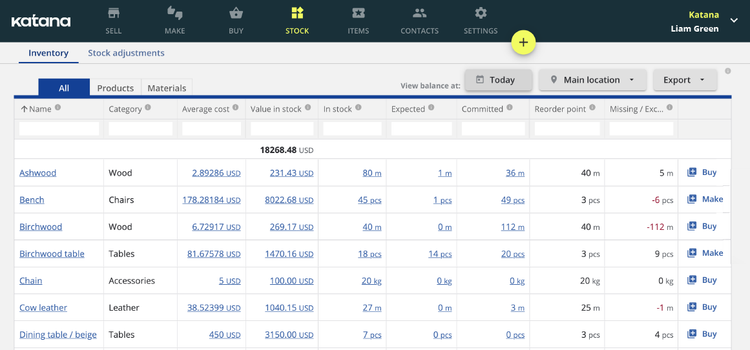

Katana - Best for Direct-to-Consumer

Katana tackles logistics and fulfillment challenges for DTC manufacturers through its order management and inventory balancing tools. Its inventory tool integrates with popular eCommerce apps like BigCommerce, Shopify, or WooCommerce. When a sale comes through on one of these platforms, Katana will auto-update your ERP’s production schedule to reflect this new order. Then, as production consumes raw materials, the inventory system updates stock levels in real time.

Additionally, you can define minimum stock levels for raw materials and finished products in Katana. When inventory falls below these levels, the system will trigger a reorder process. If you’re dealing with seasonal or promotional surges, automated reordering can help you keep pace with demand spikes without risking stockouts or downtime.

DTC brands with multiple warehouses or fulfillment centers can use Katana to monitor stock levels across different locations. This makes it easier to allocate production resources and ensure the right fulfillment centers have enough stock to ship orders promptly.

However, advanced inventory features like barcode scanning are only available in the higher-tier plans, starting at $359/month billed annually. For more advanced manufacturing tools like routing and the Shop Floor App, you’ll need to pay an add-on fee starting at $199/month. If you’re looking for a more well-rounded alternative, we would recommend DELMIAWorks, with advanced barcode capabilities built into the core system.

Learn more about Katana’s pros and cons in our full review.

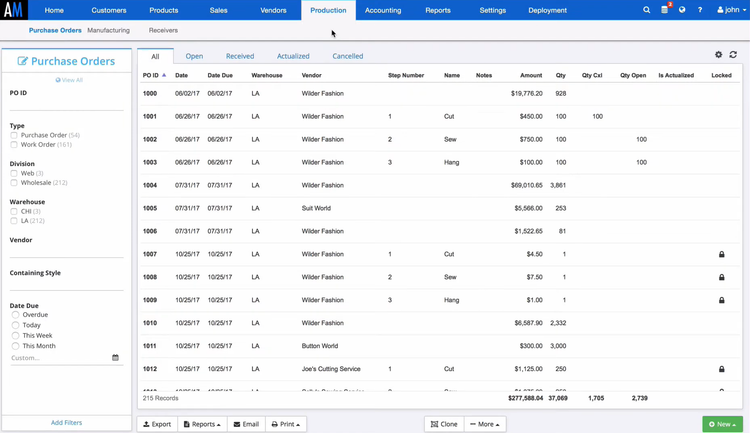

Odoo - Most Customizable

Odoo allows you to start with a single module, like inventory management or manufacturing, and expand your system as your company grows. This allows for incremental customization that won’t overwhelm your company with a fully integrated ERP system from the start. There are also over 30,000 community-built apps, so you can introduce capabilities like barcode scanning integration or build on Odoo’s existing functionalities, like product lifecycle management.

You can opt for Odoo Community, a free open-source platform that allows you to modify the source code. We recommend this if you have an in-house development team or you want full control over adapting the software to your specific workflows. With Odoo Enterprise, the paid version, you’ll get access to more advanced operations like quality management. You can compare the editions here.

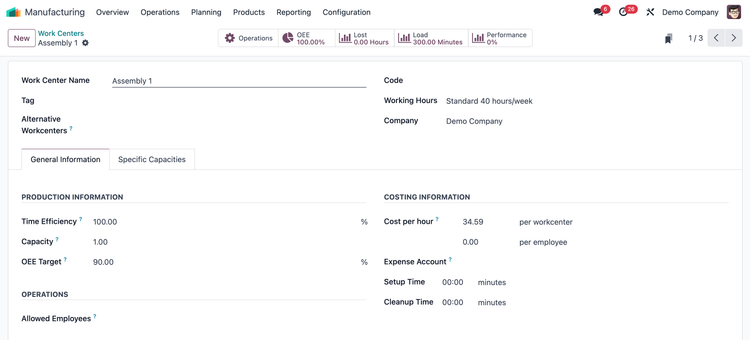

This custom manufacturing software also allows you to customize down to the workflow level. For example, you can define each work center’s cycle times, capacity, and associated costs. You can use Odoo’s Studio app to add custom fields to your manufacturing orders or product records. This might include quality checks or special instructions. Additionally, you can also set automation rules for notifications and actions upon certain conditions, like emailing the production manager if an order falls behind schedule.

Since Odoo is a modular system, its features work best when integrated together. For example, MTO manufacturers will likely need access to the product configurator tool. This is included in the sales and eCommerce modules, but you’ll need to sync the manufacturing module to fully use it in your production processes. You can access all of Odoo’s modules with its standard Enterprise plan, which is $38.90/user/month, billed monthly.

Read our full Odoo review for more on pricing.

Cetec ERP - Best for Electronics

If you’re in electronics assembly, especially building custom cables, PCBs, or wire harnesses, you know how fast things can change. Cetec ERP’s bills of materials (BOMs) revision control and traceability tool is built for these high-mix, low-volume environments. The tool doesn’t just store list parts; it’s a dynamic system that ties directly with your production workflows and traceability records.

You can start by defining a new part and entering a BOM manually, or you can import from your CAD or PLM system (like Duro or Upchain). From there, you can tweak revisions, mark them active or inactive, and even compare versions side-by-side. Cetec also lets you link subassemblies visually and assign scrap factors. For quoting fast-moving jobs, the BOM Overview screen shows you the full cost breakdown and subcomponent rollups.

When it’s time to build, all BOM data flows into work orders automatically. This includes:

- Drawings

- Serial numbers

- Work instructions

- Customer-supplied material flags

From there, Cetec helps your team pick inventory using first-in, first-out (FIFO) methods. It even locks components to a specific top-level build. Everything from materials and costs to quality data is tied to the final invoice for a full paper trail in case of recalls or customer questions.

Cetec starts at $50/user/month for the Lite plan, which includes all ERP modules and standard reporting. If you need more than 2 GB of document storage or are running full operations on Cetec, they recommend the Standard plan at $650 per company per month, plus the $50 per-user fee, with a five-user minimum.

Other Systems We Recommend

Fishbowl Inventory is inventory management software that can function as a light manufacturing system, handling work orders, managing BOMs, and scheduling production.

NetSuite starts at $3,499 for the core manufacturing package, plus $129 per user per month, though pricing is typically quote-based. While it suits basic discrete manufacturing workflows, it’s better for service-based companies rather than complex manufacturers.

Systems We Don’t Recommend

SAP S/4HANA is a manufacturing ERP system built for large enterprise companies. It’s not only too complex for a small job shop but also too expensive, with a three-year total cost of ownership easily exceeding $100,000. Also, implementation requires a dedicated IT team, which is financially straining for most small businesses.

Oracle Fusion Cloud is an ERP software that supports a variety of enterprise applications. While it is capable of handling complex and global manufacturing, it is not designed for small businesses needing an affordable system. Per-user pricing starts at $625/user/month with a 10-user minimum, totalling $6,250/month. This greatly exceeds our criteria for small business manufacturing software.

What is Small Business Manufacturing Software?

Small business manufacturing software helps growing manufacturers streamline operations as they scale beyond manual processes. These platforms are commonly used by manufacturers with 10 to 200 employees, generating under $15 million in annual revenue, though these numbers can vary.

Manufacturing software provides small businesses with tools for inventory control, production scheduling, order processing, and financial management. They typically are the next logical step when adding a new product line or scaling production capacity, as manufacturers require better visibility and control over the shop floor.

At this stage, small companies have outgrown manual methods like spreadsheets or basic accounting software and are considering complete ERP systems or lighter material resource planning (MRP) software.

Manufacturing ERP vs MRP

When small manufacturers adopt new software, the choice usually comes down to two paths: MRP systems or ERP systems. Both provide a foundation for growing manufacturers and are massive improvements from paper or Excel-based operations, but the scope of each product is very different.

-

MRP (Material Resource Planning) software is focused on core manufacturing operations. It helps manage raw materials, production schedules, and shop floor control to ensure products are built on time. It doesn’t often include financial management or employee management tools.

-

Manufacturing ERP software expands from that foundational core and adds company-wide functions such as accounting, HR management, CRM, and quality/compliance management. ERPs unify the entire business under one system and often include MRP capabilities.

If your main priority is controlling production with better material planning and job scheduling, an MRP system can be a simple and cost-effective choice. However, once a business needs to connect production with other areas of the company, then ERP becomes the stronger option. By combining manufacturing tools along with financials, employee schedules, and customer data, ERP gives growing manufacturers a platform to support long-term growth.

Small Business Manufacturing Software Benefits and Features

The value comes not only from replacing spreadsheets but from connecting processes that used to run in silos. Below are some of the most important features and benefits manufacturing software provides:

| Feature | Description | Benefit |

|---|---|---|

| BOM Management | Manages assembly instructions and detailed lists of materials, components, and equipment needed for each product. | Reduces production errors by ensuring teams always work from accurate specifications. This creates consistency across batches and makes it easier to train new staff. |

| Material Resource Planning (MRP) | Aligns purchasing and material usage with production timelines by planning what components are required and when. | Keeps production on schedule by preventing shortages and over-ordering. Manufacturers also save money by only buying what’s needed when it’s needed. |

| Production Scheduling | Organizes labor, equipment, and materials into planned tasks and timelines across all jobs. | Increases shop floor efficiency by balancing machine workloads and helps reschedule to avoid bottlenecks. Accurate scheduling also improves communication between departments and makes deadlines more realistic. |

| Quality Control | Tracks defects and inspection data for raw materials and finished goods, with structured workflows for corrective actions. | Improves product reliability and customer trust by addressing problems before they reach buyers. Over time, this creates a framework that raises quality standards company-wide. |

| Inventory Management | Monitors stock levels, product details, and costs for both raw materials and finished goods. | Prevents stockouts and excess inventory that can tie up cash flow. Better visibility also means fewer last-minute production stoppages and reduced waste from expired or obsolete items. |

| Supply Chain Management | Oversees the movement of goods from supplier sourcing to customer delivery. | Improves supplier relationships and reduces risks by making supply chains more predictable. It can help managers spot issues early, reducing material shortages and keeping customers satisfied. |

| Demand Forecasting | Projects future demand using past sales data and market trends. | Reduces the risks of overproduction and missed sales opportunities. Accurate forecasts give manufacturers confidence to plan ahead and take on larger orders. |

| Financial Management | Provides financial tools for accounting and budgeting. ERP includes a general ledger, payables, and receivables modules. | Links operational data directly to financial results, giving decision-makers a clearer picture of profitability. This connection makes it easier to monitor cash flow and secure funding for growth. |

| Performance Metrics | Measures KPIs such as throughput, employee efficiency, and equipment utilization through dashboards and analytics. | Highlights inefficiencies and shows where improvements will have the biggest impact. Over time, tracking metrics builds a culture of accountability and continuous improvement. |

ERP Selection and Evaluation Tips

If you’re a small business, you can likely use off-the-shelf software with all of the built-in capabilities you’ll need. That’s because today’s modern systems have perfected the way manufacturing companies operate. In addition to no-brainers like pricing, performance, and usability, here are some considerations to take into account when evaluating the best ERP for small manufacturing businesses:

- Scalability: Make sure the ERP can support brand expansion and company growth, allowing you to add users, locations, modules, and features without compromising performance. Can it support your 5-10 year growth plan without adding more software?

- Compliance: Ensure the system meets industry regulations and sector-specific requirements. For example, if your company handles aerospace manufacturing, it’s important to get software compliant with the AS9001 quality standards.

- Key Features: Choose software with a feature set supporting your unique manufacturing workflows. For example, food and beverage manufacturers should have additional features to manage expiry dates and recipe-based products, while apparel manufacturers should find systems that support style and size matrix management and seasonal product planning.

- Training Resources: Ensure the software developer includes training resources like online tutorials, knowledge databases, instructor-led courses, and videos.

- Vendor reputation: Review published case studies and customer success stories relevant to your industry to gauge vendor effectiveness. Ensure vendors have established experience in your type of manufacturing and can understand your workflows.

The product selection process should also factor in your plant’s manufacturing methods:

- Discrete manufacturing software supports make-to-order, make-to-stock, and engineer-to-order processes, from furniture to electronics.

- Process manufacturing caters to industries like food and beverage, pharmaceuticals, and chemicals.

Additionally, identify industry-specific software that aligns with your manufacturing needs:

| Manufacturing Sector | Estimated US Market Cap | Best Fit System(s) | Key Features | Examples of Products |

|---|---|---|---|---|

| Food and Beverage | $1.5 trillion | Food Connex, Deacom | Inventory management, compliance tracking, recipe management | Snacks, beverages, packaged meals |

| Electronics | $800 billion | NetSuite, Epicor Kinetic, SAP Business One | Product lifecycle management, quality control | Gadgets, appliances, circuit boards |

| Plastics and Rubber | $650 billion | DELMIAWorks, Global Shop Solutions | Production scheduling, material requirements planning | Bottles, rubber seals, plastic components |

| Consumer Goods | $600 billion | Acumatica, SYSPRO | Demand forecasting, inventory management | Household items, personal care products, electronics |

| Chemicals | $500 billion | Datacor | Formula management, regulatory compliance, batch processing | Paints, fertilizers, pharmaceuticals |

| Furniture | $300 billion | Katana, Infor CloudSuite Industrial | Order management, custom manufacturing capabilities | Sofas, tables, chairs |

| Textiles | $250 billion | MRPEasy, ApparelMagic | Complex BOM management, inventory control, purchasing | Clothing, home textiles, upholstery |

Pricing Guide

Pricing for small business manufacturing software varies based on your business requirements and the size of your operations. Systems like MRPeasy start at $49/user/month, while systems like Katana and xTuple start at $359/month. There are also manufacturing ERP systems that start at around $15,000/year.

To determine what fits your small business, we recommend evaluating your current systems, understanding where they fall short, and highlighting what features you require most.

Key factors that influence pricing include:

- Implementation fees

- Training needs

- User count

- Ongoing maintenance and support

- Cloud-based ERP vs. on-premises hosting

Our guide to ERP pricing states that for a small business with $1 million in annual revenue, ongoing costs range between $1,740 and $4,620 per month. Not accounting for up-front costs like per-user licensing, initial implementation fees, or training, this adds up to $20,880 to $55,440 a year.

You can calculate the ROI of your ERP solution by doing the following:

ROI = (total value of investment - total cost of investment) / total cost of investment x 100

Implementation Checklist

Read our full ERP implementation guide for a more successful installation:

- Assessment of Current Systems: Evaluate your workflows to identify gaps in inventory management, materials management, and manufacturing and supply chain management. Consider additional tools like analytics or production scheduling.

- Project Planning: Collaborate across departments to define KPIs and cross-team workflows. Put together a project team to establish objectives and ensure milestones are met along realistic timelines.

- Selection: Assess ERP vendors and compare ERPs for small manufacturing businesses based on third-party software integrations, budget, scalability, and sector-specific requirements.

- Design: Select your ERP vendor and customize the system around your operations, configuring features for financial management, production, and customer relationship management (CRM). Tailor the system to support your operations, centralized data collection, and analytics.

- Development: Migrate existing data into the new system and audit it for accuracy. Provide training materials for staff and ensure compatibility with current tools for smooth implementation.

- Testing: Conduct end-to-end and user acceptance tests to identify potential issues. Validate functionality and user experience to confirm readiness for deployment.

- Deployment and Support: Launch the system, whether on-premise or cloud-based, and finalize configurations. Vendors generally provide support post-implementation to ensure a smooth transition.

Frequently Asked Questions

Are there free ERP options for smaller manufacturers?

Yes, there are free ERP options, though they often lack advanced features found in paid versions. These include:

-

Odoo Community Edition: Open-source and highly modular, Odoo Community includes various applications, like manufacturing and inventory. However, you’ll likely need an in-house development team to manage the software. It also lacks full customer support and some modules like quality control, compared to the paid Enterprise Edition.

-

ERPNext: Another open-source solution, ERPNext includes production planning, BOM management, and stock management. However, you’ll need to self-host the software or pay for hosting services. It also does not include priority bug fixes or product warranty.

Read more about the Best Open Source ERP Software options in our roundup.

Does QuickBooks integrate with ERP?

If you’ve outgrown QuickBooks but still want to use it as your accounting system, you can integrate it with your ERP. Options include:

- MRPeasy: Integrates directly with QuickBooks Online.

- JobBOSS²: Integrates directly with QuickBooks Desktop and Online

- Katana: Integrates directly with QuickBooks Online.

A few systems like Odoo offer third-party integrations for QuickBooks Online and Desktop. Third-party connector apps developed by Odoo partners allow you to sync with these platforms.

What are the business modules in manufacturing software systems?

Manufacturing production software includes a variety of modules:

- Estimating and job costing module: Determine project profitability and expenses.

- Production planning and scheduling: Optimize workflows and allocate resources more effectively.

- BOM and routing: Calculate material requirements and production steps.

- Inventory management: Monitor stock levels, reduce material waste, and improve order accuracy.